Motorized Electric Hoist for Indonesia, Wire Rope Hoist 3 Ton10 M

ton electric hoist for sale in Indonesia. Custom electric wire rope hoist, SEW motorized electric hoist European style, variable speed control. Check !

Category: Indonesia

Your Trusted Overhead Hoist Manufacturer & Supplier

Motorized Electric Hoist for Indonesia, Wire Rope Hoist 3 Ton10 M

SEW Motorized Electric Hoist European Style, Variable Speed Control

3 ton electric hoist for sale in Indonesia. Custom electric wire rope hoist, SEW motorized electric hoist European style, variable speed control. Check !

SEW Motorized Electric Hoist for Sale Indonesia, Wire Rope Electric Hoists 3 Ton -10 M

The subject of this case presentation is the installation and utilization of the SEW motorized 3T-10M European style hoist in Indonesia. SEW is a renowned manufacturer of industrial drive technology, known for its reliability and efficiency. This specific hoist model, designated as 3T-10M, is designed to handle loads up to 3 tons and lift them to a maximum height of 10 meters. It operates on a power supply of 380V with a frequency of 50Hz and three phases.

In industrial and construction settings, hoists play a crucial role in lifting and moving heavy loads efficiently and safely. The SEW motorized hoist is a popular choice due to its robust construction, precise control, and adherence to safety standards. In Indonesia, where infrastructure development and industrial activities are burgeoning, the need for reliable lifting equipment is paramount.

Specifications of 3 Ton Electric Hoists for Slae Indonesia

The SEW motorized 3T-10M hoist boasts several key specifications:

- Load Capacity: 3 tons

- Maximum Height: 10 meters

- Power Supply: 380V, 50Hz, 3 phases

- European-style design for ergonomic operation

- SEW motor for reliable performance

- Built-in safety features including overload protection and emergency stop

Advantages of European Style Hoists:

European style hoists offer numerous benefits that make them highly effective for various lifting applications. Their compact and sturdy design, precise control capabilities, and advanced safety features ensure both operational efficiency and workplace safety.

Compact Design and Robust Construction:

- European style hoists are engineered with a focus on space efficiency, which is particularly beneficial in environments with limited space. Their compact design allows for easy integration into various workspaces, including tight and confined areas.

- The robust construction of these hoists ensures durability and longevity, reducing the need for frequent maintenance and replacements. They are built using high-quality materials and advanced manufacturing techniques, which contribute to their reliability and performance under heavy-duty conditions.

Precise Control:

- European style hoists are equipped with advanced control systems that provide precise and smooth lifting and lowering operations. This precision is crucial for applications requiring delicate handling of loads, such as in manufacturing processes where components must be positioned accurately.

- The control mechanisms often include variable speed options, allowing operators to adjust the lifting speed according to the specific requirements of the task. This flexibility enhances operational efficiency and minimizes the risk of damage to the load or surrounding equipment.

Advanced Safety Features:

- Safety is a paramount consideration in the design of European style hoists. These hoists typically come with a range of advanced safety features that protect both the operator and the equipment.

- Overload Protection: This feature prevents the hoist from lifting loads beyond its maximum capacity, thereby avoiding potential equipment failure and accidents. Overload sensors detect excessive weight and automatically halt the lifting operation.

- Emergency Braking Systems: In the event of a power failure or other emergency situations, the braking system engages automatically to secure the load in its current position, preventing sudden drops and ensuring the safety of personnel and materials.

- Additional Safety Mechanisms: European style hoists may also include features such as anti-slip clutch systems, limit switches to prevent over-travel, and thermal protection to avoid overheating of the motor. These mechanisms collectively contribute to a safer working environment.

Overall, European style hoists combine efficiency, reliability, and safety, making them an excellent choice for various industrial and commercial lifting applications.

Outdoor overhead hoist, 3 ton 10 m lifting height

3 ton wire rope electric hoist with European style

Electric hoist electrical cabinet 3 ton

Motorized electric hoist 3 ton for sale Indonesia

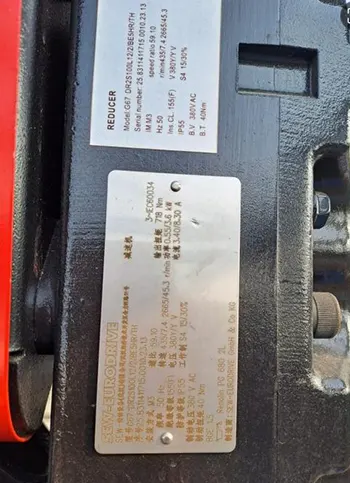

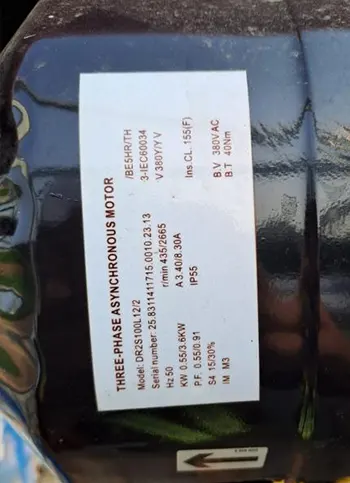

SEW Electric Hoist Moter Nameplate

Electric Hoist Motor

Configuration and SEW Motors:

European style hoists often incorporate SEW motors, which are renowned for their high performance and dependability. The integration of SEW motors into these hoists, along with their robust configuration, enhances the overall efficiency and durability of the lifting equipment.

High-Performance SEW Motor:

- The SEW motorized hoist features a SEW motor that is known for its exceptional reliability and efficiency. SEW motors are designed to deliver high torque and power while maintaining energy efficiency, making them ideal for demanding lifting operations.

- These motors are engineered to provide consistent performance even under continuous use. Their design includes advanced cooling systems and high-quality materials that prevent overheating and ensure longevity, reducing the risk of downtime and maintenance costs.

Durability for Heavy-Duty Applications:

- SEW motors are specifically designed to handle heavy-duty applications, making them suitable for industrial environments where the hoist must perform under rigorous conditions. These motors can withstand high loads and frequent use without compromising on performance.

- The robust construction of SEW motors includes features such as reinforced housings and durable components that enhance their ability to operate in harsh environments. This makes them a reliable choice for industries such as manufacturing, construction, and logistics.

Smooth and Reliable Operation:

- The configuration of the hoist includes durable steel components and precision-engineered mechanisms that ensure smooth and reliable operation. The use of high-grade steel in the construction of the hoist components contributes to its strength and durability, allowing it to handle heavy loads with ease.

- Precision engineering ensures that all moving parts of the hoist work seamlessly together. This includes the hoist's gears, bearings, and other mechanical components that are designed to minimize friction and wear, resulting in efficient and quiet operation.

- The precise alignment of these components also enhances the accuracy of lifting and positioning operations, which is critical for tasks requiring exact load placement.

In summary, the configuration of European style hoists, combined with the high-performance SEW motors, ensures a reliable, efficient, and durable lifting solution. The robust design and precise engineering of these hoists make them suitable for a wide range of industrial applications, providing consistent performance and enhanced operational efficiency.

Features of Motorized Electric Hoist for Outdoor Use Over Water Pond:

- Corrosion-Resistant Materials:1)Stainless Steel Construction. Components made from stainless steel or other corrosion-resistant materials to withstand exposure to moisture and prevent rust.2) Weatherproof Coatings. Protective coatings and finishes to shield the hoist from rain, humidity, and other environmental factors.

- Waterproof and Dustproof Enclosures: 1) IP Rating. High Ingress Protection (IP) rating, such as IP65 or higher, to protect against dust and water ingress. 2) Sealed Motor and Electrical Components. Ensuring that motors and control systems are adequately sealed to prevent water from entering and causing damage.

- Anti-Sway Technology: - Stability Controls. Systems to minimize load sway and ensure stable lifting and lowering operations over the water, which is critical for precise load handling and safety.

- Enhanced Safety Features: 1)Emergency Stop Mechanism. Easily accessible emergency stop buttons to quickly halt operations in case of an emergency.2)Overload Protection. Sensors and mechanisms to prevent the hoist from lifting loads beyond its rated capacity.3)Automatic Braking System. Reliable braking systems to hold the load securely in place, even if power is lost.

- Remote Control Operation:1) Wireless Remote Controls. Allows operators to control the hoist from a safe distance, reducing the risk of accidents and enhancing convenience.2) Waterproof Remote Controls.Ensuring the remote controls are also waterproof for use in outdoor environments.

- Galvanized or Synthetic Rope: - Rust-Resistant Ropes: Using galvanized steel ropes or synthetic materials that are resistant to corrosion and suited for outdoor use.

- High Durability and Load Capacity:1)Heavy-Duty Construction. Designed to handle heavy loads and frequent use without degrading performance.2) Load Indicators. Systems to monitor the weight of the load being lifted and ensure it is within safe limits.

- Adjustable Speed Control: Allowing operators to adjust the lifting and lowering speeds for precise handling of loads, particularly useful in delicate operations over water.

- Power Supply Considerations: - Outdoor-Rated Power Supply. Ensuring the power supply and cables are suitable for outdoor use and protected against the elements.2) Backup Power Options. Provision for backup power systems to maintain operations during power outages.

- Lighting and Visibility: LED lights to illuminate the working area, enhancing visibility and safety during operations in low-light conditions.

- Environmental Adaptability: Temperature and Weather Resistance. Designed to operate efficiently across a range of temperatures and weather conditions, including rain, snow, and extreme heat or cold.

- Regular Maintenance Features: - Easy Access for Maintenance. Design that allows easy access to components for regular inspections and maintenance, ensuring long-term reliability.

By incorporating these features, a motorized electric hoist can safely and effectively handle lifting tasks over a water pond in an outdoor setting, providing durability, safety, and reliable performance.

Hoisting and Traveling Testing:

Before being installed in the field, SEW motorized hoists are subjected to comprehensive testing to ensure they meet strict performance and safety standards. These tests are critical to verify that the hoist operates reliably and efficiently in real-world applications.

Rigorous Hoisting and Traveling Testing:

- The SEW motorized hoist undergoes a series of rigorous tests to validate its performance and ensure safety. These tests are designed to identify any potential issues and confirm that the hoist can handle the demands of its intended applications.

Hoisting Tests:

- Load Capacity Evaluation: During hoisting tests, the hoist is tested with loads of varying weights and dimensions. This ensures that the hoist can lift loads within its rated capacity without any issues. The tests confirm that the hoist can safely handle maximum loads and function correctly under different loading conditions.

- Performance Verification: The hoisting tests also evaluate the speed and smoothness of lifting operations. This involves checking the hoist's ability to lift and lower loads accurately and efficiently, without excessive vibration or noise. The performance of the braking system is also tested to ensure it can securely hold the load in place.

Traveling Tests:

- Horizontal Movement: The traveling tests assess the hoist's ability to move loads horizontally along a track or beam. This includes evaluating the stability and control of the hoist during horizontal movement, ensuring it can transport loads smoothly and accurately to different positions.

- Vertical Movement: In addition to horizontal testing, the hoist's vertical movement is tested to verify its stability and control while lifting and lowering loads. This ensures that the hoist can operate safely and reliably during vertical transportation tasks.

- Stability and Control: Both horizontal and vertical traveling tests focus on verifying the stability of the hoist during movement. This involves checking for any unwanted swaying or oscillations that could affect load handling. Control systems are also tested to ensure precise positioning and smooth transitions between movements.

These comprehensive testing procedures ensure that the SEW motorized hoist meets high standards of performance and safety. By rigorously evaluating both hoisting and traveling capabilities, manufacturers can provide a reliable and efficient hoisting solution that performs well under various operating conditions.

Utilization and Performance:

Since installation, the 3 ton electric hoist has been utilized extensively in various industrial applications across Indonesia. Its precise control and robust construction have facilitated smooth lifting operations, contributing to increased productivity and safety in the workplace. The 3 ton electric hoist has demonstrated its effectiveness and reliability in a wide range of industrial applications across Indonesia. Its extensive use and consistent performance have highlighted several key benefits that contribute to improved workplace productivity and safety.

Extensive Utilization in Industrial Applications:

- Diverse Industries: The hoist has been employed in various sectors, including manufacturing, construction, logistics, mining, and marine industries. Its versatility allows it to handle different types of materials and loads, from heavy machinery parts to construction materials and shipping containers.

- High Frequency of Use: Due to its robust construction and reliable performance, the hoist is used frequently in day-to-day operations. Its durability ensures that it can withstand continuous use in demanding environments without significant wear and tear.

Precise Control for Smooth Lifting Operations:

- Accurate Load Handling: The hoist's advanced control systems enable precise lifting and lowering of loads. This is particularly important in tasks that require careful positioning and handling of delicate or bulky items. Operators can control the hoist with high accuracy, reducing the risk of load damage or accidents.

- Variable Speed Control: The ability to adjust the lifting speed enhances operational flexibility. Operators can choose the appropriate speed for different tasks, ensuring efficient handling of loads while maintaining safety standards.

Robust Construction for Reliability and Durability:

- Heavy-Duty Design: The hoist is constructed with high-quality materials and components designed to handle heavy loads up to 3 tons. This includes reinforced steel structures, durable motor components, and high-strength cables or chains.

- Environmental Resistance: The hoist is built to operate in various environmental conditions, including high humidity, extreme temperatures, and exposure to dust and debris. This makes it suitable for both indoor and outdoor applications.

Contribution to Increased Productivity:

- Efficiency in Operations: The reliable performance and precise control of the hoist have significantly reduced the time required for lifting and moving materials. This efficiency translates to higher productivity as tasks are completed more quickly and with less downtime.

- Reduced Manual Labor: By automating lifting operations, the hoist reduces the need for manual handling of heavy loads. This not only speeds up processes but also minimizes the physical strain on workers, contributing to a safer and more comfortable working environment.

Enhanced Workplace Safety:

- Safety Features: The hoist is equipped with numerous safety features, such as overload protection, emergency stop mechanisms, and automatic braking systems. These features ensure safe operation, protecting both the operators and the equipment.

- Training and Ease of Use: Operators are trained to use the hoist efficiently and safely. The intuitive controls and safety mechanisms make it easier for workers to handle the hoist, reducing the likelihood of accidents and improving overall safety standards.

In summary, the 3 ton electric hoist's utilization across various industrial applications in Indonesia highlights its capability to enhance productivity and safety. Its precise control, robust construction, and reliable performance make it an indispensable tool in modern industrial operations.

Maintenance and Support:

Regular maintenance schedules have been established to ensure the continued performance and longevity of the hoist.Ensuring the continued performance and longevity of the 3 ton electric hoist involves a well-structured maintenance program and comprehensive support services. These measures are crucial in maximizing the efficiency and reliability of the equipment.

Regular Maintenance Schedules:

- Preventive Maintenance: Regular preventive maintenance schedules are established to keep the hoist in optimal working condition. This includes routine inspections, lubrication of moving parts, checking the integrity of electrical connections, and ensuring that safety features are functioning correctly.

- Scheduled Inspections: Periodic inspections are conducted to detect and address wear and tear early. This helps prevent potential breakdowns and ensures that any issues are rectified before they can affect the hoist's performance.

- Detailed Checklists: Maintenance activities are guided by detailed checklists covering all critical components of the hoist. This systematic approach ensures that nothing is overlooked and that the hoist operates safely and efficiently.

Comprehensive Support Services:

- Spare Parts Availability: A readily available inventory of spare parts ensures that any worn-out or damaged components can be quickly replaced, minimizing downtime. The availability of genuine spare parts also guarantees compatibility and maintains the integrity of the hoist.

- Technical Assistance: Providing technical support is essential for troubleshooting and resolving any operational issues. Expert technicians are available to offer guidance and support, either remotely or on-site, ensuring that any problems are swiftly addressed.

- Training Programs: Ongoing training programs for operators and maintenance personnel help them understand the hoist's operation and maintenance requirements. This ensures that the equipment is used correctly and maintained properly, further enhancing its longevity and performance.

Enhancing Reliability:

- Documentation and Records: Maintaining detailed records of all maintenance activities and any issues encountered helps track the hoist's performance over time. This information is valuable for identifying patterns and making informed decisions about future maintenance and upgrades.

- Software and Diagnostics: Advanced diagnostic tools and software may be used to monitor the hoist's performance in real-time. These tools can alert operators and maintenance staff to any irregularities, allowing for proactive maintenance.

- Warranty and Service Agreements: Offering extended warranties and service agreements provides additional peace of mind to users. These agreements often include regular maintenance visits, priority technical support, and cost-effective spare parts replacement.

By implementing regular maintenance schedules and providing comprehensive support services, the reliability and efficiency of the 3 ton electric hoist are significantly enhanced. This proactive approach ensures that the hoist continues to operate smoothly, reducing the risk of unexpected failures and extending its operational lifespan.

Conclusion:

The SEW motorized 3T-10M European style hoist has proven to be a valuable asset in the industrial landscape of Indonesia. Its combination of robust construction, precise control, and adherence to safety standards makes it an ideal choice for lifting heavy loads in various settings. Through proper installation, utilization, and maintenance, this hoist continues to contribute to the efficiency and safety of lifting operations in Indonesia.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch