1 ton Overhead Cranes for Sale and Their Facility Adaptability

1 ton overhead cranes for sale, designed for versatile facility use, offering efficient lifting solutions with space-saving adaptability and easy installation

Category: Light Duty Crane 1, 2, 3 Ton

Your Trusted 1 Ton Overhead Crane Manufacturer & Supplier

1 Ton Overhead Cranes for Sale and Their Facility Adaptability

1 ton overhead cranes are versatile, reliable, and cost-effective solutions designed for light-duty lifting and material handling tasks in a variety of industrial sectors. These cranes are widely used in manufacturing plants, warehouses, construction sites, workshops, and maintenance facilities, offering significant advantages in terms of operational efficiency and workspace optimization. With their compact size and flexible design, they can move materials within confined spaces while handling loads up to 1 ton. Choosing the right crane for a facility is critical to ensuring smooth operations, reducing downtime, and maximizing productivity.

Importance of Selecting the Right Crane for the Facility

- Efficiency and Workflow Optimization: Selecting the appropriate 1 ton overhead crane directly influences operational efficiency. Cranes are often used to lift and transport components, materials, and equipment throughout the facility. A crane that matches the facility's layout and lifting requirements helps avoid unnecessary delays, reduces manual handling, and ensures that materials are delivered to the correct locations in the most efficient manner.

- Minimizing Downtime: Proper crane selection reduces the chances of breakdowns and service interruptions. A crane that is ill-suited to the demands of the facility can lead to frequent repairs and increased maintenance costs. For instance, a poorly installed or mismatched crane may struggle to meet the required load capacity or operating conditions, slowing down production and workflow.

Crane Selection and Facility Features: Enhancing Operational Efficiency

- Space Utilization: The right 1 ton overhead crane should maximize available space in the facility. Some cranes, like under-running bridge cranes, are ideal for low-clearance areas and compact workspaces, as they are designed to operate within limited vertical space. Meanwhile, top-running bridge cranes offer more flexibility and greater coverage for larger facilities. Ensuring that the crane's movement capabilities align with the available space reduces congestion and enhances workflow.

- Load Handling Requirements: It's essential that the crane meets the specific load capacity needed for the facility's tasks. A 1 ton crane can typically handle small to medium-sized components, but some tasks may require specialized features such as adjustable lifting heights, telescoping arms, or specific lifting mechanisms. Understanding the load characteristics and the typical materials handled within the facility ensures the crane can perform efficiently.

How Proper Crane Choice Improves Workflow

- Increased Safety: Selecting the right crane is crucial for improving safety in the workplace. Cranes that are suitable for the space and load requirements reduce the risk of accidents caused by overloading or improper crane movement. This contributes to a safer working environment for employees, as cranes that are well-matched to the facility minimize the chances of load spills or equipment malfunctions.

- Productivity Boost: The proper crane not only improves safety but also increases productivity. For example, when workers can rely on an efficient overhead crane to quickly and safely move materials, they can focus more on their core tasks, such as assembly or production. Cranes that are easy to operate and that seamlessly integrate into the workflow reduce the need for manual intervention, which speeds up operations.

- Long-Term Value: Investing in the right crane can offer long-term benefits, including reduced maintenance costs, fewer repairs, and better overall performance. Cranes that are properly matched to the facility's requirements will have a longer lifespan and deliver better value over time, helping businesses avoid the additional costs associated with crane replacements and extensive repairs.

Choosing the right 1 ton overhead crane for your facility is not just about lifting capacity; it's about optimizing your entire operation. A crane that aligns with your facility's layout, load requirements, and workflow can significantly improve operational efficiency, reduce downtime, and boost productivity. By carefully considering the specific needs of your workplace, you can maximize the benefits of your crane investment, ensuring long-term value and operational success.

Key Types of 1 ton Overhead Cranes

Design Options for 1 ton Overhead Cranes

When selecting a 1 ton overhead crane, the weight capacity is manageable, but the real challenge lies in choosing the right crane design for your specific facility needs. The right crane must align with factors such as cost, facility layout, space, and material handling requirements. Fortunately, with a 1 ton load, there are various design options available, each with distinct advantages.

Several types of overhead cranes are suitable for handling 1 ton loads. These include:

- Overhead Bridge Crane

- Gantry Crane

- Swing Jib Crane

- Monorail Crane

- KBK Crane System

- Portable Crane

Subtypes for 1 ton Lifting Requirements Based on Facility Features

Each of the crane types mentioned above can be further customized to suit different applications. Based on facility layout, lifting requirements, and environment, these cranes come in various configurations:

- Overhead Bridge Cranes: Available in top-running or under-running designs to suit different ceiling heights and space configurations.

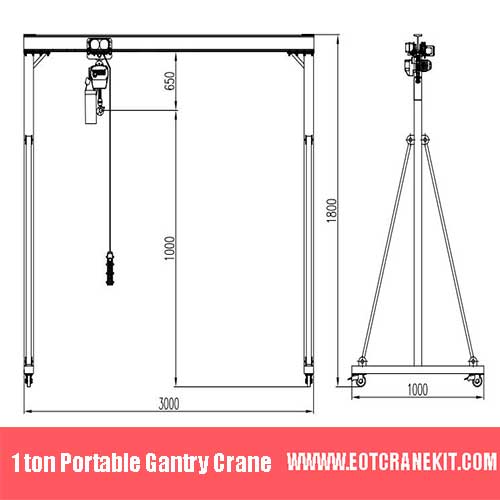

- Gantry Cranes: Can be configured as portable gantries or fixed full/half gantry designs, depending on the need for mobility or the type of load handling.

- Swing Jib Cranes: Can be floor-mounted or wall-mounted for added flexibility in workspace design.

- Monorail Cranes: Available with both straight or curved tracks for different material flow designs and operational needs.

- KBK Cranes: These cranes can be modular, adjustable, and come with various load-handling attachments to suit specific tasks.

- Portable Cranes: Can be designed with manual or electric lifting capabilities to handle lighter tasks with mobility.

Selecting the best 1 ton overhead crane requires an understanding of both the crane's capabilities and your facility's unique needs. With options ranging from highly versatile bridge cranes to specialized jib or monorail cranes, you have the flexibility to choose a solution that fits your space, lifting requirements, and application environment. Whether you need a crane for mobile tasks, precise lifting in tight spaces, or continuous material handling along a fixed path, there's a 1 ton crane designed to improve efficiency, safety, and productivity in your facility.

Overview of 1 Ton Crane Types for Your Industrial Needs

Overhead Bridge Crane

Design and Features: The overhead bridge crane consists of a horizontal bridge that runs on parallel tracks, supported by runways that extend across the facility. The crane itself moves along these tracks, covering a wide area for lifting and transporting heavy materials.

Best for: Large manufacturing or warehouse facilities with high ceilings and expansive workspaces. These cranes allow for lifting across the entire span of the building, making them ideal for heavy or bulky material handling over long distances.

Key Benefits:

- Full Area Coverage: It can cover the entire work area, optimizing space usage.

- Efficient Use of Facility Space: Designed to make the most of available vertical space, reducing the need for floor space.

- Ideal for High Ceilings and Large Workspaces: Perfect for industries with large-scale operations or tall structures requiring heavy lifting capabilities.

1 Ton Overhead Bridge Crane Options for Your Facility

When selecting a 1 ton overhead crane, it's important to consider various configurations based on your facility's space, material handling requirements, and load features. Below are the key configurations and their details to help you make an informed decision:

Single Girder Underhung Overhead Bridge Crane (1 Ton)

- Crane Features: Compact and lightweight design, mounted underneath the rail system, ideal for low-headroom spaces.

- Facility Features: Best for small to medium-sized facilities with limited ceiling height.

- Load Features: Handles 1 ton loads, perfect for light materials and components.

- Material Lifting Requirements: Ideal for small tools or parts in production or assembly environments.

- Coverage: Provides full-length coverage across the facility.

- Travelling Length: Typically ranges from 5 to 20 meters.

Top Running 1 Ton Overhead Bridge Crane (Single Girder)

- Crane Features: More robust design, girder runs along the top of the runway beams, durable for wider coverage.

- Facility Features: Ideal for larger facilities with higher ceilings and more space.

- Load Features: Handles 1 ton loads efficiently, suitable for light to moderate-duty material handling.

- Material Lifting Requirements: Excellent for transporting materials over long distances.

- Coverage: Full-span coverage across the length of the building.

- Travelling Length: Typically ranges from 5 to 30 meters.

Manual Overhead Cranes (1 Ton)

- Crane Features: Operated manually, cost-effective and low-maintenance, perfect for infrequent lifts.

- Facility Features: Best for smaller workshops or facilities with low-volume tasks.

- Load Features: Efficient for 1 ton loads, suitable for lighter loads and smaller components.

- Material Lifting Requirements: Ideal for handling tools and parts in low-volume production.

- Coverage: Limited coverage but provides full access along the runway length.

- Travelling Length: Typically ranges from 3 to 10 meters.

Overhead Telescoping Cranes (1 Ton)

- Crane Features: Features a telescoping boom for adjustable reach, perfect for dynamic material handling.

- Facility Features: Ideal for facilities needing adjustable lifting distances, such as construction or specialized manufacturing.

- Load Features: Handles 1 ton loads with adjustable reach and flexibility.

- Material Lifting Requirements: Perfect for lifting large or awkward items with varying lifting distances.

- Coverage: Customizable coverage depending on the boom's extension.

- Travelling Length: Typically ranges from 5 to 20 meters or more.

Choosing the right 1 ton overhead crane depends on your facility's layout, space availability, and specific material handling needs. By understanding the unique features and applications of each crane configuration, you can maximize efficiency and productivity in your operations.

1 Ton Gantry Cranes for Sale, Types of Designs and Options for Your Selection

Design and Features: Gantry cranes have legs that travel along the ground, allowing them to operate in facilities without overhead tracks. They are available in two main configurations: full gantry (with both a bridge and legs) and semi-gantry (one leg on the ground and one overhead).

Best for: Facilities lacking overhead support or for outdoor applications. Portable gantry cranes are particularly useful in mobile environments, such as construction sites, workshops, and temporary setups.

Key Benefits:

- Ideal for Spaces with No Overhead Support: Can be installed in facilities without the need for a ceiling-mounted structure.

- Can Be Used Indoors and Outdoors: Versatile enough for both internal warehouses and external construction sites.

- Mobile and Flexible Options Available: Easy to relocate, making it ideal for temporary or mobile lifting needs.

1 Ton Overhead Gantry Crane Configurations for Your Facility

When selecting a 1 ton gantry crane for your facility, it's crucial to choose a configuration that best matches your specific material-handling needs. Here's a breakdown of popular 1 ton overhead gantry crane designs, highlighting key features, facility compatibility, and performance capabilities.

Standard 1 ton Gantry Crane with Rail Travelling (Single Girder Design)

- Crane Features: A classic design featuring a single girder, allowing the crane to move smoothly along fixed rails, ensuring consistent lifting performance.

- Facility Suitability: Ideal for larger spaces with high ceilings and enough room for track installation. Best suited for warehouses, manufacturing plants, and assembly areas.

- Load Features: Capable of lifting up to 1 ton with great precision and safety, ideal for light to moderate-duty tasks.

- Material Lifting Requirements: Designed to lift smaller parts, equipment, or containers in a controlled environment.

- Coverage: Provides complete coverage across the facility with the flexibility to extend the rail system as needed.

- Travelling Length: Offers variable traveling lengths depending on the installed track, providing flexibility for larger work areas or tight spaces.

Simple Designed 1 ton Gantry Crane with Rail Travelling

- Crane Features: A simpler design with fewer components, making it cost-effective and easy to maintain. Offers reliable performance for light lifting tasks.

- Facility Suitability: Perfect for smaller facilities or workshops that need a straightforward, low-maintenance lifting solution.

- Load Features: Suitable for handling loads up to 1 ton, perfect for moving small components and equipment in controlled environments.

- Material Lifting Requirements: Efficient for lifting smaller, lighter materials or equipment in industrial settings.

- Coverage: Limited by the length of the installed rail system but adaptable to confined spaces where a more complex system is unnecessary.

- Travelling Length: Designed for short to medium distances, offering flexibility within small to mid-sized facilities.

Single Girder Semi-Gantry Crane (1 Ton) with Rail Travelling

- Crane Features: This design features one side of the crane supported by the rail, while the other side uses floor-mounted support, offering flexibility and reduced space requirements.

- Facility Suitability: Ideal for facilities with restricted ceiling heights or where overhead support is limited. Works well in smaller shops or areas with partial overhead tracks.

- Load Features: Handles loads up to 1 ton, designed for precision and ease of use in localized lifting applications.

- Material Lifting Requirements: Perfect for smaller lifting tasks, particularly when limited space or height restrictions exist.

- Coverage: Offers excellent localized coverage where full gantry systems are impractical, making it suitable for compact workspaces.

- Travelling Length: Provides short to medium travel lengths, ideal for facilities with moderate space constraints.

These configurations of 1 ton overhead gantry cranes provide a variety of options for different lifting requirements and facility constraints. Selecting the right design ensures efficiency, safety, and optimized material handling in your operations.

Swing Jib Crane

Design and Features: A swing jib crane features a horizontal arm that rotates around a pivot, providing the ability to lift materials within a specific radius. These cranes can be mounted on the floor or attached to a wall, offering flexibility in tight spaces.

Best for: Workstations where lifting is concentrated within a specific range. Swing jib cranes are ideal for assembly lines, maintenance tasks, and areas requiring precise lifting within a fixed radius.

Key Benefits:

- Space-Efficient for Tight Areas: Its compact design makes it perfect for small workstations or areas with limited space.

- Excellent for Localized Lifting: Provides precise and targeted lifting capabilities within a defined area.

- Mountable on Walls or Floors: Can be installed in flexible ways to fit the specific needs of your facility.

Jib Crane Configurations for 1 ton Lifting Needs

Jib cranes offer flexibility for lifting materials within a fixed radius, ideal for workstations or areas where tasks are concentrated in a specific area. Below are detailed descriptions of various 1 ton jib crane configurations, highlighting their features, suitability for different applications, and performance capabilities.

Floor Mounted Jib Crane (1 Ton)

- Crane Features: Mounted directly to the floor, the floor-mounted jib crane features a horizontal arm that can swing around a pivot, allowing for precise, localized material handling within a fixed area. This type is typically designed for light-duty tasks.

- Facility Suitability: Best suited for facilities with stable, level flooring, where the crane is not required to be moved frequently. Ideal for assembly lines, workshops, and maintenance areas.

- Material Lifting Requirements: Handles light to moderate materials up to 1 ton, making it suitable for lifting small parts, tools, and equipment within a confined workspace.

- Coverage: Provides localized coverage with a defined radius of operation, typically between 180° to 360° depending on the design.

- Travelling Length: Offers limited travel distance, typically within the working radius of the crane's arm. The focus is on precision lifting in smaller areas.

Wall Mounted Jib Crane (1 Ton)

- Crane Features: This crane is mounted to the wall, freeing up valuable floor space. It features a horizontal arm that pivots to allow for easy lifting within a fixed radius, ideal for tight spaces.

- Facility Suitability: Perfect for workshops or facilities where floor space is limited or needs to be kept clear. Common in areas with walls capable of supporting the crane's weight.

- Material Lifting Requirements: Ideal for lifting lighter items, including small parts, machinery, and components within the reach of the arm. The 1 ton capacity allows for efficient handling of moderate loads.

- Coverage: Limited coverage within the fixed radius of the arm's swing, typically covering 180° or more, depending on the installation.

- Travelling Length: Offers no horizontal travel but provides precision lifting within a fixed radius, often suited for localized tasks.

Wall Traveling Jib Crane (1 Ton)

- Crane Features: A wall traveling jib crane combines the features of a wall-mounted crane with the added flexibility of traveling along a wall-mounted rail. This setup allows the crane to move horizontally, increasing the covered area.

- Facility Suitability: Suitable for longer work areas or those that require lifting at multiple locations along a wall. Ideal for facilities with larger workstations or long production lines.

- Material Lifting Requirements: Perfect for handling 1 ton loads that need to be moved between different workstations along a wall. It is often used in assembly lines or for lifting materials that need to be moved across a fixed range.

- Coverage: Provides extended coverage along the wall, often allowing the crane to travel the length of the wall and handle multiple lifting tasks across different locations.

- Travelling Length: The crane can travel along the wall, offering a significant horizontal travel length that is ideal for applications requiring flexible movement and multiple lifting points along the same wall.

These various jib crane configurations offer a range of solutions for specific applications and workspace constraints, providing tailored lifting solutions for light material handling tasks with efficient, localized coverage.

Monorail Crane

Design and Features: A monorail crane operates along a single track or rail, allowing it to travel linearly. It is a cost-effective solution for tasks that require the load to move along a fixed path from one point to another.

Best for: Environments with repetitive, linear workflows, such as assembly lines or production environments where materials need to be moved in a straight line.

Key Benefits:

- Cost-Effective for Linear Workflows: Simplifies installation and operation for straightforward lifting needs.

- Suitable for Assembly Line Operations: Ideal for tasks that require repetitive, predictable movements along a fixed path.

- Easy Installation and Operation: Simple to install, making it an efficient option for improving material transport.

Monorail Crane Configurations for 1 ton Loads

Monorail cranes are ideal for transporting loads along a fixed path, offering a streamlined, efficient solution for facilities with predictable workflows. These cranes operate on a single rail and can either be ceiling-mounted or freestanding, depending on the facility requirements. Below are the key configurations of 1 ton monorail cranes, along with their features and applications.

Ceiling Mounted Monorail Crane (1 Ton) with Straight or Curved Path

- Crane Features: Mounted to the ceiling, the monorail crane travels along a single rail. It can be designed with a straight or curved path, providing flexibility to navigate around obstacles or through complex facility layouts. The crane's design allows it to save valuable floor space while offering smooth, controlled lifting.

- Facility Suitability: Ideal for facilities with high ceilings and minimal obstructions. It is particularly useful in production lines, assembly areas, or warehouses with a linear workflow. Curved path options are beneficial for navigating tight spaces or areas with structural constraints.

- Load Features: Suitable for handling 1 ton loads, ideal for moving smaller components, parts, or tools within a predictable, linear path. The system can be adapted to various industries, from automotive to manufacturing.

- Material Lifting Requirements: Handles a range of light-to-moderate lifting tasks such as transporting parts across assembly lines or moving components between workstations.

- Coverage: Coverage is determined by the length of the rail, either straight or curved. Straight paths cover a linear area, while curved paths expand the crane's coverage by allowing it to turn corners, making it more versatile.

- Travelling Length: Typically spans the length of the facility or designated path. The crane can move along a fixed path with no lateral movement, and the length depends on the layout of the facility.

Freestanding Monorail Crane (1 Ton) with Straight or Curved Path

- Crane Features: The freestanding monorail crane features its own support structure, independent of existing ceilings or beams. This design allows it to be installed in facilities without suitable overhead support. It can be configured with either a straight or curved rail path to accommodate the specific flow of materials.

- Facility Suitability: Ideal for environments where ceiling space is limited or unavailable, such as in warehouses or industrial buildings with lower ceilings. This configuration is also suitable for areas with specific structural challenges or for expanding capacity in existing facilities.

- Load Features: Like the ceiling-mounted version, the freestanding monorail crane is designed to handle loads up to 1 ton. It is commonly used for moving materials, parts, and products along a defined path without requiring significant lifting heights.

- Material Lifting Requirements: This crane is typically used for moving medium to light loads that do not require significant vertical lifting but require consistent, predictable horizontal movement.

- Coverage: The coverage area is determined by the layout of the rail system, either straight or curved. The curved path option allows the crane to navigate obstacles, corners, or complex floor layouts.

- Travelling Length: The freestanding monorail crane offers flexibility in terms of rail length, making it adaptable to a variety of facility sizes and workflows. The crane can travel the full length of the rail, providing consistent lifting coverage over a wide range.

Both ceiling-mounted and freestanding monorail cranes are excellent choices for facilities looking for streamlined material handling solutions. The choice between straight or curved paths depends on the specific facility layout and operational needs, ensuring that 1 ton loads are efficiently moved throughout the workspace.

KBK Crane System

Design and Features: The KBK crane system is modular and lightweight, offering a high degree of flexibility. Its customizable, modular design allows it to be easily adapted for different lifting tasks and tailored to fit specific layouts in industrial settings.

Best for: Light-duty tasks in limited spaces, such as small workshops, laboratories, or specialized handling areas. The modularity of KBK cranes allows them to be adjusted for varying needs and constraints.

Key Benefits:

- Highly Customizable: Can be configured to meet specific material handling needs.

- Ideal for Limited Spaces: Perfect for small workspaces or areas where traditional cranes may not fit.

- Easy to Install and Adapt: The modular design makes it simple to install and adjust as requirements change.

KBK Crane System Configurations for 1 ton Loads

The KBK crane system is a lightweight and modular solution known for its flexibility, ease of installation, and suitability for light-duty tasks. It is especially useful in spaces with limited room or specific material handling requirements. Below is an overview of the key configurations of 1 ton KBK rail cranes, including both ceiling-mounted and floor-mounted options, and their features, applications, and operational specifications.

Ceiling Mounted KBK Rail Crane (1 Ton)

KBK Track Crane (1 Ton)

- Crane Features: This system consists of modular components that are mounted to the ceiling. It offers flexibility with easy-to-assemble tracks, allowing for smooth movement of loads. The crane can travel along the mounted rail, providing maximum utilization of available vertical space.

- Facility Features: Ideal for facilities with sufficient ceiling height and minimal obstructions. Ceiling-mounted KBK cranes are best for workshops, light manufacturing, and assembly lines where floor space is at a premium.

- Load Features: Can easily handle 1 ton loads, ideal for smaller components, tools, or parts. It offers controlled and efficient material handling for light-to-medium duty tasks.

- Material Lifting Requirements: Suitable for moving materials over short to medium distances with minimal lifting height. The system provides a smooth and predictable path for material movement within the facility.

- Coverage: Coverage is determined by the length of the rail system and can be tailored to fit the needs of the space. These cranes can operate over a linear path, extending across an entire production area or workshop.

- Travelling Length: The rail length can vary based on the facility's requirements, with the crane capable of traveling along the track as long as needed within the defined area.

Truss KBK Rail Crane (1 Ton)

- Crane Features: The truss-mounted version of the KBK rail crane offers greater stability and is ideal for facilities that require a more robust structure. The truss design helps increase the load-bearing capacity of the crane while still maintaining flexibility and ease of installation.

- Facility Features: Best for facilities with limited headroom or where ceiling-mounted tracks need additional support. The truss version can be installed in both small and large spaces, making it versatile for various setups.

- Load Features: Handles 1 ton loads with ease, suitable for light assembly, material handling, or tool movement. The truss design provides additional strength, especially when lifting items at various points within the facility.

- Material Lifting Requirements: Designed for moderate lifting tasks where controlled and reliable material movement is required. Ideal for tasks that demand both horizontal and limited vertical movement.

- Coverage: Offers similar coverage to the track crane but with the added stability and support of the truss system. It allows for efficient movement of materials along a predetermined path.

- Travelling Length: The truss-mounted crane can span longer distances compared to standard ceiling-mounted systems, offering extended operational coverage across large production or storage areas.

Floor Mounted KBK Rail Crane (1 Ton)

KBK Track Crane (1 Ton)

- Crane Features: Floor-mounted KBK cranes are supported by a track system installed directly onto the facility floor. These cranes provide flexibility and mobility, ideal for environments where ceiling installations are not feasible.

- Facility Features: Perfect for facilities with low ceilings, limited overhead space, or where additional structural support is required. Floor-mounted cranes work well in manufacturing or assembly lines that operate in open or spacious areas.

- Load Features: Handles light-duty lifting tasks up to 1 ton, providing reliable performance for smaller material or tool handling within confined or open spaces.

- Material Lifting Requirements: Ideal for tasks where materials need to be moved across the floor or at ground level. These cranes offer precise control for horizontal transportation and can handle materials that do not require significant vertical lifting.

- Coverage: The coverage area is determined by the length of the track and can be customized to fit the facility's needs. Floor-mounted systems can cover a broad horizontal area while allowing full access to the work area.

- Travelling Length: The crane travels along a fixed track, and the length can be extended as needed to meet the space requirements of the facility. It is adaptable to various layouts.

Truss KBK Rail Crane (1 Ton)

- Crane Features: The truss-mounted floor crane provides additional strength and stability compared to the standard floor-mounted design. This system features a more robust structure while still maintaining the flexibility to be installed in spaces with specific requirements.

- Facility Features: Ideal for large or heavy-duty applications where floor support is necessary. The truss design can accommodate heavier loads than the standard track crane, making it suitable for more demanding environments.

- Load Features: Capable of handling 1 ton loads with greater efficiency, providing stability when lifting larger or bulkier materials within a facility.

- Material Lifting Requirements: Suitable for medium-duty tasks requiring horizontal movement with moderate vertical lifting. The truss system provides added support for lifting heavier items.

- Coverage: Offers expanded coverage compared to standard floor-mounted systems, making it ideal for larger facilities or operations requiring wide-ranging material transport.

- Travelling Length: Similar to the standard track crane, the truss-mounted version allows for longer track lengths, offering extensive horizontal coverage within a facility.

Portable Crane

Design and Features: Portable cranes are designed for mobility, allowing them to be easily moved from one location to another. These cranes are often used for temporary lifting tasks or in areas where a permanent crane solution is not required.

Best for:

Workshops, maintenance areas, or temporary job sites where frequent relocation of the crane is needed. Portable cranes are ideal for light lifting tasks that require mobility and flexibility.

Key Benefits:

- Highly Mobile and Easy to Relocate: Can be moved quickly between different locations, ideal for temporary or flexible lifting needs.

- Suitable for Temporary Lifting Needs: Provides a convenient solution for short-term or occasional lifting.

- Cost-Effective for Occasional Use: Offers a lower-cost solution for lifting tasks without the need for a permanent installation.

Portable Crane Configurations for 1-Ton Loads

Portable cranes are ideal solutions for tasks requiring mobility, flexibility, and light lifting capacities. These cranes are particularly useful in workshops or temporary work sites where a permanent crane installation is unnecessary. Below is an overview of various 1-ton portable crane configurations, including both gantry and jib cranes, with or without battery-powered options.

Portable Overhead Crane (1 Ton) / Portable Gantry Crane (1 Ton)

- Crane Features: Portable overhead cranes, also known as portable gantry cranes, are designed with mobility in mind. These cranes are typically mounted on wheels, allowing them to be easily moved from one location to another. They are often used in workshops, warehouses, or manufacturing environments for short-distance material handling.

- Facility Features: These cranes are ideal for facilities with limited space or where cranes need to be used in various locations. The ability to move the crane around offers flexibility for businesses with changing lifting needs.

- Load Features: Capable of handling loads up to 1 ton, these cranes are perfect for lifting smaller items or materials such as tools, parts, or small equipment.

- Material Lifting Requirements: These cranes provide reliable lifting capabilities over short to medium distances, making them effective for tasks that don't require long-distance or heavy lifting.

- Coverage: The coverage is defined by the length of the rail system or tracks, allowing for flexibility in design. The portable gantry crane can cover a large area, depending on the setup and location.

- Travelling Length: The crane's ability to travel along a fixed track, or be moved manually to different locations, gives it exceptional versatility. It is perfect for areas where mobility is essential, and coverage may need to be adjusted based on specific tasks.

Battery-Powered Portable Gantry Crane (1 Ton)

- Crane Features: A battery-powered portable gantry crane offers all the mobility of a standard portable crane with the added advantage of powered lifting and movement. This crane operates without the need for an external power source, making it ideal for facilities where electrical outlets are not easily accessible.

- Facility Features: Perfect for temporary or mobile work sites, these battery-powered cranes can be used in a variety of locations, offering greater independence and flexibility for lifting tasks in remote or hard-to-reach areas.

- Load Features: Able to lift up to 1 ton, these cranes are suitable for lighter materials or equipment handling, such as tools, small machinery, or parts assembly.

- Material Lifting Requirements: These cranes are ideal for lifting items over short distances in confined or temporary spaces. The battery power ensures that they can operate without interruption, even in areas without power connections.

- Coverage: The coverage of battery-powered portable gantry cranes is typically determined by the length of the crane and track system. They are designed to move easily across a defined workspace.

- Travelling Length: With the added benefit of battery-powered mobility, these cranes can travel over short to medium distances, offering flexibility to move freely around a worksite.

- Crane Features: Portable jib cranes are compact, lightweight cranes mounted on a base that can be easily moved around a facility. The horizontal arm of the jib crane allows for precise lifting over a fixed radius, making them ideal for workstations or small, specialized tasks.

- Facility Features: These cranes are highly adaptable to a variety of spaces and are commonly used in smaller workshops, maintenance areas, or temporary setups. Their portable nature makes them easy to reposition based on changing tasks.

- Load Features: With a 1-ton lifting capacity, portable jib cranes are great for handling light materials, tools, or equipment at workstations.

- Material Lifting Requirements: Suitable for light lifting tasks, these cranes can handle materials with limited vertical lifting requirements. They are ideal for precise, controlled movements in confined spaces.

- Coverage: The coverage area of a portable jib crane is limited to the radius of its arm's movement, which can vary depending on the specific design of the crane.

- Travelling Length: These cranes are typically stationary at their base but can be repositioned by lifting the entire crane system to a new location. Some models offer additional mobility with wheeled bases.

Battery-Powered Jib Crane (1 Ton)

- Crane Features: Battery-powered jib cranes offer all the mobility and flexibility of a portable jib crane with the added convenience of battery-powered operation. This allows for effortless lifting and movement without needing external electrical sources.

- Facility Features: Ideal for workshops or mobile work sites where quick, efficient lifting is needed, especially in areas without easy access to electrical outlets. Battery-powered jib cranes offer the flexibility to be used in various locations across the facility.

- Load Features: Like their manual counterparts, battery-powered jib cranes are capable of lifting loads up to 1 ton. These cranes are perfect for handling tools, small parts, and equipment with ease and precision.

- Material Lifting Requirements: These cranes provide the necessary lifting capabilities for materials that require precision and moderate lifting, such as small equipment or assembly components.

- Coverage: The radius of operation depends on the arm length and the area in which the crane is used. Battery power ensures smooth, uninterrupted movement over moderate distances within the work area.

- Travelling Length: Battery-powered jib cranes are mobile and can be moved from one location to another, offering flexibility in their use. These cranes can be relocated easily based on changing tasks or project needs.

1 ton Overhead Crane Selection Based on Facility Features in Different Industrial Sectors

When selecting a 1 ton overhead crane, it's important to consider the specific needs and features of the facility. Here's a breakdown of crane recommendations based on various industrial sectors, including their suitability, crane features, and facility considerations:

Manufacturing Facilities

- Suggested Crane: Bridge Crane (Top Running or Under Running)

- Facility Features: Larger, open spaces with varying floor conditions, often requiring versatile movement across expansive production floors.

- Crane Features: Offers high flexibility, capable of handling materials and parts at various locations in the facility. It allows for precise movement and maximizes the use of the facility's height for lifting.

Warehousing and Logistics

- Suggested Crane: Gantry Crane or Monorail Crane

- Facility Features: High storage density with confined aisleways, and linear storage systems that demand efficient and reliable material handling across fixed routes.

- Crane Features: These cranes offer excellent flexibility, moving materials along defined paths and providing portability for adapting to layout changes. Ideal for optimized storage and quick access in high-density environments.

Construction Sites

- Suggested Crane: Portable Gantry Crane or Jib Crane

- Facility Features: Dynamic, outdoor environments that are constantly changing, often requiring mobility for lifting tasks. These cranes need to be mobile and adaptable to fluctuating job site conditions.

- Crane Features: Highly portable, these cranes are easy to move, making them perfect for construction sites that require frequent material handling over short distances. They offer flexibility to operate across different areas of the site as needed.

Workshops and Maintenance

- Suggested Crane: Jib Crane (Floor-mounted or Wall-mounted) or Under-running Bridge Crane

- Facility Features: Smaller, more confined spaces with dedicated workstations. These areas often need localized lifting solutions that don't require the large coverage area of other crane types.

- Crane Features: Offers precise, localized lifting, perfect for assembly, maintenance, and repair tasks. It allows workers to lift and maneuver equipment in tight spaces efficiently and safely.

Each industrial sector has unique requirements for overhead cranes, and choosing the right configuration depends on the size, layout, and function of the facility. From manufacturing and warehousing to construction and maintenance, selecting the appropriate crane ensures efficient workflow, safety, and productivity. By understanding the specific needs of the work environment, businesses can make informed decisions on crane types and configurations that will best suit their operational needs.

Crane Solutions for Specific Industries and Applications

Light Manufacturing and Assembly (Electronics, Textiles)

Typical Loads: Small components, electronic parts, textiles, and other lightweight materials, typically up to 1 ton.

Material Lifting Requirements: Requires precise lifting, gentle handling, and minimal disturbance to sensitive materials, often in confined spaces or tight aisles.

Recommended Crane Features:

- Monorail Cranes: Perfect for moving items along fixed, linear paths, ideal for narrow aisles and efficient in environments with limited space.

- Under-running Bridge Cranes: With their low profile, these cranes are space-efficient, making them an excellent choice for high-density areas where height and space are limited.

Automotive and Heavy Manufacturing

Typical Loads: Larger items such as engine parts, small assemblies, and heavy machinery components, all weighing up to 1 ton.

Material Lifting Requirements: Lifting tasks often involve large spans and heavy-duty lifting capacities to transport bulky components across expansive production floors.

Recommended Crane Features:

- Top-Running Bridge Cranes: These cranes are ideal for covering large production areas and handling heavy loads with ease, making them suitable for demanding manufacturing environments.

- Jib Cranes: Perfect for localized lifting tasks at workstations, providing precise and efficient handling for assembly or repair operations.

Outdoor Applications (Construction, Shipyards)

Typical Loads: Construction materials, heavy machinery parts, pipes, and large equipment found on outdoor job sites like construction zones or shipyards.

Material Lifting Requirements: Outdoor applications require cranes that can endure harsh conditions, including high winds, exposure to the elements, and rough handling.

Recommended Crane Features:

- Gantry Cranes (Portable or Fixed): Ideal for large outdoor spaces, gantry cranes are designed to move heavy loads across construction sites or shipyards with ease.

- Weatherproofing Features: Gantry cranes equipped with anti-corrosion coatings and rugged designs ensure durability and reliable operation in challenging weather conditions.

Hazardous or Corrosive Environments (Chemical Plants, Marine Operations)

Typical Loads: Chemicals, corrosive liquids, marine equipment, and sensitive materials that must be handled with care in volatile or hazardous settings.

Material Lifting Requirements: Safe handling of dangerous or corrosive materials is critical. Cranes must minimize risks like spills, exposure, and environmental contamination.

Recommended Crane Features:

- Explosion-Proof Cranes: Specifically designed to prevent sparks or accidental ignition in volatile environments, ensuring safe operation in hazardous areas.

- Anti-Corrosive Materials and Special Coatings: Cranes equipped with anti-corrosion treatments and specialized coatings provide durability in harsh marine or chemical environments, protecting against long-term damage from exposure to corrosive elements.

Choosing the right 1 ton overhead crane depends on your unique material handling requirements and the conditions in which the crane will operate. From light manufacturing environments where precision is key, to outdoor construction sites and hazardous environments that require specialized safety features, understanding the load types and crane characteristics for your industry ensures safe, efficient, and reliable lifting solutions. Tailoring your crane system to your specific needs not only boosts operational efficiency but also enhances safety and durability.

Facility Features to Consider When Selecting a 1 ton Overhead Crane

Selecting the right 1 ton overhead crane involves assessing various features of your facility to ensure the crane operates efficiently and safely. Key facility considerations include space, floor conditions, workflow, environmental factors, and crane portability.

Space Requirements

- Headroom and Clearance: The crane's lifting height and the available headroom in your facility are crucial. Underhung cranes are ideal for facilities with limited overhead space, while top-running cranes are better for taller buildings with more headroom.

- Floor Space: Consider the layout and available floor space. The crane should not only fit within the space but also allow for safe, efficient movement.

Floor Conditions

- Load-Bearing Capacity: Assess whether the floor can handle the crane's weight and the loads it will lift. This is especially important for gantry and mobile cranes that may exert more pressure on the floor.

- Environmental Conditions: Facilities like clean rooms or those with rough terrains require cranes with special considerations such as non-marking wheels or corrosion-resistant coatings.

Workflow and Production Layout

- Material Flow: Does your facility require linear movement for materials, or will the crane need to cover a large area? For linear movements, a monorail or gantry crane might be ideal, while a bridge crane offers more flexibility for extensive coverage.

- Long-Distance vs. Localized Lifting: Determine if the crane should travel across long distances or be stationed in one spot for localized tasks, which can influence whether a stationary jib crane or a more mobile overhead crane is the best option.

Environmental Conditions

- Exposure to Heat, Humidity, or Chemicals: Cranes operating in harsh environments, such as high temperatures or chemical plants, will need special protective coatings or corrosion-resistant materials.

- Specialized Coatings: Choose cranes with weatherproofing or anti-corrosion finishes for facilities exposed to elements that could degrade crane components over time.

Portability and Flexibility

- Portable Cranes: For temporary setups, or sites where the layout may change, portable gantry or jib cranes are the best choice. These cranes can be easily moved around and reconfigured as needed.

- Fixed Cranes: For more permanent, large-scale operations, top-running or under-running bridge cranes offer stability and durability for heavy-duty lifting tasks.

Conclusion: Matching Crane Features to Facility Needs, Send Us an Inquiry

When selecting a 1 ton overhead crane, evaluating your facility's space, floor conditions, workflow, and environmental factors is essential to ensure you choose the most efficient, safe, and durable crane for your specific needs.

1 ton overhead cranes offer a range of benefits that enhance efficiency, flexibility, and safety in industrial operations. Here's a summary of the key advantages:

- Space Optimization: Cranes like monorails, under-running systems, and jib cranes maximize vertical and linear pathways, making efficient use of available space, particularly in confined or crowded areas. This allows for effective material handling without consuming too much floor space.

- Flexibility and Adaptability: Cranes such as portable gantries and modular systems like KBK are highly customizable to meet specific facility needs. Their adaptability makes them ideal for dynamic environments where workflows, layouts, or material handling requirements change frequently.

- Improved Workflow and Efficiency: A well-chosen crane system streamlines material handling processes, reducing delays and downtime. Whether used in manufacturing, warehousing, or logistics, the right crane enhances productivity by ensuring fast, reliable, and efficient lifting operations.

- Safety and Durability: The selection of a crane tailored to your environment—whether for hazardous zones or outdoor applications—ensures a safer working environment. Specialized designs such as explosion-proof or corrosion-resistant cranes offer long-term durability, reduce maintenance costs, and enhance operational safety.

Choosing the right 1 ton overhead crane for your facility can significantly improve material handling, workflow, and safety. By understanding your space, operational needs, and environment, you can select a crane that not only meets immediate needs but also delivers long-term value.

Selecting the right 1 ton overhead crane is crucial for optimizing facility operations, ensuring safety, and maximizing productivity. It's important to consider key factors such as facility layout, space requirements, workflow, and environmental conditions when choosing the crane that best suits your specific lifting needs.

Final Recommendations: Contact Us to Get Your Inquiry

- Assess Facility Features: Take into account the available headroom, floor conditions, and the specific tasks required of the crane. For confined spaces or narrow aisles, a monorail or under-running crane may be ideal. For larger, open areas, a top-running bridge crane might be the best choice.

- Consider Flexibility: If your facility needs adaptability, a portable gantry crane or modular system like KBK offers flexibility and mobility for changing workflows.

- Match Crane Type with Tasks: Choose a crane that aligns with the material handling requirements—whether that's for precise, localized lifting at workstations (jib cranes), or for long-distance, large-area material movement (top-running bridge cranes).

- Plan for Safety and Durability: Make sure to select a crane that meets safety standards, particularly for hazardous environments, and choose materials that ensure durability in tough conditions, such as corrosion-resistant finishes for outdoor or chemical applications.

By carefully evaluating these factors, you'll not only improve workflow efficiency but also enhance safety and reduce maintenance costs, ensuring operational success in the long term.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch