Jib Cranes for Steel Column Erection in Confined Spaces

Jib cranes for positioning & erecting steel columns within confined construction spaces, precision, maneuverability & suitability.Get your custom jib crane.

Category: Construction

Your Trusted Overhead Jib Crane Manufacturer & Supplier

Jib Cranes for Steel Column Erection in Confined Spaces

Jib cranes for positioning & erecting steel columns within confined construction spaces, precision, maneuverability & suitability.Get your custom jib crane.

In the world of steel construction, where precision and maneuverability are paramount, the challenges posed by confined spaces during steel column erection demand innovative solutions. The success of a construction project hinges on the ability to navigate tight or hard-to-reach areas efficiently and safely. This is where the role of pillar jib cranes becomes particularly crucial.

Steel construction projects often involve working in confined spaces, where every movement counts. Precision is not just a desirable quality; it is a necessity. The accuracy with which steel columns are positioned and erected directly impacts the structural integrity of the entire project. Maneuverability, on the other hand, is the key to accessing and working in spaces where conventional equipment might struggle.

In the field of steel column erection, these specialized cranes play a vital role in overcoming the challenges posed by limited spaces. As we delve into the world of jib cranes, we'll explore their structural features, their precision and maneuverability capabilities, and how they prove to be the ideal solution for tasks such as positioning and erecting steel columns in tight construction areas.

Confined Spaces in Steel Construction

Definition of Confined Spaces

In the context of steel construction, confined spaces refer to areas with limited access and egress, not designed for continuous occupancy. These spaces may pose challenges due to their restricted dimensions, making traditional construction equipment and methods less effective.

Challenges Associated with Confined Spaces

Navigating and working in confined spaces during steel column erection present a unique set of challenges:

- Limited Access: Confined spaces often have narrow entry points, restricting the ease of access for equipment and workers.

- Restricted Movement: The confined nature of the space limits the movement of traditional cranes and construction machinery.

- Safety Concerns: Tight spaces can increase the risk of accidents and make it challenging to adhere to safety protocols.

- Precise Positioning: The need for precise positioning of steel columns becomes more critical in confined spaces to ensure proper alignment and structural integrity.

Overview of Jib Cranes

Definition and Basic Characteristics

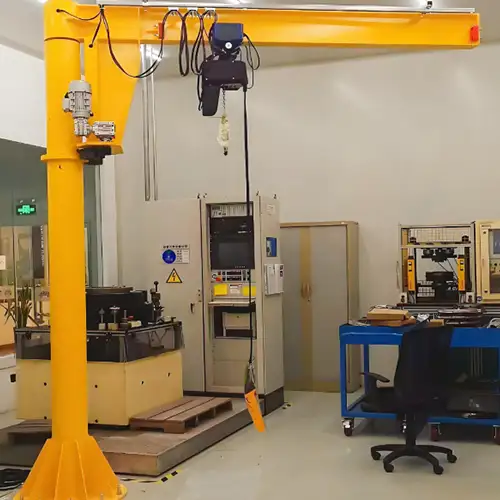

Jib cranes are a type of crane characterized by a horizontal jib or arm that supports a movable hoist. These cranes are versatile and designed for specific applications, making them particularly suitable for confined spaces in steel construction.

Structural Features

- Jib Arm: The horizontal jib arm provides lateral movement and can rotate, offering a wide range of motion within confined spaces.

- Hoist: The hoist is the lifting component, allowing vertical movement for precise positioning of steel columns.

- Rotation Capabilities: Jib cranes are designed to rotate, providing a full range of motion. This rotation is a key feature for navigating and working in confined spaces.

The combination of these structural features allows jib cranes to excel in tasks requiring precision, maneuverability, and the ability to operate within limited spaces.

Precision and Maneuverability Features of Jib Cranes

Highlighting Precision and Maneuverability

In the realm of steel construction, precision and maneuverability are non-negotiable factors, especially when working in confined spaces. Jib cranes stand out due to their specific features that contribute to the precision required for tasks like steel column erection:

- Compact Design: Jib cranes are designed with a compact structure, allowing them to operate in confined spaces with ease. Their small footprint ensures they can access and navigate areas where larger cranes may struggle.

- Rotation Range: The ability to rotate through a full 360 degrees provides unmatched flexibility. Jib cranes can precisely position steel columns in any direction, overcoming the challenges posed by confined spaces.

- Control Mechanisms: Jib cranes come equipped with advanced control systems that allow operators to make precise movements. This level of control is essential when working in tight quarters where every inch matters.

The compact design, rotation range, and sophisticated control mechanisms collectively make jib cranes an indispensable tool for navigating confined spaces with the utmost precision.

Suitability for Steel Column Erection in Confined Spaces

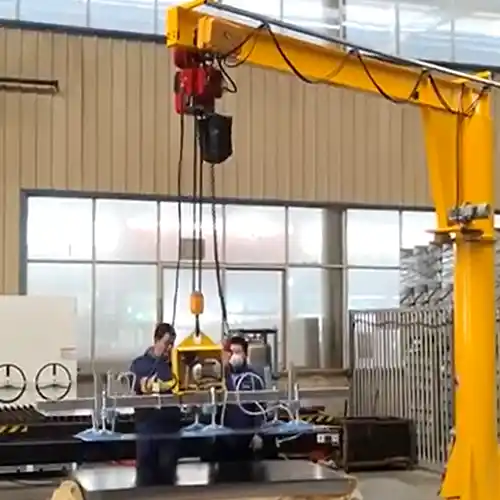

- Positioning Steel Columns: Jib cranes are adept at precisely positioning steel columns, even in areas with limited accessibility.

- Lifting in Tight Quarters: The compact design of jib cranes allows them to lift and maneuver steel columns in tight or hard-to-reach spaces.

- Erecting Columns with Precision: When erecting steel columns, the rotation range of jib cranes facilitates accurate placement, ensuring structural alignment.

- Navigating Obstacles: Jib cranes can navigate around obstacles in confined spaces, providing a versatile solution for complex construction environments.

- Enhanced Safety: The precise control afforded by jib cranes reduces the risk of accidents, promoting a safer working environment.

Case Studies

Urban High-Rise Construction: In the heart of a bustling urban environment, a high-rise construction project faced the challenge of erecting steel columns in a confined space between existing structures. Jib cranes were employed to navigate the limited space, ensuring precise positioning of each column without disrupting the surrounding buildings.

Industrial Facility Expansion: An expanding industrial facility required the installation of steel columns within an already operational area. Jib cranes proved instrumental in lifting and erecting columns without disrupting ongoing operations. The compact design of the cranes allowed for seamless integration into the existing workspace.

Architectural Marvel: The construction of an architecturally intricate building with unique structural requirements posed challenges in steel column erection. Jib cranes showcased their versatility by precisely maneuvering steel columns to meet the architectural specifications, contributing to the creation of a structural masterpiece.

These case studies exemplify the real-world application of jib cranes in confined spaces. The precision with which these cranes operate not only addresses the challenges posed by limited space but also significantly contributes to project efficiency. The ability to navigate confined areas, coupled with precise positioning capabilities, ensures that steel column erection stays on schedule and meets the highest standards of accuracy.

Advantages of Using Jib Cranes in Confined Spaces

When it comes to navigating confined spaces during steel column erection, jib cranes emerge as the unsung heroes. Their unique design and features bring forth a myriad of advantages, significantly impacting both efficiency and safety in construction projects.

Increased Efficiency and Time Savings

- Precision in Action: The primary advantage of using jib cranes in confined spaces is their unparalleled precision. These cranes can precisely position steel columns with minimal margin for error, ensuring that each component is placed exactly where it needs to be. This level of accuracy expedites the construction process, preventing delays caused by repositioning or adjustments.

- Time-Efficient Maneuverability: Jib cranes excel in their ability to swiftly maneuver within confined spaces. The compact design and rotation capabilities allow for seamless navigation around obstacles, eliminating the need for time-consuming dismantling and reassembly of equipment. This efficiency translates to time savings, a critical factor in meeting project timelines.

- Optimized Workflow: The precise control mechanisms of jib cranes contribute to an optimized workflow. Operators can execute lifting, positioning, and erecting tasks with ease, streamlining the entire construction process. This optimized workflow is particularly beneficial in confined spaces where swift and accurate movements are imperative.

- Versatility in Applications: Jib cranes showcase versatility in their applications within confined spaces. Whether it's positioning steel columns, lifting components, or navigating complex construction environments, these cranes adapt to various tasks, eliminating the need for multiple types of equipment.

Enhanced Safety Measures and Risk Reduction

- Reduced Manual Handling: Confined spaces often necessitate careful handling of materials to avoid collisions and accidents. Jib cranes, with their precise control systems, significantly reduce the reliance on manual handling. This not only enhances safety but also minimizes the risk of worker injuries associated with heavy lifting and material positioning.

- Stability and Structural Integrity: The stability provided by jib cranes contributes to the overall structural integrity of the construction site. The controlled movements ensure that steel columns are positioned without undue stress on the surrounding structures. This stability is paramount in confined spaces where the margin for error is minimal.

- Safety in Limited Visibility: Confined spaces may have limited visibility, increasing the likelihood of accidents. Jib cranes, with their ability to make controlled and precise movements, enhance safety in environments with restricted sightlines. Operators can navigate spaces with confidence, reducing the risk of collisions.

- Adherence to Safety Protocols: Jib cranes are designed with safety in mind. Their features align with industry safety protocols, and operators are equipped with controls that prioritize accident prevention. This adherence to safety standards contributes to a secure working environment in confined spaces.

- Avoidance of Collisions: The compact design and rotation range of jib cranes enable operators to avoid collisions with structures and obstacles. This proactive approach to collision avoidance minimizes the risk of damage to both the crane and the construction site.

In summary, the advantages of using jib cranes in confined spaces extend beyond operational efficiency to encompass enhanced safety measures. The combination of precision, time savings, and safety features positions jib cranes as indispensable assets in the complex landscape of steel column erection within confined construction spaces. In the next section, we will explore specific considerations when selecting and implementing jib cranes for optimal results in confined spaces.

Considerations in Jib Crane Selection for Confined Spaces

Selecting the right jib crane for steel column erection within confined spaces requires a thoughtful evaluation of various factors. The unique challenges posed by confined construction environments demand a tailored approach to crane selection. Here are key considerations to ensure optimal performance and safety:

Capacity and Load Requirements

- Evaluate Load Capacities: Understand the weight and dimensions of the steel columns and components that the jib crane will handle. Choose a crane with a capacity that comfortably accommodates the heaviest loads encountered in the confined space.

- Consider Future Needs: Anticipate potential changes in project requirements. Select a jib crane with a capacity that allows for future expansions or modifications to prevent the need for crane replacement.

Reach and Rotation Range

- Assess Spatial Limitations: Measure the available space within the confined area. Choose a jib crane with an appropriate reach and rotation range that aligns with the spatial constraints of the construction environment.

- 360-Degree Rotation: Opt for jib cranes with the ability to rotate a full 360 degrees. This feature ensures unrestricted movement and precise positioning, especially in confined spaces where maneuverability is critical.

Compact Design and Footprint

- Space Efficiency: Prioritize jib cranes with a compact design to maximize space utilization within confined areas. A smaller footprint allows for easier navigation and operation without compromising stability.

- Floor-Mounted vs. Wall-Mounted: Consider the layout of the confined space. Wall-mounted jib cranes are suitable when floor space is limited, while floor-mounted cranes provide stability and flexibility in maneuvering.

Control Systems

- Precision Controls: Choose jib cranes equipped with advanced control systems that enable precise movements. Radio remote controls or pendant controls with variable speed options enhance the operator's ability to navigate with accuracy.

- Ease of Operation: Consider user-friendly controls that facilitate ease of operation. Intuitive interfaces contribute to efficient and safe crane maneuvers, particularly in confined spaces where precision is paramount.

Safety Features

- Collision Avoidance Systems: Opt for jib cranes with built-in collision avoidance systems. These systems use sensors and alarms to alert operators to potential obstructions, reducing the risk of accidents in confined spaces.

- Overload Protection: Ensure that the jib crane has overload protection mechanisms to prevent exceeding weight capacities. This feature enhances both safety and the longevity of the crane.

Adaptability to Site Conditions

- Weather Resistance: Consider the environmental conditions of the construction site, including temperature variations and exposure to the elements. Choose jib cranes with weather-resistant features for reliable performance in diverse conditions.

- Corrosion Resistance: In corrosive environments, select cranes made from materials resistant to corrosion. This extends the lifespan of the crane and ensures continued reliability.

Compliance with Regulations

- Local Building Codes: Familiarize yourself with local building codes and regulations governing crane use in confined spaces. Ensure that the selected jib crane complies with these standards to maintain a safe and legally compliant work environment.

- Certifications: Choose jib cranes from reputable manufacturers with appropriate certifications. This ensures that the crane meets industry standards for safety and performance.

Ease of Maintenance and Serviceability

- Access for Maintenance: Evaluate the accessibility for maintenance tasks. Choose a jib crane design that allows for easy inspection and servicing to minimize downtime.

- Availability of Spare Parts: Ensure the availability of spare parts and service support from the manufacturer. This ensures timely repairs and maintenance to keep the jib crane operating at peak efficiency.

Cost Considerations

- Total Cost of Ownership: Assess the total cost of ownership, considering not only the initial purchase price but also maintenance, operating costs, and potential future upgrades. A comprehensive cost analysis helps in making informed decisions.

- Return on Investment (ROI): Evaluate the potential ROI of the jib crane based on its efficiency, time savings, and impact on project timelines. A higher initial investment may be justified by long-term gains in productivity.

In conclusion, the selection of jib cranes for confined spaces involves a thorough analysis of factors ranging from load capacities to safety features. Adapting crane specifications to the unique challenges posed by confined construction environments is crucial for maximizing efficiency and ensuring a safe working environment. The careful consideration of these factors will contribute to the successful integration of jib cranes in steel column erection projects within confined spaces.

Challenges and Solutions

Navigating confined spaces during steel column erection with jib cranes presents a set of challenges that require strategic planning and innovative solutions. Identifying potential hurdles and implementing best practices are crucial for ensuring the seamless operation of jib cranes in these constrained environments.

Challenges in Using Jib Cranes in Confined Spaces

Limited Spatial Clearance:

Challenge: Confined spaces often have limited spatial clearance, restricting the movement and operation of jib cranes.

Solution: Opt for jib cranes with adjustable jib arms or articulating jibs that can navigate around obstacles and operate within tight spaces.

Obstacle Navigation:

Challenge: Negotiating obstacles within confined spaces, such as existing structures or equipment, can pose challenges for jib crane movement.

Solution: Utilize jib cranes with advanced collision avoidance systems that use sensors and alarms to alert operators to potential obstructions. Careful planning of the crane's path can also mitigate collision risks.

Precision Positioning:

Challenge: Achieving precise positioning of steel columns in confined spaces requires careful control and maneuverability.

Solution: Select jib cranes with precise control systems, including variable speed options, allowing operators to make controlled movements for accurate positioning.

Operator Visibility:

Challenge: Limited visibility in confined spaces can hinder the operator's ability to navigate the crane safely.

Solution: Install additional lighting in the confined space to improve visibility. Implement cameras or monitoring systems to provide operators with a clear view of the crane's surroundings.

Load Weight Variability:

Challenge: The weight of steel columns may vary, requiring the jib crane to handle loads of different capacities.

Solution: Opt for jib cranes with adjustable load capacities or invest in multiple cranes with varying capacities to accommodate different load requirements.

Weather and Environmental Factors:

Challenge: Adverse weather conditions and environmental factors can impact the performance and longevity of jib cranes.

Solution: Choose jib cranes with weather-resistant features for durability in varying conditions. Implement regular maintenance schedules to address wear and tear caused by environmental factors.

Operator Training and Skill Requirements:

Challenge: Operating a jib crane in confined spaces requires specialized skills to ensure safety and efficiency.

Solution: Provide comprehensive training programs for crane operators, emphasizing the unique challenges of working in confined spaces. Regular refresher courses can help operators stay adept at handling the specific demands of the environment.

Best Practices for Overcoming Common Issues

- Pre-Construction Site Assessment: Best Practice: Conduct a thorough assessment of the confined space before initiating steel column erection. Identify potential obstacles, spatial constraints, and any environmental factors that may impact crane operation.

- Collaborative Planning with Project Teams: Best Practice: Foster collaboration between crane operators and project teams during the planning phase. Ensure that all stakeholders are aware of the crane's operational requirements and constraints within confined spaces.

- Continuous Monitoring and Communication: Best Practice: Implement continuous monitoring systems, such as cameras or sensors, to enhance operator visibility. Establish clear communication channels between operators and ground personnel to relay information in real-time.

- Regular Maintenance and Inspections: Best Practice: Schedule regular maintenance and inspections of jib cranes to identify potential issues before they escalate. Address wear and tear promptly to maintain optimal performance.

- Operator Training and Certification: Best Practice: Invest in comprehensive training programs for crane operators, focusing on the specific challenges of confined spaces. Ensure operators are certified and undergo regular training updates.

- Adaptability in Crane Design: Best Practice: Choose jib cranes with designs that offer adaptability to confined spaces. Features like adjustable jib arms, articulating jibs, and compact designs enhance the crane's adaptability.

- Utilization of Technology: Best Practice: Embrace technological advancements, such as collision avoidance systems and remote monitoring. Leverage technology to enhance crane performance and safety in confined spaces.

By addressing challenges through proactive planning, advanced technology adoption, and ongoing training, the use of jib cranes in confined spaces during steel column erection can be optimized for efficiency and safety. Implementing best practices ensures that these challenges become opportunities for innovation and successful project execution.

Wrap it Up to Get Your Jib Cranes

In the field of steel column erection within confined spaces, jib cranes emerge as indispensable partners, gracefully navigating challenges with precision and maneuverability. This article has explored the pivotal role that jib cranes play in addressing the unique demands posed by confined construction environments.

- Precision in Action: Jib cranes, with their compact design and advanced control systems, showcase precision in action. They delicately position steel columns with a level of accuracy that is paramount in confined spaces. The ability to make controlled movements ensures that each component finds its place with efficiency, contributing to the seamless progress of construction projects.

- Maneuverability in Confined Spaces: The maneuverability of jib cranes takes center stage when operating within confined spaces. Negotiating obstacles, limited spatial clearance, and achieving precise positioning demand a level of agility that conventional cranes may struggle to provide. Jib cranes, designed with adaptability in mind, navigate these challenges with ease, making them the equipment of choice in constrained construction environments.

- Significance of Specialized Equipment: As we conclude, it is essential to underscore the significance of using specialized equipment like jib cranes in confined spaces. The challenges inherent in such environments require tailored solutions, and jib cranes have proven to be a key element in overcoming these challenges. Their role goes beyond lifting; they are orchestrators of efficient and safe steel column erection within the intricacies of confined construction spaces.

- Efficiency and Safety Integration: The dual pillars of efficiency and safety stand tall in the successful integration of jib cranes. The increased efficiency, time savings, and enhanced safety measures underscore the value that these cranes bring to construction projects. From their precision controls to the incorporation of advanced safety features, jib cranes are not merely tools but strategic assets in the construction landscape.

In conclusion, the journey of steel column erection in confined spaces is not without its complexities, but with the right equipment, these challenges transform into opportunities for innovation and excellence. Jib cranes, with their precision in action and maneuverability prowess, exemplify the spirit of adaptability required in the dynamic world of construction. As we continue to push the boundaries of architectural possibilities, jib cranes stand ready, ensuring that confined spaces become canvases for structural masterpieces.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch