Case Study: Double Hook Overhead Crane for Paper Mill (15t + 10t)

Paper mill crane for sale. Optimizing material handling at Mexico Paper Mill, custom-designed 15 +10t double hook crane, enhancing efficiency & safety.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Case Study: Double Hook Overhead Crane for Paper Mill (15 Ton + 10Ton)

Paper mill crane for sale. Optimizing material handling at Mexico Paper Mill, custom-designed 15 +10t double hook crane, enhancing efficiency & safety.

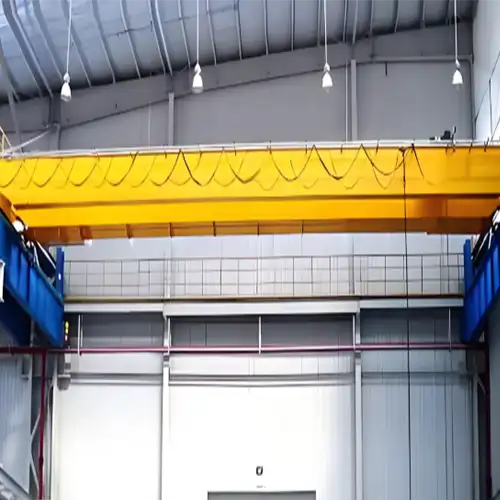

15 +10 Ton Overhead Crane with Double Hook for Paper Mill

Overview of the Paper Mill Industry

The paper mill industry has been growing steadily, driven by increasing demand for paper products such as tissue, packaging, and napkins. As more consumers rely on these everyday items, manufacturers are scaling up production to keep up. This growing demand presents new challenges for mills, especially when it comes to handling larger volumes and heavier materials.

To stay competitive, paper mills need more than just increased production capacity—they need reliable and efficient systems that can handle the increased load and speed. The right material handling paper mill crane solutions are key to meeting these demands while keeping operations smooth and cost-effective.

Need for Advanced Material Handling Solutions

As production rises, so does the need for advanced overhead crane systems to move and store materials efficiently. Paper rolls are heavy, and lifting them requires precision and safety, especially in busy environments where downtime can be costly.

- Handling Heavy Loads: Paper rolls can weigh a lot, and moving them manually is inefficient and risky.

- Reducing Downtime: A reliable crane system helps avoid disruptions and costly delays.

- Automation: With automated systems, mills can reduce manual labor, improve safety, and increase overall productivity.

In today's competitive paper industry, having the right material handling system isn't just a convenience—it's a necessity.

Purpose of the Case Study

This case study looks at how a double hook overhead crane (15t + 10t) improves operations at a paper mill. The focus is on understanding how this crane system helps the mill lift heavy paper rolls, streamline workflow, and handle increased production demands.

By diving into the details of the crane solution, we'll see how it:

- Optimizes Operations: Ensures smooth handling of paper rolls with minimal disruption.

- Improves Efficiency: Supports faster loading, unloading, and storage, boosting overall productivity.

- Supports Business Expansion: Allows the paper mill to grow without compromising on safety or workflow.

This case study will highlight the benefits of choosing the right crane system and how it plays a critical role in maintaining high efficiency and safety standards as the paper mill expands.

Company Background

The Client's Paper Mill Overview

The Client's Paper Mill is a leading manufacturer in the tissue production industry. With two large facilities located in Mexico State and Tlaxcala State, the company has a significant presence in the market. These mills produce a variety of paper products, including:

- Toilet paper

- Napkins

- Packaging paper

Since its establishment, the company has seen steady growth. Starting in 2014, The Client's Paper Mill began expanding its operations to keep up with increasing demand. This expansion not only included upgrades to production lines but also a focus on improving storage and material handling systems to support the growing volume of paper produced.

Challenges Faced by the Mill

As production demand surged, The Client's Paper Mill encountered several challenges that required immediate attention:

- Increased Production Demands: The growing market for paper products meant that the mill had to significantly ramp up production to meet customer needs. This required scaling operations, optimizing workflows, and ensuring that material handling systems could handle the increased volume.

- Need for Improved Material Handling: With more products being produced, the mill faced difficulties in handling large paper rolls efficiently. The old systems were not designed to manage the heavier loads or the speed required by the expanded operations. There was a need for more robust and automated material handling solutions to keep up with the increased output.

These challenges highlighted the need for a better material handling system that could support higher output, increase efficiency, and keep operations running smoothly.

Requirements and Initial Challenges

Material Handling Needs

As The Client's Paper Mill expanded its operations, handling the increased volume of heavy paper rolls became a major concern. These rolls are large and heavy, requiring precise lifting and careful movement to avoid damage.

The mill's material handling system needed to:

- Efficiently handle heavy loads: The system had to be able to lift and move paper rolls, which can weigh several tons, without causing strain on the equipment or workers.

- Minimize downtime: Every minute of downtime costs money. The new system needed to be reliable, ensuring that production could continue smoothly without interruptions.

- Improve workflow efficiency: The paper mill's warehouse and production areas had to be optimized for fast, effective movement of materials, from storage to production lines and vice versa.

With these needs in mind, the mill required a solution that could handle increased production volumes while improving overall operational efficiency.

Specific Lifting Requirements

Given the scale of the operation, lifting paper rolls had to be done with precision and minimal disturbance. Paper rolls must be carefully handled to prevent any damage, as they are sensitive to impacts that can ruin the quality of the product.

- Precision lifting: The crane system needed to pick up paper rolls accurately and place them exactly where they were required, without causing any disruption to the surrounding area or other ongoing operations.

- Capacity and scale: The lifting system needed to handle a combined weight of up to 25 tons (15t + 10t), as large and small rolls needed to be moved around the facility. This required a crane system capable of handling different load sizes and types without compromising performance.

Design Considerations

The design of the crane system was crucial for its integration into the existing mill infrastructure. Several key factors had to be addressed during the design process:

- Integration with existing infrastructure: The crane had to fit into the existing warehouse and production layout, ensuring that it worked seamlessly with other equipment like conveyors and storage systems. This meant considering factors like span, height, and operational flow to avoid any disruptions.

- Operational safety and reliability: Safety was a top priority. The crane system had to meet strict safety standards to protect workers and avoid accidents. Additionally, the system needed to be highly reliable, with minimal risk of breakdowns that could halt production or cause delays. Reliability would help the mill avoid costly repairs and maintain consistent output.

The crane system had to be carefully tailored to meet these specific lifting and design requirements while ensuring that it could keep pace with the growing demands of the paper mill.

Solution Provided

Crane Design and Specifications

Clescrane provided a tailored solution with the Double Hook Overhead Crane with 15 Ton Main Hook + 10 Ton Auxiliary Hook to meet the paper mill's heavy lifting and operational requirements. This crane was designed with a number of features that made it ideal for the mill's needs:

- Load Capacity: 15 tons (main hook) and 10 tons (auxiliary hook), providing flexibility to handle both large and small paper rolls.

- Span: 16.59 meters, offering ample coverage of the mill's warehouse and production areas for easy movement of paper rolls across different sections.

- Working Class: A5, ensuring the crane is robust enough to handle regular operations and the heavy-duty demands of the mill's increased production.

- Lifting Height: 8.5 meters, allowing the crane to lift paper rolls to the required heights for stacking or loading onto conveyors.

This crane was custom-designed to perfectly align with the specific operational needs of the paper mill, ensuring maximum efficiency and safety in lifting and transporting paper rolls.

System Integration

The crane's design also took into account the need for seamless integration with existing infrastructure:

- Integration with Warehouse Management Systems (WCS, WMS): The crane was integrated with the mill's Warehouse Control System (WCS) and Warehouse Management System (WMS). This integration enabled real-time coordination between the crane and the mill's inventory management system, ensuring precise movements and accurate storage of paper rolls.

- Coordination with Conveyor Systems: The crane was also designed to work with existing conveyor systems, streamlining the process of moving paper rolls between production areas and storage. This integration improved the overall material flow, ensuring minimal manual intervention.

Minimal Downtime

The design of the crane also emphasized minimal downtime:

- Quick Installation: The crane was engineered to be installed efficiently, minimizing disruption to ongoing production during the installation phase.

- Operational Continuity: With high reliability and a robust design, the crane ensured continuous operation, reducing the risk of costly downtime. This was crucial for maintaining the paper mill's production schedule and meeting growing customer demand.

The combination of custom design, seamless integration, and advanced automation allowed the crane to support the paper mill in its expansion, enhancing overall efficiency and ensuring smooth day-to-day operations.

Benefits and Impact

Operational Efficiency

The Double Hook Overhead Crane significantly improved operational efficiency at The Client's Paper Mill:

- Streamlined Lifting and Handling: The crane's ability to handle heavy paper rolls with precision allowed for smooth and efficient movement across the facility. Paper rolls could be quickly lifted, transported, and stored without delays.

- Increased Throughput: With faster material handling, the mill was able to process more paper rolls in less time. This increased the overall throughput of the mill, helping it meet rising production demands and keep operations running smoothly.

- Reduced Operational Delays: The crane's efficiency reduced delays that were previously caused by slower manual handling and equipment breakdowns, allowing the mill to maintain a steady production pace.

Improved Warehouse Management

The crane also had a direct impact on warehouse operations:

- Better Organization and Storage: The automated handling system helped organize the storage of paper rolls in a more systematic way. With precise movements and real-time data integration, the crane ensured that paper rolls were stored optimally, reducing clutter and improving space utilization.

- Optimized Storage: The integration with the mill's Warehouse Control System (WCS) ensured that the storage process was quick and accurate, improving the retrieval process when paper rolls were needed for production.

Enhanced Safety

Safety was a top priority with the new crane system:

- Reduced Manual Handling: The crane minimized the need for workers to manually handle heavy paper rolls, reducing the risk of injuries and accidents.

- Improved Safety Protocols: With automation in place, the risk of human error was reduced. The crane's design included built-in safety features that ensured smoother operations and better adherence to safety standards.

The paper mill now operates in a safer environment, with fewer risks associated with manual lifting and handling.

Long-Term Cost Savings

The crane's design offered long-term financial benefits for the paper mill:

- Lower Maintenance Costs: The robust design of the crane reduced the likelihood of breakdowns and the need for frequent maintenance. This lowered maintenance costs, helping the mill keep its operating expenses under control.

- Increased Equipment Lifespan: The crane's high-quality materials and durable construction meant that it would last longer without needing major repairs. This increase in lifespan led to a better return on investment (ROI) for the mill over time.

Customer Satisfaction

The Client's Paper Mill expressed high satisfaction with the crane solution:

- Overall Satisfaction: The paper mill was pleased with how the crane met its lifting requirements and integrated seamlessly into existing operations. The solution helped the mill meet production demands while improving efficiency and safety.

- Ongoing Collaboration: The successful implementation of the crane solution laid the groundwork for a long-term relationship between The Client's Paper Mill and our crane factory . The mill looks forward to future collaboration for any crane upgrades and further expansion as their operations continue to grow.

Overall, the crane solution provided played a vital role in improving both the operational efficiency and safety of The Client's Paper Mill, while also offering long-term financial benefits and increasing customer satisfaction.

Conclusion

Summary of the Project

The Double Hook Overhead Crane (15t + 10t) provided a comprehensive solution to The Client's Paper Mill's material handling challenges. The crane effectively addressed the mill's need for efficiently lifting and moving heavy paper rolls, supporting increased production and minimizing operational delays. With its customized design and seamless integration into the mill's existing operations, the crane optimized both the warehouse management system and production flow, significantly improving overall efficiency. By automating many aspects of the material handling process, the crane also reduced manual labor and increased safety across the facility.

Long-Term Strategic Benefits

Choosing the right crane solution has proven to be a crucial decision for the long-term success of The Client's Paper Mill:

- Support for Business Growth: The crane system's reliability and scalability have allowed the paper mill to meet growing production demands. With enhanced efficiency, the mill can continue expanding its operations without worrying about material handling bottlenecks or safety concerns.

- Positive Impact on Operational Efficiency and Scalability: The crane has played a key role in reducing downtime, improving throughput, and streamlining workflows. This has not only made the paper mill more efficient but also more adaptable to future business growth, setting the stage for continued success in an increasingly competitive market.

The continued partnership between The Client's Paper Mill and our crane factory signals an ongoing commitment to future growth and technological advancement. Both companies look forward to collaborating on further expansions and crane upgrades to accommodate evolving production needs. This long-term relationship ensures that the paper mill will continue benefiting from reliable, efficient lifting solutions that grow alongside their operations.

Moreover, this case study has broader implications for the paper mill industry as a whole. It highlights the importance of adopting modern, automated lifting solutions to meet increasing demands and maintain high levels of operational safety and efficiency. As more mills embrace these advanced technologies, the industry will see improved productivity, reduced costs, and greater sustainability in their operations.

Recommendations for Other Paper Mills

Key Takeaways for Similar Industries

For paper mills looking to improve their material handling systems, several important lessons can be drawn from the The Client's Paper Mill case study:

- Select the Right Crane for Your Production Needs: It's essential to choose a crane system that matches the specific demands of your operation. Consider factors like load capacity, span, and lifting height to ensure the crane can handle the materials and volumes you work with.

- Tailor the Solution to Your Workflow: A custom-designed crane solution, like the one provided , ensures better integration with your existing processes. Understanding how your mill operates and how materials move through the facility will allow you to select a crane that fits seamlessly into your workflow.

- Adaptability to Future Growth: Choose a crane solution that not only addresses current needs but is also flexible enough to accommodate future business growth. Scalable systems can help mills stay efficient as they expand and take on new production demands.

Considerations for Integrating Cranes into Existing Infrastructure

When planning to integrate a new crane system, consider the following:

- Existing Facility Layout: Ensure that the crane can be installed without disrupting other equipment or workflows. Space constraints and height limitations need to be factored into the design.

- Coordination with Other Systems: As seen with the The Client's Paper Mill, integration with conveyor systems and warehouse management systems (WMS and WCS) is crucial. This helps improve material flow, storage efficiency, and overall productivity.

- Safety Features and Compliance: Ensure that the crane system complies with industry safety standards and includes necessary safety features, such as emergency stop functions, overload protection, and automated safety protocols.

Suggestions for Enhancing Crane Performance

To maximize the performance and lifespan of the crane system, paper mills should consider the following:

- Regular Maintenance: Routine inspections and maintenance are essential to ensure smooth operation. Keep an eye on critical parts such as hoists, hooks, and controls to avoid potential issues before they become bigger problems.

- Performance Monitoring: Implement monitoring systems to track the crane's performance and identify areas for improvement. This allows for proactive maintenance and timely adjustments to prevent downtime.

- Operator Training: Properly train operators to maximize the crane's potential and reduce the likelihood of human error. Automated features can improve safety, but having skilled operators ensures smooth handling of materials.

Technological Innovations in Crane Systems

The crane industry continues to evolve, with technological innovations that can further improve the efficiency and reliability of material handling systems. Looking ahead, paper mills should keep an eye on:

- Smart Crane Systems: Future cranes may incorporate AI and machine learning to predict maintenance needs and optimize load handling in real-time.

- Energy Efficiency: Newer crane designs may focus on energy-saving features, such as regenerative braking systems and low-energy motors, reducing overall operational costs.

- Remote Monitoring and Control: Advances in IoT (Internet of Things) can allow for remote monitoring of crane performance and diagnostics, giving operators real-time insights into the system's health and helping prevent unscheduled downtime.

By considering these recommendations, other paper mills can improve their operations, enhance safety, and ensure long-term cost savings with the right material handling systems.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch