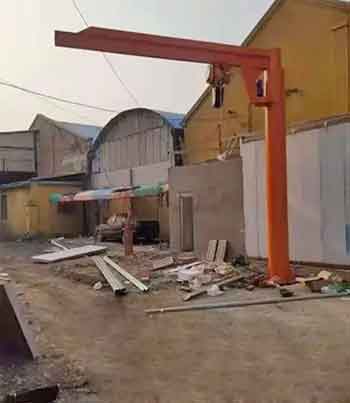

Floor Mounted Marine Industrial Jib Crane, Custom Outdoor Jib Crane

Marine industrial jib crane for sale. Floor-mounted marine industrial jib cranes, ideal for outdoor use, available in 2, 3, 5, 10, and 16-ton capacities.

Category: Floor Mounted Crane

Your Trusted loor Mounted Marine Industrial Jib Crane Manufacturer & Supplier

Floor Mounted Marine Industrial Jib Crane, Custom Outdoor Jib Crane

Marine Jib Crane for Sale, 2, 3, 5, 10, & 16 Ton Capacities

Marine industrial jib crane for sale. Floor-mounted marine industrial jib cranes, ideal for outdoor use, available in 2, 3, 5, 10, and 16-ton capacities.

Floor mounted marine industrial jib cranes, designed with capacities ranging from 3 tons to 16 tons, provide the perfect solution for a wide variety of lifting tasks. These cranes, characterized by their robust construction and flexibility, are particularly valuable in environments where floor space is at a premium, and where reliable performance in harsh conditions is essential.

A floor mounted marine industrial jib crane is a type of crane that is mounted independently on a concrete foundation rather than being attached to a building or a wall. This freestanding design provides several benefits, including greater flexibility in placement and the ability to rotate 360 degrees, offering a wide range of motion for lifting and moving loads. The basic structure of these cranes includes a vertical mast or column, a horizontal boom (or jib), and a hoist system that moves along the boom.

The floor mounted design is particularly advantageous in marine and industrial environments where large, open spaces are available, and where the crane needs to be moved or repositioned periodically. Unlike wall-mounted or mast-type cranes, floor mounted jib cranes do not rely on surrounding structures for support, making them a more versatile choice for varied applications.

Advantages of Floor-Mounted Industrial Jib Crane Design

The floor-mounted industrial jib crane design offers a range of advantages that make it an essential piece of equipment in various industrial and marine environments. Its unique characteristics provide flexibility, adaptability, and efficiency, making it a preferred choice in settings where precise load handling and space optimization are crucial.

Versatility in Installation and Location Flexibility

One of the primary benefits of a floor-mounted jib crane is its versatility in installation. Unlike wall-mounted or ceiling-mounted cranes, floor-mounted models can be installed in virtually any location, provided there is a stable foundation to support the crane's weight and operational load. This flexibility makes them ideal for diverse environments such as shipyards, docks, manufacturing plants, and large warehouses.

- Customizable Placement:

The ability to install the crane in various locations within a facility allows for better space utilization and workflow optimization. Businesses can position the crane exactly where it is needed, enhancing efficiency and reducing the need for additional material handling equipment. - Adaptability to Different Environments:

The floor-mounted design is particularly beneficial in environments where traditional mounting options are not feasible due to structural limitations or space constraints. Whether in a marine dock, an industrial warehouse, or a manufacturing plant, these cranes can be adapted to fit the specific needs of the facility.

Full 360-Degree Rotation for Enhanced Load Handling

Another significant advantage of the floor-mounted industrial jib crane design is its full 360-degree rotation capability. This feature allows operators to move loads around a complete circle, offering unmatched versatility in material handling.

- Precision in Load Positioning:

The 360-degree rotation is particularly valuable in environments where space is limited, such as shipyards or crowded warehouses. The ability to rotate the crane's boom in any direction enables precise positioning of loads, which is essential for tasks that require high accuracy, such as assembling ship components or placing heavy machinery in tight spaces. - Improved Efficiency:

The full rotation capability reduces the need for repositioning the load or moving the crane, thereby saving time and labor. Operators can quickly and easily maneuver loads to the desired location, increasing overall productivity and reducing the risk of accidents caused by cumbersome load handling. - Optimal Use of Space:

In marine environments, where dock space is often at a premium, the ability to rotate the crane freely allows for better use of available space. Loads can be moved directly to where they are needed without requiring additional equipment or manual intervention, streamlining operations and minimizing delays.

Stability and Load Handling Capacity

The floor-mounted design also contributes to the crane's stability and load-handling capacity. By being anchored to the ground, these cranes can handle heavier loads with greater safety and reliability.

- Increased Load Capacity:

Floor-mounted cranes are designed to handle substantial weights, making them suitable for heavy-duty applications such as lifting ship engines, large machinery, or bulk materials. The stable base ensures that the crane can support these loads without compromising safety. - Durability and Longevity:

The stability provided by the floor-mounted design contributes to the crane's overall durability. These cranes are built to withstand the stresses of daily use in demanding environments, ensuring a long service life with minimal maintenance requirements.

Cost-Effective Solution for Large-Scale Operations

The combination of flexibility, 360-degree rotation, and stability makes floor-mounted industrial jib cranes a cost-effective solution for large-scale operations. Their ability to perform a wide range of tasks with precision and efficiency reduces the need for multiple pieces of equipment, leading to significant cost savings.

- Reduced Equipment Costs:

By investing in a floor-mounted jib crane with a broad range of capabilities, businesses can reduce the need for additional material handling equipment, lowering capital expenditures. - Operational Efficiency:

The versatility and efficiency of floor-mounted jib cranes translate into faster project completion times and reduced labor costs. The ability to handle a variety of loads and tasks with a single piece of equipment enhances overall productivity and supports a more streamlined workflow.

In summary, the advantages of the floor-mounted industrial jib crane design are clear. Its versatility in installation, full 360-degree rotation, stability, and cost-effectiveness make it an invaluable tool in various industrial and marine environments. These cranes not only improve operational efficiency but also offer a durable and reliable solution for heavy-duty material handling tasks.

Capacity Options of Floor Mounted Pillar Jib Cranes

Technical Parameter of BZ Pillar Slewing Jib Crane with Anti-Corrosion Design for Marine Use | ||||||

| Capacity | t | 0.5 | 1 | 2 | 3 | |

| Valid radius | R(m) | 3~12 | 3~12 | 3~12 | 3~12 | |

| Lifting height | m | 3~8 | 3~8 | 3~8 | 3~8 | |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | |

| Trolley speed | m/min | 10(20) | 10(20) | 10(20) | 10(20) | |

| Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | |

| Slewing angle | 0°~360° | 0°~360° | 0°~360° | 0°~360° | ||

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | ||

| Capacity | t | 5 | 10 | 16 | 20 | |

| Valid radius | R(m) | 3~12 | 3~15 | 3~15 | 3~15 | |

| Lifting height | m | 3~8 | 3~8 | 3~8 | 3~8 | |

| Lifting speed | m/min | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) | |

| Trolley speed | m/min | 10(20) | 10(20) | 18 | 14 | |

| Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.4~0.7 | 0.4~0.7 | |

| Slewing angle | 0°~360° | 0°~360° | 0°~360° | 0°~360° | ||

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | ||

Detailed Analysis of Various Floor Mounted Marine Jib Cranes

3 Ton Floor Mounted Marine Jib Cranes

Typical Applications and Use Cases:

The 3-ton floor-mounted marine jib crane is designed for environments where moderate lifting capacity is needed. This crane is ideal for tasks like lifting and moving small to medium-sized loads in shipyards, marinas, and light industrial settings. Common uses include maintenance work on vessels, where the crane can lift engines, parts, and other equipment that require precise handling. Its smaller footprint makes it suitable for locations with limited space.

Technical Specifications and Key Features:

- Boom Length: Typically ranges from 3 to 7 meters, providing sufficient reach for various tasks.

- Rotation Capability: Full 360-degree rotation allows for versatile and precise load positioning.

- Materials: Constructed with anti-corrosion materials such as galvanized steel or epoxy-coated components, ensuring durability in harsh marine environments.

- Hoist System: Available in both manual and motorized options, depending on operational requirements.

Pros and Cons:

Pros:

- Ideal for smaller spaces and moderate lifting tasks.

- Cost-effective solution for light to medium-duty applications.

- Easy to install and maintain.

Cons:

- Limited capacity may not be suitable for heavier loads.

- Manual operation may require more effort compared to motorized systems.

5 Ton Floor Mounted Marine Jib Cranes

Typical Applications and Use Cases:

The 5-ton floor-mounted marine jib crane is suited for a broader range of applications, including handling larger components and equipment in shipyards, ports, and industrial warehouses. This crane is particularly effective for loading and unloading smaller vessels and general material handling tasks in industrial settings.

Technical Specifications and Key Features:

- Boom Length: Typically ranges from 4 to 8 meters, offering greater reach for various lifting tasks.

- Rotation Capability: Full 360-degree rotation for flexible load handling.

- Materials: Constructed with anti-corrosion materials and reinforced structure to support increased weight capacity.

- Hoist System: Equipped with a motorized hoist system for easier and more efficient operation, particularly for heavier loads.

- Safety Features: Includes advanced safety features such as overload protection and emergency stop systems.

Pros and Cons:

Pros:

- Suitable for a wider range of lifting tasks, including industrial applications.

- Enhanced safety features make it ideal for demanding environments.

- Motorized operation reduces physical strain on operators.

Cons:

- Higher cost compared to 3-ton models.

- Larger footprint may require more installation space.

10 Ton Floor Mounted Marine Jib Cranes

Typical Applications and Use Cases:

The 10-ton floor-mounted marine jib crane is designed for heavy-duty applications, such as lifting large machinery, equipment, and materials in shipyards, ports, and industrial plants. It is particularly effective in operations requiring the precise movement of large, bulky items.

Technical Specifications and Key Features:

- Boom Length: Typically ranges from 5 to 10 meters, providing extensive reach for heavy lifting tasks.

- Rotation Capability: Full 360-degree rotation for versatile and precise load handling.

- Materials: Built with heavy-duty materials to handle significant loads, including galvanized steel and epoxy-coated components for corrosion resistance.

- Hoist System: Features a motorized hoist and rotation system for smooth, controlled movements.

- Safety Features: Includes advanced load monitoring systems to ensure safe operation under heavy loads.

Pros and Cons:

Pros:

- Capable of handling heavy loads with precision.

- Robust construction ensures long-term durability.

- Ideal for large-scale industrial and marine applications.

Cons:

- Requires substantial installation space and a strong foundation.

- Higher initial investment and maintenance costs.

16 Ton Floor Mounted Marine Jib Cranes

Typical Applications and Use Cases:

The 16-ton floor-mounted marine jib crane is the pinnacle of heavy-duty lifting solutions in the marine and industrial sectors. This crane is indispensable for demanding applications such as lifting and maneuvering heavy machinery, large equipment, and even entire sections of vessels in shipyards and offshore platforms. It is also valuable in large-scale industrial plants for efficiently and safely moving heavy components like large motors, generators, and structural steel.

Technical Specifications and Key Features:

- Boom Length: Typically ranges from 8 to 12 meters, providing ample reach for extensive lifting tasks.

- Rotation Capability: Full 360-degree rotation for versatile load handling and precise positioning.

- Materials: Constructed with high-strength galvanized steel, epoxy-coated components, and stainless steel to resist corrosion and ensure long-term durability.

- Hoist System: Features a motorized hoist system with advanced load monitoring and control for smooth, efficient operation.

- Safety Features: Includes overload protection, emergency stop systems, and a weather-resistant design to ensure safe and reliable performance under challenging conditions.

Pros and Cons:

Pros:

- Capable of lifting very heavy loads, making it suitable for large-scale industrial and marine operations.

- Robust construction and anti-corrosion features ensure long-term durability.

- Advanced safety systems and remote control options enhance operational safety and efficiency.

Cons:

- Requires a large installation area and a strong foundation, which may limit its placement options.

- Higher initial cost compared to cranes with smaller capacities.

Each floor-mounted marine jib crane model, from 3-ton to 16-ton capacities, offers distinct advantages and is suited for specific applications. The 3-ton and 5-ton models are ideal for moderate lifting tasks in smaller spaces, offering flexibility and ease of installation. The 10-ton and 16-ton models, on the other hand, are designed for heavy-duty applications in larger industrial and marine environments, providing robust performance and advanced safety features. Understanding the unique benefits and limitations of each model can help businesses select the right crane for their specific operational needs.

Free standing floor mounted jib crane with electric chain hoist with rain cover for outdoor use

Freestanding floor mounted jib cranes with grab bucket for outdoor loads handling

Material and Design Considerations of Floor-Mounted Marine Jib Cranes

Anti-Corrosion Design: Importance in Marine Environments

In marine environments, anti-corrosion design is essential due to the constant exposure to saltwater, humidity, and harsh weather conditions. These elements can accelerate corrosion, compromising the structural integrity and operational performance of the crane. An effective anti-corrosion design not only extends the crane's lifespan but also minimizes maintenance costs and reduces the risk of operational failures. This is particularly critical in marine applications where equipment failure can lead to significant operational disruptions and safety hazards.

Materials Used: Galvanized Steel, Stainless Steel, Epoxy Coatings

To combat corrosion, marine jib cranes are constructed from materials that resist rust and deterioration:

- Galvanized Steel: Coated with a layer of zinc, galvanized steel provides sacrificial protection, where the zinc corrodes instead of the steel. This is particularly effective in protecting the crane's structural components, such as the boom and base, from exposure to moisture and salt.

- Stainless Steel: Known for its inherent corrosion resistance, stainless steel is often used in critical components like fasteners, bearings, and the crane's boom. The chromium in stainless steel forms a passive layer of chromium oxide, which self-heals when damaged, maintaining the integrity of the crane.

- Epoxy Coatings: Applied as a thick, durable barrier, epoxy coatings protect against moisture, chemicals, and physical wear. These coatings are often used in conjunction with galvanization, providing an additional layer of defense against corrosion, particularly in extremely harsh environments.

Structural Integrity: Boom Length, Height, and Rotation

The structural integrity of the crane is paramount to its performance and safety. The boom length and height are carefully designed to balance the crane's lifting capacity with stability and maneuverability:

- Boom Length and Height: For a 16-ton marine jib crane, the boom length typically ranges from 8 to 12 meters, providing ample reach for various lifting tasks. The height of the crane is optimized to ensure that it can handle the maximum load capacity without compromising stability.

- Rotation Capability: A full 360-degree rotation allows the crane to move loads in any direction, offering maximum flexibility in tight or complex workspaces. This feature is particularly valuable in shipyards and offshore platforms where precise load positioning is crucial.

Base Design and Stability in Floor-Mounted Cranes

The stability of a floor-mounted marine jib crane is heavily dependent on its base design. The base must be securely anchored to a solid foundation, ensuring that the crane remains stable during operation, even under heavy loads or adverse conditions:

- Foundation Anchoring: The crane's base is typically bolted to a reinforced concrete foundation, designed to handle the crane's weight and the dynamic forces exerted during operation. Proper anchoring prevents the crane from tipping or shifting during use.

- Weight Distribution and Environmental Factors: The base design must account for weight distribution to maintain balance. It should also consider environmental factors like wind loads, which can affect stability, especially in outdoor marine environments. In regions prone to seismic activity, the base must be engineered to withstand potential ground movements without compromising the crane's stability.

These material and design considerations ensure that floor-mounted marine jib cranes remain reliable, safe, and efficient in demanding marine and industrial settings.

Operational Features and Safety Mechanisms of Pillar-Mounted Marine Jib Cranes

Power and Control Systems: Manual vs. Motorized Operation

The power and control systems of a 16-ton floor-mounted marine jib crane are crucial to its performance and operational efficiency. These cranes can be equipped with either manual or motorized systems:

- Manual Operation: Manual systems are often simpler and more cost-effective, ideal for environments where power availability is limited or for lighter, less frequent lifting tasks. While they require more physical effort from the operator, they offer a level of control that can be advantageous in certain applications, particularly where precision and slower movement are needed.

- Motorized Operation: Motorized systems enhance efficiency by automating the lifting and rotational functions of the crane. These systems are especially beneficial for heavy lifting tasks, as they reduce the physical strain on operators and increase the speed and precision of operations. Motorized cranes also allow for smoother and more controlled movements, which is critical when handling heavy or delicate loads.

Remote Control Options: Enhancing Flexibility and Safety

Remote control systems significantly enhance the flexibility and safety of crane operations. These systems allow operators to control the crane from a safe distance, which is particularly beneficial in hazardous environments, such as shipyards or offshore platforms. Key benefits include:

- Enhanced Safety: By enabling operators to control the crane remotely, they can avoid being in close proximity to heavy loads, reducing the risk of injury. This is especially important in environments where the risk of falling objects or collisions is high.

- Improved Precision: Remote control systems provide operators with the ability to make fine adjustments to the crane's movements, which is essential for tasks requiring precise load positioning. This is particularly useful in confined spaces or when maneuvering large, bulky items.

- Integration with Crane Functions: Remote controls can be integrated with various crane functions, such as hoist movement, boom rotation, and load monitoring. This integration allows for seamless operation and improves the overall efficiency of lifting tasks.

Overload Protection and Safety Systems

Safety mechanisms are critical in the design and operation of a 16-ton floor-mounted marine jib crane. These cranes are equipped with advanced safety systems to prevent accidents and ensure safe operation:

- Overload Protection: This system is designed to prevent the crane from lifting loads that exceed its rated capacity. It works by monitoring the weight being lifted and automatically stopping the operation if the load exceeds the safe limit. This feature is essential for preventing structural damage to the crane and ensuring the safety of the operators and surrounding equipment.

- Emergency Stop Systems: In the event of an unexpected issue, such as a power failure or mechanical malfunction, the emergency stop system allows operators to quickly halt all crane operations. This system is critical for preventing accidents and minimizing damage in emergency situations.

- Load Monitoring Systems: These systems provide real-time data on the load being handled by the crane, including weight, position, and movement. By continuously monitoring these parameters, the crane can operate within safe limits, reducing the risk of accidents and equipment damage.

Weather Resistance and Maintenance Requirements

Given the challenging conditions in marine environments, pillar-mounted marine jib cranes are designed with weather-resistant features to ensure durability and reliable performance:

- Weather Resistance: The crane's components are constructed with materials and coatings that protect against corrosion, salt spray, and extreme weather conditions. For instance, galvanized steel, stainless steel, and epoxy coatings are commonly used to prevent rust and deterioration. Additionally, the crane's electrical systems are typically sealed and waterproofed to protect against moisture and saltwater exposure.

- Maintenance Requirements: Regular maintenance is essential to keep the crane in optimal condition and extend its operational life. Maintenance tasks typically include routine inspections, cleaning, lubrication of moving parts, and servicing of anti-corrosion components. Special attention should be given to inspecting the crane's structural components for signs of wear or corrosion, as well as checking the integrity of the electrical and control systems. Scheduled maintenance helps to prevent unexpected failures and ensures the crane operates safely and efficiently over time.

These operational features and safety mechanisms ensure that the 16-ton pillar-mounted marine jib crane can perform reliably in demanding marine environments, providing both efficiency and safety for heavy lifting tasks.

Customization and Flexibility

Customization Options for Specific Industrial Needs

Our 16-ton floor-mounted marine jib cranes offer extensive customization options to meet the unique demands of various industrial applications. Recognizing that different environments and tasks require specific configurations, we provide tailored solutions that enhance the crane's functionality and integration into your operations. Whether you need to adjust the crane for confined spaces, special load handling, or unique operational workflows, our customization options ensure that the crane fits seamlessly into your industrial processes.

Modifications in Boom Length, Rotation, and Mounting Options

- Boom Length Adjustments: The boom length can be customized to reach specific areas within your operational space, ensuring that the crane can handle loads in both wide-open and confined environments. Whether you need a longer reach for expansive shipyards or a shorter boom for tight dockside operations, our customization options allow you to configure the boom length to suit your exact needs.

- Tailored Rotation Capabilities: Depending on the layout of your workspace and the nature of the tasks at hand, you may require different rotational capabilities. Our cranes can be modified to offer limited or full 360-degree rotation, providing the flexibility needed to maneuver loads with precision, even in challenging spaces. This customization is particularly beneficial in complex work environments where precise positioning of heavy loads is essential.

- Mounting Options and Special Bases: The crane's mounting options can be customized to integrate with your existing infrastructure or to optimize space utilization. For instance, special base designs can be developed to fit specific foundation types or to enhance the stability of the crane in environments with unique structural requirements. Whether you need a base that can withstand high winds, seismic activity, or other environmental challenges, our custom solutions ensure that the crane is securely anchored and operates safely under all conditions.

By offering these customization and flexibility options, we ensure that our 16-ton floor-mounted marine jib cranes can be perfectly adapted to meet the demands of your specific industrial environment, providing a tailored lifting solution that enhances both efficiency and safety.

Special Features for Hazardous and Corrosive Environments

In hazardous or corrosive environments, such as those found in marine, chemical, or offshore industries, the operational demands on floor-mounted marine jib cranes are exceptionally high. To address these challenges, specific features are integrated into the crane's design to enhance safety, durability, and performance.

- Explosion-Proof Components: In environments where flammable gases or dust may be present, explosion-proof components are essential. These components are designed to prevent ignition sources within the crane's electrical and mechanical systems, reducing the risk of explosions. This feature is critical for cranes operating in oil refineries, chemical plants, or offshore drilling platforms.

- Enhanced Anti-Corrosion Coatings: While standard anti-corrosion measures, such as galvanized steel and epoxy coatings, provide robust protection, environments with extreme corrosive potential, such as saltwater immersion or chemical exposure, require even more advanced solutions. Enhanced coatings might include multi-layered epoxy systems, specialized paints, or even sacrificial anodes, which offer superior protection and extend the crane's service life.

Case Studies of Customized Floor Mounted Marine Jib Cranes

- Shipyard Application with Custom Boom and Rotation: In a large shipyard, a 16-ton floor-mounted marine jib crane was customized to meet specific operational needs. The crane's boom was extended beyond standard lengths to facilitate the lifting and positioning of large vessel sections. Additionally, the rotation capability was enhanced to allow for seamless maneuvering within the tight confines of the shipyard. The customized design significantly improved workflow efficiency, reducing the time needed for complex lifting operations.

- Offshore Platform with Advanced Weather Resistance: An offshore oil platform required a crane that could withstand the harshest marine conditions, including high winds, salt spray, and heavy rainfall. A 16-ton crane was customized with advanced weather-resistant features, including specialized coatings and weather seals on all moving parts. Additionally, the crane was equipped with remote control capabilities to enhance safety, allowing operators to control the crane from a secure location. The customization ensured that the crane remained operational even during severe weather, minimizing downtime and maintaining productivity.

These case studies highlight how customized features can address specific challenges in hazardous and corrosive environments, ensuring that floor-mounted marine jib cranes perform reliably and safely under demanding conditions.

Economic and Operational Benefits of Floor-Mounted Marine Jib Cranes

Cost-Effectiveness of Floor-Mounted Marine Jib Cranes

Investing in a 16-ton floor-mounted marine jib crane represents a significant financial commitment, especially when compared to smaller or less robust models. However, this initial investment is justified by the long-term cost-effectiveness of the crane. The primary factors contributing to its cost-effectiveness include durability, lower maintenance requirements, and increased operational efficiency. These elements not only lead to immediate savings but also result in a strong return on investment (ROI) over time.

- Initial Investment vs. Long-Term Savings:

The upfront cost of a 16-ton floor-mounted jib crane is higher due to its heavy-duty construction and advanced features. However, its long operational life, combined with reduced maintenance needs, offsets these initial costs. Businesses can expect fewer breakdowns and less frequent repairs, which translates into lower ongoing expenses. - Operational Efficiency:

The crane's ability to handle heavy and complex loads efficiently reduces the time and labor required for various tasks. This efficiency leads to quicker project completion, lower labor costs, and the ability to take on more work, all of which contribute to the crane's cost-effectiveness.

Long-Term Durability and Reduced Maintenance Costs

The 16-ton floor-mounted marine jib crane is designed for long-term durability, even in harsh marine environments. The use of anti-corrosion materials such as galvanized steel, stainless steel, and epoxy coatings ensures that the crane can withstand exposure to saltwater, humidity, and other corrosive elements without significant wear and tear.

- Extended Operational Life:

The robust construction of the crane means it can remain in service for many years, providing reliable performance even under heavy use. This longevity reduces the need for frequent replacements, which is a significant cost-saving factor for businesses. - Lower Maintenance Requirements:

The anti-corrosion features and high-quality materials used in the crane's construction result in fewer maintenance interventions. Regular maintenance is simplified, and the likelihood of unexpected breakdowns is minimized. This reliability reduces downtime and the associated costs, making the crane a cost-effective solution in the long run.

Enhanced Productivity in Marine and Industrial Applications

The operational capabilities of a 16-ton floor-mounted marine jib crane directly contribute to enhanced productivity in both marine and industrial settings. The crane's ability to lift and move heavy and bulky loads with precision and ease allows for faster and more efficient operations.

- Increased Load Handling Capacity:

With a capacity of 16 tons, this crane can manage large, heavy, and irregularly shaped loads that would be difficult or impossible to handle with smaller cranes. This capability is particularly beneficial in environments such as shipyards, ports, and offshore platforms, where heavy lifting is a regular requirement. - Advanced Features for Efficiency:

The crane's advanced features, such as remote control operation, overload protection, and customizable boom length and rotation, further enhance its operational efficiency. These features allow operators to perform tasks more quickly and safely, reducing the time spent on each operation and minimizing the risk of accidents or damage to equipment. - Reduced Downtime:

The crane's reliability and efficiency contribute to reduced downtime, ensuring that operations can continue smoothly without unnecessary interruptions. This uninterrupted workflow leads to higher productivity and the ability to meet tight deadlines, which is crucial in competitive industrial and marine sectors.

Comparison of Investment vs. ROI (Return on Investment)

When evaluating the investment in a 16-ton floor-mounted marine jib crane, it's essential to consider the long-term return on investment (ROI). The crane's durability, reduced maintenance costs, and enhanced productivity contribute to a favorable ROI, making it a wise investment for businesses that require heavy-duty lifting solutions.

- Initial Investment Considerations:

While the initial purchase price of a 16-ton crane may be higher than that of smaller cranes or alternative lifting solutions, this cost must be viewed in the context of the crane's expected lifespan and operational benefits. The crane's ability to operate reliably over many years, with minimal maintenance, means that the total cost of ownership is spread out over a longer period, reducing the overall financial impact. - Operational Savings and Revenue Generation:

The increased efficiency and reduced downtime provided by the crane lead to operational savings in terms of labor, time, and maintenance. Additionally, the crane's capabilities allow businesses to take on more demanding projects or increase their throughput, generating additional revenue that contributes to a positive ROI. - Long-Term Value:

Over time, the crane's contribution to increased productivity and reduced operational costs outweighs the initial investment. This long-term value is further enhanced by the crane's ability to maintain its performance in harsh environments, ensuring that businesses can rely on it for years to come.

In summary, the 16-ton floor-mounted marine jib crane offers significant economic and operational benefits. Its cost-effectiveness, long-term durability, and enhanced productivity make it an excellent investment for businesses in marine and industrial sectors. The favorable ROI, supported by reduced maintenance costs and increased efficiency, ensures that the crane remains a valuable asset throughout its operational life.

Installation and Maintenance of Floor Mounted Marine Jib Cranes

Installation Process: Key Steps and Considerations

The installation of a 16-ton floor-mounted marine jib crane is a complex process that requires careful planning and execution to ensure safety and optimal performance. Here are the key steps involved:

- Site Preparation and Assessment:

Before installation, it's essential to conduct a thorough site assessment to determine the crane's placement, considering factors like load capacity, space constraints, and proximity to other equipment. The floor must be evaluated to ensure it can support the crane's weight and operational loads. This may involve reinforcing the foundation to handle the stress exerted by the crane during operation. - Foundation Design and Construction:

The foundation for the floor-mounted jib crane must be designed to meet the specific load requirements. This includes calculating the required depth and materials needed for the concrete base. Once designed, the foundation is constructed, ensuring that it is level and capable of withstanding the dynamic forces generated by the crane. Proper curing time for the concrete is essential to achieve the required strength. - Crane Assembly:

The crane components, including the base, boom, and mast, are delivered to the site and assembled according to the manufacturer's specifications. The assembly process typically involves bolting the mast to the foundation and attaching the boom. Precise alignment is critical during this step to ensure smooth operation and to prevent unnecessary wear on the crane components. - Electrical and Control Systems Installation:

If the crane is motorized, the electrical systems must be installed and connected to the control panel. This includes wiring the motors, installing limit switches, and setting up remote control systems if applicable. Electrical systems should be tested to ensure they are functioning correctly and safely. - Testing and Commissioning:

After installation, the crane undergoes a series of tests to verify its performance and safety. Load testing is conducted to ensure that the crane can handle its rated capacity without any issues. The control systems are tested for responsiveness, and safety mechanisms, such as emergency stop systems and overload protection, are verified. The crane is only commissioned for use after it passes all required tests. - Operator Training:

Once the crane is installed and tested, operators must be trained on its use, including safe operation, load handling, and emergency procedures. Proper training is crucial to prevent accidents and ensure the crane is used correctly.

Maintenance Best Practices for Longevity and Performance

To ensure the long-term durability and optimal performance of a floor-mounted marine jib crane, regular maintenance is essential. The following best practices should be adhered to:

- Routine Inspections: Conduct regular inspections of all crane components, including the boom, mast, base, and electrical systems. Look for signs of wear, corrosion, or damage. Inspections should be performed weekly, with more detailed checks conducted monthly or quarterly, depending on usage.

- Lubrication of Moving Parts: All moving parts, such as bearings, gears, and pivot points, should be regularly lubricated to minimize friction and wear. Use the manufacturer's recommended lubricants to ensure compatibility with the crane's materials and operating conditions.

- Corrosion Protection: Given the marine environment, special attention should be paid to corrosion prevention. Regularly inspect the crane's anti-corrosion coatings, such as galvanization or epoxy, and repair any damage immediately. This prevents the underlying metal from becoming exposed to corrosive elements.

- Electrical System Maintenance: Check electrical connections for signs of wear, corrosion, or damage. Ensure that all wiring is secure and that control systems, including limit switches and emergency stops, are functioning correctly. Regular testing of electrical systems helps prevent unexpected failures.

- Load Testing: Periodically perform load testing to ensure the crane can handle its rated capacity. This testing should be done in accordance with industry standards and regulations. Load testing not only verifies the crane's capacity but also helps identify any weaknesses in the structure or mechanical systems.

- Operator Refresher Training: Periodically conduct refresher training for operators to ensure they are familiar with the latest safety protocols and operating procedures. This training can also address any issues observed during operation or maintenance.

Common Issues and Troubleshooting Tips

Despite regular maintenance, issues can arise with floor-mounted marine jib cranes. Here are some common problems and troubleshooting tips:

Operational Failures:

- Symptom: The crane fails to lift or move loads as expected.

- Possible Causes: Electrical system failure, motor burnout, or mechanical obstruction.

- Troubleshooting: Check the electrical connections and control systems for faults. Inspect the motor for signs of burnout and replace if necessary. Look for any physical obstructions or damage to the moving parts.

Corrosion:

- Symptom: Rust or deterioration of crane components, particularly in areas exposed to moisture.

- Possible Causes: Damage to anti-corrosion coatings, exposure to harsh marine environments.

- Troubleshooting: Repair or reapply anti-corrosion coatings as needed. Consider upgrading to more corrosion-resistant materials if the problem persists.

Mechanical Problems:

- Symptom: Unusual noises, vibrations, or difficulty in crane movement.

- Possible Causes: Worn bearings, lack of lubrication, or misalignment of components.

- Troubleshooting: Lubricate moving parts and check for wear. Align components correctly and replace any worn or damaged parts.

Electrical Issues:

- Symptom: Erratic operation, unresponsive controls, or power loss.

- Possible Causes: Faulty wiring, damaged control systems, or power supply issues.

- Troubleshooting: Inspect and repair wiring and control systems. Ensure a stable power supply and replace damaged components.

By adhering to these installation and maintenance practices, the performance and lifespan of floor-mounted marine jib cranes can be maximized, ensuring safe and efficient operations in demanding environments.

Global Standards and Compliance

- Compliance with International Standards (e.g., ISO, ANSI):Our 16-ton floor mounted marine jib cranes comply with international standards such as ISO and ANSI, ensuring they meet the highest quality and safety requirements. Compliance with these standards guarantees that the crane adheres to best practices and regulatory guidelines.

- Environmental Considerations and Sustainability in Design:Our cranes are designed with environmental considerations in mind, including the use of sustainable materials and practices. The anti-corrosion features help reduce environmental impact by extending the crane's lifespan and reducing the need for frequent replacements.

- Adherence to Safety Regulations in Marine and Industrial Sectors:The crane adheres to stringent safety regulations applicable to marine and industrial sectors. This includes features such as overload protection, emergency stop systems, and weather-resistant design to ensure safe operation under all conditions.

Conclusion

The 16-ton floor mounted marine jib crane offers exceptional lifting capacity and advanced features designed for demanding marine and industrial applications. Its robust construction, anti-corrosion design, and safety mechanisms make it a reliable and effective solution for heavy-duty lifting.

Selecting the appropriate crane capacity is crucial for ensuring optimal performance and safety. The 16-ton crane is ideal for applications requiring substantial lifting power and versatility, making it a valuable investment for industries with high demands.

floor mounted marine industrial jib cranes provide significant benefits, including enhanced productivity, long-term durability, and cost-effectiveness. Their ability to handle heavy loads efficiently and safely makes them a crucial asset in both marine and industrial environments. Investing in a high-quality crane ensures reliable operation and a strong return on investment, supporting the efficient and effective handling of heavy and bulky materials.

- Requires a large installation area and a strong foundation, which may limit its placement options.

- Higher initial cost compared to cranes with smaller capacities.

- Galvanized Steel: Provides a protective zinc coating that prevents rust and corrosion, ensuring the crane remains operational despite exposure to harsh marine conditions.

- Stainless Steel: Offers superior resistance to rust and corrosion, particularly in highly saline environments, making it ideal for components that face direct exposure to seawater.

- Epoxy Coatings: Applied to surfaces to create a durable, protective layer that shields against moisture, chemicals, and physical wear.

Emergency Stop Systems: Allows operators to quickly halt crane operations in case of an emergency, enhancing overall safety.

- Site Preparation: Ensure the installation site is prepared with a solid, level foundation capable of supporting the crane's weight and operational stresses.

- Foundation Construction: Construct a foundation or base that meets engineering specifications for stability and load distribution.

- Assembly: Assemble the crane components, including the mast, boom, and hoist system, following manufacturer guidelines and safety protocols.

- Testing: Conduct thorough testing to ensure the crane operates correctly and safely before putting it into service.

- Regular Inspections: Perform routine inspections to identify and address any wear or damage.

- Cleaning: Keep the crane clean to prevent corrosion and debris buildup.

- Lubrication: Regularly lubricate moving parts to ensure smooth operation.

- Service: Schedule periodic servicing by qualified technicians to maintain performance and safety.

- Operational Failures: Check power and control systems, and ensure all connections are secure.

- Corrosion: Inspect and repair any damage to protective coatings and replace any corroded components.

- Mechanical Problems: Verify alignment and lubrication of moving parts, and consult technical manuals for guidance.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch