Small Bridge Crane for Sale, Addressing Height Limitations with Small Bridge Cranes

Small bridge cranes maximize vertical space in low-clearance environments, enhancing efficiency and safety in various industrial applications and settings.

Category: Bridge Crane

Your Trusted Small Overhead Crane Manufacturer & Supplier

Small Bridge Crane for Sale 500kg, 1 Ton 2 Ton, 3 Ton

Addressing Height Limitations with Small Bridge Cranes

Small bridge cranes maximize vertical space in low-clearance environments, enhancing efficiency and safety in various industrial applications and settings.

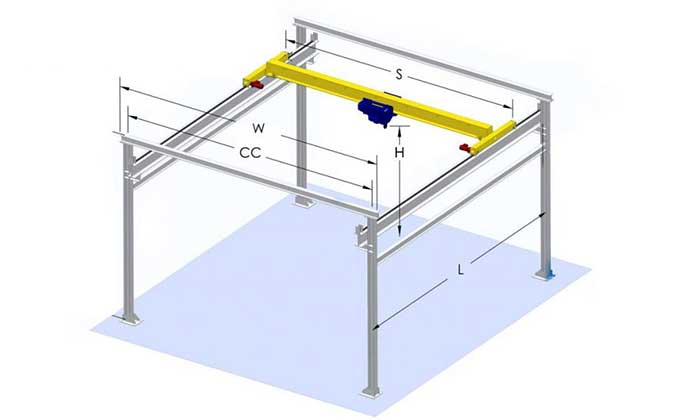

Small bridge cranes are specialized lifting devices designed to move heavy materials horizontally across a defined workspace, typically found in industrial environments. Unlike larger bridge cranes, small bridge cranes have a compact design, making them ideal for facilities with limited overhead space. These cranes consist of a horizontal beam (the bridge) supported by two vertical tracks, which allows the hoist mechanism to travel along the length of the beam. Key design features include:

- Reduced Dimensions: Smaller physical size allows for installation in facilities with low ceilings or tight spaces.

- Lightweight Construction: Often made from high-strength materials, small bridge cranes maintain durability without excessive weight, enhancing their load-handling efficiency.

- Flexible Configuration: Many small bridge cranes can be customized to fit specific workspace dimensions and operational needs, ensuring optimal performance.

Importance of Height Limitations in Industrial Settings

Height limitations in industrial environments are common and can significantly impact operational efficiency. Many facilities, particularly older buildings or those with specific architectural constraints, have low ceilings that restrict the types of lifting equipment that can be used. The implications of these height restrictions include:

- Restricted Equipment Options: Traditional, larger cranes may not fit within these confines, limiting the ability to lift and move heavy materials effectively.

- Operational Inefficiencies: Height restrictions can lead to bottlenecks in workflows, causing delays in production and increased labor costs as workers struggle to maneuver materials in cramped conditions.

- Safety Risks: Working in low-clearance areas can increase the risk of accidents, such as collisions with overhead structures or falling loads, making it crucial to use equipment that is designed for such environments.

Small Bridge Cranes

Features of Small Bridge Cranes

Small bridge cranes are engineered with specific design elements that allow them to operate efficiently in low-clearance environments. Key features include:

- Compact Design: These cranes have a smaller footprint and lower overall height, making them suitable for facilities with restricted headroom. Their design maximizes vertical space while ensuring robust performance.

- Lightweight Materials: Constructed from high-strength yet lightweight materials, small bridge cranes are easier to install and maneuver. This reduces the need for extensive structural support while maintaining durability.

- Enhanced Mobility: Many small bridge cranes come equipped with advanced hoist systems that allow for smooth and controlled movements. This is particularly beneficial in tight spaces where precise positioning is essential.

- Versatile Mounting Options: Small bridge cranes can be mounted in various configurations, such as overhead tracks or side-mounted options, enabling flexibility in installation according to the specific layout of a facility.

Comparison with Standard Bridge Cranes:

- Size and Weight: Standard bridge cranes tend to be larger and heavier, making them unsuitable for low-clearance applications. In contrast, small bridge cranes are designed specifically for environments with height limitations.

- Operational Range: While standard bridge cranes are ideal for expansive areas, small bridge cranes excel in confined spaces, making them a more practical choice for many industrial settings.

- Cost-Effectiveness: Smaller cranes typically require less investment in infrastructure, leading to lower overall costs for businesses with limited vertical space.

Types of Small Bridge Cranes

Small bridge cranes come in various designs, each tailored to meet specific operational needs and industry requirements. Below are the key types of small bridge cranes, along with their features and applications.

European Style Single Girder Small Bridge Cranes

- Comprised of a single horizontal beam supported by two end trucks, resulting in a lightweight and compact structure.

- Suited for lifting capacities typically ranging from 1 to 10 tons, making them popular in smaller manufacturing plants, assembly lines, and workshops.

- Maximizes vertical space, simplifies maintenance, and allows for straightforward operation, making it ideal for environments with low ceilings.

European Style Double Girder Small Bridge Cranes

- Features two parallel horizontal beams, providing enhanced support and stability, with the hoist traveling along the top.

- est for heavy-duty applications, capable of handling loads from 10 to 50 tons, commonly found in automotive manufacturing and steel processing.

- Offers increased lifting capacity, improved stability, and better headroom, adaptable to various facility layouts within height constraints.

European Style Under-Slung Small Bridge Cranes

- Runs on the underside of the building structure, eliminating the need for overhead supports.

- Particularly effective in facilities with minimal vertical clearance, such as older warehouses.

- Maximizes usable space beneath the crane, allowing for greater flexibility in handling larger loads or equipment.

LDP Low Headroom Small Overhead Cranes with Hoist Placed Aside of Main Girder

- The hoist is positioned alongside the main girder, optimizing vertical space utilization.

- seful in tight production lines or narrow aisles where maneuverability is essential.

- nhances load handling flexibility, allowing for efficient lifting and movement of various loads.

Telescopic Sliding Cantilever Small Bridge Cranes

- Features a retractable arm that can extend or shorten based on lifting needs.

- deal for maintenance workshops, shipyards, or assembly areas with varying load sizes.

- ighly adaptable and compact, capable of effectively handling different loads while fitting within height limitations.

Manual Operated Small Bridge Cranes

- Operated manually using a hand chain or push button for load control.

- erfect for smaller facilities where automation is not necessary, allowing operators to manage lifting tasks efficiently.

- rovides flexibility and precise control in confined spaces and is a cost-effective solution for efficient lifting without automation complexities.

Each type of small bridge crane is designed to tackle specific challenges presented by low-clearance environments, ensuring industries can maintain productivity, safety, and effective use of space.

Advantages of Small Bridge Cranes

Maximizing Vertical Space

Effective Utilization of Limited Headroom: Small bridge cranes are specifically engineered to function in environments with restricted vertical space. Their compact structure allows them to operate closer to the ceiling, thus maximizing the usable height within a facility. This design is particularly beneficial in:

- Low-Ceiling Warehouses: Small bridge cranes can navigate the tight confines of older or repurposed warehouses where standard cranes may not fit.

- Maintenance Shops: In workshops with overhead equipment or fixtures, these cranes enable lifting tasks without obstruction, allowing for more efficient operations.

Customizable Designs for Unique Spaces: Many small bridge cranes offer adjustable configurations, making them adaptable to various facility layouts and height restrictions. This customization ensures that:

- Adaptability to Specific Needs: Businesses can select cranes that fit their unique operational requirements, such as varying load capacities and lifting heights.

- Space Optimization: Custom solutions can further enhance vertical space utilization, allowing for more efficient storage and equipment placement.

Increased Efficiency in Operations

Improvements in Workflow: The streamlined design and functionality of small bridge cranes significantly enhance workflow in industrial settings. They facilitate:

- Reduced Manual Labor: By automating lifting tasks, workers spend less time manually moving heavy loads, allowing them to focus on more critical aspects of production.

- Faster Load Handling: The ability to swiftly lift and position loads minimizes the time spent on each operation, leading to quicker project completion.

Enhancing Speed and Productivity: Equipped with advanced hoisting mechanisms, small bridge cranes boost operational speed and overall productivity. Benefits include:

- Quick Response Times: These cranes often feature precise controls, enabling operators to swiftly adjust lifting heights and positions, which is crucial during busy production cycles.

- Minimized Downtime: Efficient load handling reduces the waiting time between operations, ensuring a continuous workflow and higher output levels across manufacturing or assembly lines.

Versatility in Various Applications

Industries That Benefit: The adaptability of small bridge cranes makes them suitable for a wide range of industries, including:

- Automotive Manufacturing: Used for moving heavy components and assemblies with precision, even in confined spaces.

- Aerospace: Essential for handling delicate parts and machinery where space and precision are critical.

- Logistics and Warehousing: Ideal for efficiently managing inventory and materials in tight aisles.

Specific Scenarios Where They Excel: Small bridge cranes shine in environments where space constraints are prevalent, such as:

- Workshops and Maintenance Facilities: Their compact design allows them to maneuver in tight spaces, facilitating quick and efficient maintenance and repairs.

- Small Manufacturing Plants: Perfect for companies with limited floor space, these cranes allow for efficient production processes while maintaining safety and operational integrity.

Key Applications of Small Bridge Cranes

Manufacturing Facilities

Role in Factories with Low Ceilings: Small bridge cranes are essential in manufacturing facilities that operate under height limitations. These cranes play a crucial role in:

- Material Handling: They facilitate the movement of raw materials and finished products in factories where ceiling height restricts the use of standard cranes. This ensures continuous workflow without delays.

- Assembly Line Support: In assembly lines, small bridge cranes assist in lifting heavy components, enhancing efficiency and worker safety by minimizing manual lifting and reducing strain on employees.

Specific Needs Addressed: Different manufacturing sectors have unique requirements, which small bridge cranes meet effectively:

- Precision Lifting: Their design allows for accurate placement of components, which is vital in industries such as electronics or automotive manufacturing where precision is paramount.

- Adaptability: These cranes can be configured for various lifting capacities, making them versatile for different production needs.

Warehousing and Distribution Centers

Efficient Handling of Materials in Compact Spaces: Small bridge cranes are indispensable in warehousing and distribution environments, particularly those with limited vertical space. Their advantages include:

- Maximizing Storage Capacity: By operating close to the ceiling, these cranes free up valuable floor space, allowing for higher shelving units and more efficient use of available square footage.

- Rapid Material Retrieval: The cranes streamline the process of loading and unloading materials, significantly improving the speed of order fulfillment and inventory management.

Benefits in Distribution Operations: In distribution centers, small bridge cranes enhance operations in several ways:

- Flexible Configuration: They can easily be adapted to different layouts, accommodating various loading docks and storage areas.

- Increased Safety: With automated lifting capabilities, small bridge cranes reduce the risk of accidents associated with manual material handling, promoting a safer work environment.

Maintenance and Repair Shops

Utility in Workshops with Overhead Constraints: Small bridge cranes are particularly useful in maintenance and repair shops where overhead space is often limited. Their key benefits include:

- Facilitating Heavy Lifts: They allow technicians to lift heavy equipment or machinery components safely, making maintenance tasks more manageable and efficient.

- Space-Saving Design: Their compact structure fits well in smaller workshops, enabling operators to perform tasks without feeling cramped.

Specific Applications in Maintenance: Small bridge cranes serve several functions in maintenance and repair environments:

- Equipment Maintenance: These cranes can be used to lift and maneuver machinery for repairs, inspections, or servicing, ensuring that technicians have easy access to all parts of the equipment.

- Storage Solutions: In addition to lifting, small bridge cranes can assist in organizing tools and materials overhead, keeping workspaces tidy and enhancing operational efficiency.

Challenges and Considerations

Load Capacity and Stability

Limitations Due to Design and Height Constraints:

Small bridge cranes are designed to operate in tight spaces, which can impose certain limitations. Key considerations include:

Reduced Load Capacity: While these cranes are effective in low-clearance environments, their compact design often means lower load capacities compared to larger cranes. Users must carefully assess the weight of materials being lifted to ensure they stay within safe operational limits.

Stability Concerns: The height restrictions can affect the crane's stability, especially when handling heavier loads. This makes it essential to conduct regular stability assessments and implement design features that enhance balance, such as:

- Wider Base Frames: To increase stability, selecting cranes with broader base frames can help distribute the load more evenly.

- Integrated Safety Features: Utilizing cranes equipped with safety mechanisms, like load limiters and overload sensors, can mitigate risks.

Safety Measures

Importance of Safety Protocols in Low-Clearance Environments:

Operating small bridge cranes in restricted vertical spaces necessitates stringent safety measures to protect workers and equipment. Key safety protocols include:

- Regular Training: Operators should undergo comprehensive training to understand the unique challenges posed by low-clearance environments, focusing on proper operation techniques and emergency procedures.

- Routine Inspections: Implementing regular inspection schedules ensures that all components of the crane, such as cables, hooks, and controls, are functioning correctly. Identifying wear and tear early helps prevent accidents.

- Clear Signage and Communication: Establishing clear communication protocols and visible signage in low-clearance areas helps workers remain aware of their surroundings, minimizing the risk of accidents.

Customization and Integration

Need for Tailored Solutions Based on Specific Operational Requirements:

To maximize the benefits of small bridge cranes, businesses often require customized solutions that align with their unique operational needs. Considerations include:

Adaptable Designs: Customization options, such as modifying crane height, span, and lifting mechanisms, allow facilities to effectively meet their specific space and operational demands. This adaptability ensures that the crane functions optimally within the given environment.

Seamless Integration with Existing Systems: Small bridge cranes should be compatible with other equipment and workflows in the facility. Effective integration helps enhance overall efficiency and reduces potential disruptions. Key aspects to consider are:

- Hoisting Mechanisms: Selecting appropriate hoisting systems that complement existing machinery and improve lifting efficiency.

- Control Systems: Implementing user-friendly controls that allow operators to manage lifting tasks seamlessly while adhering to safety protocols.

Overall, addressing these challenges through careful planning and implementation of tailored solutions can significantly enhance the operational efficiency and safety of small bridge cranes in environments with height limitations.

Conclusion

Small bridge cranes play a pivotal role in various industries, particularly in environments with limited vertical space. Their compact design and specialized features offer numerous benefits, including:

- Space Optimization: By maximizing headroom, these cranes enable facilities to utilize vertical space effectively, accommodating taller loads without requiring significant structural changes.

- Increased Efficiency: Small bridge cranes enhance workflow by providing quick and reliable lifting solutions, which can lead to improved operational speed and productivity.

- Versatility Across Industries: These cranes are adaptable to various applications, from manufacturing and warehousing to maintenance and repair shops, making them invaluable in diverse operational contexts.

In conclusion, small bridge cranes are essential tools for operations where height limitations present challenges. Their design and adaptability not only enhance productivity but also ensure safety in confined areas. As technology continues to progress, these cranes will likely become even more efficient and integral to various industries, further reinforcing their importance in modern industrial settings. Investing in small bridge cranes is not just a practical decision; it's a strategic move toward achieving optimal efficiency and safety in height-restricted environments.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch