I Beam Gantry Crane:Steel & Aluminum A Frame I Beam Gantry Crane

I beam gantry crane for sale. Economical A frame steel gantry & aluminum gantry crane with I beam design for light loads handling, 1 t, 2t,3t to 10 ton.

Category: Beam Crane

Your Trusted Overhead I Beam Gantry Crane Manufacturer & Supplier

Portable I beam gantry crane

Economical A Frame Steel Gantry & aluminum gantry crane

I beam gantry crane for sale. Economical A frame steel gantry & aluminum gantry crane with I beam design for light loads handling, 1 ton, 2 ton, 3 ton up to 10 ton.

Portable or mobile I beam gantry cranes are self supporting free standing A frame gantries. Movable gantry cranes are mounted on wheels or casters so they may be moved from one place to another quickly and effortlessly. Any of our I beam gantries can be mounted on wheels or casters. Due to the triangular ("A") shape of its legs, these I beam cranes are also commonly referred to as a-frame hoists, rolling cranes, or gantries.

Our extensive selection of portable I beam gantry cranes is made to match any purpose and price range. A 10 ton portable gantry crane, custom portable gantry cranes up to 20 tons, fixed height portable gantry cranes, adjustable gantry cranes, steel gantry cranes, and aluminum gantry cranes are among the most popular designs of i beam cranes.

Portable steel I beam gantry crane

There are many different models of portable steel I beam gantry cranes available for varied uses. The Fixed Height and Adjustable Height Steel I Beam Gantry Cranes are the most popular. For simple transportation to the job site, there are also mobile gantry cranes built of lightweight aluminum. With customized motorized steel gantry cranes can now be relocated while the crane is loaded.

Main Parameters of Steel I beam gantry crane:

Standard Supply Scope

- Lifting Capacity: 0.25-10 tons

- Lifting Height: 1-10 m

- Span: 1-12 m

- Voltage: 220-440V 50/60Hz 1/3Phase

- Protection Class: IP44-IP55

- Working Temperature: -20-+40 ℃

- Lifting Mechanism: Electric Hoist

- Color: Blue, Yellow, Customized

If the standard crane and hoist can not meet your needs, contact us freely, we can provide a tailor-made solution for your projects.

Main types of steel i beam gantry cranes

- I Beam Gantry Crane with Fixed Height: Constructed to a precise height that cannot be changed. They are used in applications requiring repeated lifts.

- Adjustable Height of I Beam Gantries: This gantry's overall height can be changed to suit a variety of purposes. As a result, there are numerous production locations where the A frame gantry can be used. Warehouses and machine welding shops benefit greatly from steel gantries with adjustable height.

- Portable I Beam Gantries: A gantry crane that is easily disassembled, transported to a job site, and reassembled by one or two workers. Perfect for service teams or construction companies that travel to different job sites.

- Gantry crane that is mounted to a track and rolls along a floor-mounted track. This gantry moves only along the track route by using a gantry track and corresponding casters. End stops are used to prevent the gantry from rolling off either end of the gantry track.

Portable gantry crane with European style low headroom hoist

Aluminum I beam gantry crane

Customized aluminum I beam gantry crane, lightweight gantry, superior quality aluminum I beam and support legs, adjustable height, adjustable span, essentially exempt from on-site constraints.

I-beam aluminum gantry cranes from Yuantai are compact, lightweight, and incredibly stable when loaded. Aluminum I beam gantry cranes are popular with contractors that require extremely transportable lifting equipment that they can bring onto service trucks since they are simple to install and disassemble.

Aluminum i beam gantry crane

Main Parameters of aluminum I beam gantry crane:

- Lifting Capacity: 0.25-5 tons

- Lifting Height: 1-9m

- Span: 1-9 m

- Voltage: 220-440V 50/60Hz 1/3Phase

- Protection Class: IP44-IP55

- Working Temperature: -20-+40 ℃

- Lifting Mechanism: Electric Hoist, Manual Hoist

If the standard i beam crane and hoist can not meet your needs, contact us freely, we can provide a tailor-made solution for your projects.

Main types of Aluminum I Beam Gantry Cranes

The Aluminum I Beam Gantry Crane is a portable A Frame Gantry Crane with fixed height design and an adjustable height design, which can be selected based on your lifting requirements and applicaiton conditons. Lightweight extruded aluminum construction allows for easy portability. One person can easily lift the components. The light I beam A frame gantris can be used in a wide range of work environments and job sites. Carrying the components up a ladder or staircase to a rooftop work area is one of the more common applications. In addition to standard phenolic casters, inflatable pneumatic wheels for rough surfaces such as gravel and dry ground are available.

Fixed height aluminum i bem gantry crane

- Capacity up to 5 tons.

- Span up to 4 meters.

- Max. height up to 5 meters

Adjustable height i beam gantry crane

- Capacity up to 3 tons.

- Span up to 4 meters.

- Max. height up to 6 meters

Compare: Steel vs. Aluminum I Beams

Aluminum is such a wonderful substance. It looks great, is strong, and is light. So, why is there a debate about Aluminum and steel I beam gantry crane?

Aluminum and Steel Comparison

Steel vs. Aluminum comparisons involve a wide range of factors, but we'll focus on the six major ones that apply to I beam gantry cranes.

Weight -Weight, or more specifically, density, is Aluminum's primary advantage over Steel.The density of aluminum is around 2700 kg/m3.Steel has a density of 7800 kg/m3.Even while those figures may be useless on their own, if you think about them broadly, steel is almost three times as heavy for the same volume.

Strength -Is steel more robust? Obviously, that depends on the comparison alloys (Steel and Aluminum). While it is true that the strongest Steel alloys are far stronger than the strongest Aluminum alloys, the aluminums are equally robust when used as a building material for cranes. Given that there are numerous alloys, it is advisable to compare the specifications before trusting this statement. The key factor here is yield strength because that's where the point the beam permanently bends. That is not something you want to happen to your beam! However, material strength is not the only consideration. Strength is undoubtedly related to beam shape and location. Consider how the use of steel vs. aluminum in beams affects the equation.

Corrosion -Finally, aluminum does not rust, which is a huge advantage (particularly for aluminum gantries used in humidity or wet applications or corrosion conditons). Contrary to popular opinion, metal actually "oxidizes," not corrodes. Have you ever slid your hand along an aluminum piece and ended up with black skin on your hand? It is the result of surface oxidation. Aluminum is highly reactive with oxygen that having metal in the air without oxidation is practically impossible. That happens instantly when you cut it, and as time passes, it gets thicker.

Cross corrosion is a different type of corrosion that occurs when dissimilar metals come into contact with water and a few other substances in the air and on the ground. For instance, steel bolts in aluminum without additional treatments.

Why is steel used so much more frequently?

There are three benefits to steel, and two of them are areas where it significantly outperforms aluminum.

Stiffness - The comparison of aluminum and steel emphasizes the importance of deflection.Contrary to popular belief, stiffness and strength are two entirely distinct qualities.For instance, nylon rope is quite strong but not at all stiff.

Although "stiffness" is a phrase we use frequently, "Modulus of Elasticity" is the engineering term used to describe it. By alloy, there is a little but noticeable difference. Steel typically has a psi of roughly 30,000,000 and aluminum is typically around 10,000,000. Once more, the crucial factor is how much a beam will deflect under load, not the precise figures. Generally speaking, for equal beams, an aluminum beam will deflect about three times as much as a steel beam under same circumstances.

Practical Durability -A third benefit of steel is what we call Practical Durability. This is not a measurable value. Rather, the pragmatic side of designing, making, using, misusing, and owning the equipment is practical durability (crane, trailer, press, whatever). This includes benefits such as easier welds and greater resistance to damage and abuse when building with steel.

Steel is often significantly less fatigue-prone. One problem with aluminum is that metal tends to develop fractures, especially when welds are made. It takes a lot more skill and specialized equipment to weld aluminum. Also, because aluminum is less resistant to wear and abuse than other materials, we usually advise adding more gussets and other joint support. The practical benefit of employing aluminum, particularly with aluminum trailers, is that.

Naturally, this does not imply that you shouldn't employ it.It just implies that the design and building process needs to be given a bit more consideration.

Comparison: Steel or Aluminum I Beam Gantry Crane

Engineering Concepts

The phrase "Modulus of Elasticity" in engineering refers to how much a beam will flex under a specific load. It is a characteristic of the substance; aluminum, steel, titanium, plastic, and wood all have a unique "Elastic" characteristic.

The "I," or "Area Moment of Inertia," is another related engineering concept that is frequently mentioned in talks about strength and stiffness.

This is related to the beam's size and cross sectional area.To put it briefly, it refers to the quantity of material, how it is distributed throughout the beam cross section, and how far away from the areas of the beam that are under the most stress. For descriptions that are more detailed, click on the links above.

In essence, these 2 concepts work together to define how "Stiff" every beam is. This is not "Strength" — but they are sometimes connected. Though that has a lot to do with it, the beam form is not the cause.Let's examine an illustration using a straightforward Gantry Crane top beam using finite element analysis (FEA).We'll compare steel and aluminum using this amusing engineering tool because it offers some fantastic visual perspectives. (As a side note, see Safety with a Crane and the larger one, Gantry Crane Failure Modes, to understand what occurs when a crane does collapse.)

Engineering Tools' Insight

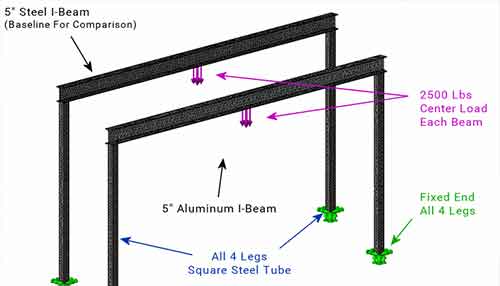

We first construct two cranes. Build cranes in CAD rather than using real cranes. One crane has an aluminum top beam, whereas the other has a steel top beam. Steel is used for all of the legs, so we can plainly see how the top beam differs from the others. Afterwards, we'll dangle 2500 pounds from the center of each of the gantry beams. The arrangement for cranes and loading is shown in the image below.

Crane and load

Finite element analysis of 5" Steel I beam & 5" Aluminum I beam gantry

FEA Setup

Each leg is constricted at the bottom. Although it's not quite true, we assume they are fixed for the sake of simplicity, since it will enough for the simple comparative study. Also, we bind (weld) the legs to the top beam, which is not quite accurate but adequate for the information we need.

Both of the upper beams in this initial test are 5′′ I-Beams.One beam is made of steel, while the other is made of aluminum.

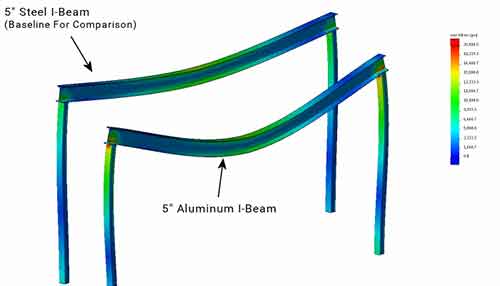

The engineering technology known as FEA, or finite element analysis, allows us to realistically observe what occurs when we apply a load to an item. In the figure below, the colors represent the stresses in the beam. In this illustration, the colors blue and green are considered "safe". Red denotes danger, whereas Yellow denotes caution. Both aluminum and steel can be used with it. In order for us to see what is happening visually, the deflection in the image has been greatly inflated. (For a genuine crane, this kind of beam bending would not occur.)The two gantry cranes for our load look something like this.

5″ I-Beams

This image displays a 30X enlarged deformation scale. In other words, there is 30 times as much deflection as what you observe. This form of exaggeration helps us see what is truly happening more clearly. We can better see the differences between steel and aluminum because it is simpler to observe and the exaggeration is the same for both beams.

Less than 0.2 inches is the actual deflection of the steel beam. Because of the setup presumptions, you should treat these data with caution. The aluminum beam deflects by almost 0.5 inches. With the exception of the hot regions near the leg connection, stress levels are noticeably similar. The larger deflection, which the legs attempt to counteract, is what causes those spots. Obviously, it is impossible to weld steel legs to an aluminum top beam. But when a deflecting beam imparts some deflection to the connecting elements, this is an intriguing connection symptom. Remember this for later.

Practically speaking, if a gantry crane's top beam deflects by 0.5 inches, it might be challenging to transfer the load along the beam because you'd be hauling it up a relatively steep slope. A weight of 2,500 pounds is substantial. Although the deflection moves with the load and is a compensation, the situation is not ideal.

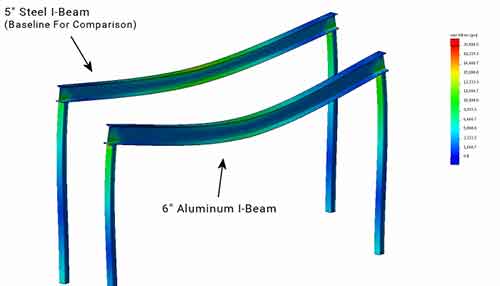

6″ Aluminum I-Beam

Let's swap out the 5" aluminum beam for a 6" aluminum beam in an effort to lessen deflection and strengthen the joints. This is what happened.

Comparison of 5" steel I beam gantry vs 6″ Aluminum I-Beam gantry

Comparison of 5" steel I beam gantry vs 8″ Aluminum I-Beam gantry

We can clearly see that there is less deflection in the FEA image. The aluminum beam now has a thickness of roughly 0.3 inches, which is better but still higher than the steel I-Beam. Furthermore, less stress is excellent. And because there are fewer hot spots, there is less beam deflection. All of these actions are positive steps.

The higher "I," or "Area Moment of Inertia," is what causes the shift in beam deflection that we observe. Only the size has changed; the aluminum substance has not changed. Yet, that is only a portion of the beam; the rest of it is shorter. Moreover, the 6′′ I-Beam has a larger cross section.

We can now determine whether the 0.3" deflection is acceptable.

In some real-world situations, it might be, but for the purposes of our analysis, let's switch back to the top aluminum beam since its deflection is still greater than that of steel. We'll do this to demonstrate how the beams made of steel or aluminum differ in terms of flexibility.

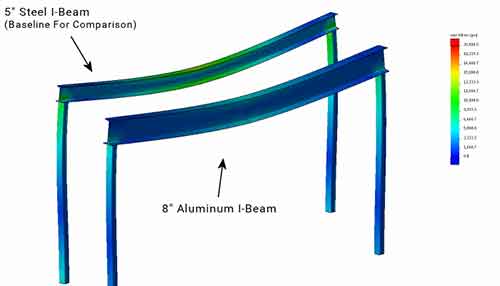

8″ Aluminum I-Beam

The next typical size up for I-Beams is 8′′, thus our study will move on to that size. Please keep in mind that we are still making comparisons to 5′′ Steel I-Beams.

It is clear from this image that the 8′′ Aluminum I-Beam further minimizes joint stress and deflection. Hot spots are no longer present, and this time, deflection is slightly below our target for a 0.2-inch steel beam. Our comparison is successful.

The new 8′′ aluminum I-Beam is obviously considerably taller and has a larger cross section. The 8′′ I-Beam is also significantly wider than the 3′′ I-Beam because we use standard size material. All of these factors contribute to a difference that is not immediately obvious from the description of 5′′ or 8′′ beams.

Note also that the stress in the 8″ I-Beam is less, quite a bit less. What that really means is we have a lot more material than we need from a strength standpoint in order to achieve the deflection goal. Remember our objective is to compare steel or aluminum for the crane, yet it is also true for a trailer frame.

Deflection Comparison: Steel vs Aluminum Beam

What then have we discovered? This is a straightforward illustration of a design where deflection, not stress, is the determining element. If we reinforce the corners with suitable gussets, even the first example had respectable strength, as shown by the stress. Deflection is usually more of a concern for longer beams.

Not that aluminum is a poor choice for crane beams. The research above just emphasizes one of the limitations when contrasting a steel or aluminum beam. Also, it demonstrates some of the distinctions between using aluminum and steel for construction. A project's material selection is usually difficult since it requires balancing aspects including strength, loading conditions, weight, and suitable safety considerations. This is especially true when creating unique blueprints, such as the gantry crane in the above illustration. We support thoughtful, customized individualization, as shown. If you have any need of i beam gantry crane, please feel free to contact us.

I Steel Gantry & I Beam Overhead Crane Video

Steel I beam gantry crane

Steel I beam overhead crane

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch