Low Profile 5 Ton Single Girder EOT Crane, Designs & Comparison

Low Profile 5 Ton Single Girder EOT Crane for sale: Custom designs optimized for tight spaces, offering efficiency, reliability & space-saving performance.

Category: Low Built Cranes & Hoists

Your Trusted Low Profile Overhead Crane Manufacturer & Supplier

Low Profile 5 Ton Single Girder EOT Crane, Designs & Comparison

Low Profile 5 Ton Single Girder EOT Crane for Sale: Custom designs optimized for tight spaces, offering efficiency, reliability & space-saving performance.

Overview of Low Profile Single Girder EOT Cranes

A low profile single girder EOT (Electric Overhead Traveling) crane is a type of overhead crane designed with a lower overall height, making it ideal for facilities with limited headroom. Unlike standard overhead cranes, these cranes have a single girder configuration and are specifically engineered to fit in tight spaces where traditional cranes might not be feasible.

In environments where ceiling height is restricted, such as older warehouses, small workshops, or facilities with low clearance areas, a low profile crane provides a practical solution. Its compact design allows for efficient material handling without requiring significant overhead space. This makes it possible to maximize the use of vertical space in a facility, improving overall operational efficiency and safety.

Significance of Custom Designs

Addressing Unique Facility Needs:

Custom designs for low profile single girder EOT cranes are essential for addressing specific needs of various facilities. Customization may include adjustments to the crane's height, load capacity, and span to perfectly match the unique dimensions and operational requirements of a given space. For instance, if a factory has an unusually low ceiling or specific load-handling needs, a custom-designed crane can be tailored to fit these constraints, ensuring that the crane operates effectively and safely within the available space.

Enhancing Operational Efficiency:

Customizing a low profile crane not only helps in accommodating physical constraints but also enhances operational efficiency. By designing the crane to fit precisely with the facility's layout, businesses can optimize their workflow, reduce downtime, and improve productivity. Custom features, such as specialized lifting gear or control systems, can be integrated to match specific tasks or processes, leading to smoother and more efficient operations. This tailored approach ensures that the crane performs at its best, providing reliable and effective material handling in a space-constrained environment.

Features of Low Profile 5 Ton Single Girder EOT Cranes

- Dimensions and Height Limitations:Low profile 5-ton single girder EOT cranes are designed with a compact profile to fit into environments with low ceiling heights. Typically, these cranes have a reduced overall height compared to standard models, making them suitable for facilities where vertical space is limite The design focuses on minimizing the distance from the crane's girder to the top of the lifting mechanism, which allows for effective use of the available headroom. This can range from just a few inches to several feet, depending on the specific design and customization.

- Load Capacity and Span:Despite their compact design, these cranes maintain a robust load capacity of up to 5 tons. They are capable of handling medium-sized loads efficiently. The span of the crane, which is the distance between its supports, is designed to suit the operational needs of the facility. The span can be customized to cover the required working area, ensuring that the crane can handle materials across the full width of the workspace.

Key Components

- Single Girder Structure:The single girder design of these cranes features a single horizontal beam that supports the loa This structure is more streamlined compared to double girder cranes, allowing for a lower profile and reduced overall height. The single girder is mounted on end trucks that travel along the rails, supporting the hoisting mechanism and providing stability.

- Hoisting Mechanism:The hoisting mechanism is a crucial component, responsible for lifting and lowering the loa In low profile cranes, this mechanism is designed to be compact yet powerful, enabling smooth and precise handling of materials. It typically includes an electric hoist with a gear system that offers reliable performance even in constrained spaces.

- Trolley and Traveling Systems:The trolley, which runs along the girder, supports the hoisting mechanism and allows it to move horizontally across the crane's span. The traveling system includes end trucks and wheels that facilitate smooth movement along the crane rails. These systems are designed for durability and ease of operation, ensuring that the crane can move loads efficiently across the workspace.

Advantages

- Space-Saving Benefits:One of the primary advantages of low profile cranes is their ability to maximize the use of available space. By reducing the overall height of the crane, facilities can utilize more of their vertical space for storage or other operations, which is particularly valuable in environments with limited headroom.

- Increased Headroom:The compact design of low profile cranes increases the available headroom beneath the crane, allowing for better clearance for machinery, workers, and materials. This is crucial for ensuring safe and efficient operation in facilities where vertical space is at a premium.

- Improved Operational Flexibility:Low profile cranes offer improved operational flexibility by fitting into tight spaces and providing the ability to handle loads efficiently within a confined are This flexibility allows businesses to adapt the crane's use to their specific needs, enhancing productivity and streamlining material handling processes in space-constrained environments.

Types of Low Profile 5 Ton Single Girder EOT Cranes

Standard Low Profile Single Girder EOT Crane with CD/MD Electric Hoist

Overview: The Standard Low Profile Single Girder EOT Crane with a CD/MD electric hoist is a widely used overhead crane in various industrial applications. The low-profile design ensures that the crane can operate efficiently in facilities with height restrictions.

Key Features:

- Low Profile Design: Optimized for facilities with limited headroom, allowing maximum lifting height within a restricted vertical space.

- CD/MD Electric Hoist: The CD (Single Speed) and MD (Double Speed) electric hoists offer reliable and efficient lifting. The CD hoist is suitable for general lifting, while the MD hoist provides more precise control with two-speed options.

- Compact Structure: The single girder configuration is lighter and less cumbersome, which reduces the overall load on the building structure.

- High Durability: Built with robust materials to withstand heavy industrial use.

Applications

- Manufacturing Facilities: Ideal for general material handling, assembly lines, and light to medium-duty lifting.

- Warehouses: Efficient for stacking and moving goods in spaces with low ceilings.

- Workshops: Suitable for lifting and transporting materials in maintenance and repair facilities.

LD Single Girder EOT Crane with Low Headroom Electric Hoist

Overview: This crane is specifically designed for applications requiring minimal headroom. The low headroom electric hoist is engineered to maximize the vertical lifting space.

Key Features:

- Low Headroom Hoist Design: The hoist is positioned in a way that minimizes the distance between the hook and the beam, allowing for more lifting height in environments with limited vertical space.

- Enhanced Safety Features: Includes overload protection, emergency stop, and smooth start/stop functions to ensure safe operation.

- Efficient Operation: The low headroom design improves efficiency in tight spaces, reducing the risk of collisions with the ceiling or other overhead obstructions.

- Customizable: Can be tailored to specific industrial needs, including load capacity, lifting speed, and control options.

Applications

- Automotive Industry: Used in assembly lines where space is constrained but precision is require

- Textile Industry: Suitable for moving large rolls of fabric in facilities with low ceilings.

- Tooling and Molding Shops: Ideal for handling heavy molds and tools within restricted spaces.

Single Girder EOT Crane with European Style Low Headroom Hoist

Overview: This crane features a European-style low headroom hoist, known for its compact, efficient design and superior performance. It combines the advantages of low headroom with advanced technology.

Key Features:

- European-Style Hoist: The hoist design is more compact and efficient, providing higher lifting capacities and better space utilization.

- Advanced Control Systems: Often includes features like variable frequency drives (VFD) for smooth and precise control over lifting and traveling operations.

- Energy Efficient: Designed to consume less power while delivering higher performance, which can result in long-term cost savings.

- Modern Aesthetics and Design: Offers a more streamlined and visually appealing design, often with improved ergonomics for operators.

Applications

- Precision Manufacturing: Used in industries like electronics or aerospace where high precision and reliability are critical.

- High-End Workshops: Ideal for high-value environments where both performance and aesthetics are important.

- Heavy Machinery Handling: Suitable for handling heavy and complex machinery with precision in tight spaces.

Single Girder EOT Crane with Underhung Bridge Crane Design

Overview: The Underhung Single Girder EOT Crane is designed with the bridge suspended from the bottom flange of the runway beams, allowing it to operate in facilities where the runway beams are mounted directly to the ceiling or roof structure.

Key Features:

- Underhung Design: Allows the crane to move along the bottom flange of the runway beam, maximizing floor space and providing more flexibility in the layout of the facility.

- Space Optimization: Ideal for environments with space constraints, as the crane does not require additional columns or support structures.

- Smooth Operation: The underhung design ensures smooth and quiet operation, reducing noise and vibrations.

- Versatility: Can be used in conjunction with monorail systems, making it adaptable to various industrial applications.

Applications

- Assembly Lines: Perfect for production lines where components need to be moved across different workstations.

- Warehouses: Efficient in storage facilities where floor space is a premium.

- Small Workshops: Suitable for workshops with limited floor space but requiring efficient material handling.

Custom Design Options

Tailoring for Specific Factory Requirements

- Custom Height Adjustments:Custom height adjustments are crucial for low profile cranes to fit specific facility constraints. Depending on the exact ceiling height and operational needs, the crane can be designed with a reduced vertical profile. This ensures that the crane operates efficiently within the available headroom while still providing adequate lifting capabilities. Custom height settings can be made to accommodate varying ceiling heights and other spatial restrictions, ensuring that the crane performs optimally in the given environment.

- Specialized Lifting Gear:To address unique operational needs, cranes can be equipped with specialized lifting gear. This includes custom hoists, trolleys, and other attachments tailored to handle specific types of loads or materials. For instance, a crane used in a food processing plant might require stainless steel lifting gear to prevent contamination, while a crane in a heavy manufacturing environment might need heavy-duty hooks and slings. Tailoring the lifting gear ensures that the crane can efficiently manage the specific materials and weights it will encounter.

- Adaptations for Unique Operational Needs:Crane designs can be adapted to meet specific operational requirements. This includes modifications such as adjustable lifting speeds, enhanced control systems, and additional safety features. For example, a crane operating in a high-temperature environment might require heat-resistant components, while a crane in a cleanroom might need features to minimize contamination risks. Custom adaptations ensure that the crane can meet the specific challenges of the operational environment.

Material and Construction Choices

- Corrosion-Resistant Materials:For environments exposed to moisture, chemicals, or harsh conditions, using corrosion-resistant materials is essential. Options include galvanized steel, stainless steel, and other treatments that protect against rust and deterioration. Corrosion-resistant materials extend the lifespan of the crane and reduce maintenance needs, making them ideal for applications in coastal areas, chemical plants, or other corrosive environments.

- Structural Reinforcement Options:Structural reinforcements are employed to enhance the crane's durability and load-bearing capacity. Reinforced girders, heavy-duty end trucks, and additional bracing can be incorporated into the design to support heavier loads or withstand more challenging conditions. These reinforcements are particularly useful in heavy-duty or high-stress environments, ensuring that the crane maintains its integrity and performance over time.

- Manual vs. Automated Controls:Crane control systems can be tailored to the operational preferences of the facility. Manual controls offer simplicity and direct operation, which can be advantageous in smaller or less complex operations. Automated controls, on the other hand, provide precision, reduce operator fatigue, and enable integration with advanced technologies such as load sensors and automated positioning systems. The choice between manual and automated controls depends on factors such as the complexity of operations, the need for precision, and the level of automation desire

- Integration with Existing Systems:Custom cranes can be designed to integrate seamlessly with existing systems in the facility. This includes linking the crane's control system with the facility's production line, inventory management systems, or other machinery. Integration enhances operational efficiency by allowing for coordinated operations and data sharing between systems. For example, a crane can be integrated with a warehouse management system to automate material handling tasks, improving overall workflow and reducing manual intervention.

Design Comparisons

Standard vs. Low Profile Designs

Key Differences in Structure and Function:

Structure:

- Standard Cranes: Typically feature a taller profile with a double girder or higher single girder design. They require more vertical space due to their height and larger hoisting mechanisms.

- Low Profile Cranes: Designed with a compact structure to fit in environments with limited headroom. The single girder configuration is optimized to reduce the crane's overall height and enhance space utilization.

Function:

- Standard Cranes: Suitable for environments with ample vertical space. They offer higher lifting capacities and broader spans but require more headroom.

- Low Profile Cranes: Ideal for confined spaces where vertical clearance is restricte They focus on maximizing operational efficiency in low-ceiling environments but may have reduced lifting heights and spans compared to standard cranes.

Pros and Cons of Each Design:

Standard Cranes:

- Pros: Greater lifting capacity, wider spans, and more robust structure. Suitable for heavy-duty applications and large facilities with adequate headroom.

- Cons: Not suitable for environments with limited ceiling height. Higher installation and maintenance costs due to larger size.

Low Profile Cranes:

- Pros: Efficient use of limited vertical space, increased headroom for operations, and better fit for small or older facilities. Lower installation and operational costs in constrained environments.

- Cons: Limited lifting height and span. May not handle as large or heavy loads as standard cranes.

Custom vs. Off-the-Shelf Solutions

Benefits of Custom Designs:

- Tailored Fit: Custom designs can be precisely engineered to meet the specific dimensions, load requirements, and operational needs of a facility.

- Enhanced Efficiency: Customization allows for the integration of specialized features, such as unique lifting gear or control systems, which can improve overall operational efficiency.

- Problem Solving: Custom cranes address unique challenges such as extreme space constraints or specific environmental conditions, offering solutions that off-the-shelf models cannot.

Cost Considerations and Lead Times:

Custom Designs:

- Cost: Generally higher due to bespoke engineering, design work, and material selection. Custom features and adaptations add to the overall expense.

- Lead Times: Longer lead times due to the design, manufacturing, and testing phases. Facilities must plan for extended delivery and installation periods.

Off-the-Shelf Solutions:

- Cost: Typically lower as they are mass-produced with standardized components. Economies of scale reduce the overall expense.

- Lead Times: Shorter lead times since these cranes are pre-designed and readily available. Faster delivery and installation are possible, making them suitable for urgent needs.

Design Philosophy

- Standard Low Profile Crane with CD/MD Hoist:Philosophy: Designed for general industrial applications where low headroom is needed but without extreme height restrictions.Structure: Compact and straightforward, using the well-established CD/MD hoist design.

- Low Headroom Crane with Specialized Hoist:Philosophy: Tailored for facilities where maximizing vertical lifting space is crucial due to severe height restrictions.Structure: Features a specialized low headroom hoist that minimizes the distance between the hook and beam.

- European Style Crane with Low Headroom Hoist:Philosophy: Combines compact design with advanced European technology for maximum efficiency and precision.Structure: Sleek, modern, and highly efficient, designed with a focus on reducing headroom while enhancing performance.

- Underhung Bridge Crane Design:Philosophy: Focuses on optimizing floor space by hanging the bridge from the runway beams, ideal for environments with limited floor space but standard headroom.Structure: The bridge is suspended from the bottom flange, freeing up floor space and integrating easily with monorail systems.

Space Utilization

- Standard Low Profile Crane: Optimizes the use of headroom, but not as efficiently as specialized low headroom cranes. Suitable for general purposes where space is a consideration but not the primary constraint.

- Low Headroom Crane: Superior in tight spaces, allowing for maximum lifting height. Ideal for environments with severe headroom restrictions, such as low-ceiling workshops.

- European Style Crane: Best in class for minimizing headroom usage while maintaining high performance. Suitable for modern, high-tech facilities with tight space constraints. Underhung Bridge Crane: Excels in maximizing floor space by using underhung design, particularly in facilities where ground space is at a premium.

Operational Efficiency

- Standard Low Profile Crane:Efficiency: Reliable and cost-effective for general industrial tasks. Uses a standard CD/MD hoist for consistent performance with basic control options.

- Low Headroom Crane:Efficiency: Designed for efficiency in height-constrained environments. Offers improved safety and smoother operation through specialized hoist features like smooth start/stop functions.

- European Style Crane:Efficiency: Highly efficient with advanced control systems, such as VFD, providing precise and smooth operations. Energy-efficient, reducing long-term operational costs.

- Underhung Bridge Crane:Efficiency: Offers efficient use of space and integrates well with other systems, though its performance is optimized for lighter loads and specific layouts.

Customization and Adaptability

- Standard Low Profile Crane:Offers standard customization options to suit a variety of industrial applications. Versatile but not specialize

- Low Headroom Crane:Highly customizable for specific headroom constraints. Adaptable to tight spaces with a range of load capacities.

- European Style Crane:Extensive customization options, including advanced hoist features, control systems, and energy-saving designs. Suited for high-end, specialized applications.

- Underhung Bridge Crane:Customizable based on the facility's layout and specific material handling needs. Often used in conjunction with monorail systems for complex setups.

Typical Applications

- Standard Low Profile Crane: Manufacturing, warehouses, and workshops where headroom is a concern but not critical. General-purpose material handling.

- Low Headroom Crane: Automotive and textile industries, tooling shops, and other environments with significant headroom constraints. Precision material handling in tight spaces.

- European Style Crane: High-tech manufacturing, aerospace, and electronics industries where space efficiency and precision are paramount. Heavy machinery handling in constrained spaces.

- Underhung Bridge Crane: Assembly lines, small workshops, and warehouses with limited floor space. Often integrated into monorail systems for material transport.

Cost Considerations

- Standard Low Profile Crane:Cost: Cost-effective for general use. Lower initial investment with standard features and reliable performance.

- Low Headroom Crane:Cost: Slightly higher cost due to the specialized design of the low headroom hoist. Justified by the efficiency gains in constrained spaces.

- European Style Crane:Cost: Higher initial investment, reflecting advanced technology and energy efficiency. Long-term savings due to reduced energy consumption and enhanced performance.

- Underhung Bridge Crane:Cost: Moderate cost with significant space-saving benefits. Particularly efficient in maximizing facility layout and workflow.

Installation Complexity

- Standard Low Profile Crane:Installation: Standard installation process, compatible with most facilities. Typically straightforwar

- Low Headroom Crane:Installation: Requires careful planning to accommodate height constraints. More complex due to specialized hoist placement.

- European Style Crane:Installation: May require specialized knowledge due to the advanced hoist and control systems. Installation can be more complex.

- Underhung Bridge Crane:Installation: Installation can be complex, especially when integrated with monorail systems or existing structures. Requires precise alignment.

Project Comparison: Choosing the Right Single Girder Overhead Crane for a Low, Limited-Height Space

When dealing with a low-height factory space, achieving an optimal lifting height and crane performance involves evaluating several types of single girder overhead cranes. This comparison helps in selecting the most suitable crane solution based on price, lifting height, space utilization, and post-sale maintenance.

A Case Study on Single Girder Overhead Cranes 5 Ton in Low-Height Factories

Low-height factories face unique challenges when it comes to selecting overhead cranes. The primary issue is fitting a crane into a factory with limited vertical space, which can restrict the lifting height and overall functionality of standard overhead cranes. These constraints make it crucial to find a crane solution that not only fits within the available space but also meets the operational needs of the factory. Standard cranes may not always be suitable due to their height or structural requirements, making customization a key consideration.

Single girder overhead cranes are often the preferred choice in such environments due to their simpler and more compact design compared to double girder cranes. However, even single girder cranes must be tailored to handle the specific limitations of low-height factories. This requires an understanding of various factors, such as the crane's lifting height, span, and overall dimensions, to ensure optimal performance and space utilization.

Factory Situation Analysis

Client Inquiry

The client approached us with a request to supply six 5-ton single girder overhead cranes for their manufacturing facility. Their requirement was driven by the need to enhance operational efficiency within their existing workshop setup. The cranes were intended for use across one of the factory spans, highlighting the need for precision in customization to meet both their lifting and spatial constraints.

Factory Constraints

The factory presented a significant challenge due to its low height. Specifically, the minimum height from the ground to the roof's lowest point was 5175 mm. This limitation necessitated a careful evaluation of crane options to ensure they would fit within this restricted vertical space while still delivering the required performance.

Key Data Points

- Lifting Capacity:The lifting capacity defines the maximum weight the crane can handle. For this project, the cranes needed to have a lifting capacity of 5 tons to match the client's operational needs.

- Lifting Height (H):Lifting height refers to the distance from the hook center to the groun In this low-height factory, achieving an adequate lifting height was critical to ensure that the cranes could lift loads effectively without obstruction. The available space between the factory's roof and the ground limited the maximum lifting height, influencing the design of the crane.

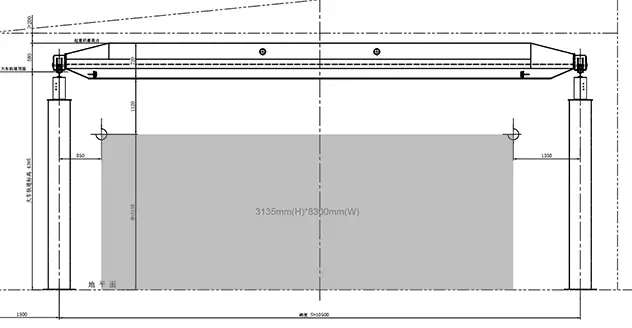

- Span (S):The span is the distance between the two runway tracks where the crane travels. It determines the width of the area that the crane can cover. For the client's workshop, the span needed to accommodate the layout and ensure the crane could reach all necessary work areas.

- Crane Traveling Length (L):This is the distance the crane can travel along the runway tracks. The length of crane travel impacts how effectively the crane can cover the entire working are For this project, the crane was required to cover a running distance of approximately 50 to 60 meters, aligning with the factory's operational requirements.

These key data points guided the selection and customization of the single girder overhead cranes, ensuring that they would meet the factory's specific needs while accommodating the constraints of the low-height environment.

Solution Matching

Crane Types Considered

- Single Girder Electric Overhead Traveling Cranes (EOT Cranes):These cranes are a common choice for various industrial applications. They feature an electric hoist that runs along a single girder, providing reliable lifting and traveling capabilities. However, the standard design may not always be ideal for low-height factories due to the height of the hoist and its components.

- Low Headroom Single Girder Overhead Cranes:Designed specifically for environments with restricted vertical space, low headroom cranes are engineered to maximize lifting height by reducing the overall height of the crane system. This type is particularly suited for factories with minimal overhead clearance, making it a viable option for the client's low-height facility.

- FEM/DIN Type Single Girder Overhead Cranes:The FEM/DIN design incorporates European standards for higher performance and durability. These cranes are known for their robust construction and ability to handle varying load capacities. They often feature more compact hoist designs, allowing for greater lifting heights in restricted spaces.

Customization Considerations

To address the client's specific requirements, detailed drawings and specifications were prepared for each crane type:

Single Girder Electric Overhead Traveling Cranes (EOT Cranes):

Specifications:- Lifting Capacity: 5 tons

- Span: 10.5 meters

- Lifting Height: 3135 mm

Adjustments included optimizing the hoist and bridge structure to fit within the factory's height constraints while ensuring effective performance.

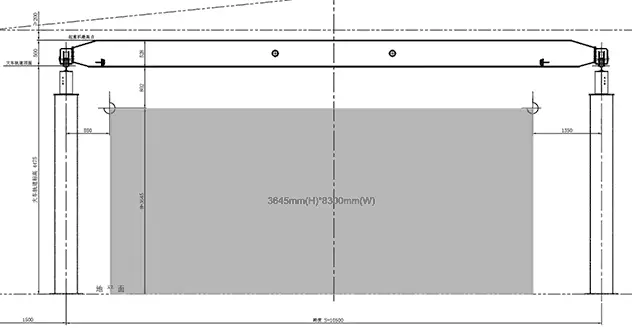

Low Headroom Single Girder Overhead Cranes:

Specifications:- Lifting Capacity: 5 tons

- Span: 10.5 meters

- Lifting Height: 3645 mm

Focused on reducing the crane's height through a low headroom hoist design, allowing more efficient use of the available vertical space.

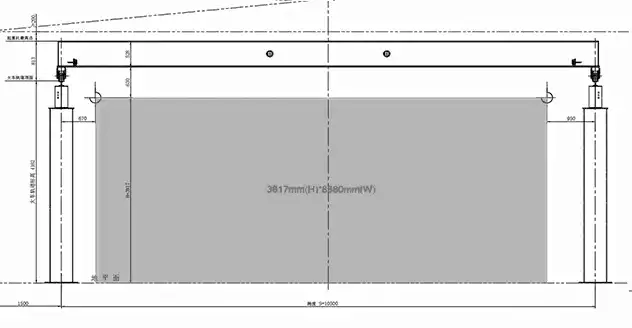

FEM/DIN Type Single Girder Overhead Cranes:

Specifications:- Lifting Capacity: 5 tons

- Span: 10.5 meters

- Lifting Height: 3817 mm

Included advanced design features to maximize lifting height and ensure compliance with high-performance standards. This crane type offered the highest lifting height among the options considere The customization process involved analyzing the factory's dimensions and constraints to determine the most suitable crane type. Each option was evaluated for its ability to fit within the limited vertical space while meeting the operational requirements of the workshop. This thorough assessment ensured that the selected crane design would provide optimal performance and efficiency in the low-height factory environment.

Scheme Analysis

Price Comparison

Single Girder EOT Cranes:

- Cost: $2700.00 per set

- Features: Basic design with standard hoisting mechanisms, suitable for factories with moderate height requirements.

- Pros: Cost-effective solution with straightforward design and installation.

- Cons: Limited headroom and height adjustments compared to other options.

- Cost: $3100.00 per set

- Features: Designed specifically for low-height spaces, providing better headroom and maximizing lifting height.

- Pros: Optimal for environments with restricted vertical space. Higher lifting height compared to standard EOT cranes.

- Cons: Higher initial cost compared to standard EOT cranes.

- Cost: $6000.00 per set

- Features: Advanced design adhering to European standards, offering the highest lifting height and enhanced performance.

- Pros: Superior construction, durability, and lifting capabilities, suitable for more demanding applications.

- Cons: Higher cost and potentially over-specified for some low-height environments.

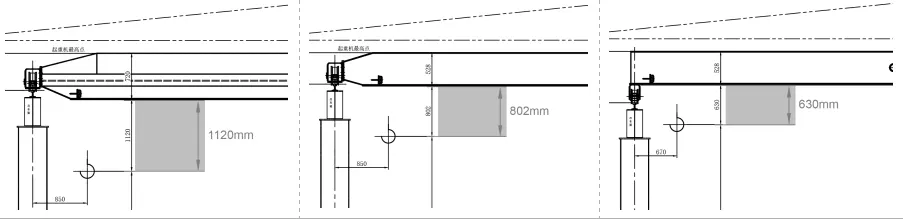

Headroom Lifting Height Comparison for Electric Hoists

Headroom Lifting Height Comparison for Electric Hoists

- CD Type Wire Rope Electric Hoist: 1120mm

- Low Headroom Type Wire Rope Electric Hoist: 802mm

- Euro-Type Wire Rope Electric Hoist: 630mm

The differences in headroom lifting height are due to the structural design variations:

- CD Type Hoist: Trolley wheels are positioned at the top of the hoist structure.

- Low Headroom and Euro-Type Hoists: Trolley wheels are positioned in the middle of the hoist structure.

The elevated trolley wheel placement in the CD type hoist allows the hoist body to rise above the main beam, thereby increasing the lifting height of the single girder overhead crane.

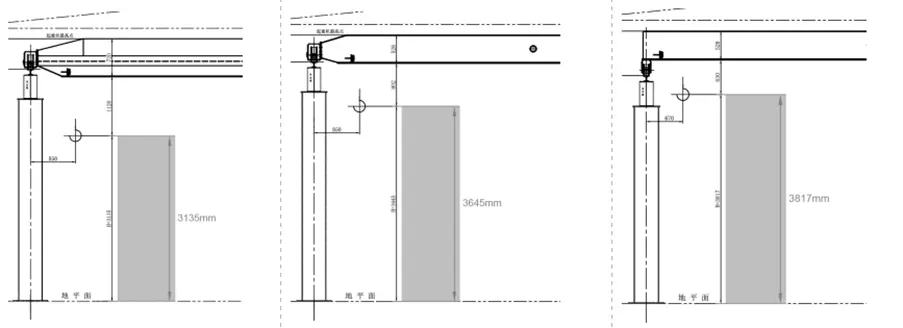

Lifting Height Comparison

Lifting Height Comparison

Single Girder EOT Crane:

- Lifting Height: 3135 mm

- Description: Provides a standard lifting height suitable for typical industrial needs but may be limiting for very low-height spaces.

Low Headroom Crane:

- Lifting Height: 3645 mm

- Description: Offers a greater lifting height within constrained vertical space, making it a better fit for low-height factories.

FEM/DIN Crane:

- Lifting Height: 3817 mm

- Description: Maximizes lifting height with advanced design features, ideal for environments where every millimeter of headroom counts.

Working Coverage

Single Girder EOT Cranes:

- Coverage: Typically designed to cover the span of the factory, with operational ranges extending to both extreme left and right positions.

- Operational Range: Adequate for general tasks but limited in terms of flexibility compared to low headroom or FEM/DIN designs.

Low Headroom Cranes:

- Coverage: Similar to EOT cranes but with enhanced operational range due to optimized headroom design.

- Operational Range: Allows for more efficient coverage of the workspace, especially in confined areas.

FEM/DIN Low Headroom Single Girder EOT Cranes:

- Coverage: Extensive coverage capabilities with robust design, suitable for handling larger or more complex operations.

- Operational Range: Provides the greatest flexibility and reach, accommodating a wide range of operational needs.

Post-Sale Maintenance Requirements

Single Girder EOT Cranes:

- Brake Inspection: Regular checks to ensure braking system functionality.

- Fault Code Display and Troubleshooting: Basic fault indicators for easier troubleshooting.

- Motor and Cable Management: Standard maintenance practices to ensure longevity.

Low Headroom Cranes:

- Brake Inspection: Similar maintenance needs as standard EOT cranes, with additional focus on compact design features.

- Fault Code Display and Troubleshooting: Enhanced diagnostic tools to address more complex issues related to headroom design.

- Motor and Cable Management: Requires careful management due to the compact design.

FEM/DIN Cranes:

- Brake Inspection: Comprehensive maintenance to ensure performance meets high standards.

- Fault Code Display and Troubleshooting: Advanced diagnostic systems for efficient troubleshooting and maintenance.

- Motor and Cable Management: High-quality management systems to maintain optimal performance in demanding environments.

This scheme analysis provides a detailed comparison of the crane types, focusing on their price, lifting height, operational range, and maintenance requirements. It helps in evaluating the most suitable option based on cost-effectiveness, operational needs, and long-term maintenance considerations.

Conclusion and Recommendations

Price vs. Performance:

- Cost-Effective Solution: The single girder EOT crane offers the most economical option.

- Best Lifting Height: Low headroom and FEM/DIN cranes provide superior lifting heights, with FEM/DIN cranes offering the highest.

Space Utilization:

- Maximum Coverage: The FEM/DIN crane excels in covering a larger working are

Maintenance Considerations:

- Lower Maintenance Needs: FEM/DIN cranes require less frequent maintenance and offer advanced features, though they are more expensive.

Client Decision: Given the client's low frequency of use and focus on pricing and lifting height, the low headroom single girder overhead crane was chosen for its balance between cost and performance. A contract for 6 sets was signe

Installation and Maintenance

Installation Considerations

Site Preparation:

Before installing a low profile 5-ton single girder EOT crane, thorough site preparation is essential to ensure a smooth and successful installation. Key steps include:

- Structural Assessment: Evaluate the existing building structure to confirm that it can support the crane and its loa This may involve checking the ceiling's load-bearing capacity and ensuring that any necessary reinforcements are in place.

- Space Evaluation: Measure the available headroom and workspace to ensure the crane will fit correctly and operate efficiently within the given dimensions. This includes accounting for both the crane's dimensions and the space needed for movement.

- Ground and Floor Conditions: Ensure that the installation area has a stable and level floor that can support the crane's base and rails. Any necessary adjustments or reinforcements should be completed before crane installation.

Installation Process and Timeframes:

The installation process typically involves several key stages:

- Delivery and Unpacking: The crane components are delivered to the site and unpacke It's important to inspect all parts upon arrival to ensure they are in good condition and match the specifications.

- Assembly: The crane's main components, including the girder, hoist, trolley, and end trucks, are assembled according to the manufacturer's instructions. This may involve bolting together parts, setting up the hoisting mechanism, and attaching the trolley system.

- Mounting and Alignment: The crane is mounted on the rails or support structure. Proper alignment is crucial to ensure smooth operation and prevent mechanical issues. This involves adjusting the crane to ensure it runs correctly along the rails and that all components are level.

- Testing: Once assembled and mounted, the crane undergoes a series of tests to verify its performance. This includes checking the hoisting mechanisms, control systems, and overall functionality to ensure that it operates as expecte

The timeframe for installation varies based on factors such as the complexity of the crane, site conditions, and the experience of the installation team. Typically, installation can take from a few days to a couple of weeks.

Maintenance Requirements

Routine Maintenance Tasks:

Regular maintenance is essential to keep the crane in optimal condition and ensure safe, reliable operation. Key routine maintenance tasks include:

- Inspection: Regularly inspect all crane components, including the girder, hoisting mechanism, trolley, and end trucks. Check for signs of wear, damage, or misalignment.

- Lubrication: Ensure that all moving parts, such as the hoist gears, trolley wheels, and rail systems, are properly lubricated to reduce friction and prevent wear.

- Cleaning: Keep the crane and its components clean to prevent the buildup of debris and contaminants that could affect performance. This includes cleaning the rails, hoist, and control systems.

- Functionality Checks: Test the crane's controls and safety features regularly to ensure they are functioning correctly. This includes checking emergency stop buttons, limit switches, and other critical safety systems.

Common Issues and Troubleshooting:

Despite regular maintenance, some common issues may arise with low profile cranes. Troubleshooting these issues involves identifying the problem and implementing appropriate solutions:

- Unusual Noises: Grinding or squealing noises can indicate worn bearings or misaligned components. Inspect the affected parts and replace or adjust them as necessary.

- Operational Irregularities: If the crane is not operating smoothly or exhibiting jerky movements, check for issues with the hoist mechanism, trolley alignment, or rail systems. Adjustments or repairs may be neede

- Electrical Problems: Malfunctions in the control system or electrical components can disrupt crane operation. Check connections, fuses, and control panels for faults, and address any electrical issues promptly.

- Load Handling Issues: Difficulty in handling loads or uneven lifting may result from issues with the hoisting system or load distribution. Inspect the hoist, cables, and load hooks to ensure they are functioning correctly and are not damage

Effective maintenance and prompt troubleshooting help extend the lifespan of the crane and ensure its safe and efficient operation in the facility.

Conclusion

Summary of Key Points

Recap of Features and Benefits:

Low profile 5-ton single girder EOT cranes are designed to excel in environments with restricted headroom, offering several distinct advantages:

- Space-Saving Design: These cranes maximize operational efficiency in low-ceiling environments by reducing vertical space requirements.

- Customization Options: Tailoring the crane to specific facility needs enhances functionality and accommodates unique operational requirements, such as specialized lifting gear or corrosion-resistant materials.

- Varied Types: Different types of low profile cranes—standard, ultra-low, heavy-duty, and compact—address a range of applications and environments, from extremely tight spaces to heavy-duty industrial settings.

These features ensure that low profile cranes provide reliable performance while adapting to specific spatial and operational constraints, improving both space utilization and operational efficiency.

Importance of Customization:

Customization plays a crucial role in optimizing crane performance for specific applications. By addressing unique facility constraints and operational needs, customized cranes offer improved functionality, efficiency, and safety. This tailored approach ensures that the crane not only fits perfectly within the given space but also meets the precise requirements of the facility's operations.

Recommendations

Choosing the Right Design for Your Needs:

When selecting a low profile 5-ton single girder EOT crane, consider the following factors to ensure you choose the most suitable design:

- Headroom and Space Constraints: Assess the available vertical space in your facility. If headroom is extremely limited, an ultra-low profile crane may be necessary. For more general low-profile needs, standard low profile designs might suffice.

- Load Requirements: Evaluate the types of loads you need to handle. For heavier loads or harsh environments, a heavy-duty crane with reinforced components may be appropriate. For compact spaces with lighter loads, a compact low profile crane could be ideal.

- Customization Needs: Determine if your facility requires specific customizations, such as specialized lifting gear, corrosion-resistant materials, or unique control systems. Custom designs can provide enhanced performance and address specific operational challenges.

Factors to Consider in Decision-Making:

- Budget: Consider the total cost, including initial purchase, installation, and ongoing maintenance. Custom cranes typically involve higher upfront costs but can offer long-term benefits and efficiency improvements.

- Lead Time: Factor in the time required for custom design and installation. Off-the-shelf solutions offer quicker delivery but may not meet all specific needs.

- Future Needs: Think about potential future changes or expansions in your facility that might affect crane requirements. Opting for a flexible design or customization can help accommodate future needs.

By carefully evaluating these factors, you can make an informed decision that ensures the selected crane design aligns with your facility's operational requirements and maximizes both efficiency and safety.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch