European-Style Gantry Cranes for Sale Philippines 5 Ton, 10 Ton

Gantry crane for sale Philippines. 7 sets of 10-ton and 5-ton European-style gantry cranes for sale in the Philippines. Get your Gantry Crane solution.

Category: Featured

Your Trusted Gantry Crane Manufacturer & Supplier

European-Style Gantry Cranes for Sale Philippines 5 Ton, 10 Ton

Gantry crane for sale Philippines. 10-ton and 5-ton European-style gantry cranes for sale in the Philippines. Get your Gantry Cranesolution.

Introduction to European-Style Gantry Cranes for Sale in the Philippines

This case study provides a comprehensive look at the 7 sets of European-style gantry cranes currently available for sale in the Philippines. These cranes are designed to meet the needs of a wide range of industrial applications, from heavy manufacturing to general material handling. By exploring the specifications, features, and potential uses of these cranes, this study aims to give businesses and industries a clear understanding of how these machines can improve their operations.

The cranes for sale include two main types: MGO double girder and MHO single girder gantry cranes. These models offer different designs to cater to varying lifting needs, ensuring flexibility for both small and large-scale industrial tasks.

Purpose of This Case Study

The primary goal of this case study is to provide a detailed examination of the 7 sets of European-style gantry cranes, focusing on their specifications, features, and industrial applications. This will help prospective buyers make informed decisions about which crane best suits their specific needs based on factors like capacity, lifting height, span, and intended usage.

Location: The cranes are available for sale in the Philippines, a growing market for industrial equipment and infrastructure projects. The Philippines offers a dynamic business environment where industries such as manufacturing, construction, and logistics are expanding, creating a demand for reliable and high-quality lifting equipment.

Crane Types:

- MGO Gantry Crane – This double girder crane is built for heavy-duty applications. It is ideal for handling large loads in factories, steel mills, and construction sites.

- MHO Gantry Crane – A single girder crane that offers a more cost-effective solution for medium-to-heavy lifting tasks. It provides great performance for general material handling, storage, and lighter construction projects.

Capacities:

- 10 Tons: The 10-ton models (both MGO and MHO) are designed for handling heavier loads, making them suitable for demanding industrial environments.

- 5 Tons: The 5-ton MHO cranes offer a lighter but still powerful solution for smaller lifting tasks in workshops, warehouses, and smaller construction sites.

Key Benefits

- Durability: The cranes are built to withstand the tough conditions of industrial environments. With solid European engineering, they are made to perform reliably over the long term, reducing downtime and maintenance costs.

- Efficiency: Designed to optimize workflow, these gantry cranes help reduce the time it takes to move heavy or bulky materials. This increased efficiency can lead to smoother operations and better productivity, particularly in fast-paced environments like manufacturing and construction.

- Suitability for Various Industrial Environments: Whether you're working in a factory, warehouse, construction site, or port, these cranes are versatile and adaptable. The ability to handle both heavy and lighter loads makes them suitable for a wide range of industries, including automotive, steel production, logistics, and general manufacturing.

In conclusion, this case study aims to give potential buyers a deeper understanding of how these European-style gantry cranes can enhance productivity, support operations, and meet the diverse lifting needs of various industrial sectors in the Philippines.

Crane Types and Specifications

In this section, we will provide detailed specifications for each of the seven gantry cranes available for sale in the Philippines. These include both MGO double girder cranes and MHO single girder cranes, offering a variety of lifting capacities, spans, and heights to suit different industrial needs.

MGO European Style Gantry Crane – Double Girder (1 Set)

- Capacity: 10 Tons

- Crane Span: 20 Meters

- Lifting Height: 9 Meters

- Design: Double Girder (stronger and more stable for heavy lifting)

- Voltage: 440V, 60Hz, 3P

- Applications: Heavy-duty lifting operations in manufacturing and construction.

The MGO gantry crane is equipped with a double girder design, making it an ideal choice for heavy lifting tasks that require maximum stability and strength. With a 10-ton capacity, 20-meter crane span, and a lifting height of 9 meters, this crane can handle large, heavy loads with ease. It is perfect for use in manufacturing plants, steel mills, construction sites, and other high-demand environments where reliability and power are critical. The double girder structure provides excellent load distribution and reduces strain on components, ensuring the crane operates smoothly and with minimal maintenance.

MHO European Style Gantry Crane – Single Girder (1 Set)

- Capacity: 10 Tons

- Crane Span: 20 Meters

- Lifting Height: 9 Meters

- Design: Single Girder (cost-effective and compact)

- Voltage: 440V, 60Hz, 3P

- Applications: Medium-to-heavy lifting tasks with a focus on space efficiency and lower maintenance.

The MHO single girder gantry crane offers a 10-ton capacity and features a compact single girder design, making it an excellent option for operations where space is limited but heavy lifting is still required. With a 20-meter span and 9-meter lifting height, it provides substantial reach and lifting ability without taking up excessive floor space. This crane is well-suited for warehouses, logistics facilities, and general manufacturing settings where cost-effectiveness and ease of maintenance are top priorities. Its single girder design simplifies the crane's overall construction, reducing both initial investment and long-term maintenance costs.

MHO Gantry Crane – Single Girder (3 Sets)

- Capacity: 10 Tons

- Crane Span: 20 Meters

- Lifting Height: 7.5 Meters

- Design: Single Girder (space-saving and versatile)

- Voltage: 440V, 60Hz, 3P

- Applications: Suitable for lighter heavy lifting operations or applications requiring multiple cranes in a facility.

These three sets of MHO single girder gantry cranes are designed to handle 10-ton loads with a lifting height of 7.5 meters and a 20-meter crane span. Their single girder design allows for space-saving solutions, making them perfect for smaller factories or facilities where floor space is at a premium. These cranes are also ideal for dividing lifting tasks across multiple sets, allowing for simultaneous operations without compromising on performance. Whether for assembly lines, material handling, or maintenance tasks, these cranes provide flexibility and efficiency for industrial operations.

MHO Gantry Crane – Single Girder (2 Sets)

- Capacity: 5 Tons

- Crane Span: 20 Meters

- Lifting Height: 7.5 Meters

- Design: Single Girder (ideal for smaller or lighter loads)

- Voltage: 440V, 60Hz, 3P

- Applications: Smaller lifting tasks, maintenance, and general material handling.

The two sets of MHO single girder cranes are designed for lighter-duty lifting tasks with a 5-ton capacity. These cranes are equipped with a 20-meter span and a 7.5-meter lifting height, making them well-suited for general material handling, light lifting, and maintenance applications. The single girder design ensures that the cranes are both cost-effective and easy to maintain, making them an excellent choice for businesses that need reliable, low-maintenance cranes without the need for heavy-duty lifting capabilities. Ideal for warehouses, maintenance departments, and general industry, these cranes offer a good balance of functionality, performance, and affordability.

Summary of Specifications:

| Crane Type | Capacity | Crane Span | Lifting Height | Design | Applications |

|---|---|---|---|---|---|

| MGO Gantry Crane (Double Girder) | 10 Tons | 20 Meters | 9 Meters | Double Girder | Heavy-duty manufacturing, construction |

| MHO Gantry Crane (Single Girder) | 10 Tons | 20 Meters | 9 Meters | Single Girder | Medium-to-heavy lifting, space efficiency, lower maintenance |

| MHO Gantry Crane (Single Girder) | 10 Tons | 20 Meters | 7.5 Meters | Single Girder | Lighter heavy lifting, multi-crane applications |

| MHO Gantry Crane (Single Girder) | 5 Tons | 20 Meters | 7.5 Meters | Single Girder | Smaller lifting tasks, maintenance, material handling |

Key Features of the Gantry Cranes

The European-style gantry cranes available for sale in the Philippines are built to provide exceptional performance, reliability, and efficiency across various industrial applications. This section outlines the key features that make these cranes an excellent choice for businesses seeking long-lasting, high-quality lifting solutions.

European Engineering Standards

- High-Quality Construction and Design

The gantry cranes are built to the highest standards of European engineering, ensuring that they are not only robust but also efficient in their operation. The MGO double girder and MHO single girder models are designed to handle heavy and light loads, respectively, without compromising on structural integrity. High-grade materials and cutting-edge manufacturing techniques are employed to guarantee a long service life, even in the most demanding environments. - Compliance with International Safety Standards

Safety is a critical consideration in industrial crane operations. These gantry cranes meet all the relevant international safety standards, including CE certification, ensuring that they are safe to operate under various conditions. Features such as overload protection, emergency stop buttons, and limit switches are incorporated into the crane's design, which minimizes the risk of accidents and ensures safe lifting operations at all times. - Advanced Control and Electrical Systems

The cranes are equipped with state-of-the-art control systems that make lifting operations smoother and more efficient. These advanced electrical systems ensure precise load control, smooth movement, and easy operation, which can improve productivity and reduce the likelihood of errors. Additionally, the control panels are user-friendly and designed to meet the needs of operators, whether they are handling heavy or lighter loads. The electrical systems are also engineered for reliability, minimizing the risk of downtime and maintenance issues.

Durability and Maintenance

- Designed for Long-Term Use in Tough Industrial Environments

The gantry cranes are constructed to withstand the harsh conditions of industrial environments, from high temperatures to corrosive atmospheres. Whether used in manufacturing plants, construction sites, or warehouses, these cranes are made to operate efficiently and reliably over the long term. The double girder design (in the MGO cranes) offers additional strength and stability, making them suitable for handling larger, heavier loads without compromising on durability. - Low Maintenance Requirements Due to Efficient Design and Quality Materials

The cranes are engineered for low-maintenance operation, which helps reduce downtime and operational costs. By using high-quality components, such as sealed bearings, high-strength steel, and advanced coatings, the cranes are resistant to wear and corrosion. This results in fewer maintenance requirements, allowing businesses to focus on operations rather than repairs. Additionally, the self-lubricating systems and modular components simplify maintenance tasks and extend the crane's operational life.

Energy Efficiency

- Powered by 440V, 60Hz, 3-Phase Electricity

The gantry cranes are designed to run efficiently using 440V, 60Hz, 3-phase power, which is the standard for most industrial applications. This voltage configuration ensures that the cranes have a steady, reliable power supply, enabling them to perform at optimal levels while consuming power efficiently. - Designed for Energy-Efficient Operations and Reduced Energy Costs

Energy efficiency is a key feature of these cranes, as they are built with energy-saving technologies that help reduce the overall operating costs. The advanced electrical systems and motors used in the cranes are designed to minimize power losses, optimizing energy consumption. This is especially important in industries where cranes are used frequently, as reduced energy consumption translates into lower operating costs and a smaller carbon footprint. Additionally, the cranes are designed for smooth and controlled movements, which helps reduce energy waste during lifting and lowering operations.

Summary of Key Features:

| Feature | Details |

|---|---|

| European Engineering Standards | High-quality construction and design, compliance with international safety standards, advanced control and electrical systems for reliable performance. |

| Durability and Maintenance | Designed for long-term use in tough industrial environments, low maintenance requirements due to efficient design and quality materials. |

| Energy Efficiency | Powered by 440V, 60Hz, 3-phase electricity, designed for energy-efficient operations and reduced energy costs. |

These key features ensure that the gantry cranes are not only high-performing but also long-lasting and efficient. By combining European engineering excellence with durability, safety, and energy efficiency, these cranes provide excellent value for businesses in the Philippines looking for reliable and cost-effective lifting solutions.

Gantry crane legs and ground beams for the 5 ton and 10 ton projects in the Philippines

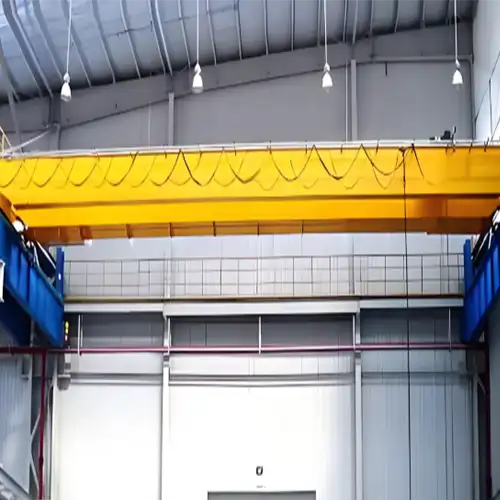

Main girder of gantry crane projects

gantry crane main parts and components for sale Philippines

single girder hoist for gantry crane

double girder hoist for gantry crane

Applications of the Gantry Cranes

These 7 sets of European-style gantry cranes are designed for use across a variety of industrial sectors. Their versatility and high performance make them ideal for numerous applications, where they can provide significant operational advantages.

Industrial and Manufacturing Facilities

Heavy-Duty Lifting in Factories and Workshops

These gantry cranes are well-suited for heavy-duty lifting tasks in factories and workshops, such as those in the steel manufacturing and automotive assembly sectors. The MGO double girder crane, with its 10-ton capacity, is especially effective for handling large components, machinery, and equipment that are essential to these industries.

- In steel manufacturing, these cranes can be used to lift heavy steel beams, coils, and other bulk materials.

- In automotive assembly, they are used to move car bodies, engine components, and other heavy subassemblies through various stages of production.

Handling of Large Components, Machinery, and Equipment

The cranes' lifting capacities of 10 tons and 5 tons make them ideal for moving large components and machinery. Whether it's a large mold in a factory or heavy equipment in a workshop, these cranes provide the strength and precision required to handle complex, oversized loads safely and efficiently.

Construction and Infrastructure Projects

Material Handling for Large-Scale Construction Projects

These gantry cranes are perfectly suited for construction and infrastructure projects, where heavy materials need to be moved on-site. Whether it's building skyscrapers, bridges, or infrastructure projects, these cranes are essential for lifting and positioning large, heavy components.

- The MHO 10-ton cranes are ideal for lifting steel beams, precast concrete, and other structural materials that are frequently used in construction.

- With their large spans and strong lifting capacities, these cranes are well-equipped to handle materials in tight or difficult-to-access areas of construction sites.

Lifting Steel Beams, Precast Concrete, and Other Construction Materials

The cranes' ability to handle large and heavy construction materials allows construction projects to run smoothly, reducing delays and improving overall workflow. These cranes are capable of lifting steel beams, prefabricated concrete slabs, and other heavy construction materials that require precise handling during assembly.

Warehouses and Distribution Centers

- Used for General Material Handling and Storage Management

These cranes are ideal for warehouses and distribution centers, where efficiency in material handling is key to maintaining productivity. Their high lifting capacities (5 tons to 10 tons) and flexible configurations (single or double girder) make them capable of handling a wide range of materials, including goods, packages, and pallets.

- They can be used to lift and move heavy products from one location to another within the warehouse, making storage and inventory management much more streamlined.

- With their adjustable lifting heights and spans, these cranes can easily reach and organize materials stored at various levels in multi-story warehouses.

- Ideal for Warehouses that Require Flexibility and High Load Capacity

Warehouses that handle high volumes of inventory or large, heavy items benefit greatly from the versatility of these cranes. Their flexibility in handling different types of loads and their high load capacities make them indispensable for businesses in sectors like e-commerce, retail, and logistics. The 20-meter crane span and the 10-ton lifting capacity make them effective in warehouses with substantial operational needs.

Benefits of Purchasing These Cranes

Investing in these European-style gantry cranes offers several key advantages, from versatility and cost-effectiveness to a quick return on investment (ROI). Let's take a closer look at these benefits:

Versatility

- Multiple Crane Configurations (Single Girder and Double Girder) for Different Lifting Needs

These cranes are available in both single girder and double girder designs, providing flexibility to suit a variety of operational requirements. Single girder cranes, like the MHO 5-ton and 10-ton models, are ideal for lighter-duty lifting tasks or when space is limited. On the other hand, the MGO double girder crane offers superior stability and lifting power for heavy-duty operations, such as those found in large manufacturing plants or construction sites. - Range of Capacities (5 Tons and 10 Tons) Allows for Tailored Solutions

The cranes' available lifting capacities range from 5 tons to 10 tons, allowing businesses to choose the best option based on their load requirements. Whether the task involves lifting lightweight components or large, heavy equipment, these cranes can be easily tailored to meet specific needs, providing a customized solution for any environment.

Cost-Effectiveness

Competitive Pricing for High-Quality European-Engineered Cranes

These gantry cranes offer exceptional value for money, especially when considering their high-quality European engineering. They are built to the highest standards of safety and performance while remaining competitively priced for the market.

The European design ensures that the cranes are durable, easy to maintain, and efficient, offering businesses long-term savings and high productivity.

Reduced Operational Costs Through Energy Efficiency and Durability

The cranes are engineered for energy efficiency, reducing operational costs over time. Their advanced control systems, efficient motors, and well-designed components help minimize energy consumption while ensuring high performance.

Additionally, their durability means less frequent repairs and replacements, resulting in further savings in maintenance and downtime costs.

Fast Return on Investment (ROI)

Enhanced Productivity and Efficiency Lead to Quick ROI in Industrial Settings

One of the most significant benefits of purchasing these gantry cranes is the quick return on investment. Their ability to handle heavy loads quickly and efficiently boosts productivity in any setting. Whether used in manufacturing, construction, or warehouses, the cranes help streamline operations, reduce manual labor, and minimize downtime.

The enhanced efficiency of these cranes directly contributes to improved productivity, meaning businesses can achieve higher output in less time, ultimately resulting in faster financial returns.

In conclusion, these 7 sets of European-style gantry cranes offer a range of benefits that can significantly enhance the operational efficiency and profitability of businesses. With their versatility, cost-effectiveness, and quick ROI, these cranes are an excellent investment for companies seeking reliable, long-lasting lifting solutions.

Customer Support and Services

One of the key advantages of purchasing the 7 sets of European-style gantry cranes is the comprehensive customer support and services offered to ensure a seamless experience from purchase to long-term operation. These services are designed to support businesses throughout the life of the crane, providing peace of mind and ensuring maximum performance.

Installation and Setup

Professional Installation Services to Ensure Correct and Safe Setup

The installation of a gantry crane is a critical process that requires precision and expertise. To ensure that the crane operates safely and effectively from day one, professional installation services are provided. The installation team ensures that the crane is set up according to safety standards and manufacturer specifications, which is crucial for avoiding potential issues during operation.

- This service includes site assessment, crane assembly, and testing to verify that everything is functioning properly before the crane is put into use.

- Experienced technicians handle all aspects of the installation process, ensuring the crane is properly integrated into the customer's workflow, whether it's in a factory, construction site, or warehouse.

Ongoing Maintenance and Technical Support

Post-Purchase Support Including Maintenance Contracts, Troubleshooting, and Spare Parts Availability

Once the crane is installed, ongoing maintenance and technical support ensure that the equipment continues to perform optimally over time. Buyers are offered maintenance contracts that can be tailored to the frequency and type of service required for their operation.

- Regular maintenance checks help to identify potential issues before they become serious problems, minimizing downtime and costly repairs.

- The technical support team is available to assist with any troubleshooting, helping customers resolve issues quickly and efficiently.

- Additionally, spare parts are readily available to ensure that any component that may wear out or require replacement can be obtained promptly, preventing delays in crane operations.

Warranty and After-Sales Services

Warranty Coverage and After-Sales Service to Guarantee Long-Term Performance

Each crane comes with a robust warranty that covers defects in materials and workmanship, providing assurance that the equipment will perform reliably for years to come. This warranty is part of the overall commitment to quality and customer satisfaction, ensuring that customers have peace of mind regarding their purchase.

- The after-sales service team is always available to assist with any concerns or inquiries about crane performance, maintenance, or parts replacement. This support is designed to maximize the longevity of the crane and ensure that it continues to operate at peak efficiency.

- In the unlikely event of a malfunction or technical issue, the warranty provides coverage to repair or replace faulty components, offering long-term value for the buyer.

Conclusion

The 7 sets of European-style gantry cranes available for sale in the Philippines offer a high-quality, versatile, and reliable lifting solution for a variety of industrial applications. These cranes, featuring both MGO double girder and MHO single girder configurations, with capacities of 10 tons and 5 tons, are designed to meet the diverse needs of businesses across industries such as manufacturing, construction, and warehousing. Whether lifting heavy machinery, steel beams, or general materials, these cranes provide excellent performance, flexibility, and durability.

These cranes are not only competitively priced but also come with a range of customer support services, including professional installation, maintenance contracts, technical support, and a comprehensive warranty to ensure long-term reliability and minimal downtime.

Emphasis on the High Quality, Competitive Pricing, and Tailored Solutions for Different Industrial Applications

The European engineering behind these cranes guarantees durability and efficiency, providing a cost-effective solution for businesses that require reliable lifting equipment. Their tailored configurations, along with the flexibility of different capacities and crane types, make them suitable for a wide range of industrial applications, from heavy-duty lifting to general material handling.

Whether for steel manufacturing, construction projects, or warehouse management, these cranes offer the perfect balance of performance and value. Their adaptability ensures that businesses in various sectors can find the right solution for their unique operational needs.

We encourage potential buyers to inquire about these 7 sets of gantry cranes and take advantage of this opportunity to improve their material handling capabilities. For more information on pricing, installation details, or to schedule a consultation, please feel free to contact us. Our team is ready to provide further details, guide you through the purchasing process, and ensure that you find the best solution for your business needs. Don't miss out on this opportunity to invest in high-quality, reliable equipment that will serve your business for years to come.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch