Single Beam Monorail Gantry Crane & I Beam Gantry Crane

Single beam full & semi gantry crane with I beam & monorail girder design 500kg to 20 ton. Get your i beam gantry crane & monorail gantry crane design!

| Gantry Crane Type | Single beam gantry with i beam & monorail girder |

| Crane hoist | Monorail hoist |

| Crane capacity | 0.5~20 ton |

| Crane span | 3~35m |

| Crane lifting height | 3~30m or customized |

| Note | Customized gantry cranes are available. |

Category: Beam Crane

Your Trusted Overhead Crane Manufacturer & Supplier

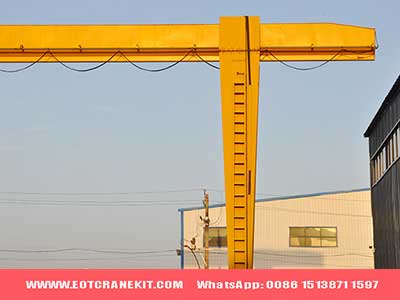

Single Beam Gantry Crane, Monorail Gantry & I Beam Gantry Crane

Full Gantry , Semi Gantry & Portable gantry with Single Beam & Monorail Girder

Single beam full & semi gantry crane with I beam & monorail girder design 500kg to 20 ton. Get your i beam gantry crane & monorail gantry crane design!

The monorail gantry crane or i beam gantry crane is an economical type of single beam gantry crane, which is designed with I beam, reinforced steel i beam, combined U shaped box girder and i beam as the crane girder to support the monorail hoist as the lifting system for material handling. The monorail/ I beam single beam gantry crane is widely used for light loads handling due to its simple crane structure and economical crane cost.

Based on the different applications and lifting requirements, the monorail gantry cranes can be customized customized into full gantry cranes and semi gantry cranes.

Single beam gantry crane with semi gantry, single leg & wall travelling design

The single leg gantry crane is also called as the semi-goliath or semi-gantry cranes. They are a variation of overhead bridge crane, which combines the features of the full gantry crane and bridge crane with one end of bridge girder supported by freestanding leg running on the floor rail and the other end supported and travelling on wall mounted runway mounted on columns or a building structure. When they are specifically designed to run underneath overhead bridge cranes in manufacturing facilities, they offer localized hook service to production cells on one side of a bay while the overhead crane provides general hook service to the entire bay. The single leg gantry cranes can be grouped into single beam or double beam design to meet different application conditions.

Single beam semi gantry crane specifications

As for the monorail semi gantry crane, the main specifications are as following:

- Lifting Capacity: 1~20t

- Span: 7.5~20m

- Lifting Height: 6/9/12m (according your needs)

- Voltage: 220-660V 50/60Hz 3Phase

- Working Class: A3, A4

- Ambient Temperature: -25~40℃

BMH Series single beam gantry cranes are equipped with CD1, MD1 electric hoists, ND European style wire rope hoists, and electric chain hoists as the lifting system. It is appropriate for lifting, transporting, loading, and unloading in doors and open-air operations such as stations, wharves, warehouses, construction sites, cement product yards, machinery or structural assembly yards, power plants, and so on. The semi-gantry crane's support legs have a height difference that can be determined based on the civil construction requirements of the use site.

It consists of a lifting mechanism and trolley, a single main beam, a support leg, and an end carriage, as well as an electric control box, an operating system, and a safety protection system, etc.

Semi gantry single beam gantry crane with i beam & monorail girder

Half gantry crane with wall mounted and travelling design

Benefit of Single beam semi gantry crane

In contrast to full gantry cranes, i beam semi gantries uses the plant's structure rather than a new crane leg. Unquestionably, it is more economical. Semi-gantry cranes have an advantage over overhead bridge cranes in terms of flexibility because they don't completely rely on the plant.

It makes better use of the plant's framework by using one side as a support leg and the other as an end carriage as an overhead crane. When compared to an overhead crane, it frees up the workshop space taken up by columns. This crane solution is very affordable!

- Semi-gantry single beam cranes with all required safety features can be installed underneath existing overhead cranes.

- Semi-gantry cranes are less expensive than full-gantry cranes.

- The semi-gantry crane is one of the useful lifting solutions for many applications, and it can be used both indoors and outdoors.

- All of the parts and components of the semi gantry crane are equipped with high quality.

Application of Single beam semi gantry crane

Single beam semi-gantry cranes are commonly used in steel, forest products, intermodal, biomass/pellet, concrete, and many other industries, and can be used both indoors and outdoors. Semi-gantry cranes are sometimes equipped with truss type outriggers when used outdoors.

There are two commonly used applications:

- Indoors, it is frequently used beneath existing overhead cranes to provide more hooks, increasing factory productivity.

- Outdoors, it is frequently used near the building, maximizing the use of the existing runway structure and thus improving the cost efficiency of your factory or plant.

Single beam gantry cranes with I beam full gantry design

The full gantry single beam crane is made up of double legs on the the both end of the gantry girder, which support the monorail beam girder and hoist for loads handling. A simple monorail gantry crane is used in conjunction with an electric monorail hoist. The can handle loads or objects weighing between 1 and 20 tons. The monorail gantry span can range between 12 and 30 meters. The working temperature of a gantry crane ranges from -20°C to 40°C. The economical monorail gantry crane is a type of material handling crane that is commonly used to load, unload, or grab materials at open ground and warehouses.

Full gantry single beam crane with i beam and monorail girder design

Floor mounted rail travelling single beam gantry crane

Main specifications of full gantry single beam crane

Loading Capacity | 0.5~20t |

Lifting Height | 3~30m or customized |

Lifting Speed | Single speed: 3~8 m/min or customized |

| Variable speed: 1/10 m/min or customized |

Span | 3~35m |

Left Cantilever | 0~4m or as require |

Right Cantilever | 0~4m or as require |

Lifting Mechanism | Wire rope hoist or electric chain hoist |

Work Duty | M3~M5 |

Power Supply | AC-3Phase-220/230/380/400/415/440V-50/60Hz |

Control Method | Ground handle control(Push button), wireless remote control, |

Application Area | Factory,workshop,warehouse,power station,logistic,etc. |

Color | Red, yellow, or customized |

Working Temperature | -20~40℃ |

Protection Class | IP54; IP55; IP65 |

Single beam gantry crane with U shaped box girder and I beam girders

MH single beam gantry crane are full gantry crane with u shaped box shaped and i beam girder. The full gantry single beam crane has the advantages of simple structure, quick manufacture and installation, light weight, etc. The i beam gantry crane can be used when the lifting weight is less than 20 tons, and with A frame gantry legs.

Main specifications of full gantry single beam crane

- Lifting Capacity: 1~20t

- Span: 6~30m

- Lifting Height: 6/9/12/18m (according your needs)

- Voltage: 220-660V 50/60Hz 3Phase

- Working Class: A3, A4

- Ambient Temperature: -25~40℃

Applications of single beam gantry cranes

Single beam gantry cranes are general material handling cranes that are commonly used in open fields, warehouses, ports, granite industries, cement pipeline industries, open storage yards, container yards, shipyards, and other locations. However, the single beam cranes are prohibited to handle molten metal, combustible.

Our factory, as one of the leading gantry crane suppliers and manufacturers, designs and manufactures gantry cranes for all industrial applications, providing solutions for both indoor and outdoor applications. Contact us to find the best gantry crane for your needs!

Composition of single beam gantry crane with full gantry & ground rail travelling design

- Main Girder: Carbon structural steel, Q235/Q345 grade. robust box design with common deflection.

- Support Legs are made of Q235/Q345 carbon structural steel. with three coats of paint, strong box design.

- Gantry Crane End Carriages -Q235/Q345 carbon structural steel. traveling motor of the Nanjing brand.

- Electric Gantry Hoist -High quality single speed and double speed electric hoist.

- -Electrical appliances are manufactured by world-renowned brands such as Schneider, ABB, Chint, and others.

- Crane Wheels - Vacuum casting, intermediate hardening by top-of-the-line equipment.

A frame single beam gantry crane with u shaped and i beam girder, equipped with monorail hoist

Maintenance ladder of single beam gantry crane

Gantry crane cable of single beam crane

Features of full gantry single beam crane

- Advanced processing equipment and manufacturing processes;

- Maintenance-free design

- Use CAD for structural design and calculations;

- Safe, reliable, durable;

- Small size, light weight, low noise, high efficiency;

- Compact structure, easy installation and maintenance, durable;

- Low building clearance height and low wheel pressure;

- The structure is novel and beautiful in appearance;

- Good craftsmanship, flexible and stable operation, safe and reliable.

Comparison of Semi Gantry Crane and Full Gantry Crane

Item | Semi gantry | Full gantry |

Girder design | I beam, U shape box girder + i beam, Box girder, truss girder, | |

No.of main girder | Single girder / double girder | |

Gantry hoist | Monorail hoist, chain or rope hoist, double rail hoist, crab hoist, open winch trolley | |

Supporting leg | Single leg | Double leg |

Mounting types | Half wall or runway mounting & half gantry leg supporting | Self standing gantry crane supporting |

Crane travelling | Wall travelling & ground rail travelling | Ground rail travelling |

Space required | Save space as it only needs a side column and a runway beam. | Double girder on both end of girder, taking more space than single leg type. |

Gantry cost | Economical | More raw steel material required and higher price than semi gantry |

Crane installation | Half Runway & high ground rail | No columns and high up runway beams required. Easy installation. |

Portable Roller travelling monorail gantry cranes

Portable or mobile monorail i beam gantry cranes are self supporting free standing A frame gantries. Movable monorail gantry cranes are mounted on wheels or casters so they may be moved from one place to another quickly and effortlessly. Any of our portable single beam gantries can be mounted on wheels or casters. Due to the triangular ("A") shape of its legs, these I beam monorail cranes are also commonly referred to as a-frame hoists, rolling cranes, or gantries.

Steel monorail gantry crane

Standard Supply Scope of monorail steel gantry crane:

- Lifting Capacity: 0.25-10 tons

- Lifting Height: 1-10 m

- Span: 1-12 m

- Voltage: 220-440V 50/60Hz 1/3Phase

- Protection Class: IP44-IP55

- Working Temperature: -20-+40 ℃

- Lifting Mechanism: Electric Hoist

- Color: Blue, Yellow, Customized

Aluminum monorail gantry crane

Main Parameters of monorail aluminum gantry crane:

- Lifting Capacity: 0.25-5 tons

- Lifting Height: 1-9m

- Span: 1-9 m

- Voltage: 220-440V 50/60Hz 1/3Phase

- Protection Class: IP44-IP55

- Working Temperature: -20-+40 ℃

- Lifting Mechanism: Electric Hoist, Manual Hoist

If the standard i beam monorail gantry crane and hoist can not meet your needs, contact us freely, we can provide a tailor-made solution for your projects.

We are dedicated to providing customers with the most efficient and cost-effective single beam gantry crane solutions and services. Choose from our extensive selection of single beam cranes, which includes MH standard gantry cranes, European gantry cranes, semi-gantry cranes, and portable gantry cranes. Contact us to get your customized single beam gantry crane.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch