Aluminum Gantry Cranes Types, Specifications & Uses 1T, 2T, 3T,5T

Aluminum gantry cranes 1 ton, 2 ton, 3 ton, 5 ton for sale. 6 Types of aluminum gantry cranes, ie. adjustable height /span, foldable, telescopic design,etc.

Category: Light Crane & Portable Crane

Your Trusted Aluminum Gantry Crane Manufacturer & Supplier

Aluminum Gantry Cranes Types, Specifications & Uses

1 Ton, 2 Ton, 3 Ton, 5 ton Aluminum Gantry Cranes with Different Types of Aluminum Gantry Designs for Wide Industrial Uses

Aluminum gantry cranes 1 ton, 2 ton, 3 ton, 5 ton for sale. Types of aluminum gantry cranes, ie. adjustable height /span, foldable, telescopic design,etc.Aluminum gantry cranes, often referred to as aluminum A frame lifting gantries, are versatile and lightweight lifting solutions that find applications in a wide range of industries. In this comprehensive guide, we'll explore everything you need to know about aluminum gantry cranes, from their construction to their various applications and where to find them for sale.

Aluminum Gantry Cranes

What is an Aluminum Gantry Crane? Aluminum gantry cranes are a type of lifting equipment designed for a wide array of tasks. They are characterized by their lightweight yet robust construction, typically featuring an A frame structure made of aluminum. The basic components of an aluminum gantry crane include:

- Gantry Frame: The frame forms the primary structure of the crane and is usually in the shape of an A frame. It provides stability and support for the load.

- Gantry Beam: This horizontal beam connects the legs of the A frame and serves as the bridge along which the hoisting equipment moves.

- Hoists and Trolleys: These are used to lift and transport loads. They can be manual or powered, depending on the specific application.

The Advantages of Using Aluminum Gantry Cranes

Aluminum gantry cranes offer several key advantages over cranes made from other materials:

- Lightweight: Aluminum is significantly lighter than steel, making these cranes highly portable and easy to move around, even in tight spaces.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, which is especially beneficial in environments where moisture and chemicals are present.

- Durability: Despite their lightweight nature, aluminum gantry cranes are durable and can withstand heavy loads.

- Customization: They can be easily customized to suit your specific lifting needs, with options for different load capacities and sizes.

- Quick Assembly: These cranes are often designed for quick assembly and disassembly, making them suitable for temporary lifting tasks.

Types of Aluminum Gantry Cranes

Precision parts and welding components shall be installed in alignment . Easy operation, stable performance and long service life .

We only use high-quality aluminum profiles, and the product quality is guaranteed.

All nuts and bolts are made of 8.8 grade high-strength steel, with corrosion resistant paint coating to enhance the service life of the product .

All our gantry cranes use heavy casters, which have a long service life and provide smooth rolling performance. Even on the rough floor, it does not

affect the use .

LT1 Height Fixed Aluminum Gantry Cranes

The aluminum alloy material is valued for its lightweight design and resistance to corrosion, making it a popular choice for various industries. With fixed height and span, it's easy to install and disassemble, offering convenience and efficiency. It's particularly favored in high-end sectors such as electronics and university laboratories, where cleanliness and material quality are crucial.

LT1 Height Fixed Aluminum Gantry Cranes up to 5 Ton

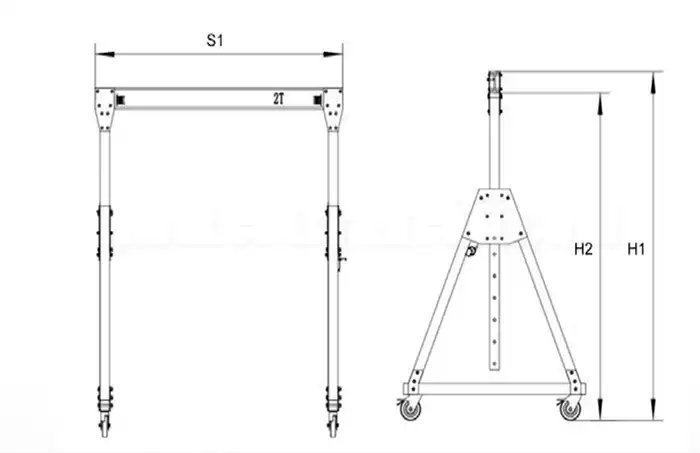

LT1 Height Fixed Aluminum Gantry Cranes Drawing

LT 1 Aluminum Gantry Crane Specification

Aluminum Gantry Cranes | S1 ( Span) | H1(mm) 3000 | H1(mm) 4000 | H1(mm) 5000 | H1(mm) 6000 |

Lifting Capacity | (mm) | H2(mm) | H2(mm) | H2(mm) | H2(mm)- |

1 ton | 2000-3000 | 2848 | 3848 | 4848 |

|

1 ton | 3000-4000 | 5848 | |||

1 ton | 4000-5000 | 2748 | 3748 | 4748 | 5748 |

2 ton | 2000-3000 | 2807 | 3807 | 4807 |

|

2 ton | 3000-4000 | ||||

2 ton | 4000-5000 | 2707 | 3707 | 4707 | 5707 |

3 ton | 2000-3000 | 2807 | 3807 | 4807 | - |

3 ton | 3000-4000 | 2707 | 3707 | 4707 | 5707 |

3 ton | 4000-5000 | 2657 | 3657 | 4657 | 5657 |

5 ton | 2000-3000 | 2707 | 3707 | 4707 | - |

5 ton | 3000-4000 | 2557 | 3557 | 4557 | 5557 |

5 ton | 4000-5000 | 2614 | 3614 | 4614 | 5614 |

LT2 Height Adjustable Aluminum Gantry Cranes

The aluminum alloy material stands out for its lightweight, corrosion-resistant properties, and sleek appearance. Its convenient installation, disassembly, and transportability make it a practical choice for various applications. With adjustable height settings using gears, it offers flexibility tailored to specific needs. Particularly well-suited for high-end industries like electronics and laboratories, it meets stringent requirements for quality and performance.

LT2 Height Adjustable Aluminum Gantry Cranes

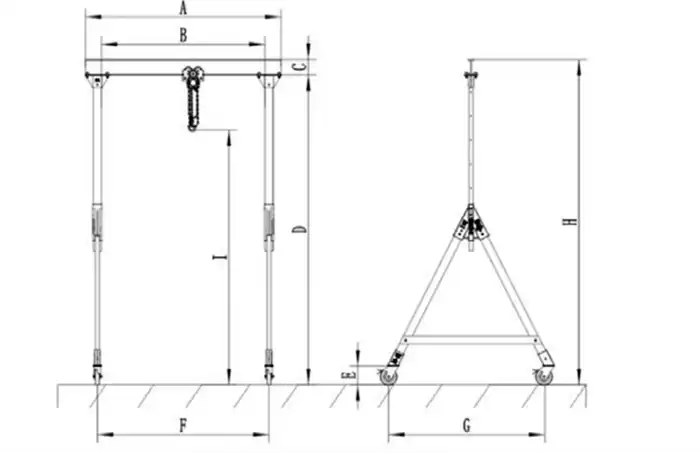

LT2 Height Adjustable Aluminum Gantry Crane Drawing for Your Reference

LT 2 Aluminum Gantry Crane Specification

Aluminum Gantry Cranes | S1 ( Span) | H1(mm)2000-3000 (adjustable) | H1(mm)2600-4000 (adjustable) | H1(mm)4000-6000 (adjustable) |

Lifting | (mm) | H2(mm) | H2(mm) | H2(mm) |

1 ton | 2000-3000 | 1848-2848 | 2448-3848 |

|

1 ton | 3000-4000 | 3848-5748 | ||

2 ton | 2000-3000 | 1807-2807 | 2407-3807 | - |

2 ton | 3000-4000 | 3807-5807 | ||

3 ton | 2000-3000 | 1807-2807 | 2407-3807 | 3807-5807 |

3 ton | 3000-4000 | 1657-2657 | 2257-3657 | 3657-5657 |

5 ton | 2000-3000 | 1707-2707 | 2307-3707 | - |

5 ton | 3000-4000 | 1657-2657 | 2257-3657 | 3657-5657 |

LT3 Dual Stage Height Adjustment Aluminum Gantry Crane:

Made from aluminum alloy, the aluminum crane boasts lightweight construction and exceptional corrosion resistance. Its innovative dual height adjustment design allows for customizable settings, with both the column and legs being adjustable to suit various needs.

Primarily utilized in demanding sectors like electronics, aerospace, and university laboratories, where stringent material requirements are essential, the aluminum crane offers reliability and precision in handling tasks.

LT3 Dual Stage Height Adjustment Aluminum Gantry Crane

LT3 Dual Stage Height Adjustment Aluminum Gantry Crane Drawing for Your reference

LT 3 Aluminum Gantry Crane Specification

Aluminum Gantry Cranes | S1 ( Span) | H1(mm)2000-3000 (adjustable) | H1(mm)2600-4000 (adjustable) |

Lifting | (mm) | H2(mm) | H2(mm) |

1 ton | 2000-3000 | 1848-2848 | 2448-3848 |

1ton | 3000-4000 | ||

2 ton | 2000-3000 | 1807-2807 | 2407-3807 |

2 ton | 3000-4000 | ||

3 ton | 2000-3000 | 1807-2807 | 2407-3807 |

3 ton | 3000-4000 | 1657-2657 | 2257-3657 |

5 ton | 2000-3000 | 1707-2707 | 2307-3707 |

5 ton | 3000-4000 | 1657-2657 | 2257-3657 |

LT4 Simple Aluminum Portable Gantry Crane:

Made from aluminum alloy, the aluminum crane combines lightweight construction with excellent corrosion resistance, ensuring durability and longevity. Its straightforward installation and disassembly process make it a practical choice for various applications.

Equipped with electric or manual walking universal castors featuring braking devices, the aluminum crane offers enhanced mobility and safety during operation. It finds primary utility in high-end industries like electronics and video production, where stringent material requirements are paramount.

LT4 Simple Aluminum Portable Gantry Crane 2 Ton

LT4 Simple Aluminum Portable Gantry Crane Drawing for Your Reference

LT 4 Simple Aluminum Gantry Crane Specification

Parameter (mm) | A | B | C | D | E | F | G | H | I |

0.5 ton | 2000 | 1600 | 152 | 1848-2848 | 170 | 1700 | 1432 | 2000-3000 | 1588-2588 |

0.5 ton | 3000 | 2600 | 152 | 1848-2848 | 170 | 2700 | 1432 | 2000-3000 | 1588-2588 |

0.5 ton | 3000 | 2600 | 152 | 2348-3848 | 170 | 2700 | 1940 | 2500-4000 | 2088-3588 |

0.5 ton | 4000 | 3600 | 152 | 1848-2848 | 170 | 3700 | 1432 | 2000-3000 | 1588-2588 |

0.5 ton | 4000 | 3600 | 152 | 2348-3848 | 170 | 3700 | 1940 | 2500-4000 | 2088-3588 |

1 ton | 2000 | 1600 | 152 | 1848-2848 | 170 | 1700 | 1432 | 2000-3000 | 1588-2588 |

1 ton | 3000 | 2600 | 152 | 1848-2848 | 170 | 2700 | 1432 | 2000-3000 | 1588-2588 |

1 ton | 3000 | 2600 | 152 | 2348-3848 | 170 | 2700 | 1940 | 2500-4000 | 2088-3588 |

1 ton | 4000 | 3600 | 152 | 1848-2848 | 170 | 3700 | 1432 | 2000-3000 | 1588-2588 |

1 ton | 4000 | 3600 | 152 | 2348-3848 | 170 | 3700 | 1940 | 2500-4000 | 2088-3588 |

2 ton | 2000 | 1600 | 193 | 1807-2807 | 180 | 1700 | 1360 | 2000-3000 | 1457-2457 |

2 ton | 3000 | 2600 | 193 | 1807-2807 | 180 | 2700 | 1360 | 2000-3000 | 1457-2457 |

2 ton | 3000 | 2600 | 193 | 2307-3807 | 180 | 2700 | 1859 | 2500-4000 | 1957-3457 |

2 ton | 4000 | 3600 | 193 | 1807-2807 | 180 | 3700 | 1360 | 2000-3000 | 1457-2457 |

2 ton | 4000 | 3600 | 193 | 2307-3807 | 180 | 3700 | 1859 | 2500-4000 | 1957-3457 |

LT5 Foldable Aluminum Gantry Crane:

Made from aluminum alloy, this aluminum crane combines lightweight construction with corrosion resistance, ensuring durability and ease of use. Its foldable design enables convenient storage in a handbag, facilitating effortless transportation.

Featuring adjustable height and span, along with both electric and manual walking capabilities, this crane offers versatility to suit various needs. Equipped with high-strength nylon wheels, it ensures swift and stable movement.

Ideal for industries with stringent material requirements, such as clean rooms and laboratories, this crane offers reliability and precision in handling tasks.

LT5 Foldable Aluminum Gantry Crane 2 Ton 3Ton

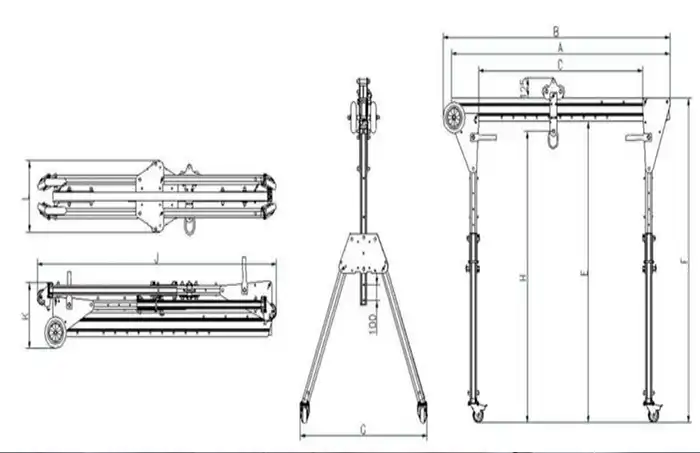

LT5 Foldable Aluminum Gantry Crane 2 Ton 3Ton drawing for your reference

LT 5 Foldable Aluminum Gantry Crane Specification

Lifting | Falling objects | Lifting Workers | Size parameters (mm) | Dead weight | ||||||||||

Weight (KG) | Numbers | A | B | C | E | F | G | H | J | K | L | |||

500 kg | 140 | 250 | 3 | 2000 | 2076 | 1100-1500 | 1914-2114 | 2064-2264 | 1158 | 1850-2050 | 2190 | 415 | 440 | 33 |

400 kg | 200 | 2 | 2300 | 2376 | 1200-1800 | 2376 | 34 | |||||||

250 kg | 125 | 1 | 4000 | 4076 | 2700-3500 | 4076 | 40 | |||||||

400 kg | 200 | 2 | 2000 | 2076 | 1100-1500 | 1818-2218 | 1968-2368 | 1215 | 1755-2155 | 2076 | 34 | |||

400 kg | 200 | 2 | 2300 | 2376 | 1200-1800 | 2376 | 34 | |||||||

250 kg | 125 | 1 | 4000 | 4076 | 2700-3500 | 4076 | 40 | |||||||

250 kg | 125 | 1 | 2000 | 2076 | 1100-1500 | 2092-2992 | 2242-3142 | 1586 | 2028-1928 | 2631 | 38 | |||

250 kg | 125 | 1 | 2300 | 2376 | 1200-1800 | 2631 | 39 | |||||||

250 kg | 125 | 1 | 4000 | 4076 | 2700-3500 | 4076 | 44 | |||||||

1000 kg | 300 | 500 | 3 | 2000 | 2077 | 1102-1507 | 1661-2161 | 1822-2322 | 1270 | 1549-2049 | 2077 | 464 | 536 | 45 |

1000 kg | 500 | 3 | 3000 | 3077 | 1902-2502 | 3077 | 53 | |||||||

500 kg | 500 | 3 | 4000 | 4077 | 1902-3502 | 4077 | 58 | |||||||

1000 kg | 500 | 3 | 2000 | 2077 | 1102-1507 | 1900-2600 | 2061-2761 | 1484 | 1859-2559 | 2200 | 49 | |||

1000 kg | 500 | 3 | 3000 | 3077 | 1902-2502 | 3077 | 54 | |||||||

500 kg | 500 | 3 | 4000 | 4077 | 1902-3502 | 4077 | 59 | |||||||

1000 kg | 500 | 3 | 2000 | 2077 | 1102-1507 | 2140-3040 | 2301-3201 | 1698 | 2099-2999 | 2830 | 53 | |||

1000 kg | 500 | 3 | 3000 | 3077 | 1902-2502 | 3077 | 58 | |||||||

500 kg | 500 | 3 | 4000 | 4077 | 1902-3502 | 4077 | 62 | |||||||

LT6 Telescopic Aluminum Gantry Crane with Adjustable Height and Span

Constructed from aluminum alloy, this portable aluminum gantry crane boasts lightweight construction and exceptional corrosion resistance, ensuring longevity and reliability. Its adjustable span and height offer flexibility to accommodate various tasks and environments.

Featuring a unique bottom beam design that can be turned over, this lightweighted gantry crane ensures stability during operation, with wheels that remain stationary when in use but can be manually pushed when necessary. Weighing only 38kg, it can be swiftly installed and disassembled by a single person in just 3 minutes, and conveniently stored after disassembly.

Ideal for use in food workshops, clean rooms, laboratories, and other high-end industries with stringent material requirements, this crane offers precision and efficiency in handling tasks.

LT6 Telescopic Aluminum Gantry Crane with Adjustable Height and Span 1 Ton 2 Ton

LT6 Telescopic Aluminum Gantry Crane with Adjustable Height and Span Drawing for Your Reference

LT 6 Aluminum Gantry Crane Specification

Lifting | Size parameters (mm) | ||||

A | B | C | D | E | |

250 kg | 1610-2260 | 1350-2000 | 1500-2500 | 1650-2650 | 1200 |

250 kg | 2760-4260 | 2500-4000 | 2500-4000 | 1650-4150 | 1600 |

500 kg | 1630-2280 | 1350-2000 | 1350-2750 | 1500-2900 | 1200 |

500 kg | 2780-4280 | 2500-4000 | 2500-4000 | 2650-4150 | 1600 |

1000 kg | 1630-2280 | 1350-2000 | 1350-2750 | 1500-2900 | 1200 |

1000 kg | 2780-4280 | 2500-4000 | 2500-4000 | 2650-4150 | 1600 |

2000 kg | 1630-2280 | 1350-2000 | 1350-2750 | 1500-2900 | 1200 |

2000 kg | 2780-4280 | 2500-4000 | 2500-4000 | 2650-4150 | 1600 |

Comparison of Each Types of Aluminum Gantry Cranes

When it comes to selecting the right aluminum gantry crane for your specific lifting needs, understanding the various types available on the market is crucial. Each type of aluminum gantry crane offers unique features and benefits tailored to different applications and environments. Here, we'll provide an overview and comparison of some of the main types of aluminum gantry cranes:

Fixed Height vs. Height Adjustable Aluminum Gantry Cranes:

Fixed Height Aluminum Gantry Cranes: These cranes have a predetermined lifting height that cannot be adjusted. They are suitable for applications where the lifting height requirements remain constant and do not vary.

Height Adjustable Aluminum Gantry Cranes: Height adjustable cranes offer the flexibility to customize the lifting height according to specific requirements. This feature allows for accommodating different load sizes or working environments, providing greater versatility.

Fixed Span vs. Adjustable Span Aluminum Gantry Cranes:

Fixed Span Aluminum Gantry Cranes: These cranes have a fixed distance between the legs, which determines the span or width of the lifting area. They are suitable for applications where the lifting requirements remain consistent, and there is no need to adjust the span.

Adjustable Span Aluminum Gantry Cranes: Adjustable span cranes feature telescopic or extendable beams that allow for the adjustment of the span or width of the lifting area. This feature provides flexibility for accommodating various load sizes or working conditions.

Telescoping vs. Foldable Aluminum Gantry Cranes:

Telescoping Aluminum Gantry Cranes: These cranes feature telescopic legs or booms that allow for both height and span adjustment. They offer versatility for various lifting applications by providing customizable height and span options.

Foldable Aluminum Gantry Cranes: Foldable cranes are designed to be collapsible for easy storage and transport. They typically feature hinged joints or collapsible components that allow the crane to be folded into a more compact form when not in use. Foldable cranes are suitable for applications where space is limited or mobility is required for transportation and storage.

Standard vs. Light or Simple Aluminum Gantry Cranes:

Standard Aluminum Gantry Cranes: These cranes are designed for heavier lifting tasks and are built with more robust construction and components. They offer higher load capacities and greater durability, making them suitable for industrial applications where strength and reliability are essential.

Light or Simple Aluminum Gantry Cranes: Light aluminum cranes are more lightweight and compact, designed for lighter lifting tasks or occasional use. They are simpler in design and construction, making them more cost-effective and easier to maneuver. Light aluminum cranes are suitable for smaller workshops, garages, or DIY projects where portability and affordability are key considerations.

Each type of aluminum gantry crane offers unique features and benefits, allowing users to select the most suitable option based on their specific lifting requirements, workspace constraints, and budget considerations.

Portable Aluminum Gantry Cranes vs. Freestanding Aluminum Gantry Cranes:

Portable aluminum gantry cranes are designed for easy transport and setup, making them ideal for applications where mobility and flexibility are paramount. These cranes feature lightweight construction and can be disassembled into manageable components for transportation between work sites. In contrast, freestanding aluminum gantry cranes are permanently installed and offer greater stability and load-bearing capacity. They are suitable for applications where a fixed lifting solution is required, such as in manufacturing facilities or warehouses with dedicated lifting areas.

Portable Aluminum Gantry Cranes and Freestanding Aluminum Gantry Cranes are two main types of aluminum gantry cranes used in various industrial applications. Here's an overview and comparison of these two types:

Portable vs. Freestanding Aluminum Gantry Cranes:

Portable Aluminum Gantry Cranes: These cranes are designed for mobility and flexibility. They are lightweight and often equipped with caster wheels, allowing them to be easily moved around a workspace. Portable gantry cranes are ideal for temporary lifting tasks or environments where mobility is required.

Freestanding Aluminum Gantry Cranes: In contrast, freestanding gantry cranes are more stable and stationary. They do not require anchoring to a structure or floor, offering greater stability for heavier lifting tasks. Freestanding cranes are suitable for permanent or semi-permanent installations where mobility is not a primary concern.

Portable Aluminum Gantry Cranes:

Overview: Portable aluminum gantry cranes are designed for easy transportation and setup, making them ideal for applications where mobility and flexibility are required. They feature lightweight construction and can be disassembled into manageable components for transportation.

Features:

Lightweight: Portable aluminum gantry cranes are typically lighter in weight compared to freestanding gantry cranes, making them easier to move and transport between different work areas.

Quick Setup: These cranes can be quickly assembled and disassembled without the need for special tools, allowing for rapid deployment and flexibility in various work environments.

Adjustable Height: Many portable aluminum gantry cranes feature adjustable height capabilities, allowing users to customize the lifting height based on the specific requirements of their application.

Portability: The portability of these cranes allows them to be easily moved from one location to another, making them suitable for temporary or changing work environments.

Applications: Portable aluminum gantry cranes are commonly used in industries such as construction, maintenance, and event staging, where mobility and flexibility are essential.

Freestanding Aluminum Gantry Cranes:

Overview: Freestanding aluminum gantry cranes are designed to be permanently installed in a specific location, providing stable and reliable lifting capabilities for long-term use. They feature a self-supporting structure and do not require additional support from building structures.

Features:

Stability: Freestanding aluminum gantry cranes offer greater stability and load-bearing capacity compared to portable gantry cranes, making them suitable for heavier lifting tasks and continuous operation.

Fixed Installation: These cranes are installed in a fixed location and are not intended to be moved frequently. They provide a permanent lifting solution for applications where consistent and reliable lifting capabilities are required.

Customization Options: Freestanding aluminum gantry cranes can be customized with various features and accessories to meet specific application requirements, such as different lifting capacities, spans, and heights.

Durability: These cranes are built to withstand long-term use in industrial environments and are constructed from high-quality materials to ensure durability and reliability.

Applications: Freestanding aluminum gantry cranes are commonly used in manufacturing facilities, warehouses, and workshops for tasks such as material handling, assembly, and maintenance.

Comparison:

Mobility: Portable aluminum gantry cranes offer greater mobility and flexibility compared to freestanding gantry cranes, making them suitable for applications where portability is essential.

Load Capacity: Freestanding aluminum gantry cranes typically have higher load-bearing capacities compared to portable gantry cranes, allowing them to handle heavier loads and continuous operation.

Installation: Portable aluminum gantry cranes are quick and easy to set up and can be moved between different work areas, while freestanding gantry cranes require permanent installation and are not intended for frequent relocation.

Cost: Portable aluminum gantry cranes are often more cost-effective than freestanding gantry cranes, making them a preferred choice for applications with budget constraints or temporary needs.

In summary, the choice between portable and freestanding aluminum gantry cranes depends on factors such as mobility requirements, load capacity, installation constraints, and budget considerations. Each type offers distinct advantages and is suited to different industrial applications.

Fixed Height Aluminum Gantry Cranes vs. Height Adjustable Aluminum Gantry Cranes:

Fixed height aluminum gantry cranes have a predetermined height that cannot be adjusted, making them suitable for applications where the lifting height requirements remain consistent. These cranes offer simplicity and reliability, requiring minimal maintenance. On the other hand, height adjustable aluminum gantry cranes feature telescoping legs or adjustable height settings, allowing users to customize the lifting height to accommodate various load sizes or work environments. These cranes offer greater flexibility and versatility, making them ideal for dynamic work environments where lifting requirements may change frequently.

Fixed Height Aluminum Gantry Cranes and Height Adjustable Aluminum Gantry Cranes are two variations of gantry cranes designed to suit different lifting needs and environments. Here's an overview and comparison of these two types:

Fixed Height Aluminum Gantry Cranes:

Overview: Fixed height aluminum gantry cranes have a stationary vertical height, meaning the height of the crane cannot be adjusted. These cranes are typically set at a specific height during assembly and remain at that height throughout their use.

Features:

Simple Design: Fixed height gantry cranes have a straightforward design with no adjustable components, making them easy to assemble, operate, and maintain.

Stability: Since the height of the crane is fixed, it provides consistent stability and load-bearing capacity during lifting operations.

Cost-Effectiveness: Fixed height gantry cranes are often more cost-effective compared to height adjustable cranes due to their simpler design and construction.

Suitable for Specific Applications: These cranes are well-suited for applications where the lifting height requirements are consistent and do not change frequently.

Height Adjustable Aluminum Gantry Cranes:

Overview: Height adjustable aluminum gantry cranes feature telescoping or adjustable legs that allow the crane's height to be easily modified to suit different lifting requirements. This adjustability makes them versatile and adaptable to various work environments.

Features:

Adjustable Height: Height adjustable gantry cranes offer the flexibility to modify the crane's height as needed, allowing users to accommodate different lifting tasks, workspace configurations, and overhead clearance requirements.

Versatility: These cranes can be used in environments where the ground is uneven or where different lifting heights are required for different tasks.

Ease of Adjustment: Height adjustable gantry cranes are designed with mechanisms that make it easy to change the crane's height, such as telescoping legs or adjustable leg extensions.

Increased Flexibility: The ability to adjust the crane's height provides increased flexibility and usability in various industrial applications.

Comparison:

Flexibility: Height adjustable aluminum gantry cranes offer greater flexibility compared to fixed height cranes, as they can be adjusted to suit different lifting heights and environments.

Adaptability: Height adjustable cranes are more adaptable to changing work conditions and lifting requirements, making them suitable for dynamic work environments.

Stability: Fixed height gantry cranes may offer slightly better stability since their height is fixed and cannot be adjusted, whereas adjustable cranes may experience some reduction in stability when the height is modified.

Cost: Height adjustable aluminum gantry cranes are typically more expensive than fixed height cranes due to the added complexity of adjustable components and mechanisms.

In summary, the choice between fixed height and height adjustable aluminum gantry cranes depends on factors such as the specific lifting requirements, workspace configurations, and budget considerations. Fixed height cranes are suitable for applications with consistent lifting height needs, while height adjustable cranes offer greater versatility and adaptability for changing work environments.

Each type of aluminum gantry crane offers specific features and benefits tailored to different load requirements, workspace configurations, and environmental conditions. The choice of the appropriate crane type depends on the specific demands of your application and the level of customization or stability required.

Fixed Span Aluminum Gantry Crane vs Span Ajustable Aluminum Gantry Cranes

Fixed Span Aluminum Gantry Cranes and Span Adjustable Aluminum Gantry Cranes are two variations of gantry cranes designed to accommodate different workspace configurations and lifting requirements. Here's an overview and comparison of these two types:

Fixed Span Aluminum Gantry Cranes:

Overview: Fixed span aluminum gantry cranes have a stationary span width, meaning the distance between the legs remains constant and cannot be adjusted. These cranes are typically set at a specific span width during assembly and remain fixed throughout their use.

Features:

Simple Design: Fixed span gantry cranes have a straightforward design with no adjustable components, making them easy to assemble, operate, and maintain.

Stability: Since the span width of the crane is fixed, it provides consistent stability and load-bearing capacity during lifting operations.

Cost-Effectiveness: Fixed span gantry cranes are often more cost-effective compared to span adjustable cranes due to their simpler design and construction.

Suitable for Specific Applications: These cranes are well-suited for applications where the span width requirements are consistent and do not change frequently.

Span Adjustable Aluminum Gantry Cranes:

Overview: Span adjustable aluminum gantry cranes feature telescoping or adjustable beams that allow the crane's span width to be easily modified to suit different workspace configurations. This adjustability makes them versatile and adaptable to various work environments.

Features:

Adjustable Span Width: Span adjustable gantry cranes offer the flexibility to modify the crane's span width as needed, allowing users to accommodate different workspace layouts, aisle widths, and material handling requirements.

Versatility: These cranes can be used in environments where the available space is limited or where different span widths are required for different tasks.

Ease of Adjustment: Span adjustable gantry cranes are designed with mechanisms that make it easy to change the crane's span width, such as telescoping beams or adjustable beam extensions.

Increased Flexibility: The ability to adjust the crane's span width provides increased flexibility and usability in various industrial applications.

Comparison:

Flexibility: Span adjustable aluminum gantry cranes offer greater flexibility compared to fixed span cranes, as they can be adjusted to suit different workspace configurations and material handling requirements.

Adaptability: Span adjustable cranes are more adaptable to changing work conditions and space constraints, making them suitable for dynamic work environments.

Stability: Fixed span gantry cranes may offer slightly better stability since their span width is fixed and cannot be adjusted, whereas adjustable cranes may experience some reduction in stability when the span width is modified.

Cost: Span adjustable aluminum gantry cranes are typically more expensive than fixed span cranes due to the added complexity of adjustable components and mechanisms.

In summary, the choice between fixed span and span adjustable aluminum gantry cranes depends on factors such as the specific workspace configurations, material handling requirements, and budget considerations. Fixed span cranes are suitable for applications with consistent span width needs, while span adjustable cranes offer greater versatility and adaptability for changing work environments.

Standard Aluminum Gantry Cranes vs Simple Aluinum Gantry Cranes

When it comes to aluminum gantry cranes, there are two main categories: standard and simple. Here's a comparison to help you understand the differences:

Standard Aluminum Gantry Cranes:

These cranes are designed for heavy-duty lifting applications.

They typically have higher load capacities and are built to withstand rigorous use.

Standard gantry cranes often feature additional safety features and customization options.

They are suitable for industrial settings where precise lifting and reliability are paramount.

Simple Aluminum Gantry Cranes:

Simple gantry cranes are more lightweight and streamlined in design.

They are ideal for lighter lifting tasks or occasional use.

These cranes are often more affordable and easier to assemble and disassemble.

Simple gantry cranes are suitable for smaller workshops, DIY projects, or applications with lower lifting requirements.

Ultimately, the choice between standard and simple aluminum gantry cranes depends on your specific lifting needs, budget, and intended use. If you require robust performance and durability for heavy-duty applications, a standard gantry crane may be more suitable. However, if you need a cost-effective solution for lighter lifting tasks, a simple gantry crane could be the better option.

Telescoping Aluminum Gantry Crane with Adjustable Height and Span

Telescoping aluminum gantry cranes combine the benefits of height adjustability and span adjustability, offering users the ability to customize both the lifting height and span of the crane. These cranes feature telescoping legs that can be extended or retracted to adjust the height, as well as telescoping beams that can be extended or contracted to adjust the span. This versatility makes telescoping aluminum gantry cranes suitable for a wide range of applications, from confined work areas to open spaces requiring extended reach.

Adjustable aluminum gantry crane with telescoping height and telescopic span with capacity of 500kg, 1 ton, 2 ton, cost-effective crane price

A Telescoping Aluminum Gantry Crane with Adjustable Height and Span is a versatile lifting solution designed to provide maximum flexibility and adaptability in various industrial applications. Here's an overview of its features and capabilities:

- Telescoping Design: This gantry crane is equipped with telescoping beams or legs that allow for easy adjustment of both the crane's height and span width. The telescoping mechanism enables smooth extension and retraction of the crane components, providing precise control over the lifting configuration.

- Adjustable Height: The telescoping aluminum gantry crane allows users to modify the crane's height to accommodate different lifting requirements and workspace configurations. The height adjustment feature ensures that the crane can effectively lift loads at various heights, from ground level to overhead positions.

- Adjustable Span: In addition to height adjustment, this gantry crane offers the flexibility to adjust the span width between the legs. By extending or retracting the telescoping beams, users can customize the crane's span to fit different aisle widths and material handling needs.

- Versatility: The telescoping aluminum gantry crane is highly versatile and adaptable to a wide range of industrial environments and lifting applications. Its adjustable height and span make it suitable for use in confined spaces, irregularly shaped work areas, and locations with overhead clearance restrictions.

- Easy Operation: Despite its advanced adjustability features, the telescoping aluminum gantry crane is designed for ease of operation. The telescoping mechanism is simple to use, allowing operators to quickly and efficiently adjust the crane's configuration to meet specific lifting requirements.

- Lightweight and Portable: Like other aluminum gantry cranes, the telescoping model is constructed from lightweight materials, making it easy to transport and assemble. Its portable design allows for rapid deployment in various work environments without the need for specialized equipment or tools.

- Durability and Stability: Despite its lightweight construction, the telescoping aluminum gantry crane is engineered for durability and stability. High-quality materials and precision engineering ensure reliable performance, even in demanding industrial settings.

Overall, the telescoping aluminum gantry crane with adjustable height and span offers unmatched versatility, allowing users to tailor the crane's configuration to suit their specific lifting needs. Whether lifting heavy loads at varying heights or maneuvering through tight spaces, the aluminum crane provides a reliable and efficient lifting solution for a wide range of applications.

Foldable Aluminum Gantry Cranewith Adjustable Height and Span

A Foldable Aluminum Gantry Crane with Adjustable Height and Span is a highly flexible and portable lifting solution designed to provide convenient mobility and adjustable functionality in various industrial settings.

Folding aluminum gantry cranes

Unfolding aluminum gantry cranes

Here's an overview of its features and capabilities:

- Foldable Design: The foldable aluminum gantry crane is engineered with collapsible components that allow for easy folding and storage when not in use. This compact design makes transportation and storage more convenient, as the crane can be folded down to a fraction of its assembled size.

- Adjustable Height: Similar to other adjustable gantry cranes, the foldable model allows users to modify the crane's height to suit different lifting requirements and workspace configurations. The height adjustment feature enables operators to lift loads at various heights, providing versatility in lifting applications.

- Adjustable Span: In addition to height adjustment, the foldable aluminum gantry crane offers the flexibility to adjust the span width between the legs. By extending or retracting the telescoping beams, users can customize the crane's span to fit different aisle widths and material handling needs.

- Portability: One of the key features of the foldable aluminum gantry crane is its portability. The foldable design, combined with lightweight materials, makes it easy to transport the crane to different job sites or work areas. This portability allows for rapid deployment and flexibility in various industrial environments.

- Easy Assembly: Despite its adjustable and foldable features, the crane is designed for easy assembly and disassembly. Quick-release pins and snap-lock mechanisms enable operators to set up or fold down the crane quickly and efficiently, without the need for specialized tools.

- Durability and Stability: Despite its lightweight and foldable construction, the aluminum gantry crane is engineered for durability and stability. High-quality materials and precision engineering ensure reliable performance, even in demanding industrial settings.

- Versatility: The foldable aluminum gantry crane with adjustable height and span is highly versatile, suitable for a wide range of lifting applications. Whether lifting heavy loads at varying heights or maneuvering through tight spaces, the aluminum crane provides a reliable and efficient lifting solution.

Overall, the foldable aluminum gantry crane with adjustable height and span offers unmatched convenience, portability, and versatility. Its foldable design, combined with adjustable functionality, makes it an ideal choice for businesses seeking a flexible and portable lifting solution for various industrial applications.

Hot Sale Capacity of Aluminum Gantry Cranes

Aluminum gantry cranes come in various tonnages to meet the specific lifting needs of different industries and applications. The choice of tonnage depends on the weight and size of the loads you need to handle. Here are some hot sale tonnages of aluminum gantry cranes and their general designs and configurations:

250kg, 300kg, and 500kg Aluminum Gantry Cranes are lightweight yet sturdy lifting solutions designed for smaller-scale applications where precision and portability are essential. Here's more detail on each capacity:250kg Aluminum Gantry Crane:

Overview: The 250kg aluminum gantry crane is engineered for light-duty lifting tasks in workshops, warehouses, and other industrial environments where smaller loads need to be lifted with precision.

Features: This crane typically features a compact and lightweight design, making it easy to maneuver in tight spaces. It may include adjustable height settings and caster wheels for enhanced mobility.

Applications: Ideal for lifting smaller items such as components, tools, and equipment in manufacturing, assembly, and maintenance operations.

300kg Aluminum Gantry Crane:

Overview: The 300kg aluminum gantry crane offers slightly higher lifting capacity while maintaining portability and ease of use. It is suitable for light to medium-duty lifting tasks in various industrial settings.

Features: Similar to the 250kg crane, the 300kg model may feature adjustable height settings, caster wheels, and a lightweight yet durable construction.

Applications: Well-suited for lifting moderately sized loads such as machinery parts, materials, and components in workshops, warehouses, and production facilities.

500kg Aluminum Gantry Crane:

Overview: The 500kg aluminum gantry crane is designed for medium-duty lifting applications where slightly heavier loads need to be lifted with precision and stability.

Features: This crane may feature a more robust construction with reinforced structural components to handle increased load capacities. It may also include adjustable height settings and larger caster wheels for improved maneuverability.

Applications: Suitable for lifting larger components, machinery, and materials in manufacturing, maintenance, and construction environments where precision and portability are essential.

1 Ton Aluminum Gantry Crane:

Overview: The 1 ton aluminum gantry crane is a lightweight yet robust lifting solution suitable for light to medium-duty applications in workshops, warehouses, and industrial settings.

Features: It typically features a compact design, adjustable height, and caster wheels for easy maneuverability. The crane may also include reinforced structural components for increased stability and load capacity.

Applications: Ideal for lifting and transporting moderately heavy loads such as machinery parts, materials, and equipment in manufacturing, assembly, and maintenance operations.

2 Ton Aluminum Gantry Crane:

Overview: The 2 ton aluminum gantry crane is a versatile lifting solution capable of handling moderately heavy loads with precision and stability.

Features: It may feature adjustable height settings, a longer span for increased stability, and larger caster wheels for improved mobility. The crane's design may include additional structural reinforcements to support the higher load capacity.

Applications: Suitable for a wide range of light to medium-duty lifting tasks in manufacturing, construction, and maintenance operations, including lifting machinery, components, and materials.

3 Ton Aluminum Gantry Crane:

Overview: The 3 ton aluminum gantry crane is a robust and popular choice for medium-duty lifting tasks in various industrial environments.

Features: It features a more extensive structural design with reinforced components to handle heavier loads and provide greater stability. The crane may also offer adjustable height settings and larger casters for improved maneuverability.

Applications: Widely used in manufacturing, construction, and maintenance operations where precision lifting of medium-sized loads such as equipment, materials, and machinery is required.

5 Ton Aluminum Gantry Crane:

Overview: The 5 ton aluminum gantry crane is a heavy-duty lifting solution designed to handle larger and heavier loads with ease and precision.

Features: It may feature a wider span, larger casters, and additional structural reinforcements to support the higher load capacity. The crane's design prioritizes stability, durability, and precision lifting.

Applications: Commonly used in manufacturing, construction, and maintenance operations where lifting heavy machinery, materials, and equipment is required. Ideal for applications demanding high load capacity and precise handling.

In summary, 1 ton, 2 ton, 3 ton, and 5 ton Aluminum Gantry Cranes offer a range of lifting capacities and features to suit various industrial applications. From light to heavy-duty lifting tasks, these gantry cranes provide the versatility, stability, and precision needed to streamline lifting operations and enhance productivity in diverse work environments.

Light Duty Aluminum Gantry Cranes:

Load Capacity: Typically up to 2 tons.

Features:

Lightweight and portable design.

Adjustable height for flexibility.

Caster wheels for easy mobility.

Benefits:

Easy to transport and set up.

Ideal for small workshops and warehouses.

Versatile for various light lifting tasks.

Applications:

Lifting and moving lightweight materials and equipment in workshops.

Loading and unloading cargo in small warehouses.

Simple material handling tasks in manufacturing and maintenance.

Medium Duty Aluminum Gantry Cranes:

Load Capacity: Generally range from 2 to 5 tons.

Features:

Robust structural design.

Adjustable height for adaptability.

Caster wheels for mobility.

Benefits:

Versatile for moderate lifting tasks.

Suitable for manufacturing, construction, and maintenance.

Stable and mobile for use in various locations.

Applications:

Handling materials, machinery, and equipment in manufacturing facilities.

Lifting components and structures in construction projects.

Versatile material handling in maintenance operations.

5 Ton Aluminum Gantry Cranes:

Load Capacity: Typically have load capacities of 5 tons and above.

Features:

Robust and heavy duty structural design.

Adjustable height for flexibility.

Large caster wheels for stability.

Benefits:

Designed for substantial lifting requirements.

Suitable for heavy industries, construction, and marine settings.

Stable and secure handling of substantial loads.

Applications:

Handling heavy machinery and equipment in heavy industries.

Lifting large construction components and materials.

Marine applications for boat maintenance, launching, and cargo handling.

Custom Tonnage Aluminum Gantry Crane:

Some manufacturers offer customizable options to meet specific load capacities beyond the standard tonnages mentioned above.

Custom designs allow businesses to tailor the crane to their unique lifting needs.

Common Configurations and Features:

- Adjustable Heights: Most aluminum gantry cranes are designed with adjustable leg heights, allowing them to be adapted to different environments and load requirements.

- Caster Wheels: These cranes often come with caster wheels for easy mobility, enabling them to be moved to various locations within a workspace.

- Corrosion Resistance: Aluminum gantry cranes are naturally resistant to corrosion, ensuring their durability in challenging environments.

- Customization: Manufacturers offer various options for customization, including the choice of hoists, trolleys, and additional accessories to match specific application needs.

- Remote Control: Many models can be operated remotely, enhancing safety and precision during lifting operations.

- Foldable Design: Some aluminum gantry cranes have a foldable design for efficient storage and transportation.

When selecting an aluminum gantry crane, it's essential to consider the weight and size of the loads you'll be handling, the available workspace, and any specific requirements for your industry or application. Customization options are often available to tailor the crane to your unique needs.

Key Features and Components

Aluminum Gantry Frame

Aluminum gantry cranes are renowned for their A frame structure, which plays a pivotal role in their design and functionality. Let's explore the key features of the aluminum gantry frame:

- Structure and Design: The A frame structure is made from high quality aluminum, which strikes a balance between strength and lightweight characteristics. This design provides exceptional stability and support for lifting operations.

- Lightweight Advantage: One of the standout features of aluminum gantry frames is their remarkable lightweight nature. This inherent lightness makes them easy to move and set up, even in confined spaces, and they are typically more portable than their steel counterparts.

- Durability: Despite their lightweight construction, aluminum gantry frames are remarkably durable. They are capable of withstanding heavy loads while maintaining their structural integrity.

Aluminum Gantry Beam

The gantry beam is a critical component of aluminum gantry cranes, as it serves as the bridge along which the hoisting equipment moves. Let's delve into the specifics of this key element:

- Role in Crane Design: The gantry beam connects the two legs of the A frame, providing a secure horizontal platform for load lifting and transportation. Its horizontal orientation makes it suitable for a wide range of applications.

- Load Bearing Capacity: The load bearing capacity of the gantry beam varies depending on the crane's design and size. Aluminum gantry cranes can be customized to accommodate different weight requirements, from small loads to heavy industrial applications.

- Customization Options: Aluminum gantry beams can be customized to meet your specific lifting needs. You can choose the length and load capacity that aligns with your application, ensuring maximum efficiency and safety.

Hoists and Trolleys for Aluminum Gantry Cranes

Selecting the right hoisting equipment is essential to maximize the performance and efficiency of your aluminum gantry crane. Here's what you need to know about hoists and trolleys:

- Hoisting Equipment Selection: The choice between manual and powered hoists depends on your specific application. Manual hoists are suitable for lighter loads and occasional use, while powered hoists offer greater lifting capacity and are more efficient for frequent use.

- Safety Features: When selecting hoists and trolleys, consider those with safety features like limit switches, emergency stop buttons, and overload protection. These features enhance the safety of your lifting operations.

- Compatibility and Integration: Ensure that the hoisting equipment you choose is compatible with your aluminum gantry crane's design. It should integrate seamlessly to provide smooth and controlled lifting and movement.

Applications of Aluminum Gantry Cranes

Aluminum gantry cranes play a vital role in various industrial settings, offering versatile lifting solutions for a wide range of tasks. Here, we'll discuss their significance in manufacturing and production environments: Aluminum gantry cranes are frequently used in manufacturing facilities to facilitate the movement of heavy machinery, equipment, and raw materials. Their lightweight yet robust construction makes them ideal for indoor and outdoor tasks, from loading and unloading machinery to assembling large components. In industrial settings, these cranes are often employed for maintenance and repair work. They allow for precise positioning of heavy equipment, enabling technicians to access and service machinery with ease. Aluminum gantry cranes excel at tasks such as relocating heavy machinery, hoisting and positioning components in assembly lines, and aiding in the movement of materials within a production area. Their adaptability and ease of use make them invaluable tools in industrial settings.

Automotive Manufacturing Facilities:

Aluminum gantry cranes are essential tools for material handling, component assembly, and equipment installation in automotive production plants. Here's how aluminum gantry cranes are utilized in automotive manufacturing:

- Material Handling: Aluminum gantry cranes are used for lifting and moving raw materials, components, and assemblies throughout the automotive manufacturing process. They facilitate the movement of parts between different production stations, such as stamping, welding, painting, and assembly lines, ensuring smooth workflow and production efficiency.

- Component Assembly: Aluminum gantry cranes assist in the assembly of vehicle components, such as chassis, engines, transmissions, and body panels. They enable workers to position and align components with precision, ensuring proper fitment and assembly quality. Aluminum gantry cranes also facilitate the installation of heavy components, such as engines and transmissions, onto vehicle chassis.

- Equipment Installation: Automotive manufacturing facilities require the installation of various production equipment, such as robotic welding cells, paint booths, and assembly line conveyors. Aluminum gantry cranes are utilized for lifting and positioning these heavy equipment pieces during installation, ensuring proper alignment and integration into the manufacturing process.

- Maintenance and Upkeep: Regular maintenance and upkeep of manufacturing equipment are essential to ensure optimal performance and production uptime. Aluminum gantry cranes assist in lifting and transporting maintenance personnel and tools to access and service automotive manufacturing equipment safely and efficiently. They enable technicians to perform routine inspections, repairs, and upgrades while minimizing downtime and production interruptions.

- Safety and Compliance: Aluminum gantry cranes used in automotive manufacturing facilities are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards to protect personnel and equipment from harm during material handling and equipment installation processes.

Overall, aluminum gantry cranes play a critical role in automotive manufacturing by facilitating material handling, component assembly, equipment installation, maintenance, and safety compliance. Their versatility, precision, and compliance with safety standards make them indispensable tools for optimizing production processes and ensuring the quality and reliability of automotive products.

Semiconductor Manufacturing:

Aluminum gantry cranes are indispensable tools in semiconductor manufacturing facilities, where precision, cleanliness, and efficiency are paramount. Here's how aluminum gantry cranes are utilized in semiconductor manufacturing:

- Wafer Handling: Aluminum gantry cranes are used for handling delicate semiconductor wafers throughout the manufacturing process. They facilitate the movement of wafers between different stages of production, such as lithography, etching, deposition, and inspection, ensuring precise and controlled handling to minimize the risk of damage or contamination.

- Equipment Installation: Semiconductor manufacturing facilities require the installation of various equipment, such as photolithography machines, chemical vapor deposition (CVD) systems, and wafer inspection tools. Aluminum gantry cranes are utilized for lifting and positioning these heavy and sensitive equipment pieces with precision, ensuring proper alignment and integration into the manufacturing process.

- Cleanroom Operations: Semiconductor manufacturing cleanrooms maintain stringent cleanliness standards to prevent contamination of semiconductor wafers and devices. Aluminum gantry cranes used in cleanroom environments are designed with smooth surfaces and sealed bearings to minimize particle generation. They facilitate material handling operations while maintaining the cleanliness and integrity of the cleanroom environment.

- Maintenance and Upkeep: Regular maintenance and upkeep of semiconductor manufacturing equipment are essential to ensure optimal performance and reliability. Aluminum gantry cranes assist in lifting and transporting maintenance personnel and tools to access and service semiconductor equipment safely and efficiently. They enable technicians to perform routine inspections, repairs, and upgrades while minimizing downtime and production interruptions.

- Safety and Compliance: Aluminum gantry cranes used in semiconductor manufacturing facilities are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards to protect personnel and equipment from harm during material handling and equipment installation processes.

Overall, aluminum gantry cranes play a critical role in semiconductor manufacturing by facilitating wafer handling, equipment installation, cleanroom operations, maintenance, and safety compliance. Their versatility, precision, and compliance with cleanliness standards make them indispensable tools for optimizing production processes and ensuring the quality and reliability of semiconductor products.

Electronics Manufacturing Facilities:

Aluminum gantry cranes are essential for material handling, equipment installation, and maintenance tasks in electronics manufacturing facilities, where precision, efficiency, and safety are paramount. Here's how aluminum gantry cranes are utilized in electronics manufacturing:

- Component Handling: Aluminum gantry cranes are used for lifting and transporting electronic components, circuit boards, and assemblies throughout the manufacturing process. They facilitate the movement of components between different production stations, such as soldering, assembly, testing, and packaging, ensuring efficient workflow and production consistency.

- Equipment Installation: Electronics manufacturing facilities require the installation of various equipment, such as pick-and-place machines, soldering stations, and testing equipment. Aluminum gantry cranes are utilized for lifting and positioning these heavy and delicate equipment pieces with precision, ensuring proper alignment and integration into the manufacturing process.

- Cleanroom Operations: Cleanroom environments are essential in electronics manufacturing to prevent contamination of sensitive electronic components and devices. Aluminum gantry cranes used in cleanroom environments are designed with smooth surfaces and sealed bearings to minimize particle generation. They facilitate material handling operations while maintaining the cleanliness and integrity of the cleanroom environment.

- Maintenance and Upkeep: Regular maintenance and upkeep of manufacturing equipment are crucial to ensure optimal performance and reliability. Aluminum gantry cranes assist in lifting and transporting maintenance personnel and tools to access and service electronic equipment safely and efficiently. They enable technicians to perform routine inspections, repairs, and upgrades while minimizing downtime and production interruptions.

- Safety and Compliance: Aluminum gantry cranes used in electronics manufacturing facilities are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards to protect personnel and equipment from harm during material handling and equipment installation processes.

Overall, aluminum gantry cranes play a critical role in electronics manufacturing by facilitating component handling, equipment installation, cleanroom operations, maintenance, and safety compliance. Their versatility, precision, and compliance with cleanliness standards make them indispensable tools for optimizing production processes and ensuring the quality and reliability of electronic products.

New Energy Battery Factories:

Aluminum gantry cranes are indispensable for material handling, equipment installation, and maintenance tasks in factories producing batteries for electric vehicles and energy storage systems. Here's how aluminum gantry cranes are utilized in new energy battery factories:

- Material Handling: Aluminum gantry cranes are used for lifting and transporting raw materials, battery components, and finished battery modules throughout the manufacturing process. They facilitate the movement of materials between different production stations, such as material storage areas, mixing and blending stations, and assembly lines, ensuring efficient workflow and production consistency.

- Equipment Installation: New energy battery factories require the installation of various production equipment, such as mixing machines, coating lines, and battery assembly stations. Aluminum gantry cranes are utilized for lifting and positioning these heavy and sensitive equipment pieces with precision, ensuring proper alignment and integration into the manufacturing process.

- Cleanroom Operations: Cleanroom environments are essential in battery manufacturing to prevent contamination of sensitive battery materials and components. Aluminum gantry cranes used in cleanroom environments are designed with smooth surfaces and sealed bearings to minimize particle generation. They facilitate material handling operations while maintaining the cleanliness and integrity of the cleanroom environment.

- Maintenance and Upkeep: Regular maintenance and upkeep of manufacturing equipment are crucial to ensure optimal performance and production uptime. Aluminum gantry cranes assist in lifting and transporting maintenance personnel and tools to access and service battery manufacturing equipment safely and efficiently. They enable technicians to perform routine inspections, repairs, and upgrades while minimizing downtime and production interruptions.

- Safety and Compliance: Aluminum gantry cranes used in new energy battery factories are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards to protect personnel and equipment from harm during material handling and equipment installation processes.

Overall, aluminum gantry cranes play a critical role in new energy battery factories by facilitating material handling, equipment installation, cleanroom operations, maintenance, and safety compliance. Their versatility, precision, and compliance with cleanliness standards make them indispensable tools for optimizing production processes and ensuring the quality and reliability of battery products for electric vehicles and energy storage systems.

Food and Beverage Production Facilities:

Aluminum gantry cranes are essential for material handling, equipment maintenance, and product assembly in food processing plants and beverage production facilities. Here's how aluminum gantry cranes are utilized in food and beverage production:

- Material Handling: Aluminum gantry cranes are used for lifting and transporting raw ingredients, packaging materials, and finished products throughout the production process. They facilitate the movement of materials between different production areas, such as storage warehouses, mixing and blending stations, cooking and processing lines, and packaging lines, ensuring efficient workflow and production consistency.

- Equipment Maintenance: Regular maintenance and upkeep of production equipment are essential to ensure food safety and product quality in food and beverage production facilities. Aluminum gantry cranes assist in lifting and transporting maintenance personnel and tools to access and service food processing equipment safely and efficiently. They enable technicians to perform routine inspections, repairs, and cleaning procedures while minimizing downtime and production interruptions.

- Cleanroom Operations: Cleanliness and hygiene are critical factors in food and beverage production to prevent contamination and ensure product safety. Aluminum gantry cranes used in cleanroom environments are designed with smooth surfaces and sealed bearings to minimize particle generation. They facilitate material handling operations while maintaining the cleanliness and integrity of the production environment.

- Product Assembly and Packaging: Aluminum gantry cranes are utilized for lifting and positioning packaging materials, filling containers, and transporting finished products to packaging lines in food and beverage production facilities. They facilitate the assembly of product components, such as bottles, cans, pouches, and labels, ensuring precise alignment and efficient packaging processes.

- Safety and Compliance: Aluminum gantry cranes used in food and beverage production facilities are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards, including food safety regulations, to protect personnel and products from harm during material handling and equipment maintenance processes.

Overall, aluminum gantry cranes play a critical role in food and beverage production by facilitating material handling, equipment maintenance, cleanroom operations, product assembly, and packaging processes. Their versatility, precision, and compliance with cleanliness and safety standards make them indispensable tools for optimizing production processes and ensuring the quality and safety of food and beverage products.

Laboratory Environments:

Aluminum gantry cranes are crucial for material handling, equipment installation, and maintenance tasks in cosmetic production facilities, where precision, cleanliness, and safety are paramount. Here's how aluminum gantry cranes are utilized in cosmetic manufacturing workshops:

- Material Handling: Aluminum gantry cranes are used for lifting and transporting raw materials, packaging components, and finished products throughout the production process. They facilitate the movement of materials between different production areas, such as storage warehouses, mixing and blending stations, filling lines, and packaging stations, ensuring efficient workflow and production consistency.

- Equipment Installation: Cosmetic manufacturing facilities require the installation of various production equipment, such as mixers, filling machines, and packaging lines. Aluminum gantry cranes are utilized for lifting and positioning these heavy and delicate equipment pieces with precision, ensuring proper alignment and integration into the manufacturing process.

- Cleanroom Operations: Cleanliness and hygiene are critical factors in cosmetic manufacturing to prevent contamination and ensure product safety. Aluminum gantry cranes used in cleanroom environments are designed with smooth surfaces and sealed bearings to minimize particle generation. They facilitate material handling operations while maintaining the cleanliness and integrity of the production environment.

- Product Assembly and Packaging: Aluminum gantry cranes are essential for lifting and positioning packaging materials, filling containers, and transporting finished products to packaging lines in cosmetic manufacturing workshops. They facilitate the assembly of product components, such as bottles, jars, pumps, and caps, ensuring precise alignment and efficient packaging processes.

- Safety and Compliance: Aluminum gantry cranes used in cosmetic manufacturing workshops are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards to protect personnel and products from harm during material handling and equipment installation processes.

Overall, aluminum gantry cranes play a critical role in cosmetic manufacturing by facilitating material handling, equipment installation, cleanroom operations, product assembly, and packaging processes. Their versatility, precision, and compliance with cleanliness and safety standards make them indispensable tools for optimizing production processes and ensuring the quality and safety of cosmetic products.

Boat and Marine Workshops:

Aluminum gantry cranes are essential for lifting and moving boats and marine vessels during maintenance, repair, and assembly tasks in boatyards and marinas. Here's how aluminum gantry cranes are utilized in boat and marine workshops:

- Boat Maintenance and Repair: Aluminum gantry cranes are used to lift boats out of the water for maintenance and repair tasks, such as hull inspections, painting, and mechanical repairs. They provide a stable and secure lifting solution, allowing technicians to access the underside of boats and perform maintenance tasks efficiently and safely.

- Engine Installation and Removal: Aluminum gantry cranes assist in lifting and positioning boat engines during installation and removal processes. They enable technicians to carefully maneuver heavy engines into position, ensuring proper alignment and integration with the boat's propulsion system.

- Rigging and Mast Work: For sailboats and yachts, aluminum gantry cranes are used to lift and support masts and rigging components during maintenance and rigging adjustments. They provide a stable lifting platform, allowing technicians to work safely at height and perform rigging inspections and repairs.

- Boat Assembly: In boat manufacturing facilities, aluminum gantry cranes are utilized for lifting and positioning boat hulls, decks, and superstructures during the assembly process. They facilitate the assembly of boat components, ensuring precise alignment and efficient production workflows.

- Safety and Compliance: Aluminum gantry cranes used in boat and marine workshops are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operation. They comply with relevant safety regulations and standards to protect personnel and boats from harm during lifting and handling operations.

Overall, aluminum gantry cranes play a crucial role in boat and marine workshops by facilitating boat maintenance, repair, assembly, and rigging tasks. Their versatility, stability, and compliance with safety standards make them indispensable tools for boatyards, marinas, and boat manufacturing facilities, ensuring efficient and safe operations in the marine industry.

Cleanroom Environments:

Aluminum gantry cranes are essential tools for material handling, equipment installation, and maintenance tasks in cleanroom environments across various industries where cleanliness and precision are critical. Here's how aluminum gantry cranes are utilized in cleanroom environments:

- Semiconductor Manufacturing: In semiconductor manufacturing facilities, aluminum gantry cranes are used for handling delicate semiconductor wafers, equipment installation, and maintenance tasks in cleanroom environments. They enable technicians to transport semiconductor processing equipment and components with precision and safety, minimizing the risk of contamination and ensuring the quality of semiconductor products.

- Nanotechnology Research: Aluminum gantry cranes play a crucial role in nanotechnology research laboratories, where cleanliness and precision are essential for manipulating nanoscale materials and structures. They facilitate the handling of nanomaterials, experimental setups, and testing equipment in cleanroom environments, enabling researchers to conduct experiments with accuracy and repeatability.

- Biopharmaceutical Production: Cleanroom environments are also utilized in biopharmaceutical production facilities for manufacturing drugs, vaccines, and biologics. Aluminum gantry cranes assist in material handling, equipment installation, and maintenance tasks, ensuring the integrity of pharmaceutical products and compliance with regulatory standards for cleanliness and sterility.

- Aerospace and Defense: In aerospace and defense industries, aluminum gantry cranes are used in cleanroom environments for assembling and testing precision components such as satellite systems, aerospace electronics, and defense equipment. They enable engineers and technicians to handle sensitive equipment and components with care, minimizing the risk of contamination and ensuring the reliability of aerospace and defense systems.

- Optics and Photonics: Cleanroom environments are essential for optics and photonics industries, where precision and cleanliness are critical for manufacturing optical components and devices. Aluminum gantry cranes facilitate the handling of optical equipment, lenses, and sensitive materials in cleanroom environments, ensuring the quality and performance of optical products.

Overall, aluminum gantry cranes are indispensable tools for maintaining cleanliness and precision in cleanroom environments across various industries. Their mobility, versatility, and compliance with cleanliness standards make them essential for optimizing material handling processes and ensuring the quality and integrity of products manufactured in cleanroom environments.Each type of aluminum gantry crane is designed to cater to specific applications and provides unique features and benefits to meet the demands of various industries and environments. The choice of the appropriate crane type depends on the specific requirements of your application and the environmental conditions in which it will be used.

Buying Aluminum Gantry Cranes

Factors to Consider When Purchasing

Investing in an aluminum gantry crane is a significant decision, and it's important to carefully consider the following factors before making your purchase:

- Load Capacity: Determine the maximum weight you'll need to lift. Ensure that the crane's load capacity aligns with your specific requirements. It's always better to opt for a crane with a higher load capacity than you think you'll need to accommodate potential future demands.

- Size and Dimensions: Assess the available space in your workspace. The size and dimensions of the crane, including the gantry beam's length and the crane's height, should be compatible with your workspace constraints.

- Environmental Conditions: Consider the environment in which the crane will operate. If it will be exposed to corrosive elements, like saltwater or chemicals, make sure to choose an aluminum gantry crane with suitable corrosion resistant features.

- Mobility and Portability: Think about how often you'll need to move the crane. If portability is crucial, look for models with caster wheels and ease of disassembly for transport.

- Safety Features: Ensure that the crane you choose has necessary safety features such as overload protection, emergency stop buttons, and limit switches. Safety should be a top priority.

- Budget: Determine your budget constraints and choose a crane that offers the best value for your investment. Consider not only the initial purchase cost but also long term maintenance and operational expenses.

Where to Find Aluminum Gantry Cranes for Sale

Once you've identified your requirements, it's essential to know where to find reputable suppliers and manufacturers of aluminum gantry cranes:

- Specialized Manufacturers: Some manufacturers specialize in the production of aluminum gantry cranes. These companies often provide high quality, customized solutions tailored to your needs. Research and reach out to established manufacturers for quotes and recommendations.

- Online Marketplaces: E commerce platforms such as Amazon, eBay, and Alibaba offer a wide range of aluminum gantry cranes from various sellers. These platforms provide an opportunity to compare prices and read user reviews.

- Industrial Equipment Distributors: Local or national industrial equipment distributors may offer aluminum gantry cranes as part of their inventory. They can provide in person guidance and support for selecting the right crane.

- Recommendations and Referrals: Seek recommendations from colleagues, industry peers, or your professional network who have experience with aluminum gantry cranes. Their insights can be invaluable in identifying reliable suppliers.

Customization Options

- Tailoring your aluminum gantry crane to your specific needs can greatly enhance its utility. Here's how you can customize your crane:

- Load Capacity: Work with manufacturers or suppliers to customize the load capacity of your crane to match your specific lifting requirements.

- Adjustable Height: Opt for gantry cranes with adjustable leg heights if you need to work in spaces with limited vertical clearance.

- Hoisting Equipment: Select the appropriate hoists and trolleys to meet your unique lifting tasks, ensuring compatibility with your crane's design.

- Additional Attachments: Explore additional attachments such as spreader bars or lifting hooks to expand the functionality of your aluminum gantry crane.

- Customization allows you to maximize the crane's performance and versatility, ensuring it meets the exact needs of your application.

Maintenance and Safety

Maintenance Tips

To ensure the longevity and optimal performance of your aluminum gantry crane, regular maintenance is essential. Here are some maintenance tips to consider:

- Inspect Regularly: Implement a routine inspection schedule. Check for any signs of wear, damage, or loose components. Pay close attention to the gantry frame, gantry beam, and hoisting equipment.

- Lubrication: Keep all moving parts well lubricated to prevent friction and ensure smooth operation. Consult the manufacturer's recommendations for the appropriate lubricants.

- Cleaning: Regularly clean the crane to remove dirt, dust, and debris that can accumulate on the components. Ensure that the crane is free from contaminants that may affect its performance.

- Replacement of Worn Parts: When you identify worn or damaged components during inspections, promptly replace them with genuine replacement parts. Using non standard components can compromise the crane's safety and functionality.

- Testing: Periodically perform load tests to ensure that the crane continues to meet its load bearing capacity. This helps identify any potential issues before they become critical.

Safety Guidelines

Safety is of paramount importance when operating an aluminum gantry crane. Here are some essential safety guidelines for operators and bystanders:

- Operator Training: Ensure that the crane operators are adequately trained and certified. They should have a thorough understanding of the crane's controls and safety features.

- Load Capacity: Never exceed the crane's specified load capacity. Overloading the crane can result in accidents and damage to the equipment.

- Clear Communication: Establish clear communication protocols between operators, signalpersons, and any other personnel involved in the lifting operation.

- Emergency Procedures: Familiarize operators with emergency procedures, including how to engage emergency stop buttons and respond to critical situations.

- Proximity to the Load: Bystanders should maintain a safe distance from the load and the crane's path to prevent accidents caused by swinging or shifting loads.

- Use of Personal Protective Equipment (PPE): Ensure that all personnel involved in crane operations wear appropriate PPE, including hard hats, safety glasses, and gloves.

- Secure the Load: Always make sure the load is properly secured before lifting. Use slings, hooks, or other attachments that are in good condition and suitable for the task.

- Regular Inspections: Conduct routine inspections of the crane to identify any issues or defects that may compromise safety. Address these issues promptly to prevent accidents.