Low Headroom Hoists & Trolleys for Single & Double Girder Cranes

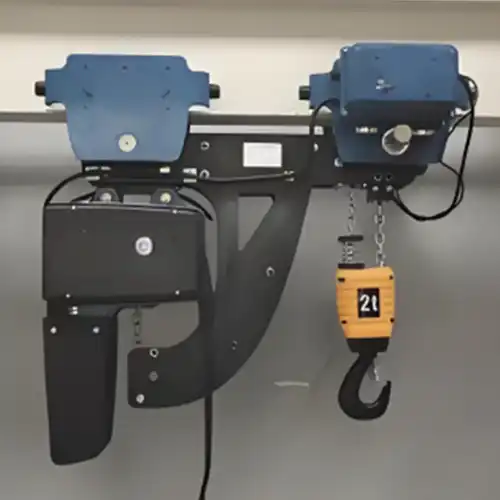

Low headroom hoists and trolley for sale, good price. Compact electric hoists maximize space, ideal for low-clearance, single and double girder cranes.

Category: Low Built Cranes & Hoists

Your Trusted Low Headroom Hoists and Trolley Hoists Manufacturer & Supplier

Low Headroom Hoists & Trolleys for Single & Double Girder Cranes

Overview of Low Headroom Hoists and Trolleys

Low headroom hoists and trolleys are specially designed lifting systems that maximize vertical space. These hoists have a compact structure, making them perfect for areas with limited ceiling height. The low profile allows for more headroom, which means more lifting height and greater flexibility in tight spaces. These systems are often used in industries where every inch of space counts.

Importance of Space Optimization in Industrial Environments

In industrial settings, space is often limited. Workshops, factories, and warehouses frequently deal with low ceilings and crowded areas. Low headroom hoists help solve this problem by reducing the space needed for lifting equipment. This optimization allows for better use of floor space and can increase the overall productivity of a facility.

Optimizing space means you can:

- Fit more equipment or products in the same area.

- Improve movement and safety within the facility.

- Increase operational efficiency by reducing obstructions and congestion.

Relevance to Both Single Girder and Double Girder Cranes

Low headroom hoists and trolleys are useful for both single and double girder cranes, though their application varies.

- Single Girder Cranes: These cranes are often used in smaller or more confined spaces. Low headroom trolleys in these systems allow for easy maneuvering and more lifting capacity within the limited space available.

- Double GirderCranes: For larger lifting capacities, double girder cranes are used. The low headroom design in these cranes still offers the same benefits—maximizing height and optimizing space—while allowing for heavy-duty operations.

In both crane types, the low headroom system helps to make the most of available space, whether it's a compact workshop or a large industrial setting.

What is a Low Headroom Electric Hoist?

Definition and Key Features

A low headroom electric hoist is a specialized type of hoist designed for environments with limited vertical space. These hoists are compact and space-efficient, making them ideal for low-ceiling workshops or tight areas where standard hoists may not fit. The key feature of a low headroom electric hoist is its ability to maximize lifting capacity while requiring minimal overhead clearance.

Key features of a low headroom electric hoist include:

- Compact Structure: The hoist is designed to have a smaller frame to reduce headroom requirements.

- Electric Power: Operates with an electric motor for easy and consistent lifting without manual effort.

- Efficient Lifting: Despite the compact design, these hoists can handle heavy loads effectively.

- Smooth Operation: Low headroom electric hoists are designed for quiet and efficient operation, even in confined spaces.

Difference Between Standard and Low Headroom Electric Hoists

The primary difference between a standard electric hoist and a low headroom electric hoist lies in their size and the space they require to operate.

- Standard Electric Hoists: These have a larger frame and require more headroom for installation and operation. While they are effective in open spaces with higher ceilings, they are not suitable for confined areas.

- Low Headroom Electric Hoists: Specifically designed for low-ceiling spaces, these hoists have a more compact build, allowing them to fit in areas where traditional hoists can't. The low profile ensures that the hoist uses minimal vertical clearance while still providing efficient lifting capabilities.

Low Headroom Electric Hoist for Single Girder Crane

Low Headroom Electric Hoist for Double Girder Crane

European Style Wire Rope Electric Hoist

The European style wire rope electric hoist is a high-performance lifting device commonly used in industrial settings. These hoists feature a wire rope mechanism for lifting, which provides durability and reliability for heavy-duty applications.

Key features of the European style wire rope hoist include:

- High Lifting Capacity: Typically used for heavier loads, the wire rope provides a strong lifting mechanism.

- Durable Construction: The European style design emphasizes strength and longevity, making these hoists suitable for demanding environments.

- Precise Control: These hoists are equipped with advanced control systems, providing smooth and accurate movements during lifting operations.

- Space-Saving Design: The compact design of European style wire rope hoists makes them suitable for low headroom applications, ensuring that vertical space is used efficiently.

Advantages of Low Headroom Electric Hoists and European Style Wire Rope Hoists in Confined Spaces

Low headroom electric hoists, especially the European style wire rope models, offer several significant advantages in confined spaces and low-ceiling environments:

- Maximized Space Utilization: The compact design of low headroom electric hoists allows for better use of available space, making them ideal for small workshops or areas with limited ceiling height.

- Heavy-Duty Performance: Despite their compact size, these hoists can lift heavy loads effectively, making them suitable for a variety of industrial applications.

- Increased Efficiency: The smooth, efficient operation of low headroom electric hoists leads to faster lifting cycles, improving overall productivity in tight spaces.

- Improved Safety: The design of these hoists reduces the risk of accidents by enabling precise lifting and reducing interference with other equipment in crowded spaces.

In summary, low headroom electric hoists and European style wire rope hoists provide powerful lifting solutions for environments with limited vertical space, combining compact designs with high lifting capacities to optimize the use of available space while maintaining safety and efficiency.

Low Headroom Electric Hoist for European Style Single Girder Crane

Features of Low Headroom Electric Hoists

Low headroom electric hoists are specifically designed to minimize the distance between the hoist and the crane structure, making them perfect for applications with limited vertical space. Here are some key features:

- Compact Design: The hoist frame is designed to fit into tight spaces, reducing the headroom required for installation.

- Efficient Lifting: Despite the reduced size, these hoists can handle heavy loads, typically ranging from 1 ton to 30 tons or more, depending on the model.

- Smooth Operation: These hoists are engineered for smooth lifting, reducing wear and tear while enhancing performance in confined spaces.

- Durable Construction: Built to last, these hoists are constructed with high-quality materials that ensure long-term reliability, even in demanding industrial environments.

- European Style: The European style hoists are known for their superior craftsmanship and design, offering advanced features like variable speed control and safety features.

Benefits in High-Demand Environments

In industries like steel mills, factories, and warehouses, where space is often a constraint, low headroom electric hoists offer several key benefits:

- Space Optimization: The compact nature of the hoist allows for more usable space in the workshop or factory floor, maximizing available vertical clearance.

- Increased Lifting Efficiency: With smoother operations and a higher lifting capacity for its size, these hoists can lift heavy materials without compromising speed or accuracy.

- Enhanced Productivity: The quick installation and easy integration into existing crane systems help streamline workflows in high-demand environments, reducing downtime and increasing operational efficiency.

- Cost-Effective: By using space more effectively, these hoists reduce the need for large, expensive overhead space adjustments, allowing companies to maximize their existing infrastructure.

Integration with Crane Systems to Maximize Efficiency

Low headroom electric hoists are designed to integrate seamlessly with both single girder and double girder cranes, improving overall system efficiency:

- Reduced Space Requirements: These hoists can be easily paired with European style single girder cranes, ensuring minimal space between the hoist and the beam, ideal for low ceiling environments.

- Efficient Load Handling: When paired with a properly designed crane, the hoist enhances the crane's ability to handle heavy loads with more precision and less energy consumption.

- Increased Flexibility: Low headroom hoists allow more flexibility in crane system design and layout, enabling businesses to utilize their space in the most efficient way possible.

Low Headroom Trolley Hoist for Double Girder Cranes

Differences in Trolley Design for Double Girder Cranes

For double girder cranes, the trolley hoist design differs significantly from single girder systems. Here's how:

- Dual Girder Support: Unlike single girder systems, which use a single beam to support the hoist, double girder cranes use two parallel beams, providing greater stability and a higher lifting capacity.

- Trolley Design: The hoist is mounted on a trolley that runs along the top of the two girders, allowing for more horizontal travel compared to a single girder crane. This increases the overall lifting area.

- Higher Lifting Heights: With two supporting girders, double girder cranes can achieve greater lifting heights, which is crucial for larger industrial applications where materials need to be lifted from significant heights.

Impact on Lifting Capacity, Stability, and Operational Safety

The design of low headroom trolleys for double girder cranes has a direct impact on several operational factors:

- Lifting Capacity: Double girder systems are capable of handling much higher loads due to the two-girder support, making them ideal for heavy-duty lifting in industries such as steel manufacturing or heavy construction.

- Stability: The dual-beam design of the crane, combined with the low headroom trolley, ensures better stability during lifts, reducing the risk of swaying or load shifts.

- Operational Safety: Safety is enhanced with features like precise control, overload protection, and more consistent lifting, which helps prevent accidents in high-stress environments.

Ideal Industries and Applications for Double Girder Systems with Low Headroom Trolleys

Low headroom trolleys used in double girder cranes are ideal for industries and applications where both heavy lifting and space optimization are essential:

- Steel Mills: These environments require cranes that can handle heavy steel products with precision and stability. Double girder cranes with low headroom trolleys offer the strength and stability needed for these high-demand operations.

- Manufacturing Facilities: Heavy machinery and large products need to be lifted and moved within tight areas, and double girder cranes provide the necessary lifting power and reliability.

- Warehouses: Warehouses with limited vertical clearance can benefit from double girder cranes with low headroom trolleys to efficiently move goods while utilizing every inch of space.

- Construction Sites: When large components need to be lifted, double girder systems with low headroom trolleys offer the power and versatility needed in busy construction zones.

By offering both high lifting capacity and space-saving design, low headroom trolley hoists for double girder cranes provide optimal solutions for a range of industries where both safety and efficiency are top priorities.

Benefits of Low Headroom Hoists and Trolley Hoists

Low headroom hoists and trolley hoists are essential for maximizing space, improving operational efficiency, and offering long-term durability. Here's how they provide value across various industrial applications:

Maximizing Available Space

- Compact Design: Low headroom hoists and trolleys are designed to fit into spaces with minimal vertical clearance, allowing businesses to fully utilize the available space.

- Improved Workflow: By reducing the space taken up by lifting equipment, more area is left open for storage, assembly, and production lines.

- Ideal for Tight Environments: Perfect for environments with low ceilings, such as warehouses or steel mills, where traditional hoists may not fit.

Increased Lifting Height and Load Capacity

- Enhanced Lifting Height: Low headroom designs allow the hoist to be mounted closer to the crane beam, increasing the lifting height, which is particularly beneficial in facilities with low ceilings.

- Increased Load Capacity: Despite their compact size, low headroom hoists and trolley hoists are capable of lifting heavy loads (up to 30 tons or more) efficiently, making them ideal for heavy-duty tasks in factories and warehouses.

- More Versatility: The added lifting height and capacity make them versatile enough for various industries, including steel, manufacturing, and construction.

Durability, Reduced Wear, and Maintenance Costs

- Sturdy Construction: Built from high-quality materials, low headroom hoists are designed to withstand tough working conditions, reducing the likelihood of breakdowns or wear.

- Reduced Maintenance: Their efficient design minimizes stress on components, leading to less frequent repairs and replacements, reducing overall maintenance costs.

- Longevity: These hoists have a longer lifespan due to their durable construction, making them a cost-effective long-term investment.

Efficiency in Manufacturing and Assembly Processes

- Faster Lifting Operations: The smooth and efficient operation of low headroom hoists improves the speed of lifting and lowering materials, helping to streamline production lines and assembly processes.

- Energy Efficiency: With advanced features like variable speed control and optimized motors, these hoists reduce energy consumption during operations, making them both environmentally friendly and cost-effective.

- Improved Safety: By minimizing load shifts and ensuring precise control, low headroom hoists enhance operational safety, reducing downtime caused by accidents or equipment failures.

Low headroom hoists and trolley hoists not only save space but also increase productivity and efficiency in a variety of industries. Whether it's in tight warehouse environments or heavy industrial plants, their benefits help businesses maximize their resources, reduce costs, and improve overall performance.

Applications in Key Industries

Low headroom hoists and trolley systems offer significant advantages in various industries where space optimization, lifting capacity, and efficiency are critical. Here's a look at some of the key industries where these systems are most beneficial:

Steel Mills, Automotive, and Heavy-Duty Manufacturing

- Steel Mills: In steel mills, where space is often limited and heavy loads are frequent, low headroom electric hoists can be crucial for lifting large steel beams, coils, and materials with precision. Their ability to operate in low-ceiling areas maximizes vertical space, a key factor in steel manufacturing environments.

- Automotive: Automotive plants rely on efficient assembly lines where space and speed are of utmost importance. Low headroom hoists provide the necessary lifting capacity to handle heavy automotive parts while improving productivity in confined spaces, such as assembly areas or storage zones.

- Heavy-Duty Manufacturing: In industries like construction equipment manufacturing or large-scale machinery production, low headroom hoists allow for lifting heavy components without compromising operational space. These hoists facilitate the handling of oversized and cumbersome loads, even in tight or narrow workshops.

Warehouse Logistics and Distribution Centers

- Efficient Storage: In warehouses and distribution centers, maximizing the vertical space is crucial. Low headroom hoists allow for higher stacking, increasing storage capacity and improving overall facility organization.

- Faster Load Handling: These systems can efficiently move heavy goods from storage areas to shipping zones, speeding up the entire logistics process, improving turnover rates, and reducing wait times for shipments.

- Space-Efficient Lifting: The compact design of low headroom hoists makes them perfect for environments with low ceilings, such as older warehouses or modern facilities that need to fit maximum storage into limited space.

Other Industries That Benefit from Low Headroom Crane Systems

- Construction: Low headroom hoists are ideal for lifting heavy construction materials, such as beams, panels, and other heavy loads in low-ceiling environments. Whether working on building sites with space constraints or in factories where heavy assembly is required, these systems improve safety and productivity.

- Aerospace: In aerospace manufacturing facilities, precision and space efficiency are crucial. Low headroom hoists handle delicate parts like aircraft fuselages and engines, optimizing vertical space and improving handling efficiency in tight spaces.

- Food and Beverage: In food processing plants, low headroom hoists are used to lift ingredients, equipment, and packaging materials. They contribute to streamlined operations while ensuring safety and hygiene, as they can be integrated with various automated systems.

Low headroom hoists and trolley hoists are valuable across a wide range of industries, from heavy-duty manufacturing to logistics and food production. Their ability to save space, increase lifting capacity, and enhance operational efficiency makes them indispensable in environments where both high performance and space optimization are essential.

Choosing the Right Low Headroom Hoist & Trolley Hoist System

Selecting the right low headroom hoist and trolley system is crucial for ensuring that your operations run smoothly and efficiently. Here's a guide on how to make the best choice for your specific needs.

Factors to Consider: Lifting Capacity, Headroom Clearance, and Space Constraints

Lifting Capacity:The first step in choosing a hoist system is understanding the weight of the loads you will be lifting. Low headroom hoists come in different capacities, so it's essential to choose one that can handle the maximum load for your tasks. Whether you're lifting heavy steel components or lighter materials in warehouses, ensure that the hoist can manage the load without strain or risk.

Tip: Always factor in a margin of safety when selecting lifting capacity to ensure that your hoist won't be operating at its maximum load all the time.

Headroom Clearance:The primary advantage of low headroom hoists is their ability to operate in environments with limited vertical space. However, it's still important to measure your available headroom accurately before choosing a system. Too little clearance can restrict the movement of the trolley or load, while too much clearance may result in underutilization of the available height.

Tip: Measure the height from the floor to the ceiling or obstruction above to ensure the hoist will fit and allow for full movement without hitting the ceiling.

Space Constraints:Low headroom hoists are specifically designed to save vertical space, but you also need to consider the overall layout of your facility. If you're working in a narrow area or near walls, the size and design of the hoist and trolley system will impact its performance and ease of movement.

Tip: Evaluate the entire space in which the system will operate, including clearance on the sides, to ensure smooth movement of the hoist.

How to Select the Best System Based on Operational Needs and Environment

Workload and Duty Cycle:If your operations require frequent lifting, you will need a hoist with a higher duty cycle rating. For heavy-duty, continuous lifting applications in steel mills or manufacturing, a system designed for high-frequency use is essential.

Tip: If lifting tasks are intermittent or not as demanding, a lighter-duty system may be sufficient, reducing costs and energy consumption.

Environment:Consider the specific environment in which the hoist will operate. For example, if you're in a dusty or wet environment, you'll need a system with additional protective features like sealed motors and corrosion-resistant components. In hazardous areas, explosion-proof hoists may be necessary.

Tip: Think about the working conditions, including temperature, humidity, and cleanliness, and choose a hoist system that can withstand these factors.

Integration with Existing Systems:Low headroom hoists and trolley systems should work seamlessly with your existing crane or overhead structure. Choose systems that are compatible with your crane type, whether single girder or double girder, and check the interface for ease of integration.

Tip: Opt for modular systems that offer easy upgrades or integration with existing setups to save costs in the long run.

Customization Options for Various Industries

- Steel Mills and Heavy-Duty Manufacturing:Customizations like reinforced steel construction, high lifting capacity, and enhanced durability are essential for industries where heavy lifting is frequent and tough. Hoists with specialized features such as high-speed lifts, explosion-proof motors, or rugged components may be required.

- Warehouses and Distribution Centers:For these environments, low headroom hoists with compact trolleys and optimized lifting speeds are essential to maximize storage space and handling efficiency. Some warehouses may also require systems with advanced control options like remote operation or automated systems for improved efficiency.

- Automotive and Aerospace:Precision is key in industries like automotive manufacturing or aerospace. Custom hoists with fine-tuned load control, quieter operation, and non-marking wheels may be necessary to handle delicate components safely.

- Food and Beverage:In food processing plants, cleanliness is paramount. Low headroom hoists with smooth surfaces, food-grade lubricants, and easy-to-clean designs are vital to maintain hygiene standards.

Choosing the right low headroom hoist and trolley system involves carefully considering factors like lifting capacity, available space, operational demands, and industry-specific needs. Customizing these systems ensures they meet the unique challenges of your industry, whether you're working in a steel mill, warehouse, or cleanroom environment. Make informed decisions to ensure efficient, safe, and reliable performance for years to come.

Conclusion: Customized Low Headroom Hoist and Trolley for Your Cranes

Low headroom hoists and trolleys play a crucial role in optimizing space, especially in environments where height limitations are a challenge. By making the most of available headroom, these systems allow businesses to operate in confined spaces without compromising lifting capacity or overall performance.

Key Benefits to Consider:

- Maximized Space: Perfect for environments where every inch of headroom matters.

- Increased Efficiency: Improves workflow and speed in lifting operations.

- Enhanced Safety: Designed to reduce risks and provide stability during lifts.

For businesses with specific lifting challenges, exploring advanced low headroom solutions tailored to your environment can make a significant difference. These systems offer customizable features that can be adapted to meet the demands of various industries, ensuring both reliability and versatility.

Final Thoughts: Investing in the right low headroom hoist and trolley system ensures not only optimal space usage but also long-term efficiency and safety. With these systems, you can maintain smooth operations while minimizing downtime and enhancing productivity.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch