10 Ton Jib Crane Sudan | Floor mounted Jib Cranes 10 Ton Project

Electric slewing jib crane for sale Sudan. Tailored floor mounted jib cranes 10 ton capacity, 240V50HZ3P for Sudan. Get good price 10 ton jib crane design!

| Jib type | Floor mounted jib crane |

| Crane capacity | 10 ton |

| Lifting Height | 6.7 m |

| Effective cantilever | 6m |

| Power supply | 240V50HZ3P |

| Project locations | Sudan |

Category: Floor Mounted Crane

Your Trusted Floor Mounted Crane Manufacturer & Supplier

10 Ton Jib Crane for Sale, Tailored Pillar Mounted Slewing Jib Crane

Floor Mounted Jib Cranes 10 Ton Capacity, 240V50HZ3P for Sudan

Electric slewing jib crane for sale Sudan. Tailored floor mounted jib cranes 10 ton capacity, 240V50HZ3P for Sudan. Get good price 10 ton jib crane design!

Floor mounted jib cranes

A floor-mounted jib crane is a versatile lifting solution designed to handle various material handling tasks within industrial settings. This type of crane is securely anchored to the floor, providing stability and strength to lift and transport heavy loads. Floor-mounted jib cranes consist of a vertical support pillar firmly attached to the ground, from which a horizontal jib arm extends. This arm can rotate along a full 360-degree radius, allowing for precise positioning of loads in different directions.

Floor-mounted jib cranes are favored for their ability to efficiently cover specific work areas without the need for extensive structural modifications. They are commonly used in workshops, warehouses, manufacturing facilities, and loading docks where localized lifting operations are frequent. With diverse configurations and lifting capacities, floor-mounted jib cranes offer a practical solution for optimizing workflow, reducing manual labor, and enhancing overall operational efficiency.

Case Study: Installation of a 10-Ton Floor Mounted Jib Crane in Sudan

A prominent industrial equipment supplier successfully executed a significant project involving the installation of a 10-ton floor mounted jib crane in Sudan. The objective was to provide an efficient lifting solution tailored to the client's needs while adhering to the specific requirements of the Sudanese industrial context.

Sudan Client's Requirements

The client, a leading player in Sudan's manufacturing sector, had a pressing need for a robust lifting mechanism to facilitate heavy load handling within their facility. The client's specifications for the project included:

- Crane Capacity: A lifting capacity of 10 tons to accommodate a diverse range of loads.

- Lifting Height: The ability to achieve a lifting height of 6.7 meters, catering to the facility's varied vertical lifting needs.

- Arm Length: An effective arm length of 6 meters to ensure extensive coverage and reach across the workspace.

- Power Supply: The crane needed to operate on a 240V, 50Hz, 3-phase power supply, aligning with the existing electrical infrastructure.

- Project Location: The crane was intended for installation in Sudan, reflecting the client's commitment to locally appropriate solutions.

Solution Provided

Floor mounted jib crane, Electric Slewing jib Crane Series 500kg to 16 ton

Floor mounted jib crane, Electric Slewing jib Crane Series 500kg to 16 ton Specifications of 10 ton floor mounted jib crane for sale Sudan

- Crane capacity: 10 ton

- Crane lifting height: 6.7 m

- Crane effective arm length: 6m

- Crane power supply: 240V50HZ3P

- Project location: Sudan

The industrial equipment supplier collaborated closely with the client to design a tailored solution that fulfilled their requirements while considering the unique challenges posed by the Sudanese industrial environment. The solution encompassed:

- Design and Engineering: Accomplished engineers devised a 10-ton floor mounted jib crane that met the stipulated lifting capacity, height, and arm length specifications. The design prioritized stability, safety, and ease of operation.

- Manufacturing: The crane's components were meticulously manufactured using premium materials, ensuring longevity and durability even in demanding industrial conditions. Stringent quality control measures were integrated into the manufacturing process.

- Customization: The crane's features were customized to align with the client's needs, encompassing the 10-ton lifting capacity, 6.7-meter lifting height, 6-meter arm length, and compatibility with the designated power supply.

- Installation: A team of proficient technicians was dispatched to Sudan for the installation phase. The team executed the secure mounting and precise calibration of the floor mounted jib crane to ensure optimal functionality within defined parameters.

The successful installation of the 10-ton floor mounted jib crane yielded an efficient and reliable solution for the client's heavy lifting requirements. The customized design and contextual considerations ensured seamless integration of the crane into the client's facility. The crane's capacity to lift substantial loads to significant heights contributed to heightened operational efficiency and a reduction in manual labor.

Main Parts and components of 10 ton floor mounted jib crane kits

I beam cantilever of freestanding floor mounted jib crane 10 ton

Pillar or column of floor mounted jib crane 10 ton for sale Sudan

Electric motorized trolley for jib hoist 10 ton

10 ton electric chain hoist with low headroom design for pillar mounted jib crane 10 ton

Electric chain hoist packed for delivery for sale Sudan

Pandeant control of 10 ton electric jib crane with floor mounted crane design

Floor mounted jib crane installation guide

How to install a floor mounted jib crane

Here's a more detailed step-by-step guide for the installation of a floor-mounted jib crane:

1. Pre-Installation Preparation:

- Review the manufacturer's installation manual thoroughly.

- Ensure that the floor's load-bearing capacity is suitable for the crane's weight and the loads it will handle.

- Check for any underground utilities or obstructions at the installation site.

- Gather all necessary tools, equipment, and components required for the installation.

2. Foundation Preparation:

- Prepare a concrete foundation pad of appropriate dimensions and depth as specified in the manufacturer's manual.

- Mark and drill anchor bolt holes in the foundation according to the crane's specifications.

- Set anchor bolts in place, ensuring they are level and properly aligned.

- Pour concrete around the anchor bolts to create a sturdy foundation.

3. Support Pillar Assembly:

- Assemble the support pillar components according to the manufacturer's instructions.

- Attach any leveling shims or base plates to ensure the pillar stands vertically and securely on the foundation.

4. Support Pillar Installation:

- Lift the assembled support pillar onto the anchor bolts.

- Use a level to ensure the pillar is plumb in both vertical directions.

- Fill the gaps around the anchor bolts with epoxy grout to secure the pillar in place.

5. Jib Arm Assembly:

- Assemble the jib arm sections and connection points as specified by the manufacturer.

- Attach any necessary bolts, braces, or reinforcement plates.

6. Jib Arm Attachment:

- Attach the jib arm to the support pillar, ensuring proper alignment and secure bolting.

- Use a torque wrench to tighten bolts to the specified torque values.

7. Hoist and Trolley Installation:

- Assemble the hoist and trolley components according to the manufacturer's instructions.

- Attach the hoist and trolley assembly to the jib arm's trolley beam.

8. Electrical Connection:

- Follow the electrical wiring diagram provided by the manufacturer to connect power to the hoist and trolley.

- Ensure all connections are properly insulated and secured.

9. Safety Features Installation: - Install safety features such as limit switches, emergency stop buttons, and warning signs as specified.

10. Load Testing: - Perform load tests to ensure the crane's lifting capacity matches the manufacturer's specifications. - Gradually increase the load and observe the crane's response for smooth operation and stability.

11. Functional Testing: - Test the crane's rotation, hoisting, and trolley movement to ensure all functions are working properly.

12. Operator Training: - Train crane operators on safe operation, including controls, load limits, and safety procedures.

13. Final Inspection: - Conduct a comprehensive inspection of all components, connections, and safety features. - Ensure the installation meets relevant safety regulations and local codes.

14. Documentation: - Maintain detailed documentation of the installation process, load testing results, and training provided.

15. Regular Maintenance: - Establish a maintenance schedule to inspect, lubricate, and maintain the crane regularly for safe and efficient operation.

Remember that safety is paramount throughout the installation process. If you encounter challenges or uncertainties during the installation, seek guidance from professionals or the crane manufacturer's technical support.

What should be noted when 10 ton jib crane installation?

Installing a floor-mounted jib crane requires careful planning and attention to detail to ensure safe and efficient operation. Here are some important factors to consider during the installation process:

- 1. Site Assessment: Before installation, conduct a thorough assessment of the site. Ensure that the floor is structurally sound and capable of supporting the crane's weight and the loads it will handle. Check for any obstacles, utilities, or obstructions that might affect the crane's movement.

- 2. Foundation and Anchoring: Properly anchor the vertical support pillar of the jib crane to a sturdy foundation. The foundation must be capable of withstanding the crane's loads and forces. Consult engineering specifications for anchor bolt size, depth, and spacing.

- 3. Clearances: Determine the required clearances around the jib crane's swing radius. Make sure there is sufficient space to safely rotate the crane arm without hitting walls, equipment, or other structures.

- 4. Headroom: Ensure that there is enough headroom for the crane to operate effectively. The vertical distance from the floor to the lowest point of the crane's jib arm should be sufficient to accommodate the loads being lifted.

- 5. Electrical Supply: Arrange for the necessary electrical connections to power the crane's hoist and trolley. Ensure that the power supply meets the crane's voltage and amperage requirements.

- 6. Assembly and Alignment: Follow the manufacturer's instructions for assembling and aligning the crane components. Accurate alignment of the jib arm and support pillar is crucial for proper operation.

- 7. Bolt Tightening: Properly tighten all bolts and fasteners according to the manufacturer's specifications. Loose bolts can compromise the crane's stability and safety.

- 8. Hoist and Trolley Installation: Assemble and attach the hoist and trolley components to the jib arm. Ensure that they are securely fastened and properly aligned.

- 9. Safety Measures: Install safety features such as limit switches, emergency stop buttons, and warning signs. These measures enhance the overall safety of crane operations.

- 10. Testing and Inspection: Thoroughly test the crane's movements, hoisting capabilities, and safety features before putting it into full operation. Conduct a load test to verify the crane's lifting capacity and stability.

- 11. Operator Training: Provide training for the crane operators to ensure they understand the controls, safety procedures, and proper usage of the crane.

- 12. Regular Maintenance: Establish a maintenance schedule to inspect, lubricate, and maintain the crane components. Regular maintenance prolongs the crane's lifespan and ensures safe operation.

- 13. Compliance: Ensure that the installation complies with relevant safety standards, regulations, and local codes.

Proper installation of a floor-mounted jib crane is essential for its safe and effective operation. If you're unsure about any aspect of the installation process, consider consulting with experienced professionals or the crane manufacturer for guidance.

To get a customized 10-ton floor-mounted jib crane that precisely suits your operational requirements, you'll need to provide specific parameters and details to the manufacturer or supplier. Here are the key parameters needed for customization:

- 1. Lifting Capacity: Specify the maximum weight the crane needs to lift. In this case, it's 10 tons.

- 2. Lifting Height: Define the vertical distance from the floor to the highest point the crane's hook needs to reach.

- 3. Boom Length: Determine the horizontal reach of the jib arm from the crane's support pillar to the tip of the arm.

- 4. Rotation Angle: Specify the range of rotation needed for the crane's jib arm. Common angles are 180 degrees or 360 degrees.

- 5. Power Supply: Provide information about the available power supply, including voltage, phase, and frequency (e.g., 240V, 3-phase, 50Hz).

6. Hoist Specifications:

- Type of Hoist: Choose between electric chain hoists or wire rope hoists based on your lifting needs.

- Lifting Speed: Specify the desired hoisting speed.

- Control Options: Decide on control methods, such as pendant control or remote control.

7. Trolley Specifications:

- Trolley Type: Choose between manual push trolley or motorized trolley.

- Trolley Speed: Specify the desired trolley travel speed.

- Control Options: Determine how the trolley will be controlled.

8. Operational Environment: - Describe the operating conditions, such as indoor or outdoor use, temperature ranges, and exposure to dust or chemicals.

9. Safety Features: - Specify any additional safety features required, such as limit switches, emergency stop buttons, overload protection, and warning indicators.

10. Control Panel Location: - Decide where the control panel will be located for easy and safe crane operation.

11. Custom Features: - If there are any specific features or accessories you need, such as hooks, spreader bars, or specialized lifting attachments, provide those details.

12. Regulatory Compliance: - Ensure that the crane design and specifications adhere to relevant safety standards and local regulations.

13. Installation Site Information: - Provide details about the installation site, including available floor space, foundation conditions, and any potential obstacles.

14. Budget and Timeline: - Clearly communicate your budget constraints and desired timeline for crane delivery and installation.

By providing these parameters and details, you enable the manufacturer to design and build a customized 10-ton floor-mounted jib crane that meets your exact needs and ensures efficient and safe material handling in your specific environment.

The project exemplifies the efficacy of collaboration between industrial equipment suppliers and clients in delivering tailor-made solutions that address specific operational demands. The installation of the 10-ton floor mounted jib crane in Sudan underscores the impact of meticulous design, precision manufacturing, and expert installation in driving productivity and operational excellence within the industrial sector.

More options for You: Main Types of 10 Ton Overhead Cranes Available for Sale in Sudan

For heavy-duty material handling and transportation, a variety of 10 ton overhead cranes are offered for sale in Sudan, catering to diverse industrial needs. These cranes play a crucial role in efficient lifting operations across industries. The main types of 10 ton overhead cranes available for sale include:

- 1. Single Girder 10 Ton Overhead Cranes: Engineered with a single horizontal girder, these overhead cranes are designed for lighter to moderate lifting tasks. They find utility in workshops, warehouses, and manufacturing setups where precision lifting is essential.

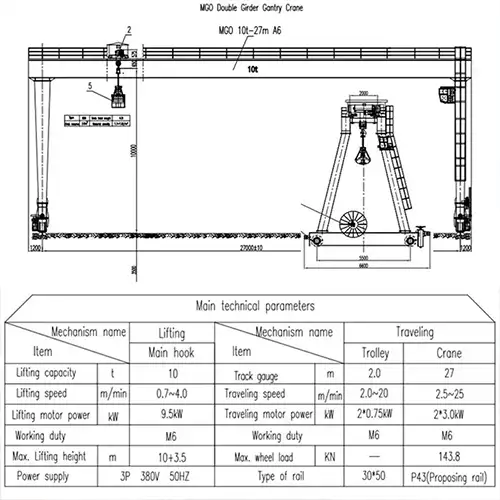

- 2. Double Girder 10 Ton Overhead Cranes: Featuring two horizontal girders, these cranes excel in lifting heavier loads and ensuring stability. Industries such as steel manufacturing, foundries, and large-scale production benefit from their enhanced lifting capabilities.

- 3. Top Running 10 Ton Overhead Cranes: These cranes operate on rails positioned atop the runway beams. They are adept at handling substantial loads efficiently, making the most of vertical space.

- 4. Under Running 10 Ton Overhead Cranes: Employing rails beneath the runway beams, these cranes optimize floor space. They are ideal for scenarios where maximizing available area is a priority.

- 5. Single Leg 10 Ton Gantry Cranes: Utilizing one or more legs for support, these gantry cranes mirror overhead crane functionality. They are particularly advantageous when structural considerations or space restrictions come into play.

- 6. Double Leg 10 Ton Gantry Cranes: With the added support of two legs, these gantry cranes excel in heavier lifting tasks. Their applications range from shipyards to construction sites and outdoor storage areas.

- 7. Semi-Gantry 10 Ton Cranes: These cranes operate with one end on an overhead runway and the other on legs. They're effective when combining elevated runway travel with floor-level mobility is required.

- 8. Truss Gantry 10 Ton Cranes: Known for their truss-style structure, these cranes offer extended lifting heights and spans. They thrive in outdoor environments like construction sites and shipping yards.

- 9. Monorail 10 Ton Cranes: Operating on a single rail, these cranes provide linear lifting and transport along a fixed path. They're invaluable for targeted material handling.

- 10. Free-Standing 10 Ton Workstation Cranes: Designed for localized lifting solutions, these cranes serve workstations and specific areas. They can be freestanding or ceiling-mounted, adapting to unique requirements.

When considering the purchase of a 10 ton overhead crane in Sudan, it's vital to evaluate your lifting demands, available space, operational setting, and budget. Choosing the right type of crane ensures optimal efficiency and performance in your material handling operations.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch