1 Ton KBK Modular Crane with Low Headroom Hoist for Small Workshop

The 1 Ton KBK Modular Crane with a low headroom hoist efficiently handles loads in space-limited small workshops, ensuring flexibility and safety.

Category: Low Built Cranes & Hoists

Your Trusted KBK Modular Crane Manufacturer & Supplier

1 Ton KBK Modular Crane with Low Headroom Hoist for Small Workshop

The 1 Ton KBK Modular Crane with a low headroom hoist efficiently handles loads in space-limited small workshops, ensuring flexibility and safety.

This case study explores the installation of a 1 Ton KBK Modular Crane with a low headroom hoist in a small workshop environment. The crane system is designed to enhance operational efficiency in a space-constrained setting, providing the necessary lifting capacity while minimizing the overhead clearance required.

Key Features of the 1-Ton KBK Crane

Project Specifications

- Crane Capacity: 1 Ton

- Crane Span: 6 meters

- Lifting Height: 3 meters

- Crane Travelling Length: 22 meters

- Crane Power Supply: 380V, 50Hz, 3-phase electrical power

- System Type: Fully electrical powered system

The 1-ton KBK crane is built to handle up to 1 ton of load, making it perfect for light to medium-duty tasks. Whether you're lifting heavy boxes or smaller components, it's reliable and gets the job done without breaking a sweat.

With a 6-meter crane span, this crane can reach across a variety of spaces, especially in smaller areas where every inch counts. It's just the right size for maneuvering materials efficiently in tighter environments.

The 3-meter lifting height is ideal for most standard industrial lifting needs. Whether you're moving pallets, parts, or tools, it gives you just the right clearance for most jobs.

And with a 22-meter travel length, this crane covers a lot of ground. It's perfect for moving materials over long distances in your facility, saving time and effort. No need to reposition – it handles the space with ease.

Client Requirements

The client, a small workshop specializing in precision assembly and light fabrication, required a crane system that could:

- Operate efficiently within the limited overhead space of their workshop.

- Provide safe, reliable lifting for loads up to 1 ton, with frequent load handling across a relatively short span.

- Operate over a traveling distance of 22 meters to cover the workshop's layout, ensuring versatility in work positioning.

- Maintain an unobtrusive profile with minimal impact on the workshop's headroom.

Solution: 1 Ton KBK Modular Crane for Malta Project

A KBK modular crane system was chosen for this project due to its flexibility, ease of installation, and low profile. The low headroom hoist component was specifically selected to maximize available space by reducing the necessary clearance between the crane and the workshop ceiling.

Key Features of the Installation

- Modular Design: The KBK modular system is made up of individual, easily adjustable components that can be customized to fit specific workshop requirements. This system allowed the crane to be tailored for the 6-meter span and the 22-meter traveling length, ensuring maximum space usage efficiency.

- Low Headroom Hoist: The low headroom design of the hoist ensures the crane's lifting height of 3 meters is utilized fully, making the best use of the workshop's available space. This feature was crucial in the small workshop environment where headroom clearance is limited.

- Efficient Power Supply: The crane system operates on a standard 380V, 50Hz, 3-phase electrical power setup, ensuring compatibility with the client's existing electrical infrastructure. The fully electric-powered crane eliminates the need for manual operation, reducing operator fatigue and increasing productivity.

- Safety Features: The crane is equipped with safety systems to ensure smooth operation. These include an emergency stop function, overload protection, and smooth start/stop mechanisms that reduce wear on both the crane and the loads being handled.

- Smooth Crane Travel: The system is designed to travel a distance of 22 meters, which was perfectly suited for the layout of the workshop. The modular design allows the crane to travel seamlessly along its tracks, giving operators the flexibility to move loads across the entire workshop floor.

Benefits and Outcomes

The 1 Ton KBK Modular Crane with Low Headroom Hoist proved to be the perfect solution for this small workshop. It met the client's requirements for compact design, efficiency, and versatility while also providing a cost-effective way to increase productivity and operational safety. The success of this installation highlights the value of KBK modular systems in optimizing workspace functionality, even in confined environments.

- Space Efficiency: The low headroom hoist maximized the available overhead space, enabling the workshop to maintain optimal storage height and clear workspace beneath the crane system.

- Increased Productivity: With its fully electric power system, the crane streamlined daily operations, allowing workers to move materials efficiently across the workshop floor. The ease of operation also reduced the need for manual lifting, improving safety and reducing the risk of injury.

- Cost-Effective Solution: The 1-ton capacity crane system was a cost-effective solution for the small workshop, providing sufficient lifting power for the workshop's needs without overspending on unnecessary capacity. Its modularity also means that future upgrades and expansions are possible without significant additional investment.

- Reliability and Durability: As the crane operates on a 380V, 50Hz, 3-phase power supply, it benefits from high reliability and consistent performance, ensuring minimal downtime and low maintenance costs over the long term.

Main Parts and Components of 1 Ton KBK Crane Kits for Marlta

The 1 Ton KBK Crane Kit is a versatile, modular system designed to meet the needs of small to medium-sized workshops or facilities requiring precise and efficient lifting solutions. Below are the key parts and components that make up the 1 Ton KBK crane kit:

KBK Crane Rail System

The foundation of the KBK crane is the KBK rail system, which consists of modular rails that support the crane's movement. These rails are made from high-quality steel to withstand the stresses of lifting and traveling.

- Crane Beam: The horizontal beam that provides the structure for the crane's lifting capacity. Typically, it is designed to handle loads up to 1 ton and is available in various lengths, depending on the system's configuration.

- End Beams: These components are mounted at both ends of the crane beam and allow for attachment of the trolley and hoist system. They help ensure smooth travel across the full span of the system.

- Track System: The rail track is designed for smooth movement of the crane along the longitudinal direction. It can be floor-mounted or suspended, depending on the workshop layout.

steel frame of kbk modular crane

griders, columns of kbk rail workstation crane

Steel frame of kbk modular crane packed for delivery

European-Style Ultra-Low Headroom Chain Hoist

Ultra-Low Headroom Hoist

- The ultra-low headroom hoist design maximizes the usable vertical space by minimizing the height of the hoist itself.

- This design allows cranes to operate in spaces with low ceiling heights, optimizing the clearance available for lifting heavy loads in confined areas.

Trolley

The trolley is the component that moves along the crane beam and supports the hoist. It allows the load to be transported horizontally across the span.

- Standard Trolley: This is typically a motorized or manual device that rolls along the crane beam, enabling controlled horizontal movement.

- Powered Trolley: For more efficient movement, especially over longer spans or with heavier loads, the trolley can be powered either electrically or with an electric motorized system.

Advantages of European-Style Hoists

- Precision Engineering: The European-style hoists are built with high-quality materials and precise engineering, which ensures durability and reliability under demanding conditions.

- Low Maintenance: These hoists require less frequent maintenance and have a longer lifespan compared to traditional hoists, reducing operational downtime and maintenance costs.

Applications of Ultra-Low Headroom Hoists

- Warehouse Use: Ideal for environments with low ceilings or limited vertical space, such as warehouses, where maximizing headroom is crucial.

- Manufacturing Plants: The hoists are well-suited for factories and production lines, where they can be used to move heavy components in constrained spaces.

- Under-Ceiling Operations: The ultra-low headroom design makes it an excellent choice for operations that require lifting loads directly under ceiling-mounted systems, such as in narrow aisles or small industrial buildings.

Low headroom electric chain hoist with European style for kbk crane system

Electric hoist for modular kbk crane system

Electric hoist packed into wooden case

Crane End Trucks

End trucks are critical for the mobility of the crane system. They are mounted on either side of the crane and enable smooth movement along the crane rails.

- Manual or Motorized End Trucks: End trucks can either be manually operated for small-scale applications or motorized for greater ease and efficiency, especially for longer spans and frequent use.

End Stops and Safety Devices

To ensure safe operation, the KBK crane kit is equipped with various end stops and safety devices:

- End Stops: These are mounted at both ends of the crane track to prevent the trolley from traveling too far and potentially damaging the crane or the load.

- Overload Protection: A crucial safety feature that prevents lifting more than the rated capacity (1 ton). This mechanism will automatically stop the hoist if the weight exceeds the specified limit.

- Limit Switches: These limit the travel of the hoist and trolley to avoid any overrun and mechanical damage.

- Emergency Stop Button: A button located on the control panel or remote system that allows the operator to stop all movements immediately in case of an emergency.

Suspension System or Support Frame

Depending on the specific configuration of the 1-ton KBK crane kit, the crane may be suspended or supported by a frame.

- Suspension System: In this case, the crane is suspended from the ceiling using rails and support brackets, which helps save valuable workshop floor space.

- Support Frame: If the crane is mounted on the floor, it will have a support frame that holds the rails and enables the system to move along the span.

Mounting and Assembly Accessories

For assembly and installation, various mounting and assembly accessories are needed:

- Brackets and Mounting Plates: These provide secure attachment points for the crane's rails and other components.

- Fasteners and Hardware: Includes bolts, nuts, washers, and other hardware necessary for assembling the crane kit.

Electrical Control System

The electrical control system manages the crane's movements, ensuring smooth operation of the hoist, trolley, and crane beams. The control system typically includes:

- Control Panel: A centralized unit that houses the controls for the crane's movements, such as buttons for lifting, lowering, and traveling.

- Wiring and Safety Features: Includes the necessary wiring, circuit breakers, and fuses to ensure safe operation, as well as emergency stop buttons and overload protection.

- Radio Remote Control: An optional feature for more flexibility, allowing operators to control the crane remotely without being in the direct vicinity.

Pendant control of kbk rail crane system

Electrical part of kbk crane kit

Electrical wiring of kbk crane kit

Parts and Components List of 1 Ton KBK Modular Crane Kit

The 1 Ton KBK Crane Kit is composed of several interconnected components designed for modularity, flexibility, and efficiency. With its modular rails, trolley system, hoist, electrical controls, and safety features, it offers a robust and customizable lifting solution for workshops and small industrial spaces. The inclusion of components like end stops, track switches, and curved rail sections ensures smooth, efficient operation, while low headroom hoists maximize the lifting height in space-constrained environments. The crane's modularity also allows for easy expansion or adaptation in the future, making it a valuable long-term investment for any workshop.

Parts and conponents of kbk crane kit 1 ton

1 ton crane kit parts for sale Marlta

Trolley and parts of modular crane

Parts and Components List of 1 Ton KBK Modular Crane Kit for Your Reference

- Round Discs: 32 pieces

- Longitudinal Rail Trolley: 2 pieces

- Hoist Trolley: 2 pieces

- Track Connectors: 2 pieces

- 41.5 Flat Cable: 50 meters

- 61.5 Cable: 17 meters

- Electrical Box: 1 piece

- Trolley Connection Plates: 3 pieces

- Bolts M1630: 16 sets (including flat washers, spring washers, caps)

- Bolts M16180: 16 sets (including flat washers, spring washers, caps)

- Bolts M1025: 4 pieces

- Suspension Rods 16320: 6 pieces

- Bolts M6110: 1 piece

- Clamps: 2 pieces

- Trolleys: 3 units

- Square Tube Connectors: 4 pairs

- Limit Stops: 1 pair

- Fire Breakers: 2 pieces

- 20.5 Cable: 4 meters

- Track Connectors: 2 pieces

- Collision Blocks: 6 pieces

- Trolley Cross Beams: 1 piece

- End Caps: 6 pieces

- Cable Trolleys: 28 pieces

- Suspension Components: 8 pieces

- Suspension Rods 16320: 10 pieces

Installation and Operation of 1 Ton KBK Modular Cranes

The installation of the KBK modular crane was completed in several phases. Due to the modular nature of the crane, the installation process was straightforward and efficient, requiring minimal downtime. The crane was mounted securely and tested for both load-bearing capacity and operational smoothness.

The system's low headroom hoist was particularly beneficial, as it allowed for full utilization of the 3-meter lifting height without compromising on safety or functionality. The crane's compact design ensured that it did not obstruct the workspace, even when the hoist was fully extended.

light kbk crane for low headroom shop

Economical material handling solution for limited space workshop

Low profile modular crane system for indoor material handling

Main Specifications Required to Get Your Customized KBK Modular Crane

To get a customized KBK modular crane, the following key specifications are essential for ensuring that the crane meets your operational requirements. These specifications help define the crane's design, capacity, and features.

- Lifting capacity of light kbk crane: __Kg

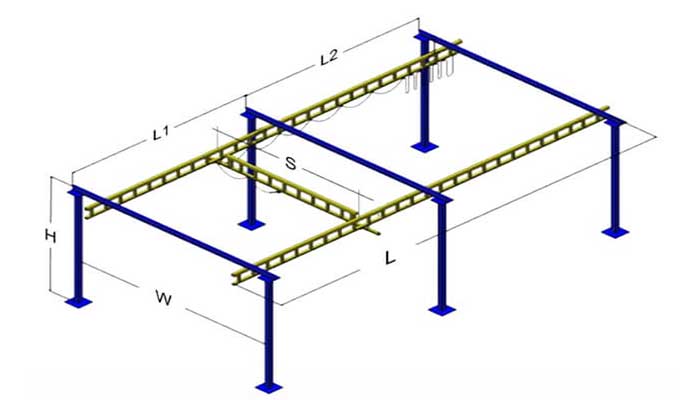

- Width (S)=__m, H=__m, L=__m, L1=__m, L2=__m

- Hoist type of light kbk crane:Electric chain hoist or Wire rope hoist or Manual chain hoist?

- Crane travel type of light kbk crane: Electrical type or Manual type?

- Voltage of light kbk crane: ____V____Hz____Phase (If electrical type)

- Control Mode of light kbk crane: Remote control or Pendant control?

- How many KBK cranes are running on the same track?

- Transportation: tell us the sea port name near you, we can quote you shipping freight.

Load Capacity

- Maximum Load: Specify the maximum weight the crane will need to lift, which ranges from 250 kg to 3.2 tons for KBK modular cranes.

- Frequency of Load Handling: Determine how frequently the crane will handle its maximum load, as this affects the design, durability, and motor specifications.

Span (Travel Distance)

- Crane Span: Measure the distance between the crane's rails (the width of the area to be covered). This defines how far the crane will travel within your facility.

Lifting Height

- Lift Height: Define the height from the floor to the highest point the crane needs to lift loads. This is influenced by your facility's headroom and the height of materials to be lifted.

Crane Type

- Single Girder vs Double Girder: Choose between a single girder (ideal for lighter loads and lower duty cycles) or a double girder (better for heavier capacity, more rigid design) crane system, depending on your load and operational requirements.

- Rail Type: Specify the rail type that suits your load and environment, such as aluminum or steel rails, or other customized options.

Hoist and Trolley System

- Hoist Type: Choose between manual, electric, or motorized hoists, depending on your load handling requirements and operational preferences.

- Trolley Type: Specify whether you need a motorized or manual trolley system to move the load horizontally along the crane rails.

Environmental Considerations

- Indoor or Outdoor Use: Indicate if the crane will be used indoors or outdoors, as outdoor cranes may require additional protection from weather and harsh environments.

- Corrosion Resistance: If your crane will be exposed to chemicals, moisture, or extreme temperatures, specify any anti-corrosion or explosion-proof requirements for the crane's components.

Control System

Control Type: Choose the control system that best suits your needs:

- Pendant Control: Wired control for operators.

- Radio Remote Control: Wireless control for ease of operation across complex or large spaces.

- Cabin Control: For larger or more complex crane systems, where the operator is housed on the crane itself.

Speed Requirements

- Travel Speed: Specify the required speed for horizontal crane movement (e.g., slow for precision handling or faster for higher throughput).

- Hoisting Speed: Define the required speed for lifting and lowering loads based on operational needs.

Power Supply

- Power Requirements: Indicate the power supply specifications (e.g., 220V, 380V, 480V), and whether you need a single-phase or three-phase system.

- Energy Efficiency: Consider any energy-saving features or systems that may be necessary to optimize power usage.

Safety Features

- Limit Switches: Ensure that limit switches are included to prevent overtravel of the crane and ensure safe operations.

- Overload Protection: Specify if overload protection is required for the crane to prevent accidents and damage.

- Anti-Collision Systems: If using multiple cranes in the same area, determine whether anti-collision systems are necessary to prevent crane interference.

Installation and Maintenance

- Mounting Type: Specify whether the crane will be mounted on existing infrastructure or if new foundations will be needed.

- Maintenance Access: Consider the crane's design to ensure easy access to components for routine inspections, servicing, and maintenance.

Conclusion

To get your customized KBK modular crane, defining these main specifications is essential. By clarifying the load capacity (from 250 kg to 3.2 tons), span, lift height, hoist and trolley types, and environmental considerations, you can ensure that your crane is designed to meet your exact operational requirements. Collaborate closely with your supplier or manufacturer to finalize these details and create the ideal crane for your facility.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch