Case Study: 5-Ton Electric Double Girder Crane for Sale Saudi Arabia

Analyzing the performance and efficiency of a 5-ton electric overhead crane in Saudi Arabia’s coal mining operations.

Category: Featured

Your Trusted Electric Travelling Overhead Crane Manufacturer & Supplier

Case Study: 5-Ton Electric Double Girder Crane for Sale Saudi Arabia

Case Study: Application of a 5-Ton Electric Double Girder Overhead Crane for Coal Mining in Saudi Arabia

This case study explores the use of a 5-ton Four-Rope Grab Bucket Overhead Crane (QZ5T model) in a coal mining operation in Saudi Arabia. The crane’s robust double girder design, paired with the four-rope grab bucket, enables efficient handling of large coal loads in a challenging mining environment. With a lifting capacity of 5 tons and a 6-meter span, the crane is perfectly suited for lifting and transporting bulk coal, making it an essential piece of equipment in coal mining operations. The four-rope grab bucket ensures precise control over the load, enabling smooth and efficient loading and unloading of coal.

The crane is located in Saudi Arabia, where extreme temperatures, dust, and humidity present significant challenges for mining equipment. In this harsh climate, it is critical to use machinery that can withstand these conditions and operate efficiently over time. The 5-ton Four-Rope Grab Bucket Overhead Crane is designed to perform reliably in such environments, minimizing downtime and ensuring the smooth flow of coal handling operations.

The crane is used in coal mining, an industry that requires powerful, durable machinery capable of managing heavy loads under demanding conditions. Coal mining operations involve the constant transportation of large quantities of coal from extraction points to storage or processing areas. The 5-ton Four-Rope Grab Bucket Overhead Crane is ideally suited for this task, offering high lifting capacity and precise coal handling. Its design enables efficient and safe loading, unloading, and transportation of coal, improving operational efficiency in the mining process. This case study demonstrates how the crane contributes to smoother, more productive coal mining operations by optimizing material handling and reducing operational delays.

Crane Specifications

- Model: QZ5T Electric Double Girder Overhead Crane

- Lifting Capacity: 5 tons

- Span: 6 meters

- Lifting Height: 14 meters

- Trolley Rail Gauge: 2 meters

- Lifting Speed: 1.5/15 m/min

- Traveling Speed: 2.0–20 m/min

- Working Duty: M7 (Heavy-duty operations)

- Trolley Rail Type: P18

- Crane Rail Type: P43

- Power Supply: 3-Phase, 380V, 50Hz

- Control Mode: Cabin Control

- Grab Type: Four-rope grab bucket with a 1.2m³ capacity

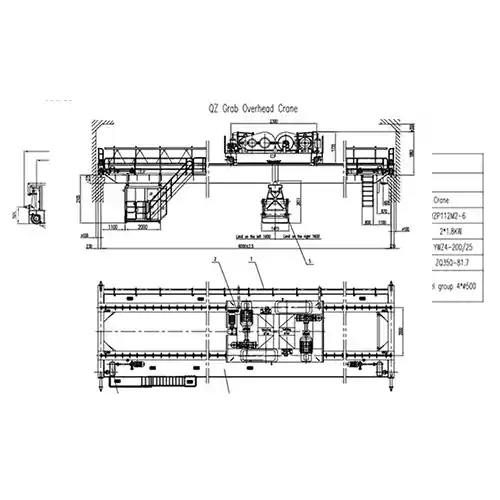

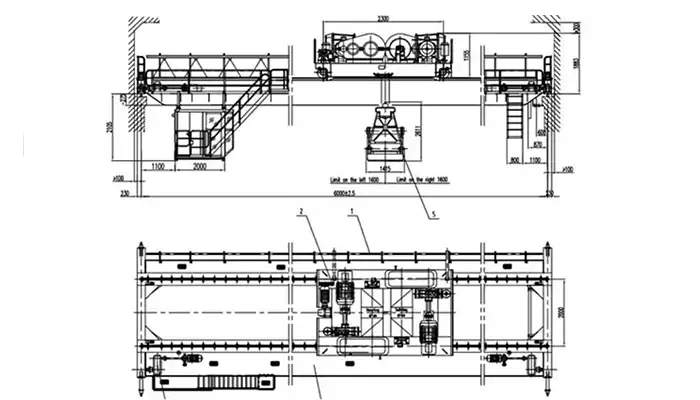

5 ton electric double girder overhead crane for sale Saudi Arabia, document picture for your reference

Electric double girder overhead crane 5 ton with grab bucket drawing desigend for client's project in Saudi Arabia

Crane Specifications

The QZ5T Electric Double Girder Overhead Crane with a four-rope grab bucket is specifically designed to meet the heavy-duty demands of industrial applications, particularly in coal mining. Below are the detailed specifications of this crane model:

- Model: QZ5T Electric Double Girder Overhead Crane

The QZ5T model features a durable double girder design, ensuring excellent stability and performance under heavy load conditions, ideal for use in demanding environments such as coal mining. - Lifting Capacity: 5 tons

The crane has a maximum lifting capacity of 5 tons, making it suitable for lifting heavy coal loads efficiently. This capacity supports large-scale mining operations that require the handling of bulky and heavy materials. - Span: 6 meters

The 6-meter span of the crane ensures flexibility in movement across a broad area within the coal mining facility. This width allows for effective coverage when loading and unloading coal, improving operational efficiency. - Lifting Height: 14 meters

With a 14-meter lifting height, the crane can handle materials over a significant vertical distance, which is crucial for managing the varying levels of stockpiles and ensuring efficient coal loading and unloading. - Trolley Rail Gauge: 2 meters

The 2-meter trolley rail gauge provides stability and smooth operation when the crane moves along the runway. This dimension ensures the crane maintains its balance while transporting heavy loads across the facility. - Lifting Speed: 1.5/15 m/min

The crane offers two-speed lifting options: 1.5 m/min for slow, precise movements and 15 m/min for faster, more efficient operations when larger, less precise movements are required. This variability allows the crane to adapt to different material handling needs. - Traveling Speed: 2.0–20 m/min

With a traveling speed range from 2.0 to 20 m/min, the crane can adjust its speed depending on the load and specific operation. Faster traveling speeds improve productivity, while slower speeds allow for greater precision and control during coal loading and unloading. - Working Duty: M7 (Heavy-duty operations)

Rated for M7 duty, this crane is built to handle continuous, heavy-duty operations. The M7 classification ensures the crane is robust enough for the high-frequency use typical in coal mining, where equipment must withstand constant operation in harsh conditions. - Trolley Rail Type: P18

The P18 trolley rail type is designed for heavy-duty use and provides a stable, durable path for the crane's trolley. This ensures smooth operation and minimizes wear and tear, even under the high loads and intense usage found in mining operations. - Crane Rail Type: P43

The P43 crane rail type offers exceptional strength and durability, ensuring the crane can travel safely and efficiently over its entire span, even under the stress of frequent and heavy load handling. - Power Supply: 3-Phase, 380V, 50Hz

The crane is powered by a 3-phase, 380V, 50Hz electrical supply, which ensures reliable and continuous operation. This power supply is standard in many industrial settings, providing the necessary energy to operate the crane efficiently without interruptions. - Control Mode: Cabin Control

The crane is operated through cabin control, offering the operator full visibility and precise control over crane movements. This control method is ideal for safely handling heavy loads, especially in environments like coal mining where visibility and accuracy are key. - Grab Type: Four-rope grab bucket with a 1.2m³ capacity

The crane is equipped with a four-rope grab bucket that has a capacity of 1.2 cubic meters (m³). This grab bucket is designed to efficiently handle bulk coal, allowing for smooth, controlled lifting and loading while maximizing the crane's productivity.

These specifications collectively make the QZ5T Electric Double Girder Overhead Crane with a four-rope grab bucket an ideal choice for coal mining operations, ensuring efficient material handling, safety, and reliability in harsh working conditions.

Project Requirements and Challenges

Coal Mining Requirements

Coal mining operations demand equipment that can handle the heavy and continuous flow of coal with minimal downtime. For this project, key requirements include:

- High Lifting Capacity: The crane must be able to lift large, heavy coal loads efficiently and safely. With a 5-ton lifting capacity, the QZ5T Electric Double Girder Overhead Crane is well-equipped to meet this need, ensuring smooth material handling throughout the mining process.

- Robust Performance in Harsh Conditions: Coal mines are challenging environments that put machinery to the test. The crane must operate under extreme temperatures, high humidity, and in areas where dust and corrosive elements are prevalent. The QZ5T crane’s double girder design and corrosion-resistant materials are specifically chosen to withstand these harsh conditions, ensuring long-lasting durability and reliability.

Challenges

Coal mining operations present several challenges that impact equipment performance:

- Managing Heavy Coal Loads: Coal is a dense and heavy material that requires cranes capable of managing large loads efficiently. The crane must maintain stability while moving heavy loads, avoiding any risk of tipping or instability. The double girder design of the QZ5T crane ensures a stable structure that can bear the load and deliver safe operations.

- Dust and Corrosive Environment: Coal mines are often dusty, and coal dust can settle on machinery, potentially causing wear and corrosion over time. Furthermore, moisture in the air and other environmental factors can contribute to rusting and reduced equipment lifespan. The crane’s design incorporates features to minimize the effects of dust and corrosion, ensuring that maintenance is kept to a minimum.

- High Safety Standards: The coal mining industry operates under stringent safety regulations due to the hazardous nature of the work. Cranes in coal mines need to adhere to the highest safety standards to protect operators and prevent accidents. The QZ5T crane’s cabin control system allows for precise operator control, reducing risks during operation. Additionally, safety features such as overload protection, emergency stop buttons, and anti-collision systems are integrated into the crane design to meet safety requirements.

main girder of electric double girder overhead travelling

travelling open winch trolley for electric travelling double girder overhead bridge crane

main parts and components of electric overhead crane for delivery to Saudi Arabia

Clamshell grab bucekt for 5 ton overhead travelling crane for delivery to Saudi Arabia

Main parts and components of 5 ton grab bucket electric bridge crane

Overhead crane parts loaded into truck for delivery to Saudi Arabia

Grab bucket overhead crane for delivery to Saudi Arabia

Crane Design Features

Double Girder Design

The double girder design of the QZ5T Electric Double Girder Overhead Crane provides excellent stability, supporting the crane’s 5-ton lifting capacity. This design allows the crane to handle heavy loads like coal with greater safety and efficiency. The increased structural strength ensures minimal deflection under load, enhancing the crane's overall performance and extending its lifespan, even under continuous, high-duty operations typical in coal mining.

Four-Rope Grab Bucket

The crane is equipped with a 1.2m³ four-rope grab bucket, an essential feature for bulk coal handling. The four-rope system offers superior control over the bucket, enabling precise and efficient lifting, loading, and unloading of coal. This grab bucket design minimizes spillage and ensures that large volumes of coal can be moved quickly, improving operational efficiency and reducing manual labor in the process. The bucket's large capacity helps increase throughput, reducing the need for multiple cycles during loading and unloading tasks.

Working Class M7

The QZ5T crane is rated for M7 duty, which means it is designed for continuous, heavy-duty operations. The M7 rating is particularly suitable for coal mining, where equipment is required to work long hours under demanding conditions. This high-duty classification ensures the crane is durable and capable of handling frequent, heavy lifting without compromising performance or safety.

Control Mode – Cabin Control

The crane features cabin control, which allows the operator to have full control over crane movements from an enclosed cabin. This control method provides clear visibility of the load and workspace, which is crucial in a dynamic mining environment. Cabin control enhances the precision and safety of the crane’s operation, as the operator can make real-time adjustments to lifting speed, direction, and positioning. This is especially important in the confined and potentially hazardous conditions of coal mining operations, where accurate movements can prevent accidents and ensure smooth operations.

Performance in the Field

Lifting Capacity and Speed

The QZ5T Electric Double Girder Overhead Crane is equipped with a 5-ton lifting capacity, which is essential for handling the heavy loads commonly encountered in coal mining operations. This crane is particularly suited for lifting large volumes of coal efficiently, ensuring that mining processes can continue without unnecessary delays.

- Traveling Speed

The crane is designed with a traveling speed range of 2.0 to 20 m/min, which provides significant flexibility in the movement of materials across the mining facility. The ability to adjust the speed depending on the load and distance to be traveled ensures that coal can be transported quickly and efficiently.

- Faster Movement: For larger distances or when urgency is required, the crane can travel at 20 m/min, covering long stretches quickly without affecting load stability.

- Precision at Slower Speeds: When more control is needed, the crane can operate at slower speeds (2.0 m/min), which is ideal for navigating confined areas and handling sensitive tasks.

Safety Features

The crane is equipped with essential safety features to ensure smooth and risk-free operations in a high-risk environment such as coal mining.

- M7 Duty Classification: The crane operates under the M7 duty cycle, which means it is engineered for continuous, heavy-duty operations. This ensures the crane can handle frequent cycles of heavy lifting without performance degradation.

- Cabin Control: The cabin control system provides the operator with excellent visibility, allowing for precise and safe operation, even in challenging or confined environments.

- Additional Safety Features: These include overload protection, anti-collision systems, and emergency stop mechanisms, which are essential for preventing accidents in high-risk mining environments.

Energy Efficiency and Maintenance

Power Supply

The QZ5T Electric Double Girder Overhead Crane runs on a 3-phase, 380V, 50Hz power supply, which is standard for industrial operations. This power configuration ensures reliable and consistent performance throughout the crane’s operations.

- Energy Efficiency: The crane is designed to consume less energy while providing optimal performance, which helps lower operational costs.

- Power Stability: The 3-phase system ensures stable energy flow, allowing the crane to function smoothly without interruptions, even during continuous operation.

Maintenance Considerations

The crane is designed for minimal maintenance, with robust components that can withstand the harsh conditions of coal mining.

- Regular Maintenance Schedule: The crane requires regular inspections and maintenance to keep all systems functioning at peak performance.

- Corrosion Resistance: Given the abrasive nature of coal and the mining environment, the crane incorporates corrosion-resistant coatings and materials, minimizing wear and tear.

- Easy Repairs: The crane’s maintenance-friendly design means that key components are easy to access for repairs and replacements, reducing downtime and maintenance costs.

- Durability: Designed to operate in harsh environments, the crane's double girder structure and high-quality materials ensure it maintains performance and longevity, even under demanding conditions.

Environmental Impact and Durability

Coal Mining Environment

Coal mining is known for its extreme environmental conditions, including exposure to heavy dust, moisture, and abrasive coal particles. The QZ5T crane is built to thrive in these environments, ensuring it can operate effectively under these challenging conditions.

- Heavy-Duty Design: The crane’s double girder structure ensures it remains stable under heavy coal loads, even during continuous operations.

- Dust and Debris: The crane is designed to cope with the high dust levels commonly found in coal mines, using sealed systems to protect mechanical components from dust damage.

- Temperature Variations: The crane is capable of operating in extreme temperatures, which is crucial for Saudi Arabia's hot climate.

Corrosion Protection

Given the harsh environmental conditions in Saudi Arabia, where high temperatures and humidity levels are common, corrosion protection is critical for ensuring long-term performance.

- Anti-Corrosion Coatings: The crane is coated with high-performance anti-corrosion materials that protect against the damaging effects of rust and deterioration caused by moisture and coal dust.

- Corrosion-Resistant Materials: The crane's main structural components are made from corrosion-resistant materials, helping to prevent degradation over time.

- Extended Durability: These protective measures ensure that the crane can endure the extreme temperatures and abrasive conditions of the coal mining environment, guaranteeing reliable performance even after years of use.

In conclusion, the QZ5T Electric Double Girder Overhead Crane is a highly reliable and efficient solution for coal mining operations. With a 5-ton lifting capacity, adjustable lifting and traveling speeds, and robust safety features, it excels in handling heavy coal loads in challenging environments. The crane’s energy-efficient design and low maintenance requirements make it an economically viable option for continuous, heavy-duty operations. Furthermore, its anti-corrosion features and durability ensure long-term, reliable performance, even in Saudi Arabia's harsh mining conditions.

Conclusion

The QZ5T Electric Double Girder Overhead Crane with a four-rope grab bucket has demonstrated exceptional performance and reliability in the coal mining operations of Saudi Arabia. Its robust design and efficient operational features, including its 5-ton lifting capacity, adjustable speeds, and M7 duty cycle, make it a valuable asset for handling the heavy and demanding tasks associated with coal mining.

- Enhanced Productivity: The crane's ability to efficiently handle large coal loads at varying speeds contributes significantly to improving overall productivity. The four-rope grab bucket further optimizes bulk handling, streamlining the loading and unloading processes.

- Durability in Harsh Conditions: Its anti-corrosion coatings and heavy-duty design allow the crane to perform reliably even under the harsh environmental conditions of Saudi Arabia, ensuring continuous operation without frequent maintenance interruptions.

In conclusion, the QZ5T Electric Double Girder Overhead Crane continues to be a highly effective solution for coal mining operations, with excellent reliability and efficiency. With ongoing upgrades and monitoring, it can continue to meet the evolving challenges of the mining industry in Saudi Arabia and beyond.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch