European Wire Rope Explosion Proof Electric Hoist 3 Ton to 50 Ton

Explosion proof hoist for sale. Designed for hazardous environment, ensuring safety, durability & precision with European style for explosive atmospheres.

Category: Hoist

Your Trusted Electric Hoist and Crane Manufacturer & Supplier

European Wire Rope Explosion Proof Electric Hoist 3 Ton to 50 Ton for Sale, Affordable Hoist Price

Explosion proof hoist for sale. Designed for hazardous environment, ensuring safety, durability & precision with European style for explosive atmospheres.

Explosion-Proof Wire Rope Electric Hoist

An explosion-proof wire rope electric hoist is a specialized lifting device designed for use in environments where explosive gases, vapors, or dust may be present. Unlike standard hoists, explosion-proof hoists are built to prevent sparks or heat generated by the motor or electrical components from igniting hazardous substances in the surrounding atmosphere.

These hoists consist of:

- A wire rope system for lifting heavy loads.

- An electric motor enclosed in a flameproof housing.

- Explosion-proof electrical components that prevent ignition sources.

Explosion-proof hoists are essential in environments like oil refineries, chemical plants, and mining operations, where safety is a top priority due to the risk of explosions.

Importance of Explosion-Proof Hoists in Hazardous Environments

Explosion-proof hoists are critical for industrial safety in environments with an increased risk of explosion. In places where flammable gases, vapors, or dust are present, even a small spark could cause a catastrophic explosion. Explosion-proof hoists are designed to eliminate this risk, providing safe and efficient lifting in such hazardous conditions.

Key reasons why explosion-proof hoists are important:

- Safety: Prevent potential ignition sources that could lead to explosions.

- Reliability: Ensure safe operations in volatile environments.

- Compliance: Meet industry standards to avoid accidents and legal issues.

These hoists provide peace of mind, ensuring that lifting operations can be conducted without compromising the safety of workers, equipment, or the environment.

Overview of European Standards for Explosion-Proof Hoists

European standards are essential in ensuring the design, manufacture, and operation of explosion-proof hoists are in line with strict safety requirements. These standards regulate every aspect of hoist construction, from materials used to the safety features incorporated.

Key European standards for explosion-proof hoists include:

- ATEX (Atmosphères Explosibles): A set of EU regulations ensuring equipment is safe for use in explosive atmospheres. ATEX-certified hoists meet these strict safety guidelines.

- IECEx (International Electrotechnical Commission Explosive Atmospheres): An international standard ensuring hoists meet global safety requirements for explosive environments.

These standards ensure that explosion-proof hoists are built to handle hazardous conditions without posing a risk of ignition. Compliance with ATEX and IECEx standards guarantees hoists operate safely in industries such as petrochemicals, mining, and chemicals, where the risk of explosions is high.

Design Features

Explosion-Proof Construction: Flameproof Enclosures and Safety Measures

European-style explosion-proof wire rope electric hoists are specifically designed to prevent any risk of ignition in hazardous environments. The key safety feature is the flameproof enclosure. These enclosures prevent any internal sparks, heat, or arcs from escaping the hoist and coming into contact with explosive gases or dust.

- Flameproof housing: Protects the motor and electrical components, preventing sparks or overheating.

- Intrinsic safety: Designed so that even if a fault occurs inside the hoist, it won't cause an ignition outside.

- Explosion-proof features: Components like motors, switches, and controllers are designed to withstand internal explosions without compromising safety.

These hoists are also built with special features like pressure relief valves and sealing mechanisms that enhance their safety and durability in explosive atmospheres.

Material Selection for Durability and Reliability

To ensure reliability in extreme conditions, the materials used in European-style explosion-proof hoists are carefully chosen. These hoists are built to endure harsh conditions while maintaining their performance.

- Corrosion-resistant materials: Hoists are made from materials that resist corrosion caused by exposure to moisture, chemicals, or harsh weather.

- Heavy-duty construction: Components are built to handle heavy-duty operations in industrial settings.

- High-strength materials: Materials used for the wire ropes, motors, and other components ensure long-lasting performance even in explosive environments.

The use of durable materials not only extends the life of the hoists but also ensures reliable operation over time, reducing maintenance needs and preventing downtime in hazardous operations.

European Standards Compliance

Overview of European Safety and Technical Standards

European safety and technical standards play a critical role in ensuring the performance and safety of explosion-proof hoists. These standards are designed to set requirements for hoists used in explosive environments, ensuring they are built to withstand harsh conditions without posing a risk to workers or the surrounding area.

- EN 13463-1: Specifies the basic safety requirements for explosion-proof equipment.

- EN 60079: Regulates electrical equipment in explosive atmospheres, including installation and maintenance guidelines.

- ISO 9001: Ensures the quality management system used in manufacturing the hoists adheres to international standards.

These standards ensure that explosion-proof hoists are safe, reliable, and suitable for use in high-risk environments.

Compliance with ATEX and IECEx Standards

- ATEX (Atmosphères Explosibles): A European Union directive that outlines the requirements for equipment used in explosive atmospheres. Explosion-proof hoists must be ATEX-certified to ensure they meet safety standards in hazardous environments.

- IECEx (International Electrotechnical Commission Explosive Atmospheres): An international standard ensuring the safety of electrical equipment used in explosive environments. IECEx certification ensures that hoists comply with global safety standards.

Both ATEX and IECEx certifications confirm that hoists are tested and approved for use in hazardous environments, providing an added layer of security for users.

Customization Options

Customization for Various Industries and Applications

European-style explosion-proof hoists can be customized to meet the specific needs of different industries. Whether the hoist is being used in mining, chemical processing, or aerospace, customization ensures it performs efficiently in the required conditions.

- Capacity and lifting height: Options to customize the lifting capacity and height to suit specific industry needs.

- Speed control: Adjustable hoisting speeds allow for more controlled and precise lifting operations.

- Mounting configurations: Customizable for use on different types of tracks or cranes.

These customization options ensure that hoists are tailored to perform optimally in each specific environment, improving safety and efficiency.

Special Features for Extreme Conditions

Explosion-proof hoists can also be equipped with special features to handle extreme conditions. Some industries face unique challenges, such as high humidity, corrosive chemicals, or very high or low temperatures.

- Corrosion-resistant coatings: Protects hoists from chemicals, saltwater, and other corrosive substances in industries like marine or chemical processing.

- High-temperature and low-temperature operation: Some hoists are designed to work effectively in extreme temperatures, ensuring they continue to function even in harsh climates.

- Enhanced sealing: Protects internal components from dust and moisture, ensuring reliability even in damp or dusty environments.

These additional features ensure that European-style explosion-proof hoists can be used safely and effectively in a wide range of challenging environments.

Safety & Performance

Explosion-Proof Safety Mechanisms: Flameproof Enclosures and Intrinsic Safety Design

Explosion-proof hoists are equipped with advanced safety mechanisms to ensure they operate without posing any risk in explosive environments. The key safety features include:

- Flameproof enclosures: These protect the internal components, such as the motor and electrical systems, from creating sparks or heat that could ignite surrounding flammable gases or dust. The flameproof design ensures that any internal malfunction won’t lead to an external explosion.

- Intrinsic safety design: This design limits the energy within the hoist’s electrical circuits, preventing any risk of ignition, even in the event of a fault. The hoist’s components are engineered to minimize the likelihood of producing sparks or overheating.

These safety mechanisms are critical in preventing ignition sources that could otherwise lead to dangerous explosions in high-risk industrial environments.

Preventing Ignition Sources in Explosive Atmospheres

Explosion-proof hoists are specifically designed to eliminate any possible ignition sources. Through comprehensive testing and adherence to international safety standards like ATEX and IECEx, these hoists are guaranteed to prevent any sparks, arcs, or heat that could trigger an explosion.

- Sealing systems: Seals and gaskets are used to prevent any dust, gas, or vapor from entering the hoist and coming into contact with the internal components.

- Energy-limited circuits: These ensure that the electrical system operates within safe parameters, preventing excessive energy that could result in sparks or heat.

By addressing these potential risks, explosion-proof hoists help maintain safe working conditions in volatile environments.

Temperature Control

Wide Operating Temperature Range

Explosion-proof hoists are designed to function effectively in a broad range of temperatures, making them suitable for extreme industrial environments. The ability to operate in both hot and cold temperatures is essential for industries like mining, oil drilling, or chemical processing, where temperature fluctuations are common.

- Hot environments: The hoists are designed to withstand high temperatures, often exceeding 40°C, without compromising performance or safety.

- Cold environments: Some models are also rated to operate in freezing conditions, ensuring reliable performance even at temperatures as low as -20°C.

This wide operating range guarantees that the hoist will perform reliably, regardless of environmental conditions.

Designed for Extreme Environmental Conditions

In addition to temperature control, explosion-proof hoists are designed with durable materials and enhanced sealing systems to handle harsh environments, including:

- High humidity: Hoists are built with corrosion-resistant materials and protective coatings to avoid damage from moisture and humidity.

- Dust and corrosive environments: Hoists can be customized with special seals and protective coatings to protect against dust, chemicals, and other harsh elements commonly found in hazardous industrial settings.

These design features ensure that hoists remain functional and safe even in the most challenging environments.

Hoisting Speed & Precision

Adjustable Speed Options for Controlled Lifting

European explosion-proof hoists offer adjustable hoisting speed options, allowing for precise control over lifting operations. This is especially important in environments where careful handling of materials is required.

- Single-speed and dual-speed configurations: These options give operators the flexibility to choose the lifting speed that best suits the task at hand.

- Variable speed: In some hoists, variable frequency drives can be incorporated, allowing for smooth acceleration and deceleration, which is crucial for delicate or heavy loads.

The ability to control the speed allows operators to work more efficiently and safely in hazardous environments, reducing the risk of accidents caused by sudden or uncontrolled movements.

Precise and Smooth Operation in Hazardous Environments

Precision is crucial in explosive environments. European explosion-proof hoists are designed to offer smooth, precise lifting motions that reduce the chances of accidents or damage to sensitive materials.

- Smooth lifting: The hoist operates smoothly without sudden jerks, which is essential for safely lifting heavy or delicate loads in volatile environments.

- Precision control: Operators can finely adjust the lifting height and speed, ensuring accurate load positioning, reducing the likelihood of accidents and ensuring safety.

This combination of speed control and precision ensures the hoist performs optimally in hazardous conditions while maintaining the highest safety standards.

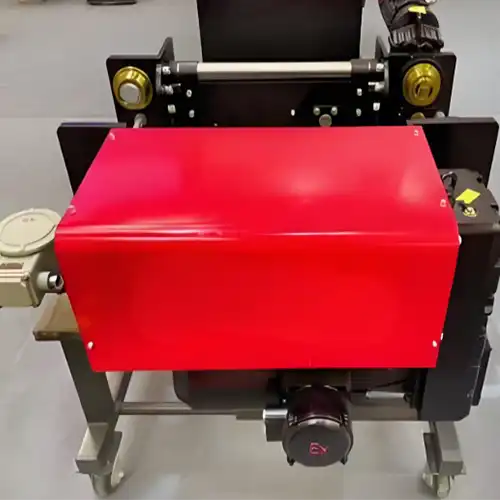

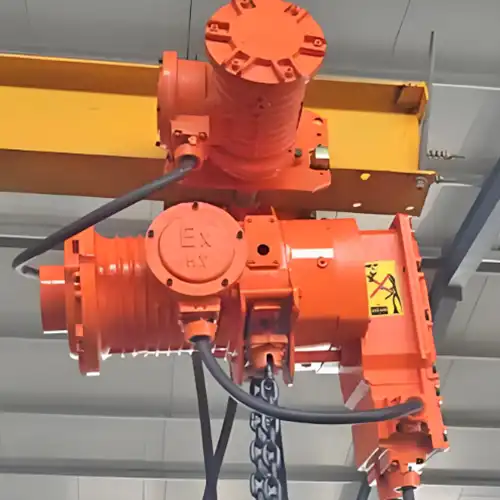

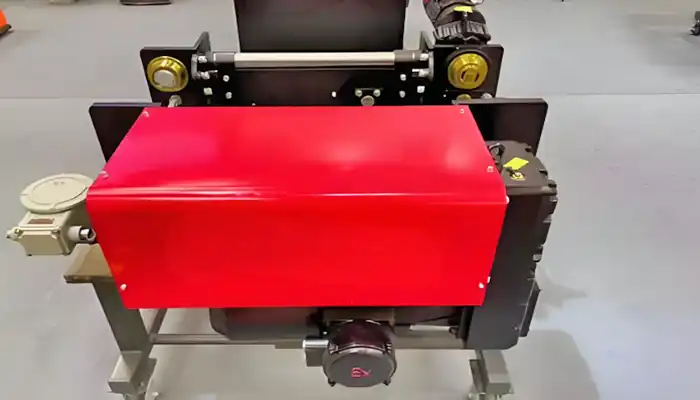

1 ton to 20 ton explosion proof hoist with European style for single girder crane

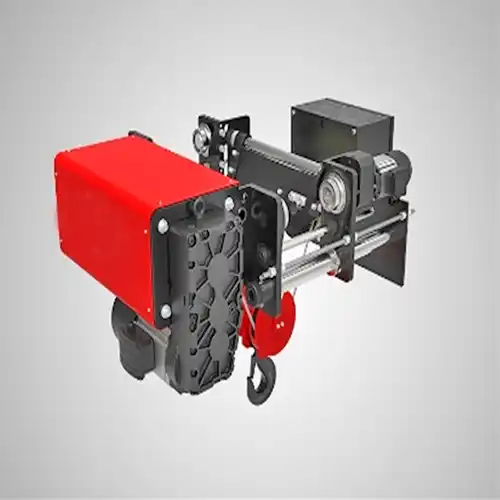

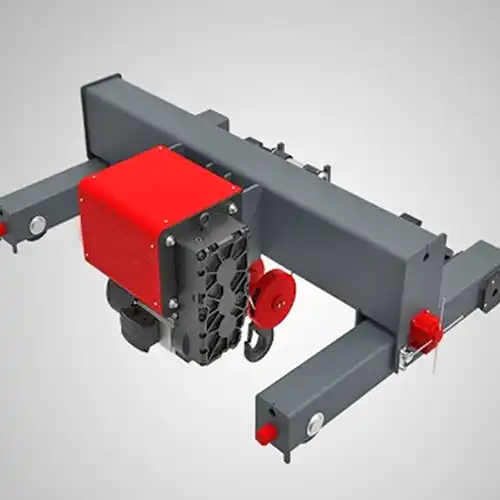

3 ton to 50 ton and 80 ton explosion proof hoist crab trolley for double girder crane

Applications

Petrochemical Industry: Hoist Usage in Oil Refineries, Gas Plants, and Offshore Platforms

Explosion-proof wire rope electric hoists are widely used in the petrochemical industry, including oil refineries, gas plants, and offshore platforms. These environments are highly hazardous due to the presence of flammable gases, vapors, and chemicals. The hoists help facilitate safe material handling and equipment maintenance.

- Oil refineries: Explosion-proof hoists are used to lift and transport heavy equipment, pipes, and tanks while ensuring safety in volatile environments.

- Gas plants: These hoists assist in lifting machinery, valves, and other equipment, keeping operations running smoothly without creating ignition sources.

- Offshore platforms: Offshore oil rigs require explosion-proof hoists for lifting heavy drilling equipment, providing essential safety measures in harsh marine environments.

By meeting stringent safety standards, these hoists ensure safe operation even in the most dangerous parts of the petrochemical industry.

Mining & Chemical Plants: Application in Mining, Processing Plants, and Chemical Facilities

The mining and chemical industries also rely on explosion-proof hoists due to the inherent risks involved in these sectors. These hoists are essential in areas where explosive gases, dust, or volatile chemicals are present.

- Mining: Explosion-proof hoists are used in underground mines and open-pit mines for handling heavy materials, machinery, and mining equipment. The hoists ensure safe lifting in potentially explosive atmospheres.

- Chemical facilities: In chemical plants, hoists are used for transporting raw materials, equipment, and finished products in areas with high chemical risks. The hoists’ flameproof design prevents any sparks or arcs that could ignite volatile chemicals.

In both industries, explosion-proof hoists ensure continuous operation without compromising safety in high-risk environments.

Other High-Risk Industries: Aerospace, Defense, and Other Industries with Explosion Risks

Explosion-proof hoists are not limited to the petrochemical, mining, and chemical sectors. They are also used in various high-risk industries, such as aerospace, defense, and any industry where there is a significant risk of explosion.

- Aerospace: Hoists are used in assembly lines and testing areas to handle sensitive and heavy aerospace components, ensuring that they are lifted without sparking.

- Defense: In defense applications, hoists are used to handle ammunition, explosives, and military equipment safely in environments with explosion risks.

- Other industries: Various industries dealing with combustible dust, gas, or other explosive materials, such as food processing or grain storage facilities, also rely on explosion-proof hoists for safe lifting operations.

In these industries, the explosion-proof features of hoists play a crucial role in maintaining operational safety, protecting both workers and valuable equipment.

European explosion-proof electric wire rope hoists parameters

| Lifting capacity(t) | 3 | 5 | 10 | 16 | 20 | 30 | 50 |

| Lifting height(m) | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 | 6~12 | 6~12 |

| Lifting speed(m/min) | 0.8~5 | 0.8~5 | 0.66~4 | 0.66~4 | 0.66~4 | 0.4~2.7 | 0.4~2.7 |

| Traveling speed(m/min) | 2~6 | 2~16 | 2~16 | 2~16 | 2~16 | 2~16 | 2~16 |

| Work class | M5 | ||||||

| Explosion-proof grade | Exd II CT4/Ex tD A21 IP65 T130℃ | ||||||

Explosion-proof hoists for the environment

Explosion-proof hoists are suitable for use in explosive gas environments Zone 1 and Zone 2 or combustible dust environments Zone 21 and Zone 22.

| Temperature Group | Maximum permissible surface temperature ℃ | |

| TA or TB | T1 | 450 |

| T2 | 300 | |

| T3 | 200 | |

| T4 | 135 | |

| T5 | 100 | |

| T6 | 85 | |

Class II explosion-proof hoist explosion-proof level and the corresponding temperature group applicable explosive gases are listed below:

| Explosion-proof grade | Temperature Group | |||||

| T1 | T2 | T3 | T4 | T5 | T6 | |

| IIA | Ethane, propane, styrene, benzene, xylene, carbon monoxide, acetone, acetic acid, methyl acetate, ammonia, pyridine | Ethanol, butane, propylene, ethyl acetate, methylene chloride, vinyl chloride, chloroethanol, thiophene, cyclopentane, dimethylamine | Pentane, hexane, ethylcyclopentane, turpentine, naphtha, petroleum (including military gasoline), fuel oil, chlorobutane, tetrahydrothiophene | Acetaldehyde, trimethylamine | Ethyl nitrite | |

| IIB | Propyne, acrylonitrile, hydrogen cyanide, coke oven gas | Ethylene, ethylene oxide, methyl acrylate, furans | Dimethyl ether, acrolein, tetrahydrofuran, hydrogen sulfide | Dibutyl ether, diethyl ether, ethyl methyl ether, tetrafluoroethylene | ||

| IIC | Hydrogen, water gas | Ethyne C2H2 | Carbon disulfide | Ethyl nitrate | ||

Dust class explosion-proof hoist each anti-dust structure form and the corresponding temperature groups of combustible dust to adapt to the following table:

| Dust explosion-proof form | Temperature Group | |

| TA、T1 or TB、T1 | TA、T2 or TB、T2 | |

| A or B | Magnesium, red phosphorus, calcium carbide, soap powder, green fuel, phenol dyes, polyethylene, polypropylene, polyurethane, polyvinyl chloride, hard rubber, natural resins, rosin, wheat flour, corn starch, granulated sugar powder, cotton fiber, synthetic staple fiber, anthracite powder, charcoal powder, coal coke powder | Sifted Rice Flour, Cocoa Flour, Malt Flour, Flax Meal Flour, Coconut Flour, Peat Flour, Lignite Flour, Bituminous Coal Flour, Coal Flour for Coke, Lignite Coke Flour |

Certification & Compliance

Explosion-Proof Certification Process

To ensure the safety and reliability of European explosion-proof wire rope electric hoists, they must undergo a rigorous explosion-proof certification process. This process ensures that the hoists are safe to operate in environments with hazardous gases, dust, or other explosive materials.

- Testing by Approved Certification Bodies: The hoists are tested by internationally recognized certification bodies, such as ATEX (the European Union’s regulatory standard for equipment used in explosive atmospheres) and IECEx (International Electrotechnical Commission for explosion protection). These organizations ensure that the hoists meet the required safety standards for operation in hazardous environments.

- Conformity Assessment and Explosion-Proof Certification Process: The hoists undergo a thorough conformity assessment, which includes testing for electrical safety, explosion protection, and performance. Only after passing all safety tests are they granted explosion-proof certification. This process confirms that the hoist will not ignite flammable gases or dust in the environment, maintaining worker safety and preventing accidents.

This certification process ensures the hoists’ integrity, offering peace of mind to industries that require safe lifting operations in hazardous conditions.

Compliance with International Standards

European explosion-proof hoists are built in compliance with stringent international safety and technical standards, ensuring they meet the highest levels of quality and safety. Some of the key standards include:

- EN Standards: European standards for explosion-proof equipment, including EN 60079 series, which outlines safety requirements for electrical equipment in explosive atmospheres.

- ISO Standards: The hoists comply with ISO 9001 for quality management systems and ISO 80079 for equipment used in explosive atmospheres.

- IEC Standards: The IEC 60079 series sets global standards for electrical equipment and protective systems used in explosive atmospheres. This includes the IECEx certification, which ensures global compliance for explosion-proof products.

These international standards ensure that European explosion-proof wire rope hoists meet the required safety criteria, making them suitable for use in various high-risk industries worldwide. The adherence to these standards provides a guarantee of quality, performance, and safety, protecting both operators and equipment in explosive environments.

Advantages of European-Style Explosion-Proof Hoists

Superior Safety and Performance Features Compared to General Designs

European-style explosion-proof hoists offer superior safety and performance features that distinguish them from general explosion-proof hoist designs. Some of the key features include:

- Advanced Explosion Protection: These hoists are designed to meet ATEX and IECEx standards, ensuring maximum safety in explosive atmospheres. They incorporate flameproof enclosures and intrinsically safe designs, preventing ignition sources in hazardous environments.

- Precision Control: With options for adjustable hoisting speed and variable frequency control, European-style hoists allow for smoother, more precise operations in volatile conditions.

- Temperature Control: The hoists are built to withstand extreme temperature fluctuations, offering reliable operation even in high-heat or freezing environments, which is critical for many industries.

These features ensure enhanced safety and operational reliability, making them the preferred choice for industries that require top-tier performance in explosive environments.

Long-Term Reliability in Hazardous Environments

European-style explosion-proof hoists are designed for long-term reliability, making them highly durable in harsh and hazardous environments.

- Durable Construction: Built with high-quality materials and designed to withstand extreme operating conditions, these hoists can handle constant use without compromising safety or performance.

- Corrosion-Resistant Materials: Many European explosion-proof hoists feature corrosion-resistant components, making them suitable for use in industries such as petrochemical, mining, and chemical plants, where exposure to harsh chemicals or corrosive materials is common.

- Low Maintenance: With robust design and fewer moving parts, these hoists require less maintenance, reducing downtime and ensuring that operations continue smoothly over long periods.

Their reliability in hazardous environments means less risk of failure and fewer interruptions, which is crucial for industries where downtime is costly.

Proven to Meet Strict International Safety and Technical Standards

European-style explosion-proof hoists are certified to meet strict international safety and technical standards, including:

- ATEX and IECEx certification, confirming that they meet the highest global safety standards for explosive atmospheres.

- EN, ISO, and IEC standards ensure that the hoists are built to maintain consistent, high-performance operation in all environments, no matter how dangerous.

These certifications and standards ensure that users can trust these hoists to meet the necessary safety and performance benchmarks in various industries worldwide.

Conclusion

Summary of Key Benefits and Features of European-Style Explosion-Proof Hoists

European-style explosion-proof hoists offer advanced safety and performance features, including robust explosion protection, precision control, and reliable operation in hazardous environments. Their long-term reliability, combined with compliance to stringent international safety standards, makes them ideal for high-risk industries.

Final Recommendations Based on Specific Industry Needs

When choosing the right hoist, it's important to consider your industry’s specific needs:

- For petrochemical and chemical industries, where explosive gases and chemicals are present, these hoists offer the highest level of protection.

- For mining or aerospace applications, the hoists’ durability and performance in extreme conditions make them ideal.

- In industries with harsh or corrosive environments, their corrosion-resistant materials and low-maintenance design are key advantages.

Choosing the Right Hoist for Maximum Safety and Efficiency in Explosive Atmospheres

When selecting an explosion-proof hoist, consider factors such as your environment's risk level, the load capacity required, and operational frequency. European-style hoists provide the perfect balance of safety, performance, and reliability, ensuring maximum protection and operational efficiency in explosive atmospheres.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch