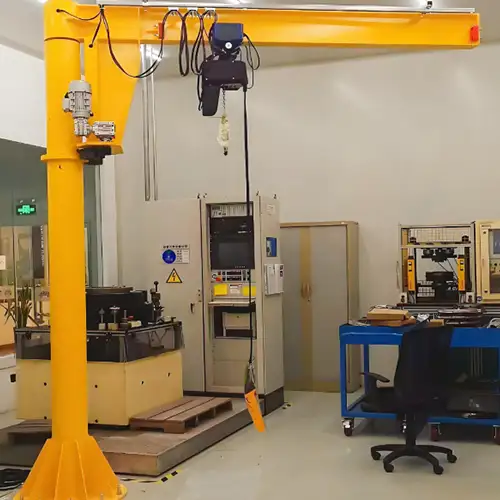

Industrial Marine Jib Crane for Sale 3 Ton, 5 Ton, 10 Ton, 16 Ton

Marine Jib Crane 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 16 ton, anti-corrosion crane design, customized for marine industrial use, indoor & outdoor jib crane.

| Industrial Jib Crane | Anti-corrosion-jib crane for outdoor use |

| Capacity of crane | 1 ton to 16 ton |

| Lifting Height | As your request |

| Crane Span | As your request |

Category: Jib Crane

Your Trusted Rotating Jib Crane Manufacturer & Supplier

Marine Jib Cranes for Sale 3 Ton, 5 Ton, 10 Ton, 16 Ton

Industrial Jib Crane for Marine Industrial Use with Anti-Corrosion Design

Marine Jib Cranes

Marine jib cranes are specialized lifting solutions designed for the demanding conditions of maritime environments. These pillar jib cranes are engineered to handle various lifting tasks, from loading and unloading cargo at ports to servicing vessels and offshore platforms. Unlike standard jib cranes, marine jib cranes are built to withstand the harsh elements found at sea, including high humidity, saltwater exposure, and extreme weather conditions. Their robust construction and precision engineering ensure reliable performance, making them indispensable in maritime operations.Marine Jib Crane for sale, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 16 ton jib crane , with anti-corrosion crane design, customized for marine industrial use, your customized indoor & outdoor jib crane.

Importance of Anti-Corrosion Design in Marine Environments

In marine settings, corrosion is a constant threat that can compromise the structural integrity and longevity of equipment. Marine jib cranes are exposed to saltwater, salty air, and constant moisture, all of which accelerate the corrosion process. An anti-corrosion design is crucial for these cranes to maintain their durability and functionality over time. This design typically involves the use of high-quality materials, such as galvanized steel or stainless steel, along with specialized coatings like epoxy or polyurethane. These measures not only protect the crane from rust and corrosion but also reduce maintenance costs and extend the equipment's lifespan, ensuring safe and efficient operations in marine environments.

Range of Capacities Available

Marine jib cranes come in a variety of capacities to meet different operational needs. The 3-ton capacity crane is ideal for lighter tasks, such as handling small cargo or equipment on docks or vessels. The 5-ton crane offers greater lifting power, suitable for mid-sized loads and more demanding applications. The 10-ton crane provides a versatile solution for heavy-duty lifting tasks, making it a popular choice for shipyards and large ports. For the most demanding operations, the 16-ton marine jib crane delivers exceptional strength and reliability, capable of lifting and maneuvering large and heavy loads with ease. Each capacity level is designed to offer optimal performance in its specific application, ensuring that users have the right tool for the job, regardless of the scale of the task.

Marine Jib Crane Capacities, Hot Sale 3 Ton, 5 Ton, 10 Ton, 16 Ton

Technical Parameter of Anti Corrosion Pillar Slewing Jib Crane | |||||

| Capacity | t | 0.5 | 1 | 2 | 3 |

| Valid radius | R(m) | 3~12 | 3~12 | 3~12 | 3~12 |

| Lifting height | m | 3~8 | 3~8 | 3~8 | 3~8 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) |

| Trolley speed | m/min | 10(20) | 10(20) | 10(20) | 10(20) |

| Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 |

| Slewing angle | 0°~360° | 0°~360° | 0°~360° | 0°~360° | |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Capacity | t | 5 | 10 | 16 | 20 |

| Valid radius | R(m) | 3~12 | 3~15 | 3~15 | 3~15 |

| Lifting height | m | 3~8 | 3~8 | 3~8 | 3~8 |

| Lifting speed | m/min | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) |

| Trolley speed | m/min | 10(20) | 10(20) | 18 | 14 |

| Slewing speed | r/min | 0.5~1 | 0.5~1 | 0.4~0.7 | 0.4~0.7 |

| Slewing angle | 0°~360° | 0°~360° | 0°~360° | 0°~360° | |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

3 Ton Marine Jib Crane

Applications and Typical Uses: The 3-ton marine jib crane is ideal for smaller-scale maritime tasks, such as handling equipment and supplies on docks, ships, and small vessels. It is commonly used in maintenance operations, where it lifts tools, parts, and other light materials. The compact size and ease of installation make it perfect for tight spaces like ship decks or dockside facilities, where maneuverability is essential.

5 Ton Marine Jib Crane

Applications and Typical Uses: The 5-ton marine jib crane is a versatile option for mid-sized lifting tasks. It is commonly used in shipyards for handling heavier equipment, such as winches, anchors, and larger supplies. This crane is also well-suited for loading and unloading cargo at smaller ports or for use on larger vessels where stronger lifting capacity is required without taking up excessive space.

10 Ton Marine Jib Crane

Applications and Typical Uses: The 10-ton marine jib crane is designed for heavy-duty lifting tasks in larger maritime operations. It is frequently used in shipyards, ports, and offshore platforms for handling large components like engines, heavy machinery, and substantial cargo loads. Its robust construction and high lifting capacity make it a reliable choice for demanding applications that require strength and precision.

16 Ton Marine Jib Crane

Applications and Typical Uses: The 16-ton marine jib crane is the powerhouse of marine lifting solutions, used in the most challenging environments such as large shipyards, industrial ports, and offshore oil rigs. It is capable of handling extremely heavy and bulky loads, such as large shipping containers, offshore drilling equipment, and other industrial-grade materials. This crane is essential for operations that require maximum lifting capacity and durability.

Custom Industrial Jib Cranes

Customization Options

- Capacity Customization: Custom industrial jib cranes can be tailored to meet specific capacity requirements beyond standard offerings. Whether you need a crane with a capacity of 3 tons, 5 tons, 10 tons, 16 tons, or something in between, customization allows for precise engineering to match your operational needs. This flexibility ensures that the crane is perfectly suited to handle the specific weights and types of loads encountered in your industry, optimizing efficiency and safety.

- Design and Structural Modifications: Customization goes beyond just capacity; it extends to the overall design and structure of the crane. This can include adjustments to the boom length, height, and rotation range to accommodate unique spatial constraints or operational demands. Structural modifications might also involve reinforcing the crane's framework for added durability or adapting the base or mounting system to fit specific installation environments, such as confined spaces or challenging terrains.

- Special Features for Specific Applications: Custom industrial jib cranes can be equipped with special features designed for unique applications. For instance, a crane used in a corrosive environment might be fitted with advanced anti-corrosion coatings or constructed from specialized materials like stainless steel or aluminum. Other custom features could include explosion-proof components for use in hazardous areas, automated control systems for remote operation, or integrated sensors for load monitoring and safety management. These tailored solutions enhance the crane's functionality and ensure it meets the exact demands of your industry.

Benefits of Customization in Industrial Settings

Customizing an industrial jib crane offers significant benefits, particularly in specialized or demanding environments. By tailoring the crane to your specific requirements, you can achieve greater operational efficiency, as the equipment is optimized for the tasks it will perform. Customization also enhances safety by ensuring that the crane's design is perfectly aligned with the type of loads and operational conditions it will encounter, reducing the risk of accidents or equipment failure. Additionally, a custom crane can be designed to integrate seamlessly with existing systems and workflows, minimizing downtime and maximizing productivity. The long-term benefits include reduced maintenance costs and extended equipment lifespan, as the crane is built to withstand the exact conditions of your operational environment.

Importance of Anti-Corrosion Design in Marine and Industrial Environments

In marine and industrial environments, equipment faces relentless exposure to moisture, saltwater, and harsh chemicals, making corrosion a significant challenge. Corrosion not only compromises the structural integrity of cranes but also introduces a cascade of issues that can severely impact operations. The presence of corrosion can lead to weakened crane components, increased risk of failure, costly repairs, and extended downtime. Moreover, safety hazards become a pressing concern as corroded structures may not withstand the loads they were designed to handle.

Long-Term Durability and Reliability

An anti-corrosion design is essential for ensuring the long-term durability and reliability of jib cranes operating in these demanding environments. Cranes equipped with robust anti-corrosion features are protected from the onset of rust and deterioration, thereby maintaining their structural integrity over time. This protection is particularly vital in marine settings where the saline environment accelerates the corrosion process, making cranes more vulnerable to damage.

By incorporating anti-corrosion materials and coatings, such as galvanized steel, stainless steel, and epoxy coatings, manufacturers can significantly extend the lifespan of the equipment. These materials act as a barrier, shielding the crane's critical components from corrosive elements. This longevity not only reduces the frequency of replacements and repairs but also enhances the overall safety and reliability of operations, as the crane remains in optimal working condition for a longer period.

Cost Savings and Maintenance

Another crucial aspect of anti-corrosion design is the reduction in maintenance costs. Regular maintenance is necessary to keep cranes in working order, but in corrosive environments, the need for maintenance increases exponentially if proper anti-corrosion measures are not in place. Cranes without these protections may require frequent inspections, part replacements, and even complete overhauls, all of which contribute to higher operational costs.

With a well-implemented anti-corrosion design, the need for such intensive maintenance is minimized. The protective coatings and materials resist the harsh conditions, meaning less frequent maintenance is required to keep the crane operational. This not only translates to direct cost savings but also minimizes downtime, allowing for more consistent and uninterrupted use of the crane.

Essential in Marine Environments

Marine environments pose a unique challenge due to the presence of salt in the air and water. Salt accelerates the oxidation process, leading to faster corrosion of metal components. In such environments, the importance of anti-corrosion design cannot be overstated. Without it, cranes would quickly succumb to the corrosive effects of the environment, leading to frequent breakdowns and potential safety risks.

For industrial jib cranes used in shipyards, ports, offshore platforms, and other marine-related facilities, robust anti-corrosion measures are not just a feature—they are a necessity. These measures ensure that the cranes can perform their heavy-duty tasks reliably, even in the face of the harshest environmental conditions. Whether lifting large ship components, handling cargo, or assisting in construction, cranes with anti-corrosion designs are equipped to deliver consistent performance, ensuring that operations run smoothly and safely.

In summary, the anti-corrosion design is a critical element in the construction of marine and industrial jib cranes. It ensures that the cranes remain durable, reliable, and cost-effective throughout their operational life, even when exposed to the most challenging environments. Investing in such cranes not only protects the equipment but also secures the safety and efficiency of the entire operation.

Materials and Coatings Used in Anti-Corrosion Design

In the construction of marine and industrial jib cranes, the choice of materials and coatings is critical to ensuring long-term resistance to corrosion. These measures not only protect the crane's structural integrity but also reduce maintenance needs and enhance overall operational safety. Below are the key materials and coatings used in anti-corrosion design, each playing a vital role in safeguarding cranes from the harsh effects of their environments.

Galvanization

Galvanization is one of the most widely employed methods in the anti-corrosion design of cranes, especially those used in marine and industrial applications. The process involves coating steel components with a layer of zinc, which serves as a protective barrier against moisture, salt, and other corrosive elements commonly found in marine environments.

Mechanism of Protection:

- Barrier Protection: The zinc coating physically isolates the underlying steel from exposure to the environment, preventing moisture and corrosive substances from reaching the metal surface.

- Sacrificial Protection: Even if the zinc layer is scratched or damaged, the zinc will corrode preferentially over the steel. This sacrificial corrosion protects the steel from rusting, thereby maintaining the crane's structural integrity. The zinc continues to provide protection until it is entirely consumed, which significantly delays the onset of rust on the steel.

Applications: Galvanized cranes are particularly well-suited for outdoor applications where they are continually exposed to the elements. This includes shipyards, ports, and offshore platforms, where the cranes face constant contact with seawater, salt spray, and high humidity levels. In these settings, galvanization ensures that the cranes remain durable and reliable, even in the face of continuous environmental stress.

Benefits:

- Long-Lasting Protection: Galvanization extends the lifespan of the crane by providing long-lasting protection against corrosion, even in highly corrosive environments.

- Cost-Effective: The process is cost-effective, offering substantial protection without the need for frequent reapplication or maintenance.

- Maintenance Reduction: The sacrificial nature of the zinc coating reduces the need for regular maintenance, as the underlying steel remains unaffected even if the zinc layer is compromised.

Epoxy Coatings

Epoxy coatings offer another layer of defense in anti-corrosion design, known for their strong adhesive properties and resistance to a wide range of corrosive agents. These coatings are particularly effective in environments where chemical exposure, moisture, and salt are persistent threats.

Mechanism of Protection:

- Chemical Resistance: Epoxy coatings are highly resistant to chemicals, making them ideal for protecting cranes in industrial settings where exposure to harsh chemicals is common.

- Impermeable Barrier: When applied, epoxy forms a thick, hard layer that adheres firmly to the metal surface, creating an impermeable barrier that prevents water, salt, and other corrosive substances from reaching the underlying material.

- Layering: Typically, epoxy coatings are applied in multiple layers, with each layer enhancing the overall thickness and durability of the protection. This multi-layer approach ensures comprehensive coverage, leaving no part of the crane exposed to potential corrosive damage.

Applications: Epoxy coatings are particularly beneficial in highly corrosive environments, such as offshore oil rigs, ports, and industrial chemical plants. These settings often involve constant exposure to a combination of saltwater, chemicals, and other corrosive substances, necessitating robust protective measures. Epoxy coatings are often used in tandem with galvanization, creating a dual-layer defense that maximizes corrosion resistance.

Benefits:

- Enhanced Durability: Epoxy coatings significantly enhance the durability of cranes, particularly in environments where chemical exposure is a concern.

- Strong Adhesion: The strong adhesion of epoxy ensures that the coating remains intact, even under harsh conditions, thereby maintaining continuous protection.

- Versatile Application: Epoxy coatings can be tailored to different thicknesses and application methods, depending on the specific needs of the crane and its operational environment.

Combined Use of Galvanization and Epoxy Coatings

In particularly harsh environments, where corrosion risks are exceptionally high, a combination of galvanization and epoxy coatings may be used to provide an even more robust anti-corrosion system. The zinc layer from galvanization offers initial sacrificial protection, while the epoxy coating adds an additional impermeable barrier that resists chemical corrosion and physical wear.

This dual protection approach is especially valuable in marine and industrial settings where cranes are subjected to continuous and aggressive corrosive forces. By combining these two protective methods, manufacturers can ensure that their cranes remain operational, safe, and cost-effective over the long term, even in the most challenging conditions.

The materials and coatings used in the anti-corrosion design of marine and industrial jib cranes are vital to their performance and longevity. Galvanization and epoxy coatings are proven methods that, either individually or in combination, provide exceptional protection against the corrosive effects of moisture, salt, and chemicals. By carefully selecting and applying these materials, manufacturers can extend the service life of their cranes, reduce maintenance costs, and ensure that they continue to perform safely and reliably in even the most demanding environments.

Stainless Steel Components: Stainless steel is inherently resistant to corrosion due to its chromium content, which forms a passive layer of chromium oxide on the surface when exposed to oxygen. This layer protects the steel from further corrosion and self-heals if damaged. Stainless steel components are frequently used in the construction of marine jib cranes, particularly in areas that are most exposed to corrosive elements, such as the boom, base, and fasteners. The use of stainless steel ensures that the crane remains strong and reliable even in the most challenging environments, reducing the need for frequent maintenance.

Maintenance and Longevity of Anti-Corrosion Designs

While anti-corrosion materials and coatings significantly enhance the durability of marine and industrial jib cranes, regular maintenance is still essential to maximize the lifespan of the equipment. Maintenance practices include routine inspections to identify any signs of wear or damage to the coatings or materials, cleaning to remove salt deposits and other corrosive substances, and periodic reapplication of protective coatings where necessary. Proper maintenance ensures that the anti-corrosion measures remain effective, preventing minor issues from developing into major problems.

By investing in high-quality materials, such as galvanized steel, epoxy coatings, and stainless steel components, and adhering to a rigorous maintenance schedule, operators can ensure that their jib cranes continue to perform reliably over many years. The combination of these anti-corrosion strategies results in equipment that not only withstands the harsh conditions of marine and industrial environments but also provides a long-term return on investment by reducing downtime, repair costs, and the need for premature replacements.

Technical Specifications and Features

Boom Length and Rotation

Marine jib cranes are designed with varying boom lengths to accommodate different lifting needs and spatial constraints. The boom length can range from 3 meters to 15 meters or more, depending on the crane's capacity and intended application. A longer boom provides extended reach, making it ideal for tasks that require moving loads over larger distances or across obstacles.

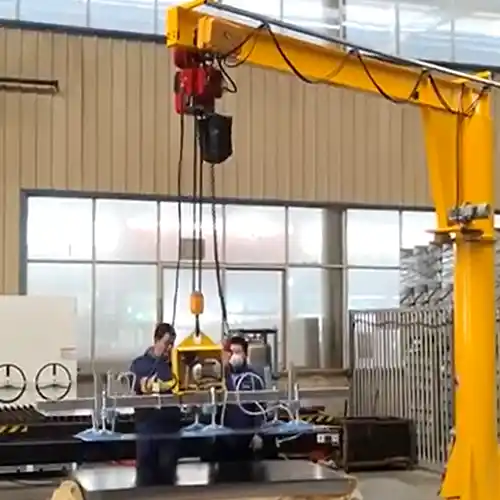

Rotation is another critical feature of jib cranes, allowing the boom to swivel horizontally. Most marine jib cranes offer full 360-degree rotation, which can be either manual or motorized. Manual rotation is typically used in lighter-duty applications, where precise positioning can be achieved through operator control. Motorized rotation is preferred for heavier loads and more demanding environments, providing smoother and more controlled movement, especially when handling large or awkwardly shaped objects.

Mounting Options (Base Mounted, Wall Mounted)

Marine jib cranes can be mounted in different ways depending on the operational environment and specific requirements:

- Base Mounted: This is the most common type of mounting, where the crane is secured to a solid foundation, such as a concrete floor or deck. Base-mounted cranes are highly stable and capable of handling heavier loads, making them ideal for shipyards, ports, and other industrial sites where large lifting tasks are common.

- Wall Mounted: Wall-mounted jib cranes are attached to a vertical structure, such as a building or a ship's bulkhead. This configuration saves floor space and is suitable for areas with limited room. Wall-mounted cranes are typically used for lighter loads or in situations where the crane needs to serve a fixed area, such as along a production line or within a confined space.

Power and Control Systems

- Manual vs. Motorized Operation: Marine jib cranes can be operated manually or with motorized systems. Manual operation is typically found in smaller, lighter-duty cranes, where loads are easily manageable without mechanical assistance. This option is cost-effective and straightforward, making it suitable for less demanding tasks.

- Motorized operation, on the other hand, is essential for larger cranes handling heavier loads. Motorized systems provide the power needed to lift and move substantial weights with ease and precision. They also reduce the physical strain on operators and increase the efficiency of the lifting process, particularly in high-demand environments.

- Remote Control Options: Modern marine jib cranes often come with remote control options, allowing operators to control the crane from a distance. This enhances safety by keeping operators clear of the load path and provides greater flexibility in positioning the crane. Remote controls can be wireless, offering the freedom to move around the worksite, or wired, providing a secure and interference-free connection. Advanced remote systems may include features such as variable speed control, precise positioning, and load monitoring, enabling more efficient and safer operations.

Safety Features

- Overload Protection: Overload protection is a critical safety feature in marine jib cranes, designed to prevent the crane from lifting more than its rated capacity. This system automatically detects when a load exceeds the crane's safe operating limit and either alerts the operator or halts the lifting process. Overload protection helps to prevent accidents, equipment damage, and structural failures, ensuring that the crane operates within its designed parameters.

- Emergency Stop Systems: Emergency stop systems are essential for ensuring immediate cessation of crane operations in case of an emergency. These systems are typically integrated into the control system and can be activated manually by the operator or automatically by the crane's safety monitoring system. An emergency stop brings the crane to a safe halt, protecting both the load and the operator from potential harm.

- Weather Resistance: Given the harsh conditions in which marine jib cranes operate, weather resistance is a vital feature. These cranes are built to withstand exposure to saltwater, high humidity, and extreme temperatures. Weather-resistant designs include sealed electrical components, corrosion-resistant materials, and protective coatings that shield the crane from the elements. This ensures reliable performance and longevity, even in the most challenging maritime environments. Weather resistance also minimizes maintenance needs and extends the crane's operational life, making it a critical aspect of marine crane design.

Applications of Marine Jib Cranes

Maritime Industries

- Shipyards: Marine jib cranes are indispensable in shipyards, where they are used for a wide range of tasks, from assembling and maintaining ships to lifting heavy machinery and components. These cranes provide the precision and strength needed to handle large and irregularly shaped loads, such as ship engines, hull sections, and other critical parts. The ability to operate in tight spaces and rotate 360 degrees makes them particularly useful in shipbuilding and repair operations, where space can be limited, and accurate load positioning is essential.

- Ports and Harbors: In ports and harbors, marine jib cranes play a vital role in the loading and unloading of cargo from ships. They are used to transfer goods from ships to docks or directly to storage facilities. The cranes' anti-corrosion design ensures reliable operation despite constant exposure to saltwater and harsh weather conditions. Their ability to handle various load sizes and weights makes them ideal for efficiently managing the diverse cargo types typically encountered in port operations, from containers to bulk goods.

- Offshore Platforms: Marine jib cranes are essential on offshore platforms, where they are used to lift and move equipment, supplies, and personnel. These cranes are specifically designed to operate in the challenging conditions found at sea, including high winds, saltwater exposure, and limited space. On oil rigs and other offshore installations, jib cranes handle everything from maintenance tools and spare parts to larger equipment like drilling components and pipelines. Their durability and corrosion resistance are crucial for ensuring continuous operation in these remote and often harsh environments.

Industrial Uses

- Warehousing: In industrial warehouses, marine jib cranes are employed to lift and move heavy materials and products. They are particularly useful in situations where floor space is limited, and precise load positioning is required. Whether mounted on a wall or a base, these cranes streamline material handling processes, reducing the time and labor needed to move goods. Their flexibility and strength make them ideal for handling a variety of items, from pallets and large containers to machinery parts.

- Manufacturing Plants: Manufacturing plants benefit from marine jib cranes by using them to handle components and products during assembly or production processes. These cranes are often customized to fit the specific needs of the manufacturing environment, whether that involves lifting heavy machinery parts, moving materials between workstations, or loading finished products for shipment. The cranes' ability to operate in confined spaces and their robust construction ensure that they can handle the demanding tasks typically found in manufacturing settings, including those with corrosive environments or stringent safety requirements.

- Construction Sites: On construction sites, marine jib cranes provide the lifting power needed to move heavy materials and equipment. Their versatility allows them to be used in various stages of construction, from laying foundations to assembling large structural components. The cranes' anti-corrosion features are particularly valuable in outdoor construction environments, where they must withstand exposure to the elements. Whether used for lifting steel beams, concrete blocks, or large equipment, marine jib cranes enhance efficiency and safety on construction sites by providing reliable and precise lifting capabilities.

Benefits of Choosing Our Marine Jib Cranes

- Reliability and Durability: When you choose our marine jib cranes, you invest in equipment that delivers exceptional reliability and durability, even in the most demanding environments. Built with high-quality materials like galvanized steel, epoxy-coated components, and marine-grade stainless steel, our cranes are engineered to withstand the harsh conditions of marine and industrial settings. The anti-corrosion design ensures that the crane maintains its structural integrity over time, reducing the need for frequent repairs and replacements. This durability translates to fewer operational interruptions, lower maintenance costs, and a longer lifespan for your equipment, providing you with a dependable solution for all your lifting needs.

- Enhanced Safety Features: Safety is paramount in any lifting operation, and our marine jib cranes are equipped with advanced safety features to protect both your personnel and your assets. Key safety systems include overload protection, which prevents the crane from lifting loads beyond its rated capacity, and emergency stop systems that allow for immediate cessation of operations in critical situations. Additionally, our cranes are designed with weather-resistant features that ensure safe operation even in adverse conditions, such as high winds, heavy rain, or saltwater exposure. These safety measures not only prevent accidents but also enhance the overall efficiency and reliability of your lifting operations.

- Customization Flexibility: We understand that every operation has unique requirements, which is why we offer extensive customization options for our marine jib cranes. Whether you need a crane with a specific lifting capacity, custom boom length, or specialized mounting configuration, we can tailor our designs to meet your exact specifications. Our cranes can also be equipped with features such as motorized rotation, remote control systems, and specialized coatings for added corrosion resistance or explosion-proof capabilities. This flexibility ensures that you receive a crane that perfectly matches your operational needs, maximizing productivity and efficiency.

- Competitive Pricing and Warranty: We are committed to providing high-quality marine jib cranes at competitive prices, ensuring that you receive excellent value for your investment. Our pricing structure is designed to be transparent and fair, with no hidden costs, making it easier for you to budget and plan your purchase. Additionally, all our marine jib cranes come with a comprehensive warranty that covers materials, workmanship, and key components. This warranty gives you peace of mind, knowing that your equipment is protected against defects and that you can rely on our support should any issues arise. Our combination of competitive pricing and strong warranty coverage makes our marine jib cranes an economically sound choice for your lifting needs.

Customized Jib Crane for Sale

In choosing our marine jib cranes, you are investing in equipment that offers unmatched reliability, durability, and safety in even the most challenging environments. With advanced anti-corrosion designs, customizable features, and robust safety systems, our cranes are engineered to meet the specific needs of maritime and industrial operations. Whether you require a standard capacity or a fully customized solution, our marine jib cranes provide the flexibility and performance necessary to enhance your operational efficiency. Coupled with competitive pricing and a comprehensive warranty, our cranes represent a wise investment that delivers long-term value and peace of mind.

Ready to elevate your operations with a marine jib crane tailored to your exact needs? Contact us today to discuss your requirements, explore customization options, or get answers to any questions you may have. Our team of experts is here to help you find the perfect solution for your lifting challenges.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch