How to Select an Overhead Crane for Your Particular Facility Layout

Selecting an overhead crane involves considering facility layout, load capacity, lifting height, headroom, and operational requirements for efficiency.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

How to Select an Overhead Crane for Your Particular Facility Layout

Selecting an overhead crane involves considering facility layout, load capacity, lifting height, headroom, and operational requirements for efficiency.

Overhead cranes are essential tools in many industrial operations, playing a critical role in material handling and logistics. These cranes are designed to lift and move heavy loads with precision and efficiency, making them invaluable in various sectors, including manufacturing, construction, and warehousing. By utilizing overhead space, these cranes optimize the available floor area, allowing for smoother workflows and increased productivity.

Selecting the right overhead crane is crucial for any facility. A well-chosen crane enhances operational efficiency, ensures safety, and maximizes the use of space. The layout of a facility significantly impacts crane performance, as different configurations can affect lifting height, load capacity, and movement pathways. Understanding your facility's specific needs is essential to ensure that the selected crane not only fits seamlessly into the existing layout but also meets operational demands.

A thoughtful selection process can prevent costly mistakes and downtime associated with improper crane configurations. Therefore, it's vital to consider factors such as the types of materials being handled, the frequency of crane use, and the physical constraints of the facility. By aligning the crane's capabilities with the facility's layout and operational requirements, businesses can achieve greater efficiency and reliability in their material handling processes.

Understanding Your Facility Requirements

Selecting the appropriate overhead crane begins with a comprehensive understanding of your facility's unique requirements. This involves evaluating your operations, assessing spatial constraints, and considering future needs to ensure that the crane can effectively support your workflow.

Assessing Your Operations

Before selecting an overhead crane, it's essential to analyze your operational needs thoroughly. This assessment should include:

- Types of Materials and Loads to Be Handled: Different cranes are designed for various types of loads, such as heavy machinery, raw materials, or finished products. Understanding the nature of the materials being lifted is crucial. For example, if you frequently handle heavy steel beams, you may require a crane with a higher load capacity and specialized attachments. Conversely, if you're moving lighter materials, a smaller, more agile crane may be suitable. Additionally, consider whether the materials are bulky, awkwardly shaped, or sensitive to damage, as this will influence the design and features of the crane you choose.

- Frequency and Duration of Crane Usage: Evaluate how often and for how long the crane will be in operation each day. If the crane will be used continuously or for extended periods, investing in a more robust and durable crane is advisable. On the other hand, if the crane is needed only for occasional tasks, a lighter, less expensive option might suffice. Understanding usage patterns will help determine the appropriate duty cycle classification for the crane, ensuring it meets both operational needs and safety standards.

Space and Layout Considerations

The physical characteristics of your workspace play a significant role in crane selection. Consider the following:

- Dimensions of the Workspace: Measure the overall area where the crane will be installed. This includes not only the floor space but also the space required for the crane's movement and operation. A larger workspace may allow for more options in crane selection, while a confined area may necessitate a more compact design. Ensure that there is enough room for the crane to maneuver, including any lateral movement required for loading and unloading materials.

- Height Limitations and Clearance Requirements: Take note of any height restrictions in your facility, such as beams, ductwork, or other overhead structures. The crane must have enough lifting height to accommodate the loads being moved while leaving sufficient clearance for safe operation. Additionally, consider the need for headroom above the crane itself to ensure smooth operation without obstruction.

- Layout of Existing Equipment and Workflow Processes: The arrangement of other equipment and workstations can impact the crane's effectiveness. Identify where other machinery and storage areas are located, as well as the flow of materials throughout the facility. The crane should facilitate easy access to these areas without causing bottlenecks or disruptions in workflow. A well-planned layout can enhance productivity and ensure that materials move seamlessly from one process to another.

Future Expansion and Flexibility

While immediate needs are essential, considering potential future changes is equally important. This includes:

- Potential for Future Growth and Scalability: As your business evolves, you may need to increase production capacity or handle different types of loads. Selecting a crane with scalability options allows for easy upgrades or modifications to meet changing demands. For example, a crane that can be expanded to accommodate additional lifting capacity or a different configuration may save you time and money in the long run.

- Consideration of Multi-Directional Travel Requirements: Depending on your facility's layout, you may require a crane that can move in multiple directions. This flexibility can enhance operational efficiency, particularly in complex environments where loads must be transported across different areas. A crane designed for multi-directional travel can navigate tight spaces and adapt to evolving workflow needs, providing greater versatility in material handling.

By carefully assessing these factors, you can select an overhead crane that not only meets your current operational demands but also adapts to future challenges, ensuring a long-term solution for your facility.

Types of Overhead Cranes

When selecting an overhead crane, understanding the different types available is crucial to ensure you choose the one that best fits your operational needs. Each type of crane comes with its own set of features, advantages, and ideal applications.

Features:

Single girder cranes consist of a single beam or girder that supports the hoist and trolley. This design makes them lightweight and often less expensive compared to more complex systems. They typically come with a top-running or under-running configuration, allowing flexibility in installation based on the facility's layout.

Benefits:

- Cost-Effective: Single girder cranes are generally less expensive to manufacture and install than double girder cranes, making them an excellent choice for budget-conscious operations.

- Space-Saving: Their compact design requires less vertical space, allowing for improved headroom and overhead clearance, which can be particularly beneficial in facilities with height restrictions.

- Simplicity: Fewer components mean easier maintenance and reduced chances of mechanical failure.

Ideal Applications: Single girder cranes are well-suited for light to moderate lifting applications, such as:

- Assembly lines in manufacturing plants.

- Warehousing and storage facilities.

- Smaller workshops requiring occasional lifting of lighter materials.

Advantages: Double girder cranes feature two parallel girders that provide greater strength and stability. This design allows for larger lifting capacities and longer spans compared to single girder cranes.

Load Capacities:

- These cranes can typically handle loads ranging from 5 tons to over 100 tons, making them ideal for heavy-duty applications. Their robust structure allows for higher lifting heights and better load distribution.

Best Use Cases: Double girder cranes are suitable for various applications, particularly those requiring:

- Heavy lifting, such as steel fabrication, automotive manufacturing, and construction sites.

- Extended spans for wider coverage in large facilities.

- A need for more complex operational features, such as automation or specialized attachments.

Underhung Bridge Cranes: Underhung bridge cranes are a specific type of single girder crane that hangs from the building structure rather than being supported from above.

Advantages:

- Maximized Headroom: Since they are hung from the ceiling, underhung cranes offer greater vertical space, which is advantageous for facilities with low ceilings.

- Lightweight Design: These cranes are often lighter and easier to install, making them a good option for smaller facilities or retrofitting existing spaces.

Load Capacities:

- Underhung cranes typically handle loads from 1 ton to 10 tons, making them suitable for lighter applications.

Best Use Cases:

- Ideal for manufacturing environments with limited space, such as machine shops and assembly areas where overhead space is at a premium.

- Facilities needing flexibility in their lifting solutions without major structural modifications.

Other Crane Types

In addition to single and double girder cranes, various other crane types serve specific functions and applications:

- Gantry Cranes: These cranes consist of a bridge supported by two or more legs, allowing for mobility across an area. They are ideal for outdoor use and can be utilized in shipyards, construction sites, and storage yards. Gantry cranes can handle loads ranging from a few tons to over 500 tons, depending on their design.

- Jib Cranes: Jib cranes are characterized by a horizontal arm (the jib) that supports the hoist and can rotate around a vertical post. These cranes are ideal for providing coverage in smaller work areas, allowing for efficient material handling in confined spaces. Load capacities generally range from 0.5 tons to 15 tons.

- Portable Cranes: These lightweight, mobile cranes can be moved easily from one location to another. Portable cranes are ideal for temporary jobs or smaller tasks, offering flexibility in various work environments. Their load capacities typically range from 0.5 tons to 2 tons.

- Custom Cranes: Many manufacturers offer custom crane solutions designed to meet unique operational requirements. These cranes can be tailored in terms of design, load capacity, and functionality, making them suitable for specialized applications across different industries.

Comparison of Operational Efficiency: Each crane type offers different levels of operational efficiency depending on the application:

- Single Girder Cranes are excellent for cost-effective, lighter lifting needs.

- Double Girder Cranes excel in heavy-duty applications requiring high capacity and durability.

- Gantry Cranes provide mobility and versatility for outdoor and large area operations.

- Jib Cranes maximize coverage in confined spaces, enhancing efficiency in specific workstations.

- Portable Cranes offer flexibility for temporary or less frequent tasks, making them valuable in diverse environments.

Understanding the specific features and benefits of each crane type will help you choose the most appropriate overhead crane for your facility, ensuring optimal performance and safety in your material handling operations.

Load Capacity and Specifications

When selecting an overhead crane, understanding load capacity and specifications is critical to ensuring safe and efficient operation. Properly determining load requirements and assessing lifting height and span will ensure that the crane meets the operational demands of your facility.

Determining Load Requirements

Calculation of Maximum Load Weights:

The first step in determining load requirements is to calculate the maximum weight of the loads that the crane will need to lift. This involves:

- Identifying Load Types: Consider the types of materials and items that will be lifted, including their weights. This could range from raw materials like steel and aluminum to finished products or machinery.

- Weight Distribution: Assess how the weight is distributed within the load. Uneven weight distribution can affect lifting stability and safety, necessitating a more robust crane design.

- Maximum Load Capacity: Once the weights are identified, it's essential to choose a crane with a load capacity that exceeds the maximum weight of the heaviest load. It is recommended to add a safety margin (typically 20-25%) to account for unexpected variations in load weights or conditions.

Consideration of Dynamic Loads and Impact Factors:

When calculating load requirements, it is crucial to consider dynamic loads, which refer to forces exerted on the crane during operation. These can arise from:

- Acceleration and Deceleration: Loads can experience dynamic effects when being lifted, moved, or lowered. Rapid acceleration or deceleration can create additional forces that the crane must accommodate.

- Swinging Loads: If the load swings during transport, it can create varying forces on the crane, impacting its stability. This is particularly important in applications where precision is required.

- Impact Factors: These factors include any sudden changes in motion or unforeseen events that could affect the crane's operation, such as a load bumping against an obstacle. Designing for these impact factors ensures safe lifting operations.

These elements will allow for more accurate load capacity calculations and help in selecting a crane capable of handling not just static weights but also dynamic forces.

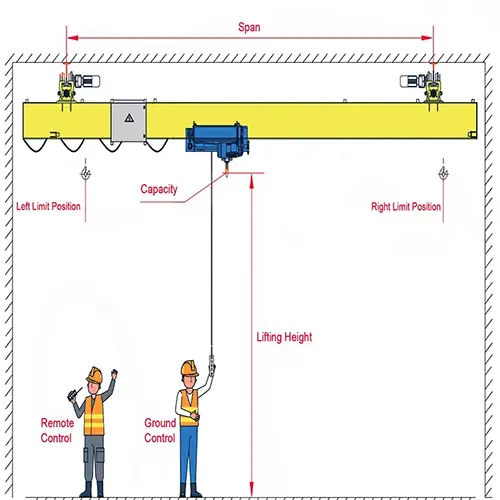

Lifting Height and Span

Assessing Vertical and Horizontal Reach Requirements:

The next key consideration in crane specifications is understanding the lifting height and span necessary for your operations:

- Vertical Reach Requirements: Assess how high the crane needs to lift loads to complete tasks effectively. This involves considering the height of the tallest structure or machinery in the facility and ensuring the crane can operate well within this height. For instance, if lifting loads to a certain level is necessary, selecting a crane with sufficient lifting height capability is essential to prevent operational constraints.

- Horizontal Span Requirements: Evaluate the horizontal distance the crane needs to cover. This includes determining the length of the area where loads will be moved. The span should be designed to reach all critical points in the facility, such as storage areas and workstations, without requiring excessive repositioning of the crane.

Importance of Headroom and Lifting Height in Design:

Headroom is a crucial aspect of crane design that directly impacts its operational effectiveness:

- Headroom Considerations: Adequate headroom must be available above the crane to allow for safe lifting operations. This includes ensuring there is enough clearance for the hook, hoist, and any attachments used during lifting. Insufficient headroom can limit the crane's ability to lift loads to the required height, making it less effective for certain applications.

- Lifting Height in Design: When designing the crane system, ensure that the lifting height is considered in conjunction with the facility's layout and height limitations. The crane should be able to lift loads to the necessary height without risk of obstruction from overhead structures.

In summary, accurately determining load requirements and assessing lifting height and span are essential components in selecting the right overhead crane for your facility. Proper evaluation of these specifications not only enhances operational efficiency but also ensures safety and reliability during material handling processes.

Crane Design and Features

Selecting the right overhead crane involves not only understanding its load capacity and specifications but also considering its design and features. A well-designed crane with appropriate features can enhance operational efficiency, safety, and adaptability to specific needs.

Control Systems

Manual vs. Automated Controls:

Control systems play a significant role in how a crane is operated. There are generally two main types of controls:

- Manual Controls: These involve a physical operator controlling the crane through a pendant or joystick. Manual controls are straightforward and often preferred for simpler operations where precision and control are necessary. They allow operators to respond quickly to changing conditions and provide a more hands-on approach to crane operation.

- Automated Controls: Automation involves using computerized systems to manage crane operations. Automated controls can improve efficiency and reduce human error, especially in repetitive tasks. They can include programmable features, allowing the crane to perform specific lifting patterns or routines automatically.

Remote Operation Capabilities:

Many modern overhead cranes come equipped with remote operation capabilities. This feature allows operators to control the crane from a safe distance, enhancing safety by reducing exposure to potential hazards. Remote operation can be particularly beneficial in:

- Hazardous Environments: In areas where there are risks associated with fumes, chemicals, or heavy machinery, remote operation can keep operators safe while maintaining productivity.

- Increased Visibility: Operators can position themselves where they have a better line of sight of the load and surroundings, improving situational awareness during lifting operations.

Safety Features

Emergency Stop Systems:

Safety is paramount in crane operations. All overhead cranes should be equipped with emergency stop systems that allow operators to halt the crane's operation immediately in case of an emergency. This feature can prevent accidents and minimize injury to personnel.

Overload Protection:

Overload protection systems are crucial to ensure that the crane does not lift weights beyond its designated capacity. These systems can include load cells or sensors that monitor the weight being lifted, triggering an alarm or shutting down operations if the load exceeds safe limits.

Anti-Collision Measures:

In facilities where multiple cranes operate, anti-collision features are essential. These systems can include sensors that detect nearby cranes or obstacles, preventing collisions and enhancing overall safety. Implementing such systems is especially important in busy environments where space is limited.

Compliance with Industry Safety Standards:

All cranes must adhere to specific safety regulations and standards set forth by organizations such as the Occupational Safety and Health Administration (OSHA) or the American National Standards Institute (ANSI). Ensuring compliance not only safeguards workers but also reduces liability and improves operational efficiency.

Customization Options

Tailoring Cranes to Specific Applications and Environments:

Every facility has unique requirements, and many crane manufacturers offer customization options to meet these specific needs. Customization can include:

- Design Modifications: Adjusting the crane design to fit particular dimensions, load capacities, or operational processes in your facility.

- Operational Features: Integrating specialized operational features such as variable speed drives, additional hoists, or unique attachments based on the tasks to be performed.

Consideration of Specialized Features:

In certain environments, especially those involving harsh conditions, customized features can significantly enhance crane performance and longevity:

- Corrosion-Resistant Materials: For operations in marine environments or chemical processing plants, using materials that resist corrosion is vital. This customization helps extend the crane's lifespan and reduces maintenance costs.

- Temperature Control Features: In facilities that operate in extreme temperatures, implementing design features to manage thermal expansion or to protect components from heat can be crucial for maintaining operational integrity.

In conclusion, considering the design and features of overhead cranes is essential when selecting the right equipment for your facility. A crane equipped with the appropriate control systems, safety features, and customization options will ensure efficient operations while maintaining safety and reliability. Understanding these elements will help you make an informed decision that aligns with your specific operational requirements.

Installation and Maintenance Considerations

Selecting and implementing an overhead crane involves careful planning, not just in terms of its features and capabilities, but also regarding its installation and ongoing maintenance. Understanding these considerations can help ensure that the crane operates effectively and safely over its lifespan.

Installation Requirements

Site Preparation and Structural Support Needs:

Before installing an overhead crane, thorough site preparation is essential to ensure a smooth and safe installation process. Key aspects include:

- Assessment of the Facility: Conduct a comprehensive evaluation of the facility to determine its structural integrity and suitability for crane installation. This may involve inspecting existing beams, ceilings, and flooring to confirm they can support the crane's weight and the loads it will handle.

- Structural Support Needs: Depending on the type and size of the crane, specific structural reinforcements may be necessary. For instance, a double girder crane will typically require more robust support than a single girder crane due to its heavier construction. It's important to engage with structural engineers to design and implement the necessary reinforcements to accommodate the crane's load requirements.

- Clearance and Space Considerations: Ensure that the installation area provides adequate clearance for the crane's operation, including headroom for lifting and horizontal reach. Additionally, consider the space required for the crane's components, such as hoists and trolleys, to function without obstruction.

Timeline and Costs Associated with Installation:

Understanding the timeline and costs involved in the installation process is crucial for effective project management:

- Installation Timeline: The time required to install an overhead crane can vary based on the crane type, the complexity of the installation, and the facility's readiness. Generally, installation can take anywhere from a few days to several weeks. Planning for potential delays due to site conditions or material availability is advisable.

- Cost Factors: The costs associated with installation can include labor, materials for site preparation and reinforcement, and equipment rentals if needed. Obtaining quotes from qualified installation teams and discussing budget constraints early in the planning phase can help prevent unexpected expenses.

Ongoing Maintenance

Importance of Regular Inspections and Servicing:

Regular maintenance is crucial for the safe and efficient operation of overhead cranes. Implementing a structured maintenance program helps identify potential issues before they escalate into major problems, ensuring longevity and reliability. Key aspects of a maintenance program include:

- Scheduled Inspections: Establish a routine for conducting inspections at specific intervals, which may include daily checks before use and more thorough monthly or quarterly assessments. Inspections should cover key components, including hoists, trolleys, electrical systems, and safety features.

- Compliance with Regulations: Ensure that maintenance practices align with industry regulations and safety standards. This may involve keeping detailed records of inspections and maintenance activities to demonstrate compliance and support safety audits.

Common Maintenance Practices to Ensure Longevity and Performance:

Implementing best practices for maintenance can significantly extend the operational lifespan of an overhead crane:

- Lubrication: Regularly lubricate moving parts, such as gears, bearings, and joints, to minimize wear and tear. This practice helps reduce friction and ensures smooth operation.

- Wear and Tear Monitoring: Pay attention to signs of wear in components like cables, chains, and hoists. Replacing worn parts promptly can prevent failures and enhance safety.

- Load Testing: Periodically conduct load tests to ensure that the crane can handle its rated capacity. This practice helps confirm the integrity of the crane's components and ensures safe operation.

- Environmental Considerations: In harsh environments, such as those with high humidity or exposure to chemicals, implement additional protective measures. This could involve using corrosion-resistant materials or applying protective coatings to components.

In summary, understanding the installation requirements and ongoing maintenance considerations is essential for successfully integrating an overhead crane into your facility. A well-planned installation, coupled with a comprehensive maintenance program, ensures that the crane operates safely and efficiently, maximizing its performance and longevity. By prioritizing these aspects, you can enhance operational productivity while minimizing risks and costs associated with crane operations.

Budgeting and Cost Analysis

When considering an overhead crane for your facility, budgeting and cost analysis are crucial to ensure that you make a financially sound decision. Understanding both the initial costs and long-term investments can help you effectively plan your budget while maximizing operational efficiency.

Initial Costs vs. Long-term Investment

Breakdown of Costs Associated with Different Crane Types:

The initial costs of purchasing an overhead crane can vary significantly depending on the type, capacity, and features. Here's a breakdown of typical costs associated with various crane types:

- Single Girder Cranes: Generally, these cranes are more affordable due to their simpler design and lower material requirements. Costs can range from $10,000 to $50,000, depending on capacity and additional features.

- Double Girder Cranes: These cranes offer greater load capacity and stability, but they also come with higher costs, typically ranging from $25,000 to over $100,000. The complexity of installation and required structural support can also contribute to higher initial expenses.

- Gantry Cranes: Portable and versatile, gantry cranes can range from $15,000 to $60,000, depending on the design and specifications. They are often more affordable for facilities with limited space.

- Custom Cranes: Custom-built cranes tailored to specific operational needs can significantly increase costs, ranging from $50,000 to several hundred thousand dollars. Factors such as unique design requirements and specialized features will influence the overall price.

Evaluating Total Cost of Ownership:

Beyond the initial purchase price, it is essential to consider the total cost of ownership, which includes ongoing maintenance, operational costs, and potential downtime. Key components to evaluate include:

- Maintenance Costs: Regular inspections and servicing are necessary to keep the crane operating efficiently. Budgeting for these costs can vary but may range from 1% to 5% of the initial purchase price annually.

- Energy and Operational Costs: Assess the energy consumption of the crane, especially for electric-powered models. Understanding the energy costs associated with regular use can help in budgeting for the long term.

- Downtime Costs: Consider the potential costs associated with crane downtime due to maintenance or repairs. Minimizing downtime through regular maintenance and inspections can help maintain productivity and reduce financial losses.

Financing Options

Overview of Leasing vs. Purchasing Considerations:

When acquiring an overhead crane, businesses often face the decision between leasing and purchasing. Each option has distinct advantages and drawbacks:

- Leasing: Leasing allows you to use a crane without a significant upfront investment. This option typically involves lower monthly payments compared to purchasing. Leasing is beneficial for businesses with fluctuating needs, as it allows for greater flexibility to upgrade or change equipment as required. However, leasing may result in higher long-term costs, as you will not own the asset at the end of the lease term.

- Purchasing: Buying a crane involves a larger upfront cost, but it provides long-term ownership and the ability to modify or sell the equipment as needed. Ownership also eliminates ongoing lease payments, allowing you to build equity in the asset. If you expect to use the crane for many years, purchasing may be more economical in the long run.

Potential Tax Benefits and Incentives:

When evaluating financing options, it's important to consider potential tax benefits and incentives associated with purchasing or leasing an overhead crane:

- Section 179 Deduction: In some jurisdictions, businesses can take advantage of the Section 179 tax deduction, allowing them to deduct the full purchase price of qualifying equipment, including cranes, in the year of purchase. This can significantly reduce the tax burden and improve cash flow.

- Investment Tax Credits: Depending on your location and the type of crane, you may be eligible for investment tax credits or grants for purchasing energy-efficient or environmentally friendly equipment.

- Depreciation Benefits: Owning a crane allows for depreciation benefits that can further reduce your taxable income over time. Understanding the depreciation schedule for your crane can be crucial for long-term financial planning.

In conclusion, budgeting and cost analysis are vital components of the decision-making process when selecting an overhead crane. By understanding the initial costs, evaluating the total cost of ownership, and exploring financing options, you can make an informed choice that aligns with your facility's operational needs and financial objectives. Considering the long-term implications of your investment will help ensure that your overhead crane contributes to operational efficiency and profitability for years to come.

Vendor Selection and Consultation

Selecting the right vendor for your overhead crane is a critical step in the procurement process. The choice of supplier can significantly impact not only the quality of the crane you receive but also the support and service you can expect throughout its lifecycle. Therefore, conducting thorough research and consultations is essential to ensure you partner with a reputable manufacturer.

Researching Suppliers

Evaluating the Reputation and Experience of Crane Manufacturers:

Before making a decision, it's crucial to evaluate the reputation and experience of potential crane suppliers. Here are some key factors to consider:

- Industry Reputation: Investigate the manufacturer's standing in the industry by looking at customer reviews, testimonials, and industry ratings. A supplier with a strong reputation for quality and reliability can provide peace of mind.

- Experience and Specialization: Consider the supplier's years in business and their specialization in overhead cranes. Companies with extensive experience and a focus on crane manufacturing are more likely to deliver high-quality products and solutions tailored to your needs.

- Certifications and Compliance: Verify that the manufacturer complies with industry standards and regulations. Certifications from recognized organizations indicate a commitment to quality and safety, ensuring that the cranes meet or exceed required specifications.

Importance of Customer Support and After-sales Service:

A supplier's customer support and after-sales service are just as important as the product quality. Look for the following:

- Technical Support: Ensure that the supplier offers comprehensive technical support, including assistance with installation, troubleshooting, and maintenance. This support can be invaluable in minimizing downtime and ensuring smooth operations.

- Warranty and Service Agreements: Review the warranty and service agreements offered by the supplier. A robust warranty and service plan can provide reassurance regarding the durability of the crane and access to ongoing support.

- Training and Resources: Check if the supplier provides training for your team on operating and maintaining the crane. Access to resources such as manuals and online training modules can enhance operational efficiency.

Requesting Quotes and Proposals

Best Practices for Obtaining Detailed Quotations:

When requesting quotes from potential suppliers, following best practices can help you gather accurate and comprehensive information:

- Provide Clear Specifications: Clearly outline your requirements, including load capacities, dimensions, and any specialized features you need. This clarity allows suppliers to provide tailored quotes that meet your specifications.

- Request Comprehensive Proposals: Ask vendors for detailed proposals that include not only pricing but also timelines, delivery options, and any additional services offered, such as installation or training.

- Clarify Cost Breakdown: Ensure that the quote includes a detailed breakdown of costs, including installation, transportation, and any additional fees. Understanding the full financial picture is essential for budgeting.

Comparing Different Vendors Based on Service and Quality:

Once you receive multiple quotes, it's important to evaluate them effectively:

- Analyze Service Offerings: Compare the level of service each vendor offers, including warranty terms, support availability, and training options. A supplier with superior service can be more valuable in the long run.

- Assess Quality and Reliability: Look beyond just the cost. Assess the quality of materials and construction techniques used by each vendor. This evaluation can often be done through third-party reviews, case studies, or by visiting their manufacturing facilities if possible.

- Check References: Don't hesitate to ask vendors for references from previous clients. Speaking directly with other businesses can provide insights into the vendor's reliability, quality of work, and customer service experience.

Conclusion

In summary, selecting the right overhead crane involves a comprehensive approach that considers the specific needs of your facility, the types of cranes available, and the associated costs. Understanding your requirements, evaluating various crane types, assessing load capacities, and factoring in installation and maintenance considerations are all essential steps in the selection process.

When choosing a vendor, prioritize manufacturers with a solid reputation, extensive experience, and strong customer support. Request detailed quotes to make informed comparisons and ensure that the selected supplier can meet your operational needs.

By taking the time to conduct thorough research and consult with industry experts, you can make an informed decision that leads to the successful implementation of an overhead crane tailored to your facility's unique requirements.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch