15 Ton Eot Cranes for Sale Pakistan: Production & Commissioning

European style15 ton overhead cranes for sale in Pakistan, efficient production & seamless commissioning for industrial use. Get your 15 ton crane design.

Category: 15 Ton Overhead Crane for Sale

Your Trusted 15 Ton Overhead Crane Manufacturer & Supplier

15 Ton Eot Cranes for Sale Pakistan: Production & Commissioning

European style15 ton overhead cranes for sale in Pakistan, efficient production & seamless commissioning for industrial use. Get your 15 ton crane design.

European Style 15 Ton Overhead Cranes for Sale in Pakistan: Production & Commissioning

Explore our 15-ton overhead cranes for sale in Pakistan, featuring efficient production and seamless commissioning for industrial applications.

When it comes to heavy lifting in industrial settings, advanced overhead cranes are the choice. These material lifting equipment play a crucial role in streamlining operations, especially in the steel mill industry, where efficiency and safety are paramount. They're designed to handle hefty loads with precision, ensuring that materials move smoothly and safely through the production process.

In Pakistan, the relevance of these cranes can't be overstated. Steel mills are often bustling environments where heavy materials need to be transported quickly and securely. An overhead crane not only enhances productivity but also reduces the risk of workplace accidents—something every manager wants to avoid. Trust me, nothing beats the peace of mind that comes from knowing your operations are running smoothly and safely.

As you consider investing in a 15-ton overhead crane, think about the long-term benefits. These cranes are built to last and can significantly improve workflow, making them a wise choice for any industrial operation. Plus, with features like variable speed and remote control, you gain enhanced control over your lifting tasks, which means more flexibility and better handling of materials. So, if you're looking to upgrade your facility, a 15-ton overhead crane could be just the ticket!

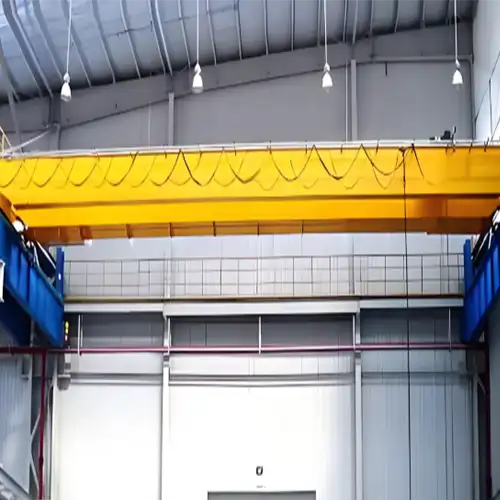

15 ton overhead crane for sale Pakistan, customized double girder top running crane

15 ton eot crane finished installation in indoor workshop

Designed Solution: Main Specifications of 15 Ton Overhead Crane Case

Crane Type

The 15-ton overhead crane features a European-style design with a robust double girder structure. This design not only enhances the crane's stability but also allows for greater lifting capacity and durability. The double girder configuration provides a solid foundation, ensuring that the crane can handle heavy loads efficiently while maintaining precision during operations.

Crane Capacity

With a lifting capacity of 15 tons, this crane is well-suited for heavy-duty applications. It's engineered to lift substantial loads with ease, making it ideal for environments like steel mills, where materials are both heavy and cumbersome. The design ensures that operators can safely manage heavy lifting tasks, boosting productivity without compromising safety.

Crane Dimensions

The crane spans 23 meters, providing ample coverage for larger work areas. This generous span allows for efficient movement of materials across the facility. The lifting height of 6.5 meters is tailored to fit standard operations in steel mills, enabling workers to lift materials to optimal heights for processing and transportation.

Power Supply

This crane operates on a power supply of 415V, 50Hz, 3-phase, which is standard for industrial equipment in Pakistan. This specification ensures compatibility with existing electrical systems, making installation straightforward and minimizing the need for additional modifications.

Application

Designed primarily for indoor use in steel mills, this crane excels in environments where heavy materials need to be moved quickly and safely. Its features are tailored to meet the demands of the steel industry, facilitating operations such as loading, unloading, and transporting raw materials and finished products.

Project Location

The significance of the Pakistani market cannot be overlooked. As the steel industry continues to grow, the demand for efficient lifting solutions like the 15-ton overhead crane becomes critical. This crane not only addresses the immediate needs of local steel mills but also positions itself as a long-term investment in enhancing productivity and safety within the industry.

Design Features of European Style Overhead Cranes with Double Girder Design

- Robust Structure: Exceptional strength and stability for handling heavier loads, ideal for demanding industrial environments.

- Increased Lifting Height: Achieves greater lifting heights, beneficial for tall structures and large materials.

- Enhanced Load Distribution: Better load distribution across the girder reduces stress and enhances safety.

- Improved Stability: Wider base and sturdy construction enhance stability during lifting operations.

- Flexible Span Options: Customizable span lengths to fit specific operational requirements, suitable for various applications.

- Advanced Control Systems: Equipped with variable speed and remote control options for enhanced convenience and precision.

- Safety Features: Incorporates overload protection, emergency stop buttons, and limit switches to ensure safe operation.

- Ease of Maintenance: Design allows for easier access to key components for inspections and maintenance.

- Compact Design: Maintains a compact footprint, optimizing space utilization within facilities.

- Versatility: Adaptable to various industries, including steel manufacturing, logistics, and construction, accommodating diverse lifting needs.

Customized Features of 15 Ton Overhead Crane Project in Pakistan

Customized Crane Control

The crane is equipped with an advanced variable speed controller, enabling operators to tailor lifting speeds to the specific load and task. Additionally, remote control options allow for operation from a safe distance, enhancing user convenience.

Enhanced Operator Convenience and Flexibility

With remote control capabilities, operators can manage the crane from a safe distance, which significantly reduces physical strain. This convenience allows for more versatile load handling, enabling operators to adjust their positions and optimize workflow without being physically tethered to the machine.

Improved Precision in Load Handling

Variable speed control provides smoother movements during operation, allowing for greater accuracy when positioning loads. This precision is crucial in bustling industrial environments where misalignment can lead to costly delays or accidents. Operators can fine-tune lifting speeds to suit specific tasks, ensuring that loads are handled safely and efficiently.

Efficiency and Safety Improvements

Operational Efficiency

Fine-tuning lifting speeds with variable speed control enhances operational efficiency. By allowing operators to adjust speeds according to the load and task, workflows become smoother, leading to faster project completion times and minimized downtime. This adaptability ensures that production schedules are met without unnecessary delays.

Case Examples Illustrating Safety Enhancements

Safety improvements are evident with the implementation of variable speed control and remote operation. There have been fewer accidents during load handling, as operators can manage loads more precisely. Additionally, the ability to respond quickly to potential hazards—thanks to remote operation—protects workers and promotes a safer work environment. This not only fosters employee confidence but also helps companies comply with safety regulations, creating a culture of safety within the workplace.

Learn more to Check the optional smart features of European-style overhead cranes.

Productions: Main Parts and Components of the 15 Ton Overhead Crane

Hoisting Mechanism

The electric hoist is a vital component of the 15-ton overhead crane, designed to lift heavy loads with precision and efficiency. It typically features a robust motor, high-strength wire rope, and reliable braking systems, ensuring smooth and secure operation during lifting tasks. This mechanism plays a crucial role in the crane's overall performance, making it essential for various industrial applications.

Bridge Structure

The crane's bridge structure employs a double girder design, which enhances its strength and stability. Made from high-quality steel, this design provides excellent load-bearing capacity while minimizing deflection. This construction is ideal for heavy-duty applications, allowing the crane to handle significant weights without compromising safety or functionality.

End Carriages

End carriages are critical for the crane's mobility, as they support the entire crane structure and facilitate smooth travel along the runway. Typically, these carriages include wheels with durable bearings that ensure stability during operation and reduce wear over time. This design aspect is crucial for maintaining efficiency in various industrial settings.

Control System

The control system of the crane is designed for ease of use, featuring user-friendly control panels that allow operators to manage all crane functions seamlessly. Safety is paramount, and the system includes features such as emergency stop buttons and intuitive controls, enhancing both the safety and usability of the crane during operation.

Safety Devices

Safety devices are integral to the operation of the overhead crane, ensuring the protection of operators and equipment. The crane is equipped with emergency stop buttons to halt operations instantly, overload protection systems to prevent handling excessive loads, and limit switches that ensure safe travel limits for the crane's movements. These features collectively enhance operational safety and significantly reduce the risk of accidents.

Main girder of the double girder overhead crane

long span main beam of double girder top running eot crane 15 ton

16 ton electric hoist for the 15 ton eot crane based on client's requirement

Variable speed control electrical box of the advanced crane for sale Pakistan

Commissioning of the 15 Ton Overhead Crane

Pre-Commissioning Checks

Before installation, thorough inspections and tests are essential to ensure everything is in order. This includes checking the crane's main components for any defects, ensuring that all safety devices are functional, and verifying the integrity of structural elements. Additionally, it's crucial to confirm that the power supply meets the specifications (415V, 50Hz, 3-phase) and that control systems are correctly calibrated to avoid operational issues later.

Installation Process

The installation of the 15-ton overhead crane follows a detailed procedure to ensure safety and functionality:

- Site Preparation: Begin by assessing the installation site, ensuring it meets structural requirements. The foundation must be level and capable of supporting the crane's weight and operational stress. This might involve pouring concrete or reinforcing existing structures.

- Assembly of Crane Components: Once the site is prepared, assemble the main components, starting with the bridge girders. Carefully align the end carriages and hoisting mechanism, securing them as per manufacturer specifications.

- Electrical Connections and Control Setup: Connect the crane to the power supply, ensuring all electrical components are correctly wired. Set up control panels, making sure operators can easily access all functions.

15 ton overhead crane for sale Pakistan: installaton and comissioning video

Testing Procedures

Testing is critical to guarantee the crane operates safely and efficiently:

- Load Testing: Conduct load tests by gradually increasing weight to the maximum capacity (15 tons) to confirm the crane can handle its rated load without issues. Monitor for any unusual sounds or movements during this process.

- Functional Testing: Test all control functions, including lifting, lowering, and moving the crane along its runway. Ensure all safety features, like emergency stops and overload protection, function correctly.

Training for Operators

Proper training for operators and maintenance staff is vital for safe and effective crane operation. Training sessions should cover:

- Operational Protocols: Instruction on how to use the crane, focusing on all controls and safety features.

- Safety Protocols: Training should emphasize safety measures, including the proper use of personal protective equipment (PPE) and emergency procedures.

- Maintenance Best Practices: Teach operators how to conduct routine inspections and basic maintenance to prolong the crane's lifespan and ensure operational reliability.

Handover to Client

After successful commissioning, a formal handover process occurs, ensuring the client is fully informed about their new equipment:

- Documentation: Provide the client with all necessary documentation, including operation manuals, maintenance schedules, and warranty information. This documentation will guide them in proper usage and maintenance.

- Final Review: Conduct a final walkthrough of the crane with the client, addressing any questions or concerns. This step ensures they are confident in operating the crane and aware of all its features.

Our engineer and the installation team at the installation and assembly site in Pakistan

Sucesseful installation and commisionning of the 15 ton crane wins ok of clients.

User Concerns Answered

FAQs About 15 Ton Overhead Cranes

1. What are the initial costs associated with purchasing a 15-ton overhead crane?

As a leading crane manufacturer in China, we offer competitive pricing. We provide a transparent breakdown of costs, including shipping and installation, and emphasize the long-term savings from reduced labor and increased efficiency.

2. What about ongoing operational expenses?

We recommend regular maintenance schedules and offer cost-effective service packages to minimize unexpected expenses. Our cranes are designed for low maintenance, which can help save money over time.

3. How do you ensure safety and compliance?

Our cranes adhere to international safety standards, including CE and ISO certifications. We can provide documentation and safety records, ensuring compliance with both local and international regulations.If you have other requirements, please consult our engineer for confirmation.

4. Will the crane really enhance operational efficiency?

Yes! Our cranes are designed for optimal performance. We provide case studies and performance metrics from similar installations, demonstrating significant efficiency gains.

6. How do you handle the installation process?

Our installation team is ready to assist you throughout the entire process, from site preparation to final testing. We provide a clear timeline and project management to minimize downtime during installation. For simpler crane installations, we also offer detailed online guidance and support, allowing clients to conduct the installation themselves if they prefer. This option can help save costs while ensuring that you have the necessary resources and expertise at your fingertips.

When purchasing overhead cranes, it's important to mention any installation requirements during the inquiry phase. This ensures that all aspects of the installation can be addressed and incorporated into the purchasing contract, giving you peace of mind that your needs will be met.

7. Can the crane be customized to fit my specific needs?

Absolutely! We specialize in custom solutions, whether you need specific lifting heights, spans, or control systems. Our engineering team will work closely with you to meet your requirements.

8. What is the expected lifespan of the crane?

The lifespan of our 15-ton overhead cranes is designed to be robust, influenced by factors such as application environment and working duty. To provide the best estimate for your situation, it's important to share these details during the inquiry phase. We also offer warranties and post-sale support to ensure the crane's durability and longevity, tailored to meet your specific operational needs.

9. What kind of support can I expect after purchase?

We pride ourselves on excellent customer support, offering 24/7 assistance, spare parts availability, and troubleshooting guidance to ensure your crane operates smoothly.

10. How does your crane compare to competitors' products?

Our cranes are competitively priced and feature advanced technology, such as variable speed controls and remote operation, which many competitors do not offer. We provide comparative analyses to illustrate these advantages.

If you have further questions or specific concerns, please reach out! We're here to help you find the best crane solution for your operations.

Conclustion: Send us an Inquiry to Get Customized 15 Ton Eot Crane

In summary, our 15-ton overhead cranes offer a robust solution for industrial applications, particularly in the steel mill sector. With a European-style double girder design, these cranes boast a lifting capacity of 15 tons, a span of 23 meters, and a lifting height of 6.5 meters. Their advanced features, including a variable speed control system and remote operation capabilities, enhance both efficiency and safety. We have detailed the key components, the commissioning process, and addressed common user concerns, ensuring potential buyers are well-informed about their investment.

We invite you to take the next step toward optimizing your operations. Contact us today for more information or to schedule a consultation. Our team is here to assist you in finding the perfect overhead crane solution tailored to your specific needs.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch