Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Types of Low Built Overhead Cranes & Hoists for Sale

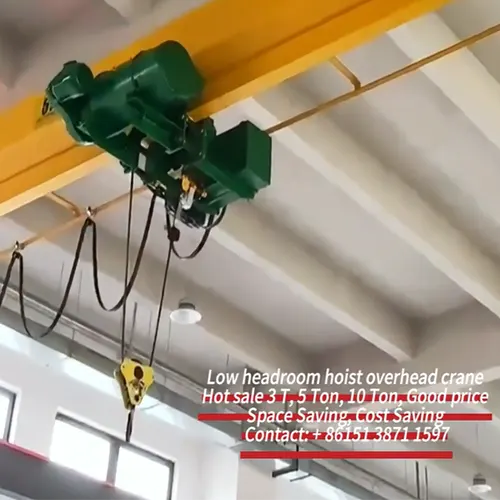

Low Headroom Design, Better Hook Height, Lower Building Cost, 3 Ton, 5 Ton, 10 Ton, 16 Ton 20 Ton, 30Ton, 50 Ton Crane for Your Benifit

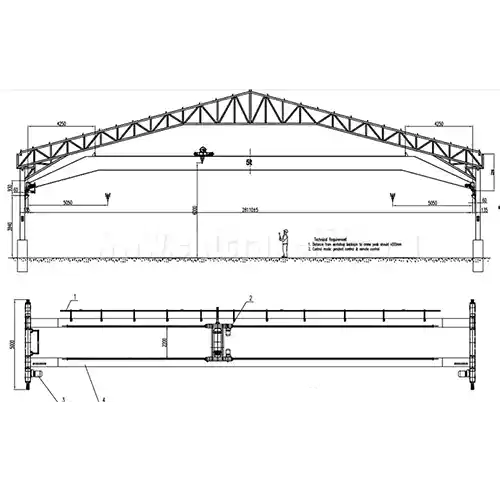

Workshops, warehouse and other facilities with low headroom may imply that employees can barely stand up straight and that material handling equipment may require additional space to function properly. The low built overhead crane and hoist system is a space-saving option that was primarily designed to provide the most vertical hook movement in tight spaces. By keeping the girder and rails at the same level, the low headroom crane is constructed to save space.

With the low profile crane and hoist system, you can construct a workspace with a great use-benefit over structural-cost ratio, where the assisting girder crane system really gets out of the way so the workstation can be more focused on meeting the operational need, even if your facility has no physical constraint in headroom. Therefore, the low clearance cranes are right for you if all you want to do is reduce visual stimuli, jagged edges, and moving parts to create a truly integrated facility. In both cases, this means creating a structure that is as flush with the ceiling as possible, which is ideal for flushing operations.

The low profile overhead cranes are routinely customized to adapt to low-overhead use. There are types of low headroom overhead crane for your selection. Typically, the low headroom bridge cranes are divided into single girder low headroom overhead crane, double girder low headroom overhead crane , and ceiling mounted low headroom underhung crane, etc.

Low headroom single girder overhead crane

Single girder low headroom cranes comes in various types and configurations, which different types of low headroom hoists. Fordifferent application conditions and lifting requirements,there are economical LD, LDP types of low headroom top running single girder overhead crane and advanced European style HD series of single girder bridge crane.

This class of lift equipment can be customized for low overhead use.

Single girder low headroom overhead crane 1 ton -32 ton HD

Low headroom bridge cranes with the European style designing features such as compact dimensions and low dead weight.

In comparison to traditional cranes, the limiting distance from hook to wall is the shortest, and headroom is the lowest, which makes the overhead cranes to operate closer to the wall and improves lifting height, which expands the usable workspace in your workshop and facility.

Economical single girder overhead crane with low headroom hoist LDA

Low headroom wire rope hoists are a new type of electric rope hoist that was developed on the basis of CD& MD electric wire rope hoists, with the same working conditions but more lifting height.

LDP types of single girder overhead crane with hoist trolley placed at one side of main girder

The low headroom bridge crane is intended for material handling and workshop applications with limited headroom. The overhead crane has a unique design. The electric hoist is installed on one side of the girder, increasing the lifting space of the hook. Customers can reduce building height and construction costs in this manner.

Comparisons of types of single girder overhead cranes and hoists

What is the difference between European style wire rope hoist and low headroom CD?

- The biggest difference between the two types of low headroom hoist is that the design standards are different. The design basis of the European style is the FEM European standard, and the low headroom CD is developed and designed on the basis of the CD;

Do the two types of low profile hoist need to run on the wider H-beam?

- The hoist beam width should be selected within the recommended range. If the width is smaller than the recommended width, there will be unbalanced problems such as hoist running and swinging.

Difference between HD European wire rope hoist crane and LDP Low headroom hoist crane?

- What is the difference in crane price? Which occasion is suitable forLDPpartial hanging hoist crane?The crane price of the two types of low headroom hoist cranes does not have much difference. Relatively, the LDP type low headroon single girder overhead cranes offer larger hook height,which isoptimal for the factory building with limited height.

- What is the capacity of the two types of low profile cranes? Both of the them is used for loads handling with capacity no more than 20 tons.

- For the same factory building height, which one has a higher lifting height?The LDP type low headroom bridge crane.

- Which one is better in terms of stress?The European style HD type low clearance overhead crane is better, the European style is a normal design, and the partial hanging style is a product developed due to the user's purchase budget and design conditions.

- Which one has the lower maintenance cost? European style low profile crane requires lower maintenance cost.

Hot sale HD type of low headroom overhead crane

Low clearance bridge cranes are a type of European crane with a low clearance height that can save warehouse height and help customers save money. The fem low clearance crane is built to European overhead crane standards that are widely accepted by European customers. European overhead crane is a new type of crane that originated in Europe (Germany, Italy and Finland). Dongqi Group is one of the few manufacturers with exclusive intellectual property rights and design.

FEM low clearance crane benefits

- European low clearance cranes are built with modest dimensions, light dead weight designing principles in mind.

- European low headroom overhead cranes have larger lifting heights, lower headroom, and the smallest limitation distance from hook to wall as compared to economical cd/md wire rope hoist cranes.

- An European low clearance crane could increase the workspace's productivity. As a result, the workplace might be constructed with fewer employees and more functions. Additionally, because the overhead crane's dead weight is less than it was previously, the low profile overhead travelling crane's wheel pressure is also reduced. The initial construction investment, long-term heating costs, air conditioning costs, and other maintenance costs, among other expenses, might all be lowered. ..

According to the information above, a European low built overhead crane is a wise choice for the client because it offers low headroom, a low investment, low production costs, and good performance efficiency.

Low headroom crane with underhung bridge crane design

Under-running cranes use end trucks that move on the crane runway's bottom flange and can be suspended directly from the overhead building structure without the use of interfering support columns. An under-hung crane system often weighs less than a top-running system, and a lengthy under-running system can readily use many runways to operate—even in very wide bays. This contributes to reducing the weight of the operational equipment and the depth of the bridge girder, lowering equipment expenses and lowering design specifications for the building or support structure.

Under-running bridge cranes are ideal for applications requiring overhead lift in a factory with limited factory space or low headroom. While low headroom top-running bridge cranes are built to lift heavy loads, under-running low headroom cranes are built with an ergonomic design that provides versatility and usability. Because under-running bridge cranes travel beneath the runway, you can maximize the distance between the ground and the hook.

Top running double girder overhead crane for low build workshop building

Double beam bridge crane with European style design can effectively use factory space, reducing headroom and limiting the distance between hook and two side walls. The European design concept reduces the overall weight of the crane and can significantly reduce plant costs.

Using advanced double speed control or frequency double speed control. Make the crane's start, acceleration, and deceleration more stable, and reduce the loaded goods swing as much as possible. Make loading positioning faster and more precise.

The ground control uses a suspension-type controller that is ergonomically designed. Operator control is possible from anywhere within the span range, which is crucial. The most secure and effective form of operation and control is wireless remote.

Custom low headroom bridge crane with the hoist trolley placed between the main girders

Low headroom workstation Bridge Cranes - ceiling mounted / Under Running Bridge Crane

Installing an overhead crane can be difficult if your facility has limited overhead space or has to deal with numerous overhead barriers. For applications requiring overhead lift in a building with restricted headroom, there are affordable solutions. Compared to top-running bridge cranes, enclosed track workstation bridge cranes are typically built to handle lesser loads. A workstation bridge crane with enclosed track is typically rated for loads up to 2 tons, therefore it might not be the best option for your application if heavy lifting is required.

Single beam underhung workstation bridge crane

A single girder underhung bridge crane combines the use of direct track standards with various auxiliary standards parts. The main beam is compatible with many electric chain hoists. The trolley is driven by a unique driving mechanism that allows it to turn, incline, and travel straight along the track. The 10m maximum span. The highest weight is 2000 kg.

Applications

modular design, light weight, affordable, enough space, and practical operation. It is frequently used in warehouses, workshops, and the machining industry.

Advantages

- The low headroom kbk track crane is suspended from the workshop's roof. Without a pillar, the space can be used to its greatest potential.

- Improve the use of plant space and reduce workshop costs.

- Lightweight construction that is simple to install and maintain.

- Low power and minimal energy usage.

- Light weight is more cost-effective and convenient to use.

Double beam underhung workstation bridge crane

Double beam workstation bridge crane are used for handling heavy loads with capacity up to 2 ton. To achieve the highest rate of lift control utilization, the hoist is positioned between the two major beam sections. They are frequently used to hoist heavier materials and spans with a wider span.

Advantages

Easy installation; reliability and durability; compact structure; light weight,·Wide application and·Good space utilization

Ceiling mounted low headroom monorail cranes and hoists

A ceiling mounted low headroom monorail crane is a type of crane that can take the place of conveyor belts and other common cranes. These cranes are typically used to move goods or commodities inside of a small space or limited space workshop. Such locations may be a factory or the entire workstation. The design of a monorail crane is simple and can be used without making significant adjustments to the building's structure.

The ceiling columns or an additional monorail beam to support the metal trolley can be used by the cranes to access the building or factory. Depending on the height of the building's ceiling and the desired lifting capacity, the trolley can either move along the beam or hanging below it. Steel cable or chain is used to attach a monorail crane hoist to the trolley, which lifts, lowers, and suspends the load to the desired spot.

With different lifting needs,the ceiling mounted monorail cranes can be designed to travel on straight and curved track or beams.

Low headroom jib cranes

Low headroom jib cranes are specifically designed to work in areas with low ceilings or height restrictions. They allow for easy handling of heavy items and can transport them to desired locations. Jib cranes designed for space-saving has to maximize the height of the attachment for the material handling . They are at right angles, as opposed to triangular jib cranes, which reduces the space required above and below the support. They can thus be integrated in confined work areas with limited available ceiling height while providing a high handling height.

They are available in wall-mounted or free-standing versions and can be customized to your work environment and other specific needs.

Freestanding low headroom jib crane

Normally installed to a concrete slab or floor structure. We can manufacture the low headroom floor crane to the exact dimensions required for the application. A dimensional drawing of low profile jib crane is developed for each project before fabrication to ensure that we always come up with the right solution.

Because this jib crane is at right angles rather than triangular, lifting devices for cardboard boxes, bags, or buckets can be hung at a higher level than standard jib cranes, resulting in a lower working height.

Manual handling assistance solutions can then be easily integrated into the most demanding environments.

Wall mounted low build & low headroom jib crane

The low headroom wall jib crane can often be supported by an existing wall or building structure, which is an option as a more affordable material handling solution in low ceiling workshops or limited space warehouses.

The low headroom wall mount jib crane is made to get around obstacles without compromising movement or quality.

Like all of our systems, it offers the highest level of protection and efficiency. Additionally, we take pride in providing you with a superior and continuously balanced trolley movement that results from our exact plum and level adjustments.

It's easy to install. Your support post or vertical structural beam can be quickly and easily fastened to our ground-breaking jib bracket system. Your column receives additional strength from this bracket system. Even if your column is out of plumb, you can plumb the jib using the double axis adjustment points.

The low headroom electric jib cranes are reliable and powerful. They can transfer cargo quickly and easily in a range of places, with a special emphasis on workspaces with little headroom or height limits. Manual handling operations with heavy loads are risky, and this is when risks and injuries start to show themselves. Jib Cranes are therefore needed to carry the weight, enhancing production and carrying out tasks that are too heavy for an individual to do.

Customized low headroom jib cranes are available. There are numerous options available to help with your application. Optional extras include motorized or manual hoists and trolleys, jib locks (single and multiple positions), slew limits, motorized slew, crane electrics, explosion protection, and custom paint systems. There are also zinc-plated and galvanised finishes available. Our technical sales representatives are available to audit your working environment in order to determine the best handling solution for your requirements.

Low headroom gantry crane for constrained space

Low headroom gantry cranes are designed to be simple and easy to use. They are ideal for various types of buildings and work areas, both indoors and outdoors, due to their specially designed steel structure. In terms of indoor use, a compact and low-profile hoist maximizes your

Low profile single girder gantry crane

The MH Model Low headroom gantry crane is designed and manufactured using advanced European style FEM standards. The single girder gantry adopts the European standard low profile electric wire rope hoist configuration, crane reducer hardened surface, driven by three-in-one driven system, PLC + Frequency Conversion control, improves the overall performance of crane operation with the low headroom crane design.

Low profile double girder gantry crane

Because of the low trolley position between the two main girders, double beam gantry cranes provided greater lifting height than single girder gantry cranes.

The Low Profile Double Girder Gantry Crane is built in accordance with FEM/DIN standards. It can be used with a larger lifting capacity, a higher working class, and more severe working conditions than a single girder gantry crane.

The low headroom double girder gantry crane is designed with advanced technology, based on international standards: FEM (Europe), DIN (Germany), ISO (International), and many advantages such as high rigidity, light dead weight, low power, outstanding structure design, and so on.

Portable gantry crane with low headroom hoist

Portable Gantry Crane can be moved freely on firm and smooth ground. It is an ideal option for all kinds of maintenance and assembling operation in workshop.

With low headroom hoist, the portable gantry crane are preferred for loads handling in workshops or workstation with capacity from 500kg - 10 ton.

For multipule purpose, the low headroom design portable gantry cranes can be designed with adjustable height to meet hook height in different application use.

Low Headroom Hoists

Low headroom electric hoists, with their compact structure, larger lifting height, and single and double lifting speeds, are widely used for general material handling in existing workshops with limited overhead clearance or newly built buildings where the low headroom hoists can increase the utilization rate of working space inside the workshops, reduce the blind area, lower workshop construction costs, and improve customer investment efficiency. The electric wire rope hoist crane, with its low profile and low clearance hoist design, will be a cost-effective overhead traveling solution for you!

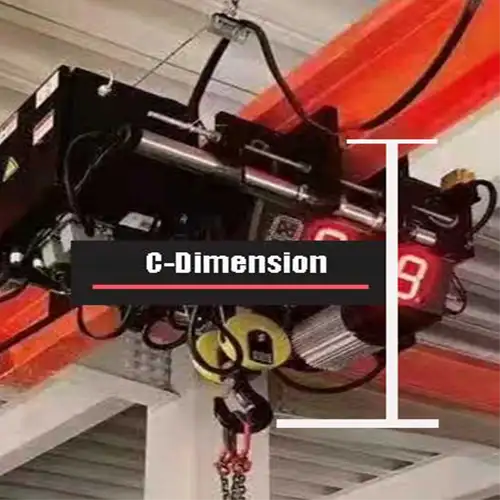

What is a hoist's headroom? Headroom is the distance between the suspension point of the hoist and the fully raised saddle of the hook. The distance between the saddles of the top hook and the fully raised lower hook is the headroom dimension of a hoist with top-hook suspension.

Types of low headroom hoists

single girder low headroom electric wire rope hoist ND

Low headroom manual chain hoist

Benefits of low headroom crane and hoist for new building

During the planning stage of a new building- When a new building is being planned, the use of low profile hoist and crane systems allow the structure's height to be reduced because they take up less space than standard hoists. This reduces the building's or structure's required height and save money on heating, materials, and air conditioning.

Benefits for low headroom crane and hoist existing workshops

When height becomes an issue in an existing building- A low headroom crane and hoist system is ideal when every centimetre counts for a building or structure. With this series, the load can be raised almost to the support beam. These low headroom hoists and cranes are made with cutting-edge technology and are capable of completing the tasks with ease.

Custom low headroom hoist and crane for your application

Howto select overhead cranes and hoistsfor low ceiling and low headroom workshops?When looking for the best cranes for low headroom applications, it's critical to work with a company that understands that there is no such thing as one-size-fits-all lifting equipment. That is why we work tirelessly with decision-makers to secure the hoist and crane equipment that overcomes space constraints and accomplishes the task in a cost-effective manner. If you are confronted with height restrictions, we are prepared to work with you to overcome these obstacles in order to increase profit-driving productivity.

What affect your selection of low headroom bridge crane and hoist?

- 1 Height from the ground to the lowest point of the workshop

- 2 Height or distance from the ground to rail top

- 3 Crane spans

- 4 The distance between the center of the track and the side of the factory building

- 5 lifting height

- 6 The model of crane travelling rail

- 7 The model of crane runway beam

Your Trusted Low Headroom Crane Manufacturer & Supplier