Monorail Bridge Cranes Overview : Design, Applications, and Comparisons

Comprehensive Guide to Monorail Bridge Cranes: Structural Overview, Applications, and Comparative Analysis with Monorail Cranes and Standard Bridge Crane Types.

Category: Bridge Crane

Your Trusted Bridge Crane Manufacturer & Supplier

Monorail Bridge Cranes Overview : Design, Applications, and Comparisons

Comprehensive Guide to Monorail Bridge Cranes: Structural Overview, Applications, and Comparative Analysis with Monorail Cranes and Standard Bridge Crane Types

Monorail bridge cranes are specialized overhead lifting systems that utilize a single main girder, typically an I-beam or H-beam, for the movement of a trolley and hoist. Unlike traditional bridge cranes that may feature double girders or box girders, monorail bridge cranes are designed to operate along a fixed path defined by the single girder. This structural simplicity allows them to be particularly effective in environments where space is limited or where a linear movement path is sufficient.

The significance of monorail bridge cranes in industrial applications cannot be overstated. They play a crucial role in enhancing productivity, improving workplace safety, and optimizing floor space utilization. These cranes are widely used across manufacturing plants, assembly lines, warehouses, and even in specialized industries such as automotive and aerospace, where precise and efficient material handling is essential.

Overview of Monorail Bridge Cranes

Monorail bridge cranes are a specialized type of overhead crane designed to facilitate the movement of materials along a fixed path. Unlike traditional bridge cranes that utilize multiple girders, monorail bridge cranes operate using a single main girder, typically constructed from an I-beam or H-beam. This structural design allows the trolley and hoist to move horizontally along the length of the girder, providing efficient and precise material handling capabilities.

Components of Monorail Bridge Cranes

- Main Girder (I-Beam or H-Beam): The main girder serves as the backbone of the monorail bridge crane, providing support and structure for the entire system. It is typically made from sturdy materials like steel I-beams or H-beams, chosen for their strength and durability.

- Trolley: The trolley is the component that moves horizontally along the length of the main girder. It houses the hoist and facilitates the lateral movement of loads, allowing for precise positioning during lifting and transporting operations.

- Hoist: Attached to the trolley, the hoist is responsible for lifting and lowering loads. It can vary in capacity depending on the specific requirements of the application, ranging from light-duty to heavy-duty operations.

- Runway Support: Monorail bridge cranes are supported by a runway system, which can be either ceiling-mounted or freestanding, depending on the layout of the facility and the specific operational needs. The runway supports the main girder and ensures smooth movement of the trolley and hoist along the designated path.

Features of Monorail Bridge Crane

- Structural Design: A single girder monorail bridge crane features a straightforward design with a single main girder, typically an I-beam or H-beam. This design choice emphasizes simplicity and cost-effectiveness while maintaining adequate strength and durability for light to moderate lifting operations.

- Movement Capabilities: The trolley of a single girder monorail bridge crane moves horizontally along the length of the main girder, facilitating precise material handling within a defined path. This movement capability makes it ideal for applications where loads need to be transported along a linear trajectory with minimal lateral movement.

- Applications: Single girder monorail bridge cranes are commonly used in manufacturing and assembly lines, where they excel in moving parts and components along a production process. They are also suitable for warehousing and distribution centers, supporting efficient inventory management and order fulfillment operations.

Design and Functionality

Structural Design

Monorail bridge cranes are characterized by their structural simplicity and efficiency in material handling operations. The main components include:

- Main Girder Types (I-Beam or H-Beam): The main girder of a monorail bridge crane is typically constructed from robust materials such as steel I-beams or H-beams. This choice of girder type ensures strength and durability, essential for supporting the weight of loads being lifted and moved.

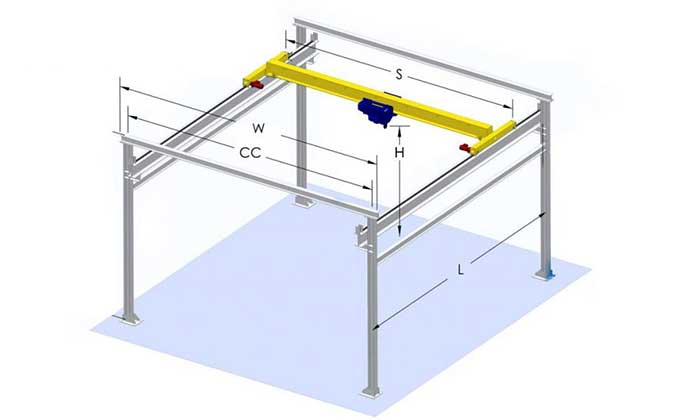

- Configuration and Mounting Options (Ceiling-mounted, Freestanding): Monorail bridge cranes can be configured in various ways to suit different industrial environments. They may be ceiling-mounted, where the main girder is attached to overhead supports, or freestanding, where the crane is supported by columns on the ground. These mounting options provide flexibility in installation and layout planning, accommodating space constraints and operational needs.

Movement Capabilities

- Horizontal Travel Along the Girder: The trolley of a monorail bridge crane moves horizontally along the length of the main girder, enabling precise positioning of loads across the workspace. This horizontal travel capability is essential for efficient material handling within a defined path.

- Vertical Lifting Capabilities: Equipped with a hoist attached to the trolley, monorail bridge cranes have robust vertical lifting capabilities. This feature allows for the safe and controlled lifting and lowering of loads to desired heights, contributing to operational efficiency and worker safety.

- Comparison with Monorail Cranes: Structural and Operational Differences: While monorail bridge cranes and monorail cranes both feature a single beam design, they serve different purposes. Monorail bridge cranes are typically used for linear material handling tasks along a fixed path defined by the main girder. In contrast, monorail cranes may operate along a fixed path or a complex network of beams and supports, providing greater flexibility in material transport and storage solutions.

Advantages of Monorail Bridge Cranes

Monorail bridge cranes offer several advantages that make them a preferred choice in industrial material handling operations:

- Space Efficiency - Minimal Floor Space Requirements: Monorail bridge cranes require less floor space compared to traditional bridge cranes with multiple girders. Their single girder design and overhead installation maximize vertical space utilization, freeing up floor space for other operations or equipment. This compact footprint is especially beneficial in facilities where space is limited or needs to be optimized for efficient workflow.

- Cost-Effectiveness - Lower Installation and Maintenance Costs: Due to their simplified design and fewer components compared to double girder bridge cranes, monorail bridge cranes generally incur lower installation and maintenance costs. The reduced structural complexity and easier access for maintenance contribute to overall cost savings throughout the crane's lifespan.

- Application Specificity - Ideal for Linear Manufacturing Processes: Monorail bridge cranes excel in linear manufacturing processes where materials or products need to be moved along a specific path. Their ability to operate along a fixed trajectory defined by the main girder makes them ideal for assembly lines, production cells, and conveyor systems. This specificity enhances operational efficiency by streamlining material flow and reducing handling time between workstations.

- Safety and Ergonomics - Enhanced Worker Safety: Monorail bridge cranes enhance workplace safety by minimizing manual lifting and handling of heavy loads. The precise control offered by the trolley and hoist reduces the risk of accidents and injuries associated with manual material handling tasks. Additionally, overhead installation keeps the floor area clear of obstacles, further reducing tripping hazards and improving overall workplace safety.

Ergonomic Benefits in Material Handling: The ergonomic design of monorail bridge cranes reduces strain on workers by automating repetitive lifting tasks. Operators can easily maneuver loads along the main girder with minimal physical effort, promoting ergonomic best practices and reducing fatigue over extended periods of operation.

Limitations of Monorail Bridge Cranes

While monorail bridge cranes offer significant advantages, they also have certain limitations that should be considered:

- Limited Movement Path - Restricted to Fixed Path Along the Girder: Monorail bridge cranes operate along a fixed path defined by the main girder. This restricts their movement capabilities to linear trajectories, which may not be suitable for applications requiring extensive horizontal coverage or complex material handling routes.

- Lower Load Capacity - Suitable for Lighter Loads Compared to Standard Bridge Cranes: Monorail bridge cranes typically have lower load capacities compared to double girder bridge cranes. They are designed for light to moderate lifting operations and may not be suitable for handling heavy or oversized loads that require higher lifting capacities.

- Complexity in Installation - Challenges in Integration with Existing Infrastructure: Installing monorail bridge cranes can pose challenges, especially when integrating them with existing facility infrastructure. Ceiling-mounted cranes require structural support that must be carefully planned and implemented to ensure safety and operational efficiency. Freestanding cranes may also require adequate floor space and foundation preparation, adding complexity to the installation process.

Applications of Monorail Bridge Cranes

Monorail bridge cranes find diverse applications across various industries, leveraging their structural efficiency and operational benefits:

Industry Uses

- Manufacturing and Assembly Lines: Monorail bridge cranes are integral to manufacturing processes, where they facilitate the movement of parts and components along production lines. Their ability to operate along a fixed path enhances workflow efficiency and supports just-in-time manufacturing practices.

- Warehousing and Distribution Centers: In warehousing and distribution facilities, monorail bridge cranes streamline inventory management and order fulfillment operations. They enable efficient movement of goods within storage areas, optimizing space utilization and reducing handling time.

- Automotive and Aerospace Industries: Monorail bridge cranes play a crucial role in automotive and aerospace manufacturing, where precision and reliability are paramount. They support assembly operations, handling of heavy and delicate components, and maintenance tasks in specialized production environments.

Specific Use Cases

- Handling of Parts and Components: Monorail bridge cranes are ideal for transporting parts and components between workstations or along production cells. Their linear movement capabilities ensure accurate positioning and smooth material flow, contributing to operational efficiency.

- Process Assembly and Production Lines: Monorail bridge cranes are well-suited for process assembly lines, where they facilitate the sequential assembly of products. They enable operators to move materials and assemblies precisely, supporting continuous production and quality control measures.

Monorail Bridge Cranes vs. Monorail Cranes

The distinction between "Monorail Bridge Cranes" and "Monorail Cranes" typically lies in their design and functionality:

Monorail Bridge Cranes:

- Structure: These cranes are usually comprised of a single girder or beam that runs along a fixed path. They are often ceiling-mounted and can span across a defined area within a facility.

- Movement: Monorail bridge cranes can move along the length of the monorail beam, allowing them to cover a linear path. They are versatile for moving loads in a straight line.

- Applications: Commonly used in assembly lines, manufacturing processes, and warehouses where there is a need to transport materials or products in a linear direction without the need for complex movement patterns.

- Structure: Monorail cranes are also single-beam cranes but are typically designed to move on a fixed track or rail system that is usually ground-mounted.

- Movement: Unlike monorail bridge cranes that move along a ceiling-mounted beam, monorail cranes move along a ground-level track. They are often used for transporting materials in a linear path within a specific area.

- Applications: Found in manufacturing environments, workshops, and assembly lines where there is a need for efficient movement of materials along a fixed path on the ground.

Key Differences:

- Mounting: Monorail bridge cranes are typically mounted on the ceiling or elevated structures, while monorail cranes are ground-mounted.

- Movement Path: Monorail bridge cranes move along a ceiling-mounted beam, offering overhead movement. Monorail cranes move along a ground-level track, providing movement along the floor.

- Applications: Both types serve similar purposes of material handling but differ in how they utilize space and move loads.

Understanding these distinctions helps in choosing the right type of crane based on specific operational needs and space constraints within industrial settings.

Comparions

Load Capacity and Stability Comparison:

Monorail Bridge Cranes:

- Load Capacity: Typically designed for medium to heavy loads, depending on the specific design and structural capacity of the beam.

- Stability: Offers stable overhead movement due to ceiling mounting, providing consistent and controlled handling of loads.

- Usage: Suitable for applications requiring precise and stable movement of loads along a linear path without ground-level obstacles.

Monorail Cranes:

- Load Capacity: Generally used for light to medium loads, depending on the design and construction of the ground-level tracks.

- Stability: Ground-mounted design provides stable movement along fixed tracks, suitable for consistent handling of loads within its capacity range.

- Usage: Ideal for applications where ground-level movement is sufficient and where overhead space might be limited or where the simplicity of ground-level installation is advantageous.

Cost and Installation Complexity:

Monorail Bridge Cranes:

- Cost: Generally higher due to the need for ceiling mounting, structural considerations, and potentially larger load capacities.

- Installation: More complex installation process due to the need for ceiling supports, beam installation, and potential structural modifications.

- Maintenance: May require specialized maintenance due to overhead components and structural integrity.

Monorail Cranes:

- Cost: Often more cost-effective compared to bridge cranes, especially for lighter duty applications.

- Installation: Relatively simpler installation process as they are ground-mounted, requiring less structural modification and overhead work.

- Maintenance: Generally straightforward maintenance due to accessible ground-level components and tracks.

Use Cases in Various Industries:

Monorail Bridge Cranes:

- Industries: Commonly used in heavy manufacturing, automotive assembly, aerospace, and other industries requiring precise overhead movement of heavy loads.

- Applications: Suitable for assembly lines, where products move along a linear path, and in warehouses for heavy material handling tasks.

Monorail Cranes:

- Industries: Found in light manufacturing, workshops, smaller warehouses, and industries with lighter material handling needs.

- Applications: Ideal for transferring materials between workstations, feeding materials to machines, and within smaller production cells where ground-level movement suffices.

Summary:

- Load Capacity and Stability: Monorail bridge cranes typically handle heavier loads with stable overhead movement, while monorail cranes are suited for lighter loads with stable ground-level movement.

- Cost and Installation Complexity: Monorail bridge cranes are generally more expensive and complex to install due to their overhead mounting, while monorail cranes offer a more cost-effective and simpler installation process.

- Use Cases: Monorail bridge cranes are prevalent in heavy industries requiring precise overhead movement, while monorail cranes are suitable for lighter applications and industries where ground-level movement is sufficient.

Choosing between these crane types depends on specific operational needs, load requirements, space availability, and budget considerations within each industry context.

Monorail Bridge Cranes vs. Overhead Bridge Cranes

The distinction between "Monorail Bridge Cranes" and "Overhead Bridge Cranes" typically lies in their design and functionality:

Monorail Bridge Cranes with I beam :

- Structure: Monorail bridge cranes are typically comprised of a single girder or beam that runs along a fixed path. They are often ceiling-mounted and can span across a defined area within a facility.

- Movement: These cranes move along the length of the monorail beam, allowing them to cover a linear path. They provide overhead movement, suitable for lifting and transporting loads in a straight line.

- Applications: Commonly used in assembly lines, manufacturing processes, and warehouses where there is a need to transport materials or products in a linear direction without complex movement patterns.

Overhead Bridge Cranes with Box girder :

- Structure: Overhead bridge cranes typically feature two parallel girders (double girder) that span across elevated runways or rails.

- Movement: They move along these elevated runways, providing both longitudinal (forward and backward) and lateral (side-to-side) movement capabilities.

- Applications: Found in industrial settings where heavy loads need to be lifted and moved across larger areas with versatile movement patterns.

Key Differences:

- Mounting: Monorail bridge cranes are mounted on the ceiling or elevated structures, maximizing overhead space utilization. Overhead bridge cranes are also ceiling-mounted but feature a double girder design for increased load capacity and movement flexibility.

- Movement Path: Monorail bridge cranes move along a single overhead beam, offering linear movement along a fixed path. Overhead bridge cranes move along elevated runways, providing both longitudinal and lateral movement, which allows them to cover larger areas and handle more complex material handling tasks.

- Applications: Monorail bridge cranes are suited for applications requiring straightforward linear movement of materials or products within a specific area. Overhead bridge cranes are preferred for tasks involving heavier loads, larger work areas, and the need for versatile movement capabilities across multiple axes.

These distinctions helps in choosing the right type of bridge crane based on specific operational needs, spatial constraints, load capacities, and movement requirements within industrial environments.

Comparison

Load Capacity and Stability Comparison:

- Monorail Bridge Cranes: Monorail bridge cranes typically have lower load capacities compared to standard bridge cranes. They are designed for light to moderate lifting operations and are suitable for handling loads up to several tons, depending on the specific model and configuration. The single girder design provides adequate stability for linear material handling tasks but may not support as heavy loads as double girder bridge cranes.

- Standard Bridge Cranes: Standard bridge cranes feature two parallel girders (double girder design) that offer higher load capacities and greater stability compared to monorail bridge cranes. They are capable of lifting heavier loads, often ranging from several tons to over 100 tons, depending on the crane specifications. The dual girder structure distributes the load more evenly, providing enhanced stability and reliability for intensive lifting applications.

Cost and Installation Complexity:

- Monorail Bridge Cranes: Monorail bridge cranes generally have lower installation and maintenance costs compared to standard bridge cranes. The single girder design and simplified structure contribute to reduced initial investment and operational expenses. Installation complexity varies based on mounting options (ceiling-mounted or freestanding) but is typically less intricate than double girder bridge cranes.

- Standard Bridge Cranes: Standard bridge cranes are often more expensive to purchase and install due to their dual girder configuration and higher load capacities. The complexity of installation increases with the need for additional structural supports and overhead runway systems. Maintenance costs may also be higher due to the larger and more intricate components involved.

Use Cases in Various Industries:

- Monorail Bridge Cranes: Monorail bridge cranes are widely used in manufacturing and assembly lines where linear material handling is required. They excel in industries such as automotive manufacturing, aerospace, and general manufacturing processes where space efficiency and precise material handling are critical.

- Standard Bridge Cranes: Standard bridge cranes are preferred in heavy industries such as steel mills, shipbuilding, and construction sites where lifting capacities exceed the capabilities of monorail bridge cranes. They are also suitable for large-scale manufacturing facilities and warehouses handling heavy or bulky materials.

Choosing the Right Monorail Bridge Crane

When selecting a monorail bridge crane for your industrial application, several considerations should be taken into account:

Considerations:

- Facility Layout and Space Constraints: - Evaluate the available space in your facility to determine the optimal mounting option for the monorail bridge crane. Consider factors such as ceiling height, floor space, and layout efficiency to ensure seamless integration without disrupting existing operations.

- Load Capacity Requirements: - Determine the maximum weight and size of loads that the monorail bridge crane will handle on a regular basis. Match these requirements with the crane's load capacity specifications to ensure safe and efficient material handling operations.

- Budget Constraints and Cost Analysis: - Conduct a thorough cost analysis, considering both the initial investment and long-term maintenance costs associated with the monorail bridge crane. Compare different models and suppliers to find a solution that meets your budgetary constraints while delivering optimal performance and reliability.

- Integration with Existing Systems and Infrastructure: - Assess how the monorail bridge crane will integrate with existing production systems, workflow processes, and infrastructure. Consider compatibility with other equipment, safety protocols, and the ease of retrofitting or modifying existing structures if necessary.

Installation and Maintenance

Installing and maintaining a monorail bridge crane requires careful planning and adherence to safety standards to ensure optimal performance and longevity.

Installation Process:

Planning and Preparation:

- Conduct a thorough assessment of the facility layout and structural requirements for mounting the monorail bridge crane. Evaluate factors such as ceiling height, floor space, and load-bearing capacity to determine the most suitable installation location.

- Coordinate with engineers, contractors, and crane specialists to develop a detailed installation plan. Ensure compliance with local regulations and safety codes throughout the planning phase.

Assembly and Mounting:

- Begin with assembling the main components of the monorail bridge crane, including the main girder, trolley, hoist, and electrical controls, according to manufacturer guidelines and specifications.

- Safely mount the crane onto the designated support structure, whether it's ceiling-mounted or freestanding. Ensure precise alignment and secure fastening to guarantee stability and operational safety.

Maintenance Requirements:

Regular Inspections and Servicing:

- Implement a routine maintenance schedule to inspect critical components of the monorail bridge crane, including the main girder, trolley wheels, hoist mechanisms, and electrical systems.

- Conduct thorough inspections for signs of wear, corrosion, or malfunction. Replace worn-out parts and components promptly to prevent operational downtime and ensure safety compliance.

Troubleshooting Common Issues:

- Train maintenance personnel to identify and troubleshoot common issues that may arise with the monorail bridge crane, such as electrical faults, mechanical failures, or alignment issues.

- Maintain a comprehensive record of maintenance activities, including inspections, repairs, and component replacements, to track the crane's performance and compliance with maintenance schedules.

Conclusion

As we conclude our exploration of monorail bridge cranes, it's essential to recap key insights and considerations for their implementation in modern industry.

Recap of Key Points:

- Monorail bridge cranes combine the structural efficiency of monorail cranes with the movement capabilities of bridge cranes, offering enhanced flexibility and precision in material handling.

- They are suitable for applications requiring linear material movement along a fixed path, supporting industries such as manufacturing, warehousing, and automotive assembly.

- Important considerations include load capacity requirements, space constraints, budget considerations, and integration with existing infrastructure.

Importance of Monorail Bridge Cranes in Modern Industry:

- Monorail bridge cranes play a crucial role in optimizing material handling processes, improving workflow efficiency, and enhancing workplace safety.

- They contribute to reducing operational costs through space-efficient designs, lower installation costs, and minimal maintenance requirements compared to standard bridge cranes.

- Their versatility and adaptability make them ideal for modern industrial environments seeking to streamline production and increase operational productivity.

Final Considerations for Implementing Monorail Bridge Cranes:

- Evaluate specific operational needs and facility requirements to determine the most suitable type of monorail bridge crane (ceiling-mounted or freestanding).

- Conduct thorough planning and coordination during the installation phase to ensure compliance with safety standards and operational efficiency.

- Implement a proactive maintenance strategy to prolong the lifespan of the crane and optimize its performance over time.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch