1/2 Ton Wall Mounted Cantilever Jib Crane, Economical Small Jib Crane

1/2-ton wall-mounted cantilever jib crane for sale, economical small crane, efficient lifting & space-saving in compact areas, 1/2 ton jib crane for sale.

Category: Jib Crane Capacity & Tonnages

Your Trusted Wall Mounted Jib Crane Manufacturer & Supplier

1/2 Ton Wall mounted cantilever jib crane, Economical Small Jib Crane

1/2-ton wall-mounted cantilever jib crane for sale, economical small crane, efficient lifting & space-saving in compact areas, 1/2 ton jib crane for sale.

Overview of Wall-Mounted Cantilever Jib Cranes

Wall-mounted cantilever jib cranes are versatile lifting solutions designed to maximize workspace efficiency. Unlike traditional free-standing cranes, these models are attached directly to a wall, which helps conserve floor space while providing substantial lifting capabilities. Their primary use is to handle and position loads in tight or confined areas where floor-mounted cranes would be impractical. These cranes are especially useful in small workshops, maintenance areas, and retail environments where space is at a premium.

The wall-mounted design offers several benefits. It allows for a more compact setup, freeing up valuable floor space for other operations or storage. This configuration also simplifies the installation process, as the crane mounts directly to a wall or structural support, avoiding the need for additional supports or bases. Additionally, this design helps in optimizing the use of available vertical space, making it ideal for environments with height restrictions.

1/2 Ton Wall Mounted Jib Crane for sale

The 1/2 ton wall-mounted cantilever jib crane is a small but efficient model tailored for light to medium-duty tasks. With a lifting capacity of 1/2 ton, it is well-suited for handling smaller loads, making it an excellent choice for operations where the volume of material to be lifted is relatively low but requires precise and frequent handling.

This model is considered economical for several reasons. Firstly, its lower capacity means a reduced initial investment compared to larger cranes, making it a cost-effective choice for businesses with modest lifting needs. Additionally, its compact design minimizes the need for extensive installation and maintenance, which further lowers overall costs. The 1/2 ton capacity strikes a balance between affordability and functionality, providing sufficient lifting power for small-scale operations without compromising on space efficiency or performance.

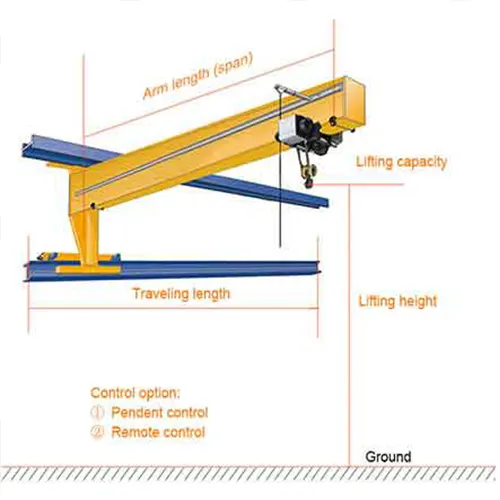

Main Specifications of 1/2 Ton Wall Mounted Cantilever Crane:

- Capacity: 0.5 tons (500 kg)

- Valid Radius: 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 meters per minute (with options of 0.8 or 8 m/min)

- Trolley Speed: 10 meters per minute (with options of 20 m/min)

- Slewing Speed: 0.5 to 1 revolutions per minute (r/min)

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4 (corresponding to moderate to heavy usage)

These specifications highlight the crane's flexibility in operation, with adjustable parameters for lifting height, radius, and speed, making it suitable for various industrial applications

Main Parts and Components of 1/2 Ton Wall-Mounted Jib Cranes

- Wall-Mounting Bracket: The wall-mounting bracket is a crucial component that attaches the jib crane to the wall or support structure. It provides the structural support needed to bear the crane's load. This bracket must be securely anchored and aligned to ensure stability and safety during operation. It typically includes mounting plates, bolts, and anchors designed to accommodate the specific load capacity of the crane.

- Jib Arm: The jib arm is the horizontal extension that reaches out from the wall-mounting bracket. It is designed to support and maneuver the load within the crane's operational range. The arm can be fixed or adjustable, allowing for variations in length to suit different workspace needs. Its design ensures a balance between strength and flexibility, enabling precise load positioning.

- Hoist: The hoist is the lifting mechanism mounted on the jib arm. It is responsible for raising and lowering the load. The 1/2 ton model typically features a manual or electric hoist, depending on the application and user preference. The hoist includes a drum or chain for lifting and lowering, and it is crucial for handling the load safely and efficiently.

- Rotation Mechanism: The rotation mechanism allows the jib arm to swivel or rotate around the mounting bracket. This component enables the crane to cover a wider area and maneuver loads more effectively. It typically includes a rotation bearing or gear system that facilitates smooth and controlled movement of the jib arm.

- Control System: The control system manages the operation of the hoist and rotation mechanism. It may include manual controls, such as levers or hand wheels, or an electric control panel with buttons or a joystick. The control system allows the operator to manage the crane's movements precisely, ensuring accurate load placement and handling.

Safety Features:

Safety features are integral to the crane's design, ensuring safe operation. These may include:

- Limit Switches: Prevent over-travel of the hoist and rotation mechanism.

- Load Limit Indicators: Warn operators when approaching the maximum load capacity.

- Emergency Stop Button: Allows for immediate cessation of operations in case of an emergency.

Support Bearings: Support bearings are used to facilitate smooth rotation and movement of the jib arm. These bearings reduce friction and wear, ensuring the crane operates efficiently and with minimal resistance. They play a key role in the longevity and reliability of the crane.

Structural Frame: The structural frame includes the main components of the crane, such as the jib arm, mounting bracket, and supporting elements. This frame is designed to withstand the forces exerted during operation and maintain the crane's integrity. It is typically made of high-strength steel or other durable materials to ensure durability and stability.

Key Features of the 1/2 Ton Wall-Mounted Cantilever Jib Crane

Space Efficiency

The 1/2 ton wall-mounted cantilever jib crane is designed to maximize space efficiency, making it an ideal solution for environments with limited floor area. By mounting directly to a wall, the crane eliminates the need for a large, freestanding base, freeing up valuable workspace. This compact design is especially beneficial for small or confined areas where floor space is at a premium, allowing for more efficient use of the available area and improving overall operational flow.

Construction and Materials

This crane features a construction designed for both durability and reliability. Made from high-strength steel or other robust materials, the crane is engineered to withstand the stresses of lifting operations while maintaining structural integrity. Despite its sturdy build, the crane remains lightweight, which facilitates easier installation and reduces the load on the supporting wall. This combination of durability and lightness ensures that the crane performs reliably over time, even in demanding conditions.

Ease of Installation

The installation process for the 1/2 ton wall-mounted cantilever jib crane is straightforward and efficient. The crane's design allows for easy attachment to existing walls or support structures, minimizing the need for extensive modifications or additional support frameworks. This ease of installation not only simplifies setup but also reduces downtime, enabling quick deployment and immediate use. Its compatibility with various structural types ensures that it can be integrated into different work environments with minimal hassle.

Versatile Load Handling

The crane's versatility in load handling makes it suitable for a range of applications. Capable of managing small to medium loads, it provides flexibility for various tasks, from moving components in a workshop to handling inventory in a retail setting. The crane's design allows for precise load positioning and maneuverability, accommodating different operational needs and enhancing overall productivity. This adaptability makes it a valuable asset in diverse settings, where efficient and effective load handling is crucial.

Applications of the 1/2 Ton Wall-Mounted Cantilever Jib Crane

Small Workshops and Facilities

In small workshops and facilities, the 1/2 ton wall-mounted cantilever jib crane excels by making optimal use of limited space. Its compact design allows it to be mounted on a wall, freeing up floor area for other activities. Typical tasks in these settings include lifting and positioning small machinery parts, tools, or materials used in various fabrication processes. The crane is ideal for workshops that require frequent repositioning of components or small-scale lifting operations without sacrificing valuable floor space.

Retail and Light Manufacturing

In retail environments and light manufacturing setups, this crane is valuable for handling small parts and inventory efficiently. It can be used to move items from storage to display areas or from assembly lines to packing stations. Its ability to handle smaller loads and precise positioning helps streamline operations, enhance workflow, and reduce manual handling. For example, it can assist in managing stock in retail warehouses or facilitate the assembly and distribution of products in a light manufacturing facility.

Maintenance and Repair Operations

The 1/2 ton wall-mounted cantilever jib crane is highly effective in maintenance and repair scenarios. It can be used to lift and position heavy equipment, tools, or components that require servicing or repair. In maintenance shops, it helps in the easy handling of parts that need to be replaced or repaired, such as motors or machinery components. For instance, it can be used to lift a motor from a machine for repairs or to reposition tools and parts within a maintenance area, thus improving efficiency and accessibility in repair tasks.

Advantages of the 1/2 Ton Model

Cost-Effectiveness

The 1/2 ton wall-mounted cantilever jib crane offers significant cost advantages. Its lower initial investment makes it an economical choice for businesses with modest lifting needs. Additionally, this model benefits from reduced operating and maintenance costs. Its simple design requires less upkeep compared to larger, more complex cranes, and its energy-efficient operation contributes to ongoing savings. This affordability makes it accessible for smaller operations or those looking to optimize their budget.

Space-Saving Design

One of the standout features of the 1/2 ton model is its space-saving design. By mounting directly on the wall, it maximizes the available floor space, which is especially valuable in areas with limited room or height restrictions. This efficient use of workspace allows businesses to maintain a clutter-free environment and utilize the floor area for other purposes, enhancing overall operational flow and flexibility in confined spaces.

Operational Efficiency

The crane's design enhances productivity by facilitating smooth and efficient operations in tight areas. Its compact size and straightforward functionality make it easy to operate and integrate into various workflows. The 1/2 ton crane simplifies load handling, reducing the time and effort required for manual lifting tasks. Its ease of maintenance further contributes to operational efficiency, as minimal downtime is needed for upkeep, allowing for continuous, effective use in demanding environments.

Why Wall Mounted Cantilever Jib Crane is Economical ?

The wall-mounted cantilever jib crane is considered economical for several reasons:

- Lower Initial Cost: The design and construction of a wall-mounted cantilever jib crane are less complex compared to freestanding cranes. This results in a lower initial purchase price, making it a cost-effective solution for businesses with modest lifting needs.

- Reduced Installation Expenses: Installation of a wall-mounted jib crane is generally simpler and less costly than installing larger, freestanding cranes. It requires fewer structural modifications and less groundwork, which contributes to lower installation expenses.

- Minimal Maintenance Costs: The crane's straightforward design means fewer moving parts and less wear and tear, leading to reduced maintenance costs. Regular upkeep is more manageable and less frequent, which helps lower the overall cost of ownership.

- Space Efficiency: By mounting on the wall, the crane saves valuable floor space. This efficient use of space can reduce the need for additional equipment or larger facilities, leading to cost savings in terms of both real estate and operational space requirements.

- Energy Efficiency: The 1/2 ton model is designed for lighter loads and lower energy consumption. Its efficient operation minimizes energy costs compared to larger, more energy-intensive cranes.

- Increased Productivity: The crane enhances productivity by simplifying load handling and reducing manual lifting efforts. Increased efficiency translates to cost savings through improved workflow and reduced labor costs.

Overall, the combination of lower initial costs, reduced installation and maintenance expenses, and operational efficiency makes the wall-mounted cantilever jib crane an economical choice for many businesses.

Safety Considerations

Pre-Operation Checks

Before operating the wall-mounted cantilever jib crane, it's crucial to conduct thorough pre-operation checks. This includes inspecting all crane components, such as the arm, pivot points, and mounting brackets, for signs of wear, damage, or corrosion. Ensure that the crane is securely mounted to the wall and that all fasteners are properly tightened. Regular inspections help identify potential issues before they become safety hazards, ensuring that the crane operates safely and effectively.

Operator Training

Proper operator training is essential for maintaining safety during crane operations. Operators should receive specialized training that covers the safe use of the crane, including understanding load capacities, operating procedures, and emergency protocols. Training programs should be comprehensive and include practical exercises to ensure that operators are familiar with the crane's controls and safety features. Certification and ongoing education help keep operators updated on best practices and safety standards.

Load Handling Protocols

Safe load handling is critical to prevent accidents and equipment damage. Ensure that all loads are properly secured before lifting, using appropriate slings or attachments as needed. Avoid exceeding the crane's load capacity, and be aware of the load's center of gravity to prevent tipping or instability. Follow established procedures for moving and positioning loads, and always communicate with ground personnel to coordinate movements. Adhering to these protocols helps maintain a safe working environment and prevents potential hazards.

Case Study: Enhancing Material Handling with a 1/2 Ton Wall-Mounted Cantilever Crane in Cyprus

Project Summary

To boost material handling efficiency and make the best use of available space, a prominent industrial facility in Cyprus implemented a BX Wall-Mounted Cantilever Crane. The goal of this project was to overcome the limitations imposed by restricted overhead space while ensuring strong lifting performance.

Crane Specifications

- Model: BX Wall-Mounted Cantilever Crane

- Capacity: 1/2 ton (500 kg)

- Crane Arm Length: 4 meters

- Lifting Height: 4 meters

- Hoist Type: Chain hoist

- Mounting: Wall-mounted

- Power Supply: 240V, 50Hz, 3-phase

Project Objectives

The key aims of the installation were:

- Enhance Material Handling Efficiency: The facility sought a solution to facilitate smooth and accurate material movement within the limited space available.

- Optimize Space Utilization: Given the constraints of overhead space, the project focused on maximizing the use of the area without sacrificing operational flexibility.

- Ensure Reliable Support: The crane needed secure wall-mounting to deliver stable and dependable support during its operations.

rotating system of 1/2 ton wall mounted jib crane for sale

mounting system of 1/2 ton wall mounted jib crane for sale

500kg electric hoist trolley of 1/2 ton wall mounted jib crane for sale

500kg electric chain hoist of 1/2 ton wall mounted jib crane for sale

Design and Implementation

The BX Wall-Mounted Cantilever Crane was selected for its cantilever design, well-suited to environments with restricted overhead space. The 4-meter cantilever arm offers flexible and unrestricted movement within the compact facility. The wall-mounted setup ensures that the crane is firmly anchored, optimizing space usage and minimizing the equipment's footprint.

Key Features

- Chain Hoist: Equipped with a chain hoist, the crane offers precise load control, essential for accurate material handling.

- Power Supply: Operating on a 240V, 50Hz, 3-phase electrical supply, the crane meets the standard industrial requirements in the region, ensuring reliability and compatibility.

Installation Process

The installation followed these crucial steps:

- Site Assessment: An in-depth evaluation of the installation site was carried out to confirm that the wall could handle the crane's load demands.

- Mounting: The crane was securely attached to the wall, adhering to all structural and safety standards.

- Calibration and Testing: The crane underwent calibration and testing to ensure it met performance specifications and functioned smoothly.

Results and Benefits

The BX Wall-Mounted Cantilever Crane delivered several advantages to the facility:

- Increased Efficiency: The crane's precise load control and flexible operation enhanced material handling, reducing downtime and boosting productivity.

- Space Optimization: By utilizing the wall-mounted design, the facility effectively maximized its workspace and improved its overall layout.

- Reliable Performance: The crane's sturdy support system and dependable operation provided a consistent solution for the facility's material handling needs.

The successful deployment of the 1/2 ton BX Wall-Mounted Cantilever Crane has proven to be a significant asset for the Cypriot facility. By addressing the challenges associated with limited overhead space and improving material handling capabilities, the crane has contributed to greater operational efficiency and optimized space utilization within the facility.

Customized Wall Mounted Cantilever Jib Cranes

When customizing wall-mounted cantilever jib cranes, several key parameters must be considered to ensure the crane meets the specific requirements of the application. These parameters include:

- Crane Type: wall mounted jib crane

- Crane capacity:_______?

- Crane lifting height:_______?

- Crane span:_______?

- Crane control:_______?

- Crane power supply_______?

- Load Capacity: Determine the maximum load the crane will need to lift. This includes not only the weight of the typical loads but also any potential peak loads. The crane's load capacity should be sufficient to handle the heaviest load expected during its operation.

- Arm Length: The length of the jib arm affects the crane's reach and operational range. Customization of the arm length should be based on the distance the crane needs to cover and the space available. Longer arms provide greater reach but may require additional support and structural reinforcement.

- Height and Reach: Specify the required height of the crane's mounting point and its reach. This includes the vertical clearance needed for lifting operations and the horizontal distance the crane needs to cover. Proper measurement ensures that the crane fits well within the working space and performs efficiently.

- Mounting and Structural Requirements: Define the type and strength of the wall or support structure where the crane will be mounted. The mounting system must be compatible with the wall's load-bearing capacity and the crane's design. Structural reinforcements may be needed for safe installation.

- Rotation Range: Consider the rotation range of the crane's arm. Most wall-mounted cantilever jib cranes offer a rotation range typically up to 180 degrees, but this can be customized based on the operational needs. Ensure that the rotation capability meets the requirements for maneuvering and positioning loads.

- Operation Type: Decide on the type of operation: manual or motorized. Motorized cranes offer ease of operation and are suitable for high-frequency tasks, while manual cranes provide precision and are often used in less frequent applications. Customization will depend on the operational environment and user preferences.

- Safety Features: Incorporate necessary safety features, such as load limiters, anti-sway mechanisms, and emergency stop buttons. These features help prevent accidents and ensure safe operation of the crane in various working conditions.

- Environmental Conditions: Specify any environmental factors that may affect the crane's operation, such as exposure to moisture, chemicals, or extreme temperatures. Customized cranes may require special coatings or materials to withstand harsh conditions and ensure longevity.

- Controls and Accessories: Determine the type of controls needed (manual or electronic) and any additional accessories such as lights, alarms, or communication systems. These components should be tailored to enhance the crane's functionality and ease of use.

- Compliance and Standards: Ensure that the customized crane meets relevant industry standards and regulations. Compliance with safety and operational standards is crucial for legal and safety reasons, and it may affect the design and features of the crane.

By addressing these parameters, you can ensure that the customized wall-mounted cantilever jib crane will meet your specific needs and operate safely and efficiently in its intended environment.

Here is a short list of the main parameters for customizing wall-mounted cantilever jib cranes:

- Load Capacity: Maximum weight the crane needs to lift.

- Arm Length: Length of the jib arm for reach and operational range.

- Height and Reach: Required vertical clearance and horizontal reach.

- Mounting and Structural Requirements: Wall strength and mounting system compatibility.

- Rotation Range: Degree of rotation for the crane's arm.

- Operation Type: Manual or motorized operation.

- Environmental Conditions: Exposure to moisture, chemicals, or extreme temperatures.

- Controls and Accessories: Type of controls and additional accessories.

Conclusion

The 1/2 ton wall-mounted cantilever jib crane offers numerous benefits, including cost-effectiveness, space-saving design, and operational efficiency. Its compact size and robust construction make it ideal for small workshops, retail environments, and maintenance tasks. By optimizing limited floor space and simplifying load handling, this crane enhances productivity and streamlines operations in confined areas.

For businesses with modest lifting needs and limited space, the 1/2 ton wall-mounted cantilever jib crane is a practical and economical choice. Its affordability, combined with its efficient use of space and ease of operation, makes it an excellent investment for small-scale operations seeking to improve workflow and reduce labor costs.

Types of Small Jib Cranes for Sale

When considering small jib cranes, several types are available to suit various needs and environments. Here's an overview of the common types:

Wall-Mounted Jib Cranes 1/2 Ton

Description: These cranes are fixed to a wall or vertical structure, making them ideal for small spaces with limited floor area. They provide efficient lifting and handling capabilities while saving valuable floor space.

Applications: Best suited for small workshops, maintenance areas, and light manufacturing environments where space is at a premium.

Key Features:

- Compact and space-saving design

- Simple installation

- Fixed mounting with rotation range typically up to 180 degrees

Floor-Mounted Jib Cranes 1/2 Ton

Description: Mounted directly on the floor, these cranes offer flexibility and stability for small-scale lifting operations. They are often used in areas where a wall-mounted crane is not feasible.

Applications: Ideal for small production lines, repair shops, and warehouses where mobility and ease of use are important.

Key Features:

- Stable base with full 360-degree rotation

- Can be positioned anywhere on the floor

- Suitable for various load sizes and weights

Description: These cranes are designed for mobility and can be moved to different locations as needed. They are typically lightweight and equipped with wheels or casters for easy relocation.

Applications: Perfect for workshops, construction sites, and maintenance tasks where flexibility and mobility are required.

Key Features:

- Easy to move and reposition

- Often features adjustable heights and arm lengths

- Suitable for light to medium loads

Articulating Jib Crane 1/2 Ton

Description: Articulating jib cranes feature an arm with multiple segments that can bend or pivot. This design allows for greater reach and flexibility in confined spaces.

Applications: Useful in areas with obstacles or limited access, such as small workshops or assembly areas with complex layouts.

Key Features:

- Multi-segment arm for extended reach

- High flexibility in positioning and load handling

- Ideal for navigating around obstacles

Cantilever Jib Crane 1/2 Ton

Description: Cantilever jib cranes have a single arm extending from a central support, allowing for efficient handling of loads without interference from supports or other structures.

Applications: Well-suited for outdoor environments, small warehouses, and areas requiring unobstructed access.

Key Features:

- Overhead clearance with minimal interference

- Ideal for reaching loads in confined spaces

- Simple design with effective load handling capabilities

Each type of small jib crane is designed to address specific needs and constraints, making it essential to choose the right type based on your operational requirements and environment.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch