Cargo Beam Spreader with Hook: Efficient Bulk Lifting Solution

Cargo Beam Spreader with Hook enables secure, efficient lifting of bulk cargo, compatible with various cranes for diverse industrial applications.

Category: Below Hook Devices

Your Trusted Crane Spreader Manufacturer & Supplier

Cargo Beam Spreader with Hook: Efficient Bulk Lifting Solution

The Cargo Beam Spreader with Hook enables secure, efficient lifting of bulk cargo, compatible with various cranes for diverse industrial applications.

The Cargo Beam with Hook is a reliable lifting tool used in industries like industrial production, construction, shipbuilding, and more. It's designed to make lifting heavy and bulky loads easier and safer, especially when handling materials like steel beams, machinery, or ship parts.

This beam is highly versatile and can be used with different types of cranes, including tire cranes and rail cranes. This flexibility makes it a great choice for various lifting tasks, whether you're working in a factory, on a construction site, or in a shipyard. Its ability to fit into different crane systems means you can use it in a wide range of environments without worrying about compatibility.

Key Features:

- Composition: The Cargo Beam with Hook is built from strong beams, sturdy hooks, transmission devices, and other essential parts. These components work together to ensure the beam is durable and reliable for heavy-duty lifting.

- Versatile Crane Compatibility: This cargo beam can be used with both tire cranes and rail cranes, making it adaptable to different lifting setups. Whether you're using mobile cranes or stationary cranes, the Cargo Beam with Hook is ready to perform, offering a flexible solution for various lifting needs.

- Security and Efficiency: The beam provides a secure connection to cranes, using pins or pin holes to ensure stability during lifting. It also features an anti-decoupling device, which prevents the hook from accidentally detaching, ensuring safety for both operators and equipment.

In addition, the design is simple and efficient. There are no complex electrical or hydraulic parts, which means easier installation and lower maintenance costs. The Cargo Beam with Hook integrates quickly into your lifting operations, reducing downtime and helping you get the job done more effectively.

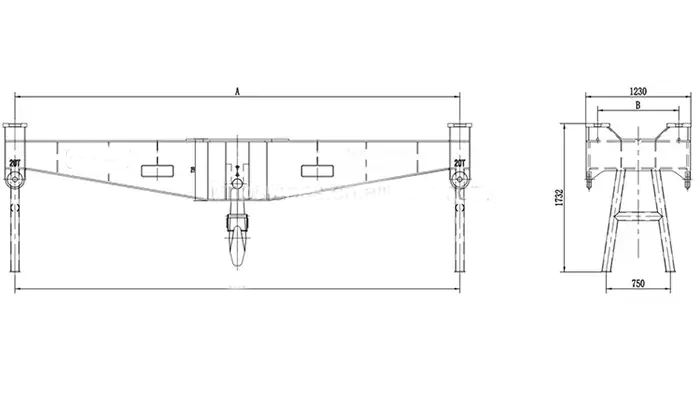

Cargo Beam Spreader with Hook

drawing of Cargo Beam Spreader with Hook

Specifications of Cargo Beam Spreader with Hook

Specifications | |||

Hook rotating | 1rpm | ||

Rated lifting load | 50~80T | ||

Self-weight | 2.7t | ||

Ambient temperature | -20°~+60° | ||

Hook form | Choose by yourself | ||

Pre-treatmentof steel | Blasting,protective painting | ||

Host connection method | Connect to the spreader or upper rack through pin holes or pins, etc. | ||

Applicable host | Tire crane, rail crane | ||

Use | For operation with bulk cargo | ||

Product Specifications

Lifting Capacity & Speed:

- Rated Lifting Load: 50~80T. The Cargo Beam with Hook can handle lifting loads ranging from 50 to 80 tons, making it suitable for heavy-duty lifting operations.

- Hook Rotating Speed: 1 rpm. The hook rotates at a steady speed of 1 rotation per minute, providing controlled and safe operation during lifting tasks.

Dimensions & Weight:Self-weight: 2.7T. The beam itself weighs 2.7 tons, designed to be sturdy yet manageable for various crane types.

Temperature & Environmental Range:Ambient Temperature: -20°C to +60°C. The Cargo Beam with Hook can be used in a wide range of temperatures, from as low as -20°C to as high as +60°C, ensuring it performs reliably in both cold and hot environments.

Hook Customization Options:Hook Form: The hook's form can be customized to meet specific operational needs, giving you flexibility in the type of hook used for different lifting tasks.

Surface Treatment:Pre-treatment of Steel: The steel components undergo blasting and protective painting to ensure they are resistant to corrosion and wear, extending the life of the beam and making it suitable for harsh working conditions.

Host Connection Methods:Connection Type: The Cargo Beam with Hook connects to the crane using pin holes or pins, ensuring a secure attachment to the spreader or upper rack for safe lifting operations.

Applicable Hosts:

- Tire Gantry Cranes: Designed to be compatible with tire cranes, offering flexibility for mobile lifting tasks.

- Rail Gantry Cranes: Also suitable for use with rail cranes, making it ideal for fixed crane systems in factories, ports, and construction sites.

Primary Use Case:

- Bulk Cargo Lifting Operations: The Cargo Beam with Hook is specially designed for lifting bulk cargo such as construction materials, heavy equipment, and ship components, making it an essential tool for industries that require frequent lifting of large, heavy loads.

Advantages of Cargo Beam with Hook

Enhanced Versatility for Bulk Cargo Lifting:

The Cargo Beam with Hook is specifically designed to handle the challenges of lifting heavy and bulk cargo, making it a perfect fit for industries that require frequent lifting of large and cumbersome materials. Whether you're working in construction, shipbuilding, or industrial production, this beam excels at managing a variety of loads, from raw materials like steel and concrete to machinery and large components.

Its versatility also extends to crane configurations. The Cargo Beam can be easily adapted to work with different types of cranes, such as tire cranes and rail cranes. This means you can use the same lifting beam across multiple projects without worrying about compatibility, making it an efficient and cost-effective solution for various lifting operations.

Easy and Quick Integration:

The design of the Cargo Beam with Hook is simple and straightforward, which means it can be integrated into your existing lifting operations with minimal setup time. There are no complicated electrical or hydraulic components, making it easy to maintain and operate. This simplicity also translates to reduced costs for both installation and long-term maintenance.

Connecting the beam to cranes is quick and hassle-free, thanks to the pin or latch mechanisms. These connection methods ensure a secure attachment to the crane's spreader or upper rack, reducing the time needed to prepare for each lift. This quick integration means less downtime for your operation, increasing overall productivity.

Safety Features:

Safety is a top priority when dealing with heavy lifting operations, and the Cargo Beam with Hook is equipped with several key features designed to protect both operators and equipment.

- Anti-Decoupling Device: The anti-decoupling device prevents the hook from accidentally detaching during operation, ensuring that the cargo remains securely attached to the crane at all times. This reduces the risk of accidents and enhances overall safety during lifting.

- Automatic Limit Protection: The automatic limit system ensures that the beam does not exceed its safe operating range. This feature helps prevent overloading and damage to both the crane and the beam.

- Anti-Collision Protection: The system is also equipped with anti-collision features, which prevent the cargo from colliding with other objects during movement. This not only protects the cargo but also ensures the safety of the surrounding equipment and personnel.

Together, these safety features provide a high level of protection for your lifting operations, reducing the likelihood of accidents and keeping your team and equipment safe.

Durability & Reliability:

The Cargo Beam with Hook is built to last, thanks to its use of high-quality steel and superior manufacturing processes. The steel components undergo thorough pre-treatment, including blasting and protective painting, to ensure they resist corrosion and wear, even in tough environments.

This beam is engineered to endure harsh weather conditions, making it suitable for a wide range of operating environments, from freezing temperatures to hot, humid conditions. The temperature range of -20°C to +60°C ensures that the Cargo Beam can be used in various geographical locations and industries without worry.

Its durability also means that it requires less frequent maintenance, helping you reduce both downtime and maintenance costs. Over time, this reliable performance helps to lower the total cost of ownership and ensures that the Cargo Beam continues to perform at a high level, even in demanding conditions.

The Cargo Beam with Hook stands out due to its versatility, ease of use, safety features, and long-term durability, making it a smart choice for businesses looking for a dependable lifting solution in a wide variety of industries.

Key Applications

Industrial Production

The Cargo Beam with Hook is commonly used in industrial production for lifting heavy materials and machinery. It is perfect for large factories and manufacturing plants where moving bulk materials is a regular task.

- Ideal for lifting raw materials and finished products

- Works well with tire cranes and rail cranes

- Increases efficiency and reduces downtime in production lines

This beam helps factories like steel mills and automotive plants improve productivity by handling heavy loads quickly and safely.

Building Construction

In building construction, the Cargo Beam with Hook is used to lift large, heavy components like steel beams, concrete panels, and prefabricated parts.

- Perfect for lifting structural materials safely

- Quick and easy connection to cranes using pins or latches

- Includes safety features like anti-decoupling and anti-collision protection

It helps construction projects move forward smoothly and safely by handling heavy loads without delays.

Shipbuilding

In the shipbuilding industry, heavy components such as hull sections and ship engines need to be moved around the shipyard. The Cargo Beam with Hook is designed to lift these large, bulky items with precision.

- Ideal for lifting large ship components

- Customizable hook options for different lifting needs

- Durable and resistant to marine environments

The beam's high lifting capacity makes it a reliable tool for shipyards where heavy lifting is required under tough conditions.

Other Industries

The Cargo Beam with Hook is also used in other sectors like:

- Port Operations: Used for lifting bulk cargo and containers.

- Warehouses and Logistics: Ideal for moving large items and heavy machinery in storage or transport.

- Heavy Equipment Rental and Maintenance: Helps lift machinery for repairs and transportation.

In these industries, the beam makes it easier to move heavy loads efficiently and safely, improving productivity and reducing risks.

Safety Features

Automatic Limit Protection

The Cargo Beam with Hook is equipped with automatic limit protection to ensure safe operation during lifting tasks. This feature prevents the beam from being overextended, ensuring the lifting system operates within its safe limits. By automatically stopping the lift if it reaches the maximum safe point, it helps avoid overloading the system and protects both equipment and cargo from potential damage.

- Prevents overextension of the beam

- Protects lifting equipment from overloading

- Increases operational safety by ensuring safe lifting limits

This feature is crucial in maintaining the integrity of both the crane and the load during high-capacity lifts.

Anti-Collision System

The anti-collision system is another key safety feature that minimizes the risk of accidents during lifting operations. It prevents the cargo from colliding with other objects or structures while being moved, reducing the chance of damage to the load, the crane, and the surrounding environment.

- Helps avoid cargo collisions with nearby structures or equipment

- Ensures safe transport of heavy or bulky materials

- Reduces the risk of equipment downtime due to accidents

With this system in place, operators can move cargo with greater confidence, knowing that the risk of accidental impact is minimized.

Operator Safety

The safety of crane operators is a top priority with the Cargo Beam with Hook. The beam is designed with several features that reduce risks during bulk cargo lifting:

- Anti-decoupling Device: Ensures the hook remains securely attached to the load, preventing accidental detachment during lifting.

- Limit Protection and Anti-Collision Features: Minimize the chance of accidents, keeping operators safe from unexpected movements or load shifts.

- Stable Operation: The beam's simple structure and reliable connections reduce the likelihood of mechanical failures that could endanger operators.

Together, these features help ensure that operators can perform their tasks safely, with minimal risk of injury or equipment damage during lifting operations.

Why Choose Our Cargo Beam with Hook?

Reliability

Our Cargo Beam with Hook has a proven track record of reliability in demanding lifting operations. With years of performance in industries like construction, shipbuilding, and industrial production, it consistently meets the toughest lifting requirements. The beam's simple yet sturdy design ensures dependable operation under heavy loads, providing peace of mind for operators in high-demand environments.

- Trusted for heavy lifting tasks in various industries

- Consistently performs under high load capacities

- Built for long-term reliability in tough conditions

By choosing our Cargo Beam, you're ensuring dependable performance for all your lifting needs.

Customizable Solutions

We offer customizable options for the Cargo Beam with Hook to fit your specific lifting requirements. Whether you need a particular hook form, lifting capacity, or connection type, we can tailor the beam to suit your operational needs. This flexibility makes the beam ideal for a wide range of applications, from bulk cargo lifting to heavy equipment handling.

- Choose from various hook forms to match your load types

- Custom connections for compatibility with your lifting system

- Adaptable to different crane types and lifting setups

Our customization options allow you to get a product that works best for your unique operational demands.

Cost-Effective

The Cargo Beam with Hook is a cost-effective solution due to its simple design with no complex electrical or hydraulic components. This leads to lower upfront costs and significantly reduced maintenance expenses over time. Without the need for specialized systems, the beam is easier to maintain and repair, saving your business money in the long run.

- No electrical or hydraulic components reduces maintenance costs

- Simple design for easier installation and operation

- Lower upfront costs compared to more complex lifting systems

Choose our Cargo Beam for an affordable and efficient lifting solution that doesn't compromise on quality or performance.

Long-Term Performance

Our Cargo Beam with Hook is designed for long-term performance, even in the harshest working conditions. Built with high-quality materials and treated for durability, it can handle high load capacities and endure extreme temperatures, weather conditions, and other environmental challenges. Whether in construction zones, shipyards, or industrial plants, it offers reliable service life, minimizing downtime and ensuring your operations keep running smoothly.

- Built to withstand harsh working environments

- Durable materials and construction for long-lasting use

- High load capacities for demanding applications

This beam is a smart investment for businesses looking for a durable, high-performance product that will serve them for years to come.

FAQs

What cranes are compatible with the Cargo Beam with Hook?

The Cargo Beam with Hook is designed to be compatible with a wide range of lifting equipment. It works seamlessly with tire cranes, rail cranes, and other lifting machines that are commonly used in industries such as construction, shipbuilding, and industrial production.

- Tire cranes: Versatile and mobile cranes used in outdoor environments.

- Rail cranes: Ideal for lifting operations on tracks or in rail yards.

- Other lifting equipment: Compatible with various lifting systems depending on the setup.

This flexibility allows for easy integration into your existing operations, ensuring reliable and efficient lifting across different types of cranes.

What is the maximum weight the cargo beam can lift?

The Cargo Beam with Hook is rated to lift loads between 50 to 80 tons, making it suitable for a variety of heavy lifting applications, from bulk cargo to large construction components.

- Rated lifting load: Up to 80 tons.

- Versatile lifting capacity for a range of industries and applications.

With this impressive lifting capacity, the beam ensures safe and efficient handling of heavy and bulky materials.

How do I maintain the anti-decoupling device?

To keep the anti-decoupling device in optimal condition, regular inspection and maintenance are required. Follow these tips to ensure the device functions properly:

- Inspect regularly: Check the anti-decoupling device for wear and tear, especially after heavy lifting tasks.

- Clean and lubricate: Keep the device clean and properly lubricated to prevent rust or buildup that could affect its function.

- Test functionality: Periodically test the device to ensure it is securely holding the hook in place and preventing accidental detachment.

- Replace damaged parts: If any components of the anti-decoupling device are damaged or worn out, replace them promptly to maintain safety.

By following these simple maintenance steps, you can ensure that the anti-decoupling device remains effective and continues to protect both the operator and the load during lifting operations.

Order Information

Product Variants

We offer a range of customizable options for the Cargo Beam with Hook to suit various lifting needs. You can select from:

- Load Capacities: Choose from different lifting capacities, with a range from 50 tons to 80 tons, depending on the weight of the materials you plan to handle.

- Hook Forms: Customizable hook types to match the specific lifting requirements for your operation. Whether you need a standard hook or a specialized design, we can provide options that best suit your needs.

- Connection Types: The cargo beam can be equipped with various connection types, including pin holes, pins, or latches, to easily integrate with your existing lifting systems, such as tire cranes and rail cranes.

These flexible configurations ensure that you get a Cargo Beam with Hook perfectly suited to your operational requirements.

Pricing & Availability

Pricing for the Cargo Beam with Hook depends on the selected load capacity, hook form, and connection type. Please contact us for an accurate quote based on your needs.

- Competitive pricing for different models

- Quick availability based on stock and customization requirements

- Flexible delivery options to meet your schedule

Our sales team will work with you to provide the best pricing and availability based on your specific requirements.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch