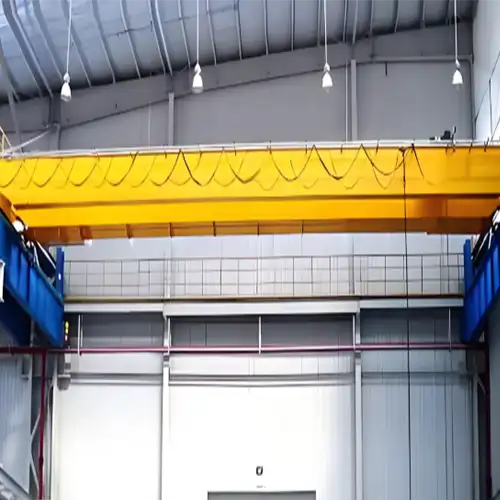

Overhead Crane 15 Ton, Custom 35M Span Bridge Crane for Workshop

Large span bridge crane for sale. Tailored 15 ton overhead crane with a 35m span for large-scale workshop operations and heavy-duty material handling.

Category: 15 Ton Overhead Crane for Sale

Your Trusted Overhead Crane Manufacturer & Supplier

Case Study: Customized 15 Ton Overhead Crane with 35M Large Span Bridge Crane for Workshop Operations

Tailored 15 ton overhead crane with a 35m span for efficient, large-scale workshop operations and heavy-duty material handling.

Meeting Heavy-Duty Lifting Demands in Workshop Environments

In industrial workshops, having the right equipment to handle heavy loads efficiently is crucial. This case study explores the implementation of a customized 15 ton overhead crane with a 35-meter large span bridge crane. Designed specifically for the client's industrial workshop, this bridge crane offers exceptional lifting capacity, wide coverage, and reliable performance.

Client Requirements

The client, an industrial workshop specializing in heavy manufacturing, faced the need for a workshop crane that could handle substantial loads across a large workspace. The key specifications for the crane were:

- Lifting Capacity: 15 tons to lift heavy machinery and materials.

- Large Span: 35 meters to cover a wide operational area efficiently.

- Customized Design: Tailored to fit the workshop's space constraints while improving operational workflows.

- Safety and Durability: Equipped with robust safety features and long-lasting components.

Crane Design and Features

Customized 15-Ton Overhead Crane for Workshop Use

The 15 ton overhead crane was designed with a double girder configuration, providing a stable and efficient lifting mechanism for heavy loads. The large span bridge crane covered a 35-meter width, making it ideal for wide workshop spaces. This configuration allowed for the smooth transport of heavy machinery and materials across the entire facility.

To address limited ceiling height in the workshop, a low-headroom hoist was integrated, optimizing vertical space while maintaining lifting efficiency. This was crucial in ensuring the crane operated seamlessly within the available space, maximizing productivity without any wasted height.

High Lifting Capacity and Large Span

With a 15 ton lifting capacity and a 35-meter span, this bridge crane was designed to handle large loads over a significant distance. The large span bridge crane provided wide coverage, eliminating the need for multiple cranes and minimizing the time spent moving materials from one end of the workshop to the other.

The crane's high capacity allowed it to easily lift heavy items like steel plates, machinery, and large fabricated components. The 35-meter span ensured that these materials could be moved across the entire workshop with minimal downtime and no need for re-positioning the equipment.

Power Supply and Safety Features

The crane was designed to operate on a 3-phase 415V electrical system, ensuring consistent and reliable power for heavy lifting operations. This efficient power supply kept the crane running smoothly under all conditions, even during extended periods of operation.

As with any industrial workshop crane, safety was a priority. The crane was equipped with overload protection, emergency stops, safety brakes, and limit switches to prevent unsafe operation. These features enhanced the crane's reliability and ensured both workers and equipment remained safe during lifting operations.

Main girder of 25 ton overhead bridge crane for sale

Low headroom wire rope electric hoist trolley for double girder crane 15 ton

15 ton electric hoist 9 m lifting height

Electrical box

Electric overhead bridge crane parts and components

Installation and Integration Process

Efficient Installation of the Large Span Bridge Crane

The installation of the 15 ton overhead crane involved careful coordination to ensure it fit the workshop's infrastructure. The 35-meter span bridge crane was delivered in components to facilitate easier transportation and handling during installation.

The installation team performed thorough assessments of the workshop's structure to ensure the crane would operate smoothly and safely. After a few weeks, the crane was installed, tested, and ready for operational use. Load testing and safety checks ensured the crane met all required standards before it was put into service.

Operational Benefits of the 15 Ton Overhead Crane with Large Span

Boosted Productivity in the Workshop

Once installed, the large span bridge crane significantly boosted workshop efficiency. The 15 ton overhead crane allowed for the smooth lifting and transportation of materials and equipment across a large area. The 35-meter span reduced the need for multiple cranes, streamlining operations and cutting down on time spent moving materials.

For example, the crane was able to move large, heavy items such as steel beams, large machinery parts, and raw materials, quickly and efficiently. This improved throughput and helped the workshop meet its production goals.

Reduced Maintenance and Downtime

With its low-maintenance design and durable components, the 15 ton bridge crane required minimal downtime. The crane's robust construction and efficient safety systems meant that it could operate continuously without frequent breakdowns, reducing maintenance costs and ensuring high levels of operational uptime.

Versatility Across Applications

The crane proved versatile for various lifting applications within the workshop. It was used for:

- Heavy machinery handling: The crane efficiently moved large machines during assembly and maintenance tasks.

- Raw material handling: Steel plates, pipes, and large components were easily lifted and transported across the workshop.

- Finished product handling: The crane was used to move finished products to shipping areas, increasing workflow efficiency.

Challenges and Solutions

Space Constraints in the Workshop

The workshop had a relatively low ceiling, making the installation of a traditional overhead crane challenging. To overcome this, the low-headroom hoist was integrated into the design, ensuring the crane operated efficiently while maximizing available space.

Power Supply Compatibility

Given that the crane required a 3-phase 415V electrical system, compatibility with the local power infrastructure was crucial. The crane was customized to integrate seamlessly with the local power supply, ensuring reliable and efficient operation.

Safety Standards

To comply with local safety standards, the crane was equipped with advanced anti-collision devices, emergency brakes, and safety limit switches. These features ensured that the crane operated safely in a busy workshop environment, reducing the risk of accidents.

Conclusion: A Tailored Solution for Heavy Lifting Needs

The installation of the customized 15 ton overhead crane with a 35-meter large span bridge crane transformed the client's workshop operations. This crane provided the necessary lifting power, wide span, and flexibility to meet the client's specific needs. It increased productivity, reduced downtime, and offered long-term reliability, all while ensuring safety and ease of maintenance.

For industries requiring high-capacity lifting solutions, the 15 ton bridge crane with a large span offers an ideal solution. It provides efficient handling of heavy materials, improved safety, and enhanced operational workflows — all crucial elements for industrial success.

Key Takeaways

- 15 ton overhead crane with 35-meter large span designed for heavy-duty workshop operations.

- Custom-built for space efficiency with a low-headroom hoist.

- Enhanced safety features, including overload protection and limit switches.

- Increased productivity, reduced downtime, and easy maintenance.

If your workshop or industrial facility requires a large span bridge crane capable of handling heavy loads, this customized solution may be the ideal choice for boosting efficiency and performance.

Frequently Asked Questions (FAQs) About Large Span Cranes

1. What are the different types of large span cranes and their applications?

- There are various types of large span cranes, including double girder overhead cranes, single girder cranes, and gantry cranes. These cranes are used across a range of industries, such as manufacturing, construction, ports, and shipyards, to lift heavy loads over large distances efficiently.

2. What design considerations should be taken into account for large span cranes?

- When designing large span cranes, several factors must be considered, including the load capacity, span length, materials used in construction, headroom requirements, and operational space. The crane's design must also ensure stability, safety, and compatibility with the workshop or facility.

3. How do large span cranes benefit workshop operations?

- Large span cranes help optimize workshop workflows by enabling the lifting and moving of heavy materials over long distances. Their ability to cover large areas reduces the need for multiple cranes, increases efficiency, and helps to streamline production processes.

4. What is the lifting capacity and performance of large span cranes?

- Large span cranes can handle varying lifting capacities, from small loads (e.g., 10 tons) to very heavy items (e.g., 50 tons or more). The crane's capacity should be chosen based on the specific lifting needs of the facility, ensuring that it can handle the maximum weight expected.

5. How can I maintain large span cranes for optimal performance?

- Regular maintenance is key to keeping large span cranes in top condition. Best practices include routine inspections, lubrication of moving parts, safety checks, and load testing. Proper maintenance helps minimize downtime, prevent breakdowns, and extend the crane's operational life.

6. What are the safety standards for large span bridge cranes?

- Safety is a major priority when using large span cranes. Safety features such as overload protection, anti-collision devices, limit switches, and emergency brakes are essential. These cranes must also comply with industry safety standards and regulations to ensure safe operation in demanding environments.

7. Why are double girder overhead cranes ideal for large span applications?

- Double girder overhead cranes are commonly used for large span applications because they provide superior stability and greater load-carrying capacity. They are ideal for heavy-duty lifting in workshops and warehouses that require large spans, offering both strength and efficiency.

8. How are large span cranes used in port and harbor operations?

- Large span cranes are vital in ports and harbors for handling containers, bulk cargo, and even large ships. These cranes are built to handle heavy, oversized loads and work efficiently across vast port areas, ensuring smooth loading and unloading processes.

9. Can large span cranes be customized for specific needs?

- Yes, large span cranes can be customized to suit various operational requirements. Customizations may include low-headroom hoists, specialized safety features, explosion-proof designs, and integration with automated systems or remote controls, depending on the environment and intended use.

10. What is the economic impact of using large span cranes in large-scale manufacturing?

- The use of large span cranes in manufacturing can significantly improve productivity by reducing handling time and increasing material throughput. With the ability to move large materials over long distances, these cranes reduce the need for additional equipment and minimize operational costs.

11. How do large span cranes impact the environment and sustainability?

- Large span cranes can help reduce environmental impact by optimizing space and minimizing energy consumption. Eco-friendly materials and energy-efficient designs in modern cranes also contribute to sustainability efforts. In addition, these cranes improve the efficiency of operations, reducing waste and operational inefficiencies.

12. What are some key innovations in large span crane technology?

- Innovations in large span crane technology include automation, AI-powered load optimization, and advanced safety features. These developments increase crane efficiency, enhance safety protocols, and reduce the risk of accidents, making cranes smarter and more reliable.

13. How do large span cranes compare to gantry cranes?

- Large span bridge cranes and gantry cranes are both used for heavy lifting over large areas. Bridge cranes are typically mounted on elevated structures and are more stable for lifting in factories or warehouses, while gantry cranes have a frame that travels on the ground and can be more versatile for outdoor use. Each type has its advantages depending on the specific application.

14. What role do large span cranes play in the construction industry?

- Large span cranes are critical in the construction industry for lifting and moving large structural components, steel beams, and machinery across construction sites. They help streamline the building process by enabling the efficient transport of heavy materials, particularly in large infrastructure projects like bridges or skyscrapers.

15. What is involved in the installation and commissioning of large span cranes?

- Installing a large span crane involves several key steps, including site assessment, infrastructure checks, crane assembly, and safety testing. After installation, load testing and inspections ensure the crane meets required operational standards. Timely commissioning ensures the crane is fully functional and safe to use.

These FAQs cover essential aspects of large span cranes, from their applications and design to safety, maintenance, and technology innovations. Each question addresses common queries that businesses or operators may have when considering these powerful lifting machines.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch