Top 4 Explosion-Proof Hoists & Select Your Best One at Good Price

Electric explosion proof hoist for sale. Explore top explosion-proof hoists & learn how to choose best one for your hazardous environment lifting needs.

Category: Featured

Your Trusted Explosion Proof Hoist Manufacturer & Supplier

Top 4 Explosion-Proof Hoists & Select Your Best One at Good Price

Explosion Proof Hoists

Explosion-proof hoists are essential in industries where the risk of explosions is high. These hoists are specially designed to prevent ignition sources from triggering hazardous situations in environments filled with flammable gases or dust. Ensuring safety in such areas is a top priority, and explosion-proof hoists are key to protecting both workers and equipment.

Industries That Require Explosion-Proof Hoists

Explosion-proof hoists are commonly used in industries where hazardous materials are present. Here are some of the main sectors:

- Chemical Plants: Flammable chemicals and gases make explosion-proof hoists a must for safe operations.

- Oil & Gas: The presence of volatile substances requires high safety standards for lifting and handling equipment.

- Military: In explosive environments, hoists need to meet strict safety regulations to prevent accidents.

- Aerospace: Lifting equipment used in aerospace facilities must be able to operate safely in environments with explosive risks.

The goal of this article is to compare four different types of explosion-proof hoists and help you understand which one is best suited for your needs. By reviewing the unique features and capabilities of each hoist, we will provide you with the knowledge to make an informed decision. Whether you need a hoist for a chemical plant or a military base, this guide will help you select the ideal option to ensure safety and efficiency.

What is an Electric Explosion-Proof Hoist?

An electric explosion-proof hoist is a specialized lifting device designed to safely operate in hazardous environments where there is a risk of explosion due to flammable gases or dust. These hoists are equipped with safety features that prevent sparks, heat, or electrical faults from igniting explosive substances. They are commonly used in industries such as chemical processing, oil and gas, mining, and manufacturing, where hazardous materials are present.

Safety Standards and Regulations

Explosion-proof hoists must meet strict safety standards and regulations to ensure they can operate safely in explosive environments. Some key regulations include:

- IEC (International Electrotechnical Commission): The IEC sets global standards for electrical equipment used in explosive atmospheres. IEC 60079 is the primary standard for explosion-proof equipment.

- ATEX (Atmosphère Explosible): ATEX is a European Union directive that defines the requirements for equipment used in explosive atmospheres, including hoists.

- UL (Underwriters Laboratories): UL standards are used primarily in North America, focusing on the safety of electrical equipment, including explosion-proof hoists.

These standards outline specific design, testing, and certification requirements for explosion-proof equipment, ensuring they can safely handle the risks associated with explosive gases and dust.

Key Considerations: Gas and Dust Explosion-Proof Classifications

Explosion-proof hoists are classified based on the type of hazardous environment they are designed to operate in. There are two main classifications:

- Gas Explosion-Proof: These hoists are built to operate in environments where flammable gases may be present. The equipment must prevent ignition sources from igniting the gas, which can be classified into different zones (Zone 1, Zone 2) based on the likelihood of the gas being present.

- Dust Explosion-Proof: These hoists are designed for environments with combustible dust. Similar to gas classifications, dust environments are also divided into zones (Zone 21, Zone 22), depending on the frequency and concentration of dust.

Both types of hoists must meet specific requirements for temperature ratings, protection methods (such as flameproof enclosures), and safety features to prevent the ignition of hazardous substances.

Types of Electric Explosion-Proof Hoists

Electric explosion-proof hoists are designed for specific industrial needs, each offering unique features for handling hazardous environments. Below, we explore two prominent types of electric explosion-proof hoists: Traditional Explosion-Proof Electric Wire Rope Hoist and Low Headroom European Explosion-Proof Electric Wire Rope Hoist.

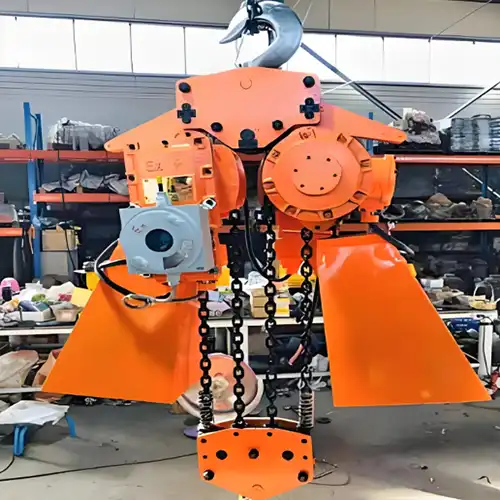

Traditional Explosion-Proof Electric Wire Rope Hoist

Key Features:

- Compact Design: The Traditional hoist features a space-saving structure, ideal for environments with limited space and reducing installation challenges.

- High Capacity: With lifting capacities ranging from 0.5 tons to 50 tons, this hoist is well-suited for demanding, heavy-duty tasks.

- Heavy Lifting: Built specifically for lifting heavy materials, the Traditional hoist excels in industries where large, weighty items need to be handled.

Applications:

The Traditional Explosion-Proof Electric Wire Rope Hoist is perfect for hazardous environments, including:

- Chemical Processing Plants

- Oil & Gas Industry

- Manufacturing Facilities

Pros and Cons:

Pros:

- Reliability: Known for its sturdy construction, the Traditional hoist ensures consistent performance even in dangerous environments.

- High Capacity: Offers significant lifting capabilities, making it ideal for industries requiring the transportation of heavy materials.

Cons:

- Size and Weight: Due to its high lifting capacity, it tends to be bulkier, which might pose installation challenges in smaller spaces.

- Cost: Given its heavy-duty design, the Traditional hoist can be more expensive than lighter alternatives.

Low Headroom European Explosion-Proof Electric Wire Rope Hoist

Key Features:

- European Standard Compliance: This hoist is designed to meet rigorous European explosion-proof standards, ensuring top-notch safety and quality.

- Lightweight Design: With its lightweight construction, the Low Headroom hoist is easier to maneuver and install compared to bulkier models.

- Multiple Safety Features: Equipped with advanced safety features such as dual brakes and continuous safety monitoring, the Low Headroom hoist ensures optimal operation in hazardous environments.

Applications:

The Low Headroom European Explosion-Proof Electric Wire Rope Hoist is perfect for high-performance industries requiring superior safety standards, including:

- High-Performance Manufacturing

- Aerospace

- Pharmaceuticals

- Petrochemical Industries

Pros and Cons:

Pros:

- Enhanced Safety Features: Dual brakes and continuous monitoring systems ensure high operational safety, making it suitable for critical operations.

- International Standard Compliance: Meets strict ISO/IEC safety and quality standards, ensuring reliable performance in global markets.

Cons:

- Higher Initial Costs: Due to its adherence to international standards and additional safety features, the Low Headroom hoist comes with a higher price tag compared to some other models.

This format highlights the key features, applications, and pros and cons of both hoists, making it easier to compare them at a glance.

| Hoist Model | Key Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Traditional Explosion-Proof Electric Wire Rope Hoist | - Compact design- High capacity (0.5t to 50t)- Suitable for heavy lifting | - Chemical processing plants- Oil & gas industry- Manufacturing facilities | - Reliable performance- High capacity for heavy lifting | - Bulky design- Higher cost |

| Low Headroom European Explosion-Proof Electric Wire Rope Hoist | - European standard compliance- Lightweight design- Multiple safety features (dual brakes, monitoring) | - High-performance manufacturing- Aerospace- Pharmaceuticals- Petrochemical industries | - Enhanced safety features- International standard compliance (ISO/IEC) | - Higher initial costs |

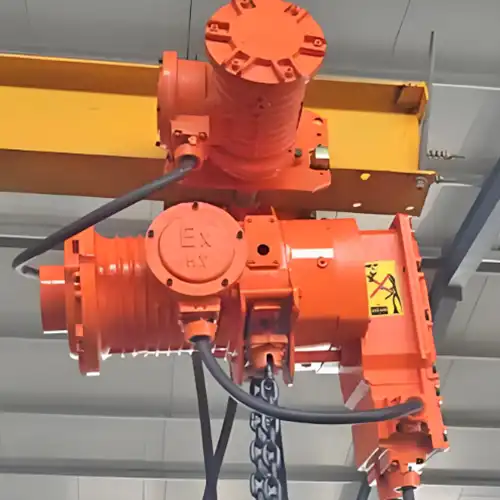

Explosion-Proof Electric Chain Hoists

Key Features

Explosion-proof electric chain hoists are designed for lighter lifting capacities while ensuring safety in hazardous environments. Here are their key attributes:

- Explosion-Proof Design: Features explosion-proof motors and electrical components to protect against sparks and hazards.

- Compact Size: Ideal for confined spaces, these hoists are perfect for installations in tight areas.

- Adjustable Lifting Capacity: Provides flexibility for moderate lifting needs, with the ability to adjust speed and load capacity.

- Cost-Effective: More affordable than heavy-duty hoists, making them suitable for budget-conscious operations.

Applications

These hoists are best suited for industries with moderate lifting requirements, such as:

- Automotive Assembly Lines

- Light Manufacturing

- Warehouses

- Smaller Chemical Processing Plants

Their compact design makes them suitable for small workspaces, while their moderate lifting capacity is ideal for tasks like material handling, assembling small components, and lifting less demanding loads.

Pros and Cons

Pros:

- Compact and Affordable: Perfect for limited spaces and budgets.

- Ease of Installation: Quick to install in small or confined areas.

- Cost-Effective: A budget-friendly option for industries that don't require heavy-duty lifting.

Cons:

- Limited Capacity: Not suitable for heavy-duty applications due to lower lifting capacities.

- Less Robust: Might wear out faster in high-load or continuous operations.

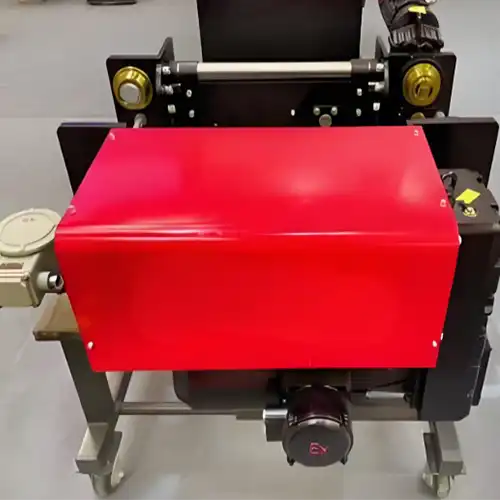

Explosion-Proof Fixed Hook Hoists

Key Features

Explosion-proof fixed hook hoists are built for stationary lifting tasks with a focus on reliability and safety:

- Fixed Hooks: Uses fixed hooks for lifting, making it ideal for repetitive lifting in a fixed position.

- Explosion-Proof Design: Built with explosion-proof motors and electrical components to ensure safe operation in hazardous environments.

- Durable Construction: Engineered for high durability, these hoists are reliable in extreme conditions.

Applications

Commonly used in industries that require repetitive lifting of fixed loads, such as:

- Assembly Lines

- Warehouses

- Manufacturing Plants

- Oil & Gas

- Chemical Processing

Fixed hook hoists are ideal for tasks that do not require movement across large areas, such as loading, unloading, and positioning materials in a fixed location.

Pros and Cons

Pros:

- Cost-Effective: Generally cheaper than more complex hoisting systems, making them suitable for budget-conscious operations.

- Simple Maintenance: Fewer moving parts make them easier and less costly to maintain.

- Reliable for Repetitive Tasks: Perfect for consistent performance in fixed-position lifting scenarios.

Cons:

- Limited Mobility: These hoists are stationary and cannot move freely across a workspace.

- Limited Versatility: Suitable only for tasks requiring lifting at a single point, not for moving loads across different areas.

- Lower Capacity for Dynamic Lifting: Best for stationary applications, with lower capacity for dynamic or high-demand operations.

| Type of Hoist | Explosion-Proof Electric Chain Hoists | Explosion-Proof Fixed Hook Hoists |

|---|---|---|

| Key Features | - Suitable for smaller lifting capacities- Flexible installation- Cost-effective | - Simple and reliable- Suitable for fixed-position lifting- Durable design |

| Applications | - Automotive industry- Light manufacturing- Chemical processing (moderate loads) | - Assembly lines- Warehouses- Manufacturing plants- Oil & gas industries |

| Pros | - Compact and affordable- Easy to install in small spaces- Cost-effective | - Cost-effective- Simple maintenance- Reliable for repetitive tasks |

| Cons | - Limited capacity for heavy loads- Not as robust for heavy-duty applications | - Limited mobility- Limited versatility- Lower capacity for dynamic lifting |

This table breaks down the key features, applications, pros, and cons of the explosion-proof electric chain hoists and fixed hook hoists for easy comparison.

Comparing the 4 Types of Explosion-Proof Hoists

Performance and Capacity

In this section, we compare the performance and capacity of the four explosion-proof hoists, focusing on lifting capacity and speed. Each hoist type is suited for different lifting needs, whether for heavy-duty tasks or moderate applications.

| Hoist Type | Lifting Capacity | Lifting Speed |

|---|---|---|

| Traditional Explosion-Proof Electric Wire Rope Hoist | 0.5t to 50t | 2.4 to 8 m/min |

| Low Headroom European Explosion-Proof Electric Wire Rope Hoist | Up to 50t | 0.4 to 5 m/min |

| Explosion-Proof Electric Chain Hoists | 0.5t to 5t | 2 to 5 m/min |

| Explosion-Proof Fixed Hook Hoists | 0.5t to 10t | 1 to 3 m/min |

Safety Features

Safety features are crucial when working in hazardous environments. This table compares the safety certifications, including gas and dust explosion-proof features, of each hoist type.

| Hoist Type | Explosion-Proof Standards | Gas vs. Dust Protection |

|---|---|---|

| Traditional Explosion-Proof Electric Wire Rope Hoist | IEC, ATEX, UL | Gas explosion-proof (Zones 1, 2) |

| Low Headroom European Explosion-Proof Electric Wire Rope Hoist | ISO/IEC standards | Gas and dust explosion-proof (Zones 1, 2, 21, 22) |

| Explosion-Proof Electric Chain Hoists | Gas explosion-proof | Gas explosion-proof (Zones 1, 2) |

| Explosion-Proof Fixed Hook Hoists | Gas explosion-proof | Gas explosion-proof (Zones 1, 2) |

Design and Durability

The design and durability of each hoist are key factors that influence their performance in harsh environments. This table outlines their size, weight, and durability.

| Hoist Type | Size and Weight | Durability |

|---|---|---|

| Traditional Explosion-Proof Electric Wire Rope Hoist | Compact but heavier | Built for heavy-duty environments |

| Low Headroom European Explosion-Proof Electric Wire Rope Hoist | Lightweight and compact | Long-term durability, high-grade materials |

| Explosion-Proof Electric Chain Hoists | Small and lightweight | Reliable for moderate-duty use |

| Explosion-Proof Fixed Hook Hoists | Simple and lightweight | Extremely durable for fixed applications |

Cost and Maintenance

This section compares the initial cost, maintenance needs, and long-term operational costs for each type of hoist.

| Hoist Type | Initial Cost | Maintenance Needs | Long-Term Costs |

|---|---|---|---|

| Traditional Explosion-Proof Electric Wire Rope Hoist | Higher initial cost | Regular maintenance required | High ROI for heavy-duty industries |

| Low Headroom European Explosion-Proof Electric Wire Rope Hoist | Premium cost | Higher maintenance costs due to advanced features | High long-term investment but worth it |

| Explosion-Proof Electric Chain Hoists | Affordable | Low maintenance | Lower long-term costs, good value |

| Explosion-Proof Fixed Hook Hoists | Low upfront cost | Minimal maintenance | Low operational costs for simpler tasks |

How to Select the Electric Explosion-Proof Hoist for Your Applications

Selecting the right electric explosion-proof hoist for your specific application is crucial to ensure safety, efficiency, and longevity in hazardous environments. Below are key factors to consider when making your decision:

1. Determine Lifting Requirements

Lifting Capacity: Choose a hoist that can handle the maximum weight of the load you plan to lift. Make sure to account for any additional weight from equipment, materials, or attachments that may be used in the lifting process.

- For heavy lifting needs, such as in chemical plants or oil refineries, opt for hoists with higher capacities like wire rope hoists (e.g., up to 50 tons).

- For moderate lifting, electric chain hoists or fixed hook hoists may suffice.

Lifting Speed: Assess how quickly you need to lift and move materials. Some operations require a fast lifting speed, while others may prioritize control and precision.

- If speed is essential, look for hoists that offer adjustable speed settings, allowing for more flexibility in operations.

2. Consider the Hazardous Environment

Explosion-Proof Standards: Ensure that the hoist meets the required explosion-proof certifications. These are typically based on international standards such as:

- IECEx (International Electrotechnical Commission)

- ATEX (EU standards)

- UL (Underwriters Laboratories for North America)

These certifications will guarantee that the hoist has been tested to withstand explosive gases or dust, providing a safe lifting solution.

Gas or Dust Explosion Protection: The type of explosive environment will affect your hoist choice:

- For gas explosion protection, hoists should be rated for zones where flammable gases or vapors exist.

- For dust explosion protection, consider hoists that are equipped with features to prevent the ignition of flammable dust particles in the air.

3. Evaluate Space and Installation Requirements

Size and Weight: Consider the space available for the hoist and its installation. Some hoists, such as wire rope hoists, are more robust and require more space, while others like electric chain hoists or fixed hook hoists are more compact and can be installed in smaller areas.

- If space is limited, a compact hoist like an electric chain hoist will be easier to install.

- If your workspace has more room and heavy lifting is required, consider a wire rope hoist for higher lifting capacity.

Installation Flexibility: Some hoists are more adaptable to different mounting configurations (e.g., overhead beams, monorails), while others are more rigid in their installation requirements. Choose one that suits your facility layout and lifting tasks.

4. Consider Durability and Maintenance

- Durability: The hoist should be able to withstand the harsh conditions of your environment. Look for hoists made from high-quality materials such as stainless steel or reinforced aluminum to ensure longevity and resistance to corrosion in harsh conditions (e.g., high humidity or exposure to chemicals).

- Maintenance Needs: Consider the maintenance requirements of each hoist. Some hoists require frequent servicing, while others are designed for long-term use with minimal upkeep. Fixed hook hoists and chain hoists, for example, generally require less maintenance than wire rope hoists due to their simpler design.

5. Assess Safety Features

- Braking Systems: Hoists used in explosive environments should be equipped with reliable braking systems to prevent accidents. Look for hoists with dual brakes, mechanical brakes, or electromagnetic brakes for added safety.

- Safety Monitoring: Some hoists come with integrated safety monitoring systems to monitor factors like load weight, motor temperature, or overload conditions. This ensures that the hoist operates within safe limits and helps avoid potential failures or accidents.

6. Budget Considerations

- Initial Cost: While more advanced hoists with higher capacities or enhanced safety features can be more expensive, it’s essential to balance the initial investment with the return on investment (ROI) over time.

- Long-Term Costs: Consider the lifetime cost of the hoist, including maintenance, servicing, and potential downtime. Some hoists may have a higher initial cost but offer lower long-term costs due to their durability and less frequent maintenance needs.

- Cost of Spare Parts: Verify the availability and cost of spare parts and servicing. Some hoists may require expensive parts or specialized servicing, which could impact your overall budget.

7. Review Compliance with Industry Standards

Industry-Specific Regulations: Make sure the hoist complies with the industry-specific regulations required for your application. For example, pharmaceutical facilities, aerospace, and petrochemical industries may have different regulatory needs.

Compliance with ISO/IEC standards may be mandatory in certain high-performance applications, while other industries may require compliance with more specific local or national standards.

Selecting the right electric explosion-proof hoist is a vital decision that can impact safety, efficiency, and long-term cost-effectiveness in your operation. By evaluating the lifting requirements, hazardous environment, space constraints, maintenance needs, and budget, you can ensure that you choose a hoist that meets both your safety standards and operational goals. Always prioritize safety features and compliance with industry standards to protect both workers and equipment in hazardous environments.

Conclusion

Choosing the right explosion-proof hoist is critical for ensuring the safety and efficiency of operations in hazardous environments. The hoist must meet both the explosive risks of the environment and the specific needs of your operation.

To make an informed decision, consider:

- The type of hazardous environment (gas, dust, or both) and the required explosion-proof ratings (e.g., IECEx, ATEX, UL).

- Lifting capacity based on the weight of the materials to be moved.

- Installation constraints such as space and mounting options.

- Durability, maintenance requirements, and cost-effectiveness over the long term.

For industries like chemical processing, oil & gas, or pharmaceuticals, selecting a hoist that complies with strict international standards and features advanced safety systems is vital. Electric chain hoists may be ideal for light-duty, space-constrained applications, while wire rope hoists are better suited for heavier lifting tasks in larger spaces.

Ultimately, by considering the specific hazards, load requirements, and safety standards of your environment, you will make the best choice for a reliable, long-lasting, and safe lifting solution in hazardous areas.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch