Low Headroom Hoist 10 Ton Gantry Crane for Low Ceiling Workshops

Low profile gantry crane for sale. Compact gantry crane with integrated hoist trolley for efficient heavy lifting & space-saving in low-ceiling workshops.

Category: Low Built Cranes & Hoists

Your Trusted Low Headroom Gantry Crane Manufacturer & Supplier

Optimized 10-Ton Gantry Crane for Low Ceiling Workshops

A compact gantry crane with integrated hoist trolley designed for efficient heavy lifting and space-saving in low-ceiling workshops.

Introduction of Case Study on Low Headroom Gantry Crane 10 Ton

In workshops with low ceilings, regular lifting equipment often doesn’t fit or doesn’t work well. This case study looks at the need for better lifting solutions in these tight spaces. Specifically, we focus on the 10-ton gantry crane with an integrated hoist trolley. This crane system is designed to maximize space while providing the lifting power needed in low ceiling environments.

- Optimizing space: Workshops need equipment that works well in tight areas.

- Efficiency: Lifting solutions must save time and reduce strain on workers.

The 10-ton gantry crane offers a simple yet effective way to solve these problems. It’s designed to fit into smaller spaces without sacrificing lifting capacity. This makes it an excellent choice for workshops that face ceiling height restrictions.

Relevance of Low Ceiling Workshops

Low ceiling workshops come with a number of challenges. Limited vertical space means it’s hard to lift heavy loads or move equipment around efficiently. Traditional overhead cranes can’t always be used in these spaces, leading to inefficiency and frustration.

- Space constraints: There isn’t enough height for traditional cranes.

- Limited lifting options: Workers struggle to move heavy loads or work in tight areas.

The 10-ton gantry crane is specifically designed to overcome these challenges. Its compact design fits comfortably in low ceiling environments, and its integrated hoist trolley allows smooth lifting and movement, even in tight spaces.

By using a gantry crane, businesses can make the most of their available space, keep workflows moving, and maintain high productivity despite the spatial constraints. The gantry crane brings flexibility, power, and efficiency to workshops with low ceilings.

Background

Overview of Gantry Cranes

Gantry cranes are a type of lifting equipment used to move heavy loads. They consist of a bridge that is supported by two legs, which run along tracks on the ground. The crane can move along these tracks to pick up and drop off items in various locations.

- Basic function: Gantry cranes lift and transport heavy loads within a set area.

- Design: The bridge structure moves along a set path, allowing flexibility in lifting.

This type of crane is known for its ability to carry heavy loads over short or long distances. Unlike other cranes, gantry cranes are often used in open spaces, where they can cover large areas or in smaller spaces like workshops, where they need to fit under low ceilings.

Evolution and Advantages of Gantry Cranes in Industrial Settings

Gantry cranes have been around for decades, with early versions used in shipyards and large manufacturing plants. Over time, the design and materials have improved, making these cranes more versatile, durable, and safer to use.

- Early use: Initially, gantry cranes were used in large industries like shipbuilding.

- Modern improvements: Today’s gantry cranes are lighter, stronger, and more adaptable for various industries, including small workshops with low ceilings.

The key advantage of gantry cranes is their flexibility. They can be adapted for different environments and lifting tasks, from outdoor construction sites to tight indoor workshops. The ability to customize the crane size and hoist features makes them especially useful in industrial settings where space and safety are concerns.

Challenges in Low Ceiling Environments

Low ceiling environments present several challenges when it comes to lifting heavy loads.

- Reduced lifting height: The most obvious issue is the lack of vertical space. Traditional cranes require significant overhead room to operate, and in a low ceiling workshop, this can limit how high you can lift objects or how big the loads can be.

- Spatial limitations: Workshops with low ceilings often have limited floor space as well. This means that not only do the cranes need to fit under the ceiling, but they also need to operate in tight, confined spaces without restricting access or movement.

- Safety concerns: When working in low ceiling environments, safety becomes a major concern. Limited visibility, restricted movement, and tight working conditions can increase the risk of accidents. It's crucial that the crane is designed to minimize these risks and operate smoothly in confined spaces.

The 10-ton gantry crane addresses all of these issues. It’s designed to fit comfortably in these low ceiling environments while providing the lifting power and safety features needed for efficient operation.

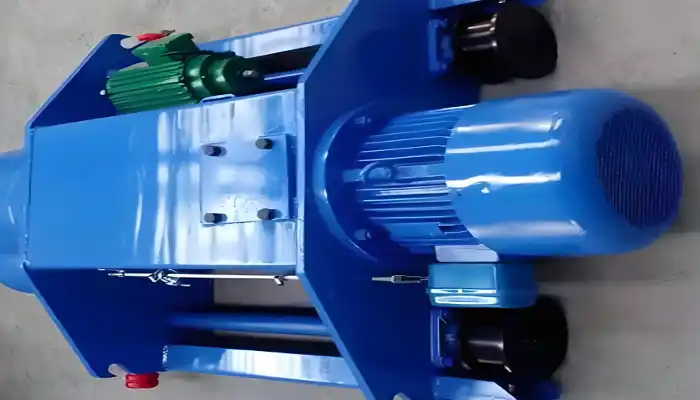

Design and Features of the 10 Ton Gantry Crane

Gantry Crane Structure

The design of the 10-ton gantry crane is tailored to function in low ceiling environments. Here’s how it’s structured:

- Compact Design: The crane’s height is minimized to fit in workshops with limited overhead space, while still maintaining lifting capacity.

- Narrow Legs: The crane’s legs are designed to be narrow, ensuring it fits easily in tight spaces without compromising stability.

Material Considerations:

- High-strength steel: The crane is made from steel, known for its strength and ability to support heavy loads without adding unnecessary weight.

- Reinforced joints: The joints and beams are specially reinforced to maintain structural integrity even when carrying heavy loads in confined spaces.

This design allows the crane to deliver high performance while ensuring it doesn’t take up more space than necessary in a low-ceiling workshop.

Purpose and Function: The hoist trolley is the heart of the crane, responsible for lifting and lowering the load. It moves along the crane's bridge to carry the hoist, offering smooth and precise movement.

Efficient Operation in Tight Spaces:

- The hoist trolley allows the crane to operate in confined spaces by moving the load across the full length of the bridge.

- Its integration with the crane helps save space and allows for better load control, even when space is limited.

By combining the gantry crane with the hoist trolley, this system works efficiently in tight areas, offering reliable lifting power without taking up too much room.

Safety Features

Safety is built into every aspect of the 10-ton gantry crane, especially for operation in low-ceiling environments where space can be a concern.

Load Limiters and Overload Protection:

- The crane is fitted with load limiters to ensure it doesn’t lift more than its rated capacity, preventing overloading.

- Overload protection safeguards both the crane and the load, ensuring smooth operation without risking damage.

Emergency Stop Systems:

- Emergency stop buttons are easy to access, allowing operators to halt the crane quickly if needed.

- These systems are a vital safety feature, ensuring a fast response in case of any operational issues.

Operator Safety:

- The crane includes safety features like operator cabins or remote control systems for improved visibility and safer control of the crane.

- Protective barriers and safety rails ensure the safety of operators during lifting operations.

With these safety features, the 10-ton gantry crane is designed to provide secure and efficient lifting in low ceiling workshops, prioritizing both performance and safety.

Operational Efficiency

Space Optimization

The 10-ton low headroom crane is designed to make the most of limited space in low-ceiling workshops. Here’s how it does it:

- Compact Design: The crane's low profile ensures it fits under low ceilings, maximizing the available vertical space. This allows for higher lifts and better use of the full height in the workshop.

- Efficient Movement: The hoist trolley moves smoothly along the bridge, allowing it to cover a large area without requiring excessive space. The narrow legs also help reduce the amount of floor space the crane occupies.

- Space-Saving Layout: The crane's design enables it to be positioned in strategic areas of the workshop, allowing workers to use the space around it effectively. This reduces clutter and ensures that the crane's movement doesn't block access to other equipment or work areas.

In a low-ceiling workshop, space is often limited, but the gantry crane’s design makes sure that every inch is used efficiently. The crane ensures optimal workspace utilization while taking up minimal space itself.

Productivity Gains

The 10-ton gantry crane isn’t just about saving space; it also boosts productivity in several key ways:

- Improved Workflow: With its smooth and precise operation, the crane allows for quicker and more efficient material handling. Workers can move heavy loads faster, reducing time spent on each task and improving overall workflow.

- Faster Lifting Speeds: The crane’s hoist trolley is designed to lift and move loads quickly, reducing downtime between tasks. This speed allows for more lifting operations to be completed in less time.

- Reduction in Manual Labor: Before the crane, lifting heavy items manually or with inefficient equipment slowed things down. Now, the crane handles these tasks, freeing up workers to focus on more skilled or high-priority tasks. This leads to less physical strain and fewer injuries.

- Reduced Operational Downtime: The reliable design of the crane reduces the chances of mechanical failures and maintenance needs. This means fewer interruptions and less time spent fixing issues, keeping the workshop running smoothly.

In summary, the 10-ton gantry crane improves the workflow, reduces manual labor, and speeds up lifting tasks. These factors all combine to create a more efficient and productive working environment, making the most of both space and time in a low-ceiling workshop.

Challenges and Solutions

Limitations of Low Ceiling Spaces

Low ceiling heights present several technical limitations that can affect crane performance. Here are the most common challenges:

- Reduced Lifting Height: With limited vertical space, lifting equipment must work within strict height restrictions, making it difficult to lift heavy loads to their required height without interference from the ceiling.

- Limited Range of Movement: In a low-ceiling workshop, the height of the crane’s bridge and hoist often needs to be kept to a minimum. This reduces the crane’s reach and ability to cover larger areas or handle taller loads.

- Safety Risks: With less room to maneuver, there is an increased risk of the crane or hoist trolley coming into contact with the ceiling or other obstacles, leading to potential damage or accidents.

How the Crane’s Design Addresses These Issues:

The 10-ton gantry crane was specifically designed to tackle these issues, ensuring optimal performance in low-ceiling environments.

- Low-Profile Design: The crane's height is kept to a minimum while still allowing for lifting capability, maximizing the available vertical space.

- Optimized Hoist Trolley: The hoist trolley is designed to be compact and efficient, offering precise control over loads while minimizing the need for excessive height.

By addressing these limitations directly through design adjustments, the crane ensures it can be used effectively in low-ceiling workshops without compromising on lifting performance or safety.

Operational Considerations

Despite its thoughtful design, working in a low-ceiling environment can still present some challenges when it comes to maneuvering the crane and hoist trolley. Some common difficulties include:

- Tight Spaces for Maneuvering: In a confined workshop, there might not be much room for the crane to move freely. The hoist trolley must operate within narrow pathways, limiting how much space the crane has to move loads.

- Precise Control Needed: Given the space constraints, the crane must be operated with high precision to avoid damaging the workshop or the load. Any errors in movement could cause delays or accidents.

Solutions for Maneuvering and Operational Efficiency:

- Smooth Trolley Movement: The hoist trolley is designed to operate smoothly and with minimal resistance, ensuring it can move precisely along the crane’s bridge even in tight spaces.

- Operator Training and Control Systems: The crane includes easy-to-use controls, allowing operators to manage the hoist trolley’s movement accurately. Training programs help operators maximize the crane's efficiency in confined areas, ensuring safety and productivity.

Maintenance Challenges and Solutions

With any heavy lifting equipment, ongoing maintenance is key to ensuring reliable performance. In low-ceiling workshops, maintaining the crane may come with some unique challenges:

- Restricted Access for Repairs: The compact design of the crane may make it harder to access certain components for maintenance, especially when dealing with limited ceiling height.

- Wear and Tear on Trolley and Hoist: Constant use of the hoist trolley and lifting mechanisms may result in wear and tear, which needs to be addressed to prevent breakdowns and maintain efficiency.

Maintenance Solutions:

- Easy Access Design: Despite its compact size, the 10-ton gantry crane is designed with maintenance in mind. Key components are positioned for easier access, and the crane can be serviced without major disruptions to the workspace.

- Regular Inspections: Routine inspections are recommended to check for wear and tear, especially on the hoist trolley and load-bearing parts. This ensures the crane operates at full capacity and minimizes downtime.

- Durable Components: High-quality, durable materials are used throughout the crane, ensuring that even under frequent use, parts like the hoist and trolley last longer, reducing the frequency of replacements and repairs.

By addressing operational and maintenance challenges, the 10-ton gantry crane continues to deliver high performance, even in the demanding conditions of low-ceiling workshops.

Conclusion

Summary of Key Findings

The 10-ton gantry crane provides significant advantages for low-ceiling workshops, where space and operational efficiency are critical. Key benefits include:

- Space Optimization: The crane’s compact, low-profile design ensures it fits under low ceilings without sacrificing lifting power. Its efficient layout allows for better use of available space, making it ideal for tight environments.

- Operational Efficiency: With fast lifting speeds, precise control, and reduced manual labor, the crane enhances workflow and productivity. It minimizes operational downtime and improves the overall efficiency of material handling.

- Safety: The crane’s integrated safety features, including load limiters and emergency stop systems, ensure safe operation in confined spaces, reducing the risk of accidents and enhancing worker protection.

- Cost-Benefit Value: Although there is an initial investment, the long-term savings in labor, operational delays, and accident-related costs ensure a strong return on investment. Routine maintenance is manageable and helps maintain the crane's performance over time.

Future Recommendations

While the 10-ton gantry crane already offers strong performance, there are areas for potential improvement:

- Enhanced Automation: Incorporating more advanced automation and robotics could improve the crane’s operational efficiency even further, reducing the need for operator intervention and increasing precision in load handling.

- Smart Maintenance Systems: Introducing IoT-enabled sensors for predictive maintenance could help identify issues before they become major problems, reducing unplanned downtime and improving long-term reliability.

- Energy Efficiency: Further optimizing the crane’s energy use, such as through more energy-efficient hoists or regenerative braking systems, could reduce operating costs and make the crane even more sustainable in the long run.

By implementing these upgrades, the crane can continue to evolve and adapt to future industrial needs, offering even greater benefits.

The 10-ton gantry crane exemplifies the importance of customized lifting solutions in specialized industrial environments. Low-ceiling workshops often present unique challenges, but this crane’s tailored design shows how innovative solutions can address space constraints, enhance productivity, and improve safety.

As industries continue to require more efficient and adaptable lifting equipment, solutions like the 10-ton gantry crane will remain essential in helping businesses operate effectively in specialized settings. With further advancements and thoughtful upgrades, lifting equipment can continue to evolve to meet the needs of an ever-changing industrial landscape.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch