Ask Prices for Floor Jib Crane & Wall Jib Crane 1T, 2T,3T,5T,10T

Critical factors to consider when seeking prices for floor & wall jib cranes: load capacity, reach, mounting options, installation requirements. Click!

Category: Overhead Crane Prices

Your Trusted Rotating Jib Crane Manufacturer & Supplier

Ask Prices for Floor Jib Crane & Wall Jib Crane 1T, 2T,3T,5T,10T

Critical factors to consider when seeking prices for floor & wall jib cranes: load capacity, reach, mounting options, installation requirements. Click!

Comprehensive Guide to Requesting Prices for Floor and Wall Jib Cranes

When it comes to efficient material handling and lifting solutions in industrial settings, jib cranes stand out due to their versatility and effectiveness. Jib cranes, which can be either floor-mounted or wall-mounted, are essential tools in various industries, including manufacturing, warehousing, and maintenance. They are designed to handle repetitive lifting tasks, facilitating the precise movement of heavy loads with ease.

Jib crane prices can vary significantly based on several factors, including the type of crane, its load capacity, specific design features, and the manufacturer. By gaining a clear understanding of these pricing factors, businesses can make informed decisions that align with their operational needs and budget. Floor jib cranes are mounted on the ground and provide a stable lifting solution, ideal for heavy-duty applications. Wall jib cranes, on the other hand, are attached to walls or vertical supports, making them perfect for workspaces with limited floor space. Both types of cranes can be customized to fit specific operational needs, enhancing productivity and safety in the workplace. Jib crane prices can vary widely based on several factors, including the type of crane, its capacity, design features, and the manufacturer. Factors like load capacity (e.g., 500 kg, 1 ton, 2 ton, 5 ton), boom length, rotational degree, and additional features such as motorization or advanced safety systems can significantly impact the cost.

Being well-informed about these price determinants enables businesses to budget accurately and choose the most cost-effective solutions that meet their specific needs. This guide will help you navigate through the process of requesting and comparing prices for both floor and wall jib cranes, ensuring that you make an informed decision.

Types of Jib Cranes

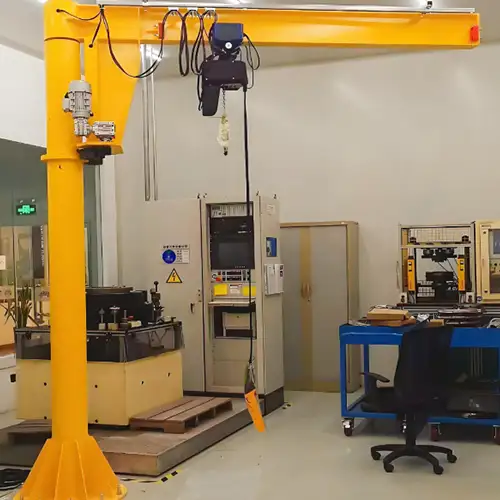

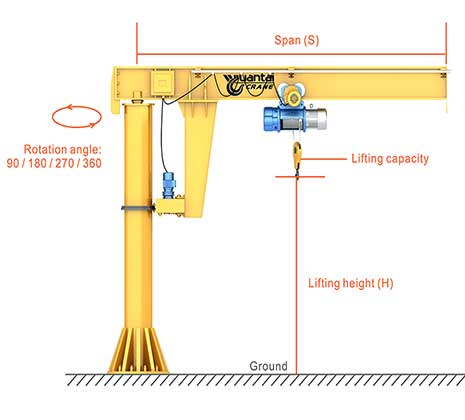

Pillar Mounted Jib Crane

Pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: A3.Ask for free standing jib crane price.

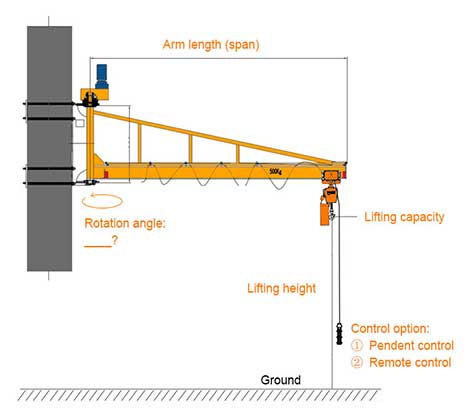

Wall Mounted Jib Crane

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for wall mounted jib crane price.

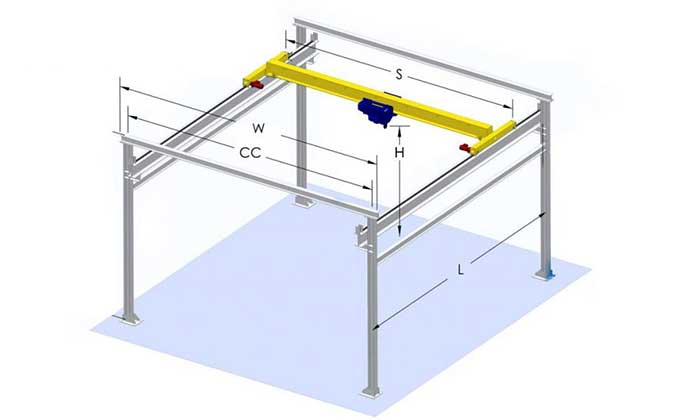

Wall Travelling Jib Crane

Wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3. Ask for wall travelling jib crane price.

Slewing Jib Crane

Slewing jib cranes -floor & wall jib cranes- flexible swing or slewing jib arm & rotary crane design, 180, 270 &360 degree rotating jib crane for sale. Ask for slewing jib crane price.

Portable Jib Crane

Portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.Ask for portable jib crane price.

Process Jib Crane

Process jib cranes for your specific application to lower your jib crane cost. Contact us to get your customized process jib crane design and your jib crane rate and crane price.

Floor Jib Cranes

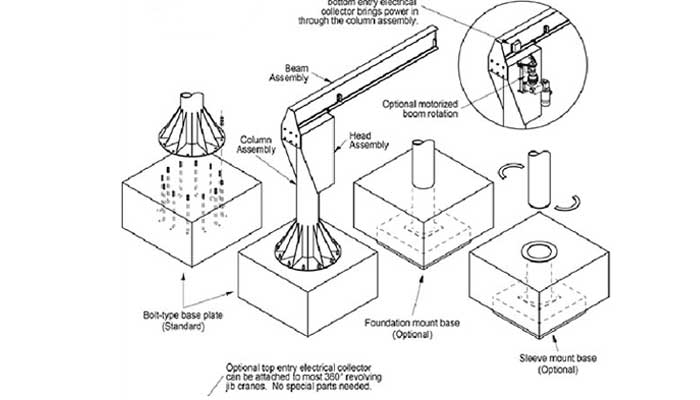

Floor jib cranes are free-standing structures mounted on a concrete foundation or base plate. These cranes typically consist of a vertical mast and a horizontal boom, which can rotate around the mast. They are designed to handle heavy lifting tasks in various industrial environments. Floor jib cranes are often found in manufacturing plants, warehouses, and assembly lines where they assist in loading, unloading, and moving materials.

Key Factors Affecting the Price

- Load Capacity: The price of a floor jib crane is significantly influenced by its load capacity. Cranes with higher capacities, such as those rated for 2 tons or 5 tons, require more robust construction and materials, leading to higher costs.

- Boom Length: The length of the boom determines the reach of the crane. Longer booms provide a greater working radius but also increase the material and engineering costs.

- Rotation Angle: Floor jib cranes can have varying degrees of rotation, ranging from 180° to 360°. Cranes with full 360° rotation offer more flexibility but may be more expensive due to the need for more complex bearing systems.

- Mounting Type: The method of mounting—whether it's a base plate or a foundation-mounted design—can affect the price. Base plate-mounted cranes may be less expensive but might not offer the same level of stability as those anchored in a concrete foundation.

- Materials and Construction Quality: Higher-quality materials and superior construction techniques increase durability and performance but also raise the cost.

- Additional Features: Features such as motorized rotation, variable speed controls, and advanced safety mechanisms can add to the overall price. Customizations tailored to specific industrial needs also play a role in determining cost.

Wall Jib Cranes

Wall jib cranes are mounted directly to a wall or vertical support structure. They feature a horizontal boom that extends out from the wall and can pivot to cover a designated area. Wall jib cranes are ideal for applications where floor space is at a premium. They are commonly used in workstations, maintenance areas, and production lines for tasks that require repetitive lifting and positioning of materials.

Key Factors Affecting the Price

- Load Capacity: Similar to floor jib cranes, the load capacity of a wall jib crane is a major cost factor. Cranes with capacities ranging from 500 kg to 5 tons will vary in price, with higher capacities demanding stronger materials and engineering.

- Boom Length: The reach provided by the boom impacts the price. Longer booms require additional materials and more precise engineering, which can increase the cost.

- Rotation Angle: Wall jib cranes typically have a limited rotation compared to floor-mounted models, usually up to 180° or 270°. The rotation angle affects the complexity and cost of the crane's design.

- Mounting and Installation: The complexity of mounting the crane to a wall or vertical structure affects the price. Proper installation is crucial for safety and efficiency, and specialized mounting hardware or installation services can add to the cost.

- Materials and Build Quality: The quality of materials used in constructing the crane influences durability and performance. Higher-quality materials will increase the price but ensure better longevity and reliability.

- Additional Features: Optional features like motorized pivoting, ergonomic controls, and enhanced safety systems can raise the cost. Custom configurations designed to meet specific operational needs will also affect the overall price.

Factors Influencing Jib Crane Prices

Capacity and Load (e.g., 500 kg, 1 ton, 2 ton, 5 ton)

How Capacity Affects Cost

The capacity and load-bearing capability of a jib crane are critical factors in determining its price. Capacity refers to the maximum weight the crane can safely lift and move. As the capacity increases, so does the complexity and robustness required in the crane's design and construction, which directly impacts the cost. Here's how capacity affects the price:

- Structural Requirements: Higher capacity cranes require stronger and more durable materials to ensure safety and performance. This includes thicker steel for the mast and boom, as well as reinforced base plates or mounting structures.

- Engineering and Design: Cranes with higher capacities need more advanced engineering to ensure they can handle the increased loads without compromising on safety or efficiency. This often means higher design and manufacturing costs.

- Safety Features: As capacity increases, so does the need for enhanced safety features such as overload protection, more robust braking systems, and advanced control systems. These features add to the overall cost.

- Certification and Compliance: Higher capacity cranes may require more rigorous testing and certification to meet industry standards and regulations, which can increase the price.

Examples: Jib Crane Prices by Capacity

- Jib Crane 500 kg Price: A jib crane with a 500 kg capacity is suitable for lighter tasks and typically has a simpler design and lower material costs. Prices for 500 kg jib cranes can start from a few thousand dollars, depending on the features and brand.

- Jib Crane 1 Ton Price: A 1-ton jib crane is a versatile option for medium-duty lifting tasks. The price for a 1-ton jib crane generally ranges from $5,000 to $10,000. The cost varies based on additional features such as motorized rotation and boom length.

- Jib Crane 2 Ton Price: Cranes with a 2-ton capacity are designed for heavier industrial applications. These cranes require stronger construction and more advanced safety features. Prices typically range from $10,000 to $20,000, influenced by factors such as rotational degree and customization options.

- Jib Crane 5 Ton Price: A 5-ton jib crane is a heavy-duty solution for demanding applications. Due to the significant structural and engineering requirements, prices for 5-ton cranes can range from $20,000 to $50,000 or more. The final cost depends on the specific design, features, and manufacturer.

By understanding how capacity and load influence the price of jib cranes, businesses can make informed decisions based on their specific lifting needs and budget constraints. This knowledge helps in selecting the most appropriate jib crane that offers the best value for the investment.

Crane Design and FeaturesRotational Degree (e.g., 180°, 270°, 360°)

The rotational degree of a jib crane refers to the range of motion it provides around its vertical axis. This feature plays a significant role in the crane's versatility and ability to reach different areas within its coverage zone. The rotational degree affects the crane's price in the following ways:

- Complexity of Design: Cranes with a wider rotational range, such as 360°, require more complex designs and mechanisms to facilitate smooth and continuous rotation. This complexity translates to higher manufacturing and engineering costs, thus increasing the overall price of the crane.

- Increased Material Usage: Jib cranes with greater rotational degrees often require longer booms and additional reinforcement to support the extended reach and maintain stability throughout the rotation. This results in higher material costs, contributing to a higher price tag.

- Enhanced Versatility: Cranes with higher rotational degrees offer greater flexibility in maneuvering and positioning loads, making them more versatile for a variety of tasks and work environments. The added versatility and functionality justify the higher price for these cranes.

Boom Length

The boom length of a jib crane refers to the horizontal arm that extends from the crane's mast. The length of the boom directly impacts the crane's reach and coverage area. Here's how boom length influences the price of a jib crane:

- Extended Reach: Longer boom lengths allow the crane to reach farther distances, covering a larger area within its operational range. Cranes with longer booms are often preferred for applications where materials need to be lifted or moved over greater distances, such as loading and unloading trucks or reaching across large work areas.

- Additional Material Costs: Longer booms require more materials for construction, including steel beams, supports, and reinforcement. The increased material usage contributes to higher manufacturing costs, which are reflected in the price of the crane.

- Customization Options: Some jib crane manufacturers offer customizable boom lengths to meet specific customer requirements. Customization options may include telescoping booms or adjustable boom lengths, allowing businesses to tailor the crane's reach to their exact needs. However, customized features typically come with an additional cost.

By considering the rotational degree and boom length when selecting a jib crane, businesses can choose a configuration that best suits their lifting requirements while staying within budget constraints. Understanding how these design features influence the price helps businesses make informed decisions and optimize their investment in material handling equipment.

Type of Mounting (Base Plate, Wall-Mounted)

The mounting type of a jib crane refers to how it is attached to its supporting structure, whether it's mounted on a base plate on the floor or directly to a wall or vertical support. The mounting type influences the crane's stability, footprint, and overall cost. Here's how the type of mounting affects jib crane prices:

Jib crane installation and foundation construction

Base Plate Mounted Cranes

Base plate mounted jib cranes are secured to the floor using a base plate anchored with bolts. They offer stability and flexibility in positioning, making them suitable for various industrial applications. Factors affecting the price of base plate mounted cranes include:

- Foundation Requirements: Base plate mounted cranes typically require a sturdy concrete foundation to anchor the base plate securely. The cost of preparing the foundation adds to the overall installation cost.

- Material and Construction: Base plate mounted cranes need a robust base plate and support structure to withstand loads and provide stability. The additional material and construction requirements may increase the manufacturing cost, thus affecting the crane's price.

- Versatility: Base plate mounted cranes offer versatility in terms of positioning and relocation within the facility. The ability to move the crane to different locations without major structural modifications can justify the higher initial investment.

Wall-Mounted Cranes

Wall-mounted jib cranes are directly attached to a wall or vertical support structure, utilizing the existing infrastructure for support. They are ideal for applications where floor space is limited, providing efficient material handling solutions while minimizing obstruction. Factors influencing the price of wall-mounted cranes include:

- Simplicity of Installation: Wall-mounted cranes typically have a simpler installation process compared to base plate mounted cranes since they utilize existing vertical structures. This can result in lower installation costs, contributing to a more affordable overall price.

- Space-saving Design: Wall-mounted cranes help optimize floor space by utilizing vertical space effectively. Businesses with limited floor space can benefit from the space-saving design of wall-mounted cranes, potentially reducing the need for costly facility expansions or reconfigurations.

- Load Distribution: Wall-mounted cranes distribute loads vertically through the supporting wall or structure, reducing the need for extensive foundation work. This can lead to cost savings in terms of both installation and ongoing maintenance.

By considering the type of mounting when selecting a jib crane, businesses can choose a configuration that best fits their operational needs, space constraints, and budget. Understanding how the mounting type influences the crane's price helps businesses make informed decisions and optimize their investment in material handling equipment.

Material and Build QualityThe material and build quality of a jib crane are crucial determinants of its durability, reliability, and performance. High-quality materials and superior construction techniques contribute to a longer lifespan and reduced maintenance costs. Here's how material and build quality affect jib crane prices:

- Material Selection: The choice of materials used in constructing the crane's components, such as the mast, boom, and supporting structure, directly impacts its price. High-strength steel alloys and robust fabrication methods enhance structural integrity but may increase manufacturing costs.

- Build Quality: Attention to detail in manufacturing processes, such as precision welding, machining, and surface treatment, ensures that the crane meets quality standards and performs reliably under operational loads. Cranes built with superior craftsmanship typically command a higher price due to the investment in quality assurance measures.

- Long-Term Cost Savings: While jib cranes with higher material and build quality may have a higher upfront cost, they often offer better value in the long run by minimizing downtime, repair expenses, and the need for premature replacements. Investing in a durable and well-built crane can result in significant cost savings over its lifespan.

Brand and Manufacturer

The reputation of the brand and manufacturer plays a significant role in determining the price of a jib crane. Established brands with a history of reliability and customer satisfaction may command a premium price due to the perceived value they offer. Here's how brand and manufacturer influence jib crane prices:

- Brand Recognition: Well-known brands often invest in research and development, quality control processes, and customer support infrastructure, all of which contribute to higher manufacturing costs. Customers may be willing to pay a premium for the assurance of product reliability and aftersales service.

- Industry Expertise: Manufacturers with extensive experience in designing and producing jib cranes for specific industries or applications may offer specialized solutions tailored to customer needs. These niche products may come with a higher price tag but provide added value through optimized performance and efficiency.

- Warranty and Support: Reputable manufacturers typically offer warranties and comprehensive customer support services, including installation assistance, training, and maintenance programs. These value-added services contribute to the overall cost of the crane but provide peace of mind to customers knowing they are backed by reliable support.

Additional Features and Customization

Jib cranes often come with a range of optional features and customization options to meet specific customer requirements. While these additional features enhance functionality and versatility, they can also impact the crane's price. Here's how additional features and customization affect jib crane prices:

- Advanced Functionality: Features such as motorized rotation, variable speed controls, and remote operation add convenience and efficiency to crane operations but may increase the overall cost due to the inclusion of specialized components and control systems.

- Safety Enhancements: Advanced safety features, such as overload protection systems, anti-collision sensors, and emergency stop mechanisms, are essential for ensuring workplace safety and compliance with regulatory standards. The incorporation of these safety enhancements may result in higher crane prices.

- Customization Options: Manufacturers may offer customization options to tailor the crane's specifications to the customer's specific requirements, such as custom boom lengths, paint colors, or specialized attachments. While customization allows for greater flexibility, it can also increase production costs and lead times, contributing to higher prices.

By considering factors such as material and build quality, brand reputation, and additional features when selecting a jib crane, businesses can make informed decisions that align with their operational needs and budget constraints. Understanding how these factors influence jib crane prices helps businesses optimize their investment in material handling equipment and maximize long-term value.

Preparing to Request a Jib Crane Quote

Determining Your Needs

Before reaching out to suppliers for jib crane quotes, it's essential to assess your specific requirements to ensure you select the right crane for your application. This involves evaluating factors such as load capacity requirements and the characteristics of your work environment.

Assessing Load Capacity Requirements

- Understanding Load Characteristics: Determine the maximum weight of the loads you need to lift and maneuver using the jib crane. Consider not only the weight of the load itself but also any additional factors such as the weight of lifting attachments or containers.

- Accounting for Future Growth: Anticipate any potential increases in load capacity requirements due to business growth or changes in operations. Selecting a jib crane with a slightly higher capacity than your current needs can future-proof your investment and prevent the need for premature upgrades.

- Consideration of Load Dynamics: Evaluate the dynamics of the loads being lifted, including their shape, size, and center of gravity. Irregularly shaped or unbalanced loads may require special handling considerations and could impact the selection of the appropriate jib crane.

Evaluating the Work Environment

- Space Constraints: Assess the available space in your facility where the jib crane will be installed. Consider factors such as ceiling height, floor layout, and any obstructions that may affect crane operation or installation.

- Operational Workflow: Analyze the specific tasks and processes for which the jib crane will be used. Determine the frequency and duration of crane operation, as well as any unique requirements or challenges associated with your workflow.

- Environmental Conditions: Consider the environmental conditions in your facility, such as temperature extremes, humidity levels, and exposure to corrosive substances. Select a jib crane with appropriate materials and coatings to withstand these conditions and ensure long-term reliability.

- Safety Considerations: Identify any safety hazards or regulatory requirements relevant to crane operation in your facility. Ensure that the selected jib crane complies with applicable safety standards and includes features such as overload protection and emergency stop controls.

By thoroughly assessing your load capacity requirements and evaluating the characteristics of your work environment, you can provide suppliers with accurate information when requesting jib crane quotes. This enables suppliers to recommend the most suitable crane solutions that meet your specific needs and ensure optimal performance and safety in your facility.

Preparing to Request a Jib Crane Quote

Before requesting a quote for a jib crane, it's crucial to gather relevant information about your site and operational needs. This ensures that suppliers can provide accurate quotes tailored to your specific requirements.

Site Dimensions and Constraints

- Physical Space: Measure the available space where the jib crane will be installed, including ceiling height, floor area, and any spatial constraints such as nearby structures or equipment. Provide this information to suppliers to help them recommend jib crane models that fit within your space limitations.

- Obstructions and Clearances: Identify any obstructions or obstacles in the installation area that may impact crane operation, such as overhead pipes, ventilation ducts, or support columns. Communicate these constraints to suppliers to ensure that the selected crane can be installed safely and efficiently.

- Accessibility: Consider accessibility to the installation site for crane assembly, maintenance, and future servicing. Assess factors such as door widths, hallways, and maneuvering space for crane components and equipment.

Specific Operational Needs

- Task Requirements: Clearly define the specific tasks and applications for which the jib crane will be used. Provide details about the types of loads to be lifted, their frequency, and any unique handling requirements.

- Workflow Integration: Evaluate how the jib crane will integrate into your existing operational workflow. Consider factors such as load pickup and drop-off points, workflow patterns, and proximity to other equipment or workstations.

- Specialized Features: Identify any specialized features or functionality required for your application, such as motorized rotation, variable speed controls, or ergonomic operator interfaces. Communicate these requirements to suppliers to ensure that the selected crane meets your operational needs.

- Regulatory Compliance: Determine any regulatory requirements or industry standards that apply to crane operation in your facility, such as OSHA regulations or local building codes. Ensure that the selected crane complies with these requirements to maintain a safe and compliant work environment.

By gathering comprehensive information about your site dimensions, constraints, and specific operational needs, you provide suppliers with the necessary details to recommend jib crane solutions that are tailored to your facility and application requirements. This enables suppliers to provide accurate quotes and ensures that the selected crane meets your performance, safety, and compliance objectives.

Preparing to Request a Jib Crane Quote

Budget Considerations

Establishing a clear budget is essential when planning to purchase a jib crane. Understanding your financial constraints helps you narrow down options and select a crane that offers the best value while meeting your operational needs. Here are some factors to consider:

- Initial Investment: Determine the maximum amount you are willing to invest in a jib crane. Consider not only the upfront purchase cost but also any additional expenses such as installation, shipping, and taxes.

- Total Cost of Ownership: Evaluate the total cost of ownership over the crane's lifespan, including maintenance, repairs, and operational expenses. A higher upfront investment in a quality crane may result in lower long-term costs due to reduced downtime and maintenance requirements.

- Return on Investment (ROI): Assess the potential return on investment associated with the purchase of a jib crane. Consider factors such as increased productivity, labor savings, and reduced material handling errors that may result from crane implementation.

- Budget Flexibility: Determine if there is flexibility in your budget for optional features or customizations that may enhance crane performance or safety. Prioritize essential features while keeping optional upgrades within budgetary constraints.

- Financing Options: Explore financing options such as leasing or equipment financing to spread out the cost of the crane over time. Compare terms, interest rates, and repayment schedules to find the most cost-effective financing solution for your business.

- Cost-Saving Opportunities: Look for cost-saving opportunities, such as bulk purchasing discounts, package deals, or incentives offered by crane manufacturers or suppliers. Negotiate pricing and explore different suppliers to ensure you get the best value for your investment.

- Long-Term Planning: Consider your future growth and expansion plans when budgeting for a jib crane. Invest in a crane that can accommodate potential increases in workload or capacity requirements to avoid the need for premature upgrades.

By carefully considering budgetary factors and financial considerations when planning to purchase a jib crane, you can make informed decisions that align with your business goals and financial resources. This ensures that you select a crane that delivers the performance, reliability, and value you need while staying within your budgetary constraints.

Crafting an Effective Inquiry

Crafting a well-defined inquiry is crucial when requesting quotes for a jib crane. Providing suppliers with detailed information about your project requirements ensures that they can offer accurate and tailored solutions. Here's how to craft an effective inquiry:

Contact Information

- Full Name and Title: Provide your full name and job title for proper identification.

- Company Name: Include the name of your company or organization.

- Contact Details: Provide contact information such as phone number and email address for easy communication.

- Preferred Contact Method: Indicate your preferred method of contact, whether it's via phone, email, or both.

Detailed Project Description

- Specifics on the Crane Type:Clearly specify whether you are interested in a floor-mounted or wall-mounted jib crane.

- Required Load Capacity:Specify the load capacity you need the crane to handle, such as 1 ton, 2 tons, or 5 tons.

- Special Features or Customizations Needed:Outline any special features or customizations required for your application, such as motorized rotation, extended boom length, or specialized attachments.

Questions to Include

- Lead Time and Delivery:Inquire about the lead time for manufacturing and delivery of the crane. Ask for estimated delivery dates to plan your project timeline accordingly.

- Installation Services:Determine if the supplier offers installation services and if they are included in the quote. Ask about any additional costs associated with installation and whether they provide assistance with site preparation.

- Warranty and After-Sales Support:Request information about the warranty coverage for the jib crane, including the duration and what is included. Inquire about after-sales support services such as maintenance, repairs, and technical assistance.

By including comprehensive contact information, a detailed project description, and pertinent questions in your inquiry, you ensure that suppliers have all the necessary information to provide accurate quotes and address your specific needs effectively. This streamlines the quoting process and enables you to make informed decisions when selecting a jib crane supplier.

Evaluating Quotes and Making a Decision

Once you've received quotes from jib crane suppliers, it's essential to carefully evaluate them to make an informed decision. Here's how to effectively assess quotes and choose the right supplier:

Comparing Prices

- Understanding the Breakdown of Costs:Review the itemized breakdown of costs provided in each quote. Understand what each cost component represents, including the base price of the crane, any optional features or customizations, shipping fees, taxes, and installation charges.

- Hidden Costs to Watch Out For:Look for any hidden costs or fees that may not be immediately apparent in the quote. These could include additional charges for special packaging, handling, or expedited production. Clarify any ambiguities with the supplier to avoid unexpected expenses later on.

Assessing Value

- Quality Versus Price:Consider the overall value proposition offered by each supplier, taking into account both price and quality. A lower-priced crane may save money upfront but could end up costing more in the long run if it lacks durability or requires frequent repairs. Evaluate the quality of materials, construction, and components to ensure long-term reliability and performance.

- Reputation of the Manufacturer:Research the reputation and track record of each jib crane manufacturer or supplier. Look for reviews, testimonials, and references from past customers to gauge their reliability, customer service, and product quality. A reputable manufacturer with a history of satisfied customers is more likely to deliver a reliable and high-quality product.

Final Considerations

- Total Cost of Ownership:Look beyond the initial purchase price and consider the total cost of ownership over the crane's lifespan. Factor in maintenance, repairs, spare parts, and operational expenses to determine the true cost of each option. Choose a supplier that offers a balance of upfront affordability and long-term value.

- Customer Reviews and Testimonials:Take into account feedback from other customers who have purchased jib cranes from the suppliers you are considering. Positive reviews and testimonials indicate customer satisfaction and confidence in the supplier's products and services. Conversely, negative reviews or complaints may raise red flags and warrant further investigation.

By carefully comparing prices, assessing value, and considering final considerations such as the total cost of ownership and customer reviews, you can make an informed decision when selecting a jib crane supplier. Choose a supplier that not only offers competitive pricing but also delivers high-quality products, reliable service, and excellent customer support.

Conclusion

In conclusion, the process of selecting a jib crane supplier requires careful consideration and evaluation to ensure that you choose the best solution for your specific needs. Here's a recap of key points to keep in mind:

Key Points:

To know your load capacity requirements and evaluate the characteristics of your work environment to determine the type of jib crane that best suits your needs.

- Gather comprehensive information about your site dimensions, constraints, and specific operational needs to provide suppliers with accurate details when requesting quotes.

- Craft an effective inquiry that includes contact information, a detailed project description, and questions about lead time, installation services, and warranty support.

- Evaluate quotes from multiple suppliers by comparing prices, understanding the breakdown of costs, and assessing the overall value proposition.

- Consider factors such as quality versus price, the reputation of the manufacturer, and the total cost of ownership when making your final decision.

Don't hesitate to request detailed quotes from multiple suppliers to ensure that you have a comprehensive understanding of your options. Gathering multiple quotes allows you to compare jib crane prices, features, and services to make an informed decision.

Selecting the right jib crane supplier is crucial for the success of your material handling operations. By making an informed decision based on thorough research, careful evaluation, and consideration of key factors, you can minimize risks, maximize efficiency, and achieve long-term value for your investment.

In summary, take the time to thoroughly evaluate your options, seek detailed quotes from reputable suppliers, and make a decision that aligns with your operational needs and budgetary constraints. By following these guidelines, you can confidently select a jib crane supplier that meets your requirements and ensures the success of your material handling operations.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch