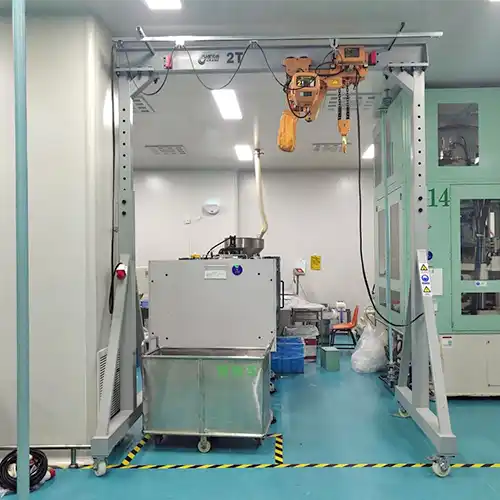

Pump Handling Aluminum Gantry Crane 2 Ton V.S Steel Gantry Cranes

2 ton gantry cranes for sale. Custom portable & mobile gantry crane with aluminum gantry design for pump handling. Check 2 ton aluminum gantry crane case!

Category: Mobile Gantry Crane For Sale

Your Trusted Portable and Mobile Gantry Crane Manufacturer & Supplier

Pump Handling Aluminum Gantry Crane 2 Ton V.S Steel Gantry Cranes

Custom Portable & Mobile Gantry Crane with Aluminum Gantry Design for Pump Handling

2 ton gantry cranes for sale. Custom portable & mobile gantry crane with aluminum gantry design for pump handling. Check 2 ton aluminum gantry crane case!

Gantry cranes play a pivotal role in the world of material handling, serving as reliable workhorses across various industries. These versatile machines are essential for efficiently lifting and moving heavy loads, simplifying tasks that would otherwise be laborious and time-consuming. In this article, we delve into the world of gantry cranes, with a specific focus on a remarkable piece of equipment: the 2-ton aluminum gantry crane designed for the specialized task of pump handling.

Our primary objective is to shed light on the significance and advantages of this particular gantry crane model. In the realm of industrial processes, the efficient handling of pumps is a critical task, often requiring precision, safety, and reliability. The 2-ton aluminum gantry crane is tailor-made to excel in this role, and we will explore its features, benefits, and real-world applications.

The scope of this article encompasses a comprehensive understanding of gantry cranes, their role in pump handling, and the specific attributes that make the 2-ton aluminum gantry crane a standout choice. We will examine the considerations involved in selecting such a crane, its installation and operation, and even delve into case studies showcasing its prowess. Furthermore, we'll discuss cost considerations and compare it with alternative crane types, ensuring you make informed decisions when it comes to material handling in the pump industry. So, let's embark on this journey to explore the 2-ton aluminum gantry crane and its remarkable contributions to pump handling tasks.

Overview of Gantry Crane

Gantry cranes, often referred to as portal cranes, are indispensable heavy-duty material handling machines used across a wide spectrum of industries. They derive their name from the gantry, which is a horizontal beam or framework supported at each end by legs or uprights. The primary function of gantry cranes is to lift, lower, and move heavy objects within a defined workspace.

These cranes operate by suspending loads from a hook, magnet, or other specialized lifting attachments, which are connected to a trolley that moves horizontally along the gantry beam. Gantry cranes are highly versatile, capable of handling various load types, including machinery, construction materials, containers, and more.

Types of Gantry Cranes and Their Key Characteristics

Gantry cranes come in several types, each tailored to specific applications and environments. Some common types include:

Advantages of Using Aluminum Gantry Cranes

Aluminum gantry cranes offer a unique set of advantages that make them a preferred choice in specific scenarios:

- Lightweight: The use of aluminum as the primary material results in a lightweight crane, making it easy to transport and assemble.

- Corrosion Resistance: Aluminum gantry cranes are highly resistant to corrosion, making them suitable for outdoor use and industries where hygiene is crucial.

- Mobility: Equipped with wheels, aluminum gantry cranes are highly mobile, allowing for easy movement within a workspace.

- Adaptability: Telescopic legs and adjustable height features provide adaptability to varying load heights and configurations.

- Cleanroom Applications: The corrosion-resistant and clean nature of aluminum makes these cranes ideal for cleanroom environments in industries like pharmaceuticals and electronics.

These advantages, coupled with their versatility and efficiency, make aluminum gantry cranes an excellent choice for a wide range of applications, including pump handling tasks, which require precision and reliability.

Importance of Pump Handling

Pump handling is a fundamental industrial process that involves the careful and precise movement, installation, and maintenance of pumps used for various purposes. Pumps are integral components in industries such as manufacturing, oil and gas, construction, water treatment, and more. They play a crucial role in transferring liquids, gases, or other fluids within a facility or from one location to another.

The process of pump handling encompasses not only the installation and removal of pumps but also their routine maintenance, repair, and replacement. The efficiency and safety of pump handling operations have a direct impact on the overall productivity and functionality of industrial systems.

Significance of Efficient and Safe Pump Handling in Various Industries

The significance of efficient and safe pump handling cannot be overstated, as it directly affects several key aspects of various industries:

- Productivity: Efficient pump handling ensures that pumps are installed, replaced, or maintained swiftly and accurately, minimizing downtime and production interruptions.

- Quality Assurance: In industries such as food processing, pharmaceuticals, and chemical manufacturing, the quality and integrity of the products often rely on precise pump operations. Any mishandling can lead to product contamination or quality issues.

- Safety: Safe pump handling practices are essential to protect workers and prevent accidents. Pumps often handle hazardous materials, and mishaps can result in spills, leaks, or chemical exposure.

- Cost-Effectiveness: Proper pump handling extends the lifespan of pumps and reduces the frequency of replacements or repairs, leading to cost savings in the long run.

- Environmental Responsibility: Responsible pump handling minimizes the risk of environmental contamination due to leaks or spills, aligning with environmental regulations and sustainability goals.

Challenges Associated with Pump Handling Tasks

Pump handling tasks pose several challenges that need to be addressed:

- Weight and Size: Pumps can vary significantly in size and weight, making their handling challenging, especially in confined spaces.

- Precision: Accurate alignment and positioning of pumps are crucial to prevent damage and ensure proper functioning.

- Safety: Handling pumps often involves exposure to hazardous materials, requiring strict safety measures and equipment.

- Maintenance: Routine maintenance and replacement of pump components demand skilled technicians and suitable equipment.

- Accessibility: Pumps may be located in hard-to-reach areas, necessitating versatile material handling equipment.

Given these challenges and the critical role pumps play in various industries, the choice of material handling equipment, such as the 2-ton aluminum gantry crane for pump handling, becomes paramount in ensuring efficient and safe operations.

Overview of 2 Ton Aluminum Gantry Crane

Detailed Description of the 2-Ton Capacity Aluminum Gantry Crane

The 2-ton aluminum gantry crane is a specialized material handling solution designed for the efficient and safe handling of pumps and other heavy equipment. Its key characteristics include:

- Frame: The gantry crane features a robust aluminum frame, which is not only lightweight but also highly durable and corrosion-resistant. This ensures longevity and suitability for outdoor and cleanroom environments.

- Adjustable Height: Telescopic legs allow for easy height adjustment, accommodating varying load heights and configurations. This adaptability is crucial when handling pumps of different sizes.

- Wheels: Equipped with sturdy wheels, the crane offers exceptional mobility. Operators can easily move it to the desired location within a workspace, enhancing flexibility during pump handling tasks.

- Lifting Capacity: With a lifting capacity of 2 tons, this gantry crane is well-suited for a wide range of pumps commonly used in industrial applications.

Features and Specifications of the Crane

The key features and specifications of the 2-ton aluminum gantry crane include:

- Capacity: 2 tons, making it suitable for lifting and positioning pumps with varying sizes and weights.

- Span Width: Typically available in various span widths to accommodate different workspace dimensions.

- Adjustable Height Range: Telescopic legs provide an adjustable height range, ensuring compatibility with different pump configurations.

- Material: Constructed primarily of lightweight yet durable aluminum, which is corrosion-resistant and ideal for cleanroom or outdoor use.

- Mobility: Equipped with wheels for easy maneuverability, allowing operators to transport it to various locations within a facility.

Benefits of Choosing an Aluminum Gantry Crane for Pump Handling

Opting for an aluminum gantry crane for pump handling offers several advantages:

- Lightweight: Aluminum's lightweight nature simplifies transportation and assembly, reducing the time and effort required for setup.

- Corrosion Resistance: The crane's aluminum construction makes it highly resistant to corrosion, ensuring longevity and suitability for outdoor or chemically challenging environments.

- Mobility: The inclusion of wheels grants exceptional mobility, enabling operators to position the crane precisely where it's needed for pump handling tasks.

- Adaptability: Telescopic legs and adjustable height features make the crane adaptable to various pump sizes and configurations.

- Cleanroom Suitability: Its clean and corrosion-resistant properties render it an excellent choice for cleanroom environments, such as those found in pharmaceutical or electronics manufacturing.

The 2-ton aluminum gantry crane's features and specifications, coupled with these benefits, make it an ideal choice for efficient, safe, and versatile pump handling in industrial settings.

Pump Handling Considerations

Factors to Consider When Selecting a Gantry Crane for Pump Handling

When choosing a gantry crane for pump handling, several crucial factors must be taken into account to ensure efficient and safe operations:

- Weight Capacity Requirements: Determine the weight capacity needed for your pump handling tasks. The crane's lifting capacity should comfortably exceed the weight of the heaviest pump you'll handle. This ensures safety and prevents overloading.

- Space Limitations: Assess the available workspace where the gantry crane will operate. Consider the crane's span width and height adjustment capabilities to ensure it fits within the allocated space. It's essential to have sufficient clearance both horizontally and vertically.

- 3. Environmental Factors (Corrosion Resistance, Outdoor Use): Evaluate the environment in which the crane will operate. If the pump handling tasks involve exposure to corrosive substances or outdoor use, selecting a gantry crane with corrosion-resistant materials, such as aluminum, becomes crucial. Aluminum gantry cranes excel in such conditions due to their resistance to rust and corrosion.

Safety Measures and Regulations Related to Pump Handling

Pump handling tasks come with inherent risks, and it's imperative to prioritize safety. Adhering to safety measures and regulations is essential:

- Training: Ensure that personnel responsible for pump handling are properly trained and certified to operate the gantry crane. Comprehensive training programs should cover crane operation, load handling, and safety protocols.

- Load Inspection: Prior to lifting a pump, inspect it for any defects, damage, or irregularities. Only handle pumps that are in good condition to prevent accidents.

- Secure Attachment: Safely secure the pump to the lifting attachment, such as hooks or slings, using appropriate rigging techniques. A secure attachment is critical to prevent load slippage during lifting and positioning.

- Weight Monitoring: Keep a vigilant eye on the weight being lifted and ensure it remains within the crane's specified capacity. Overloading can result in equipment damage and safety hazards.

- Clear Communication: Establish clear communication between the crane operator and ground personnel involved in pump handling tasks. Effective communication is vital for safe and precise load positioning.

- Regulatory Compliance: Familiarize yourself with local and national regulations related to material handling equipment and crane operations. Compliance with these regulations is essential to avoid legal issues and ensure workplace safety.

- Safety Devices: Use safety devices and accessories, such as limit switches and emergency stop buttons, to enhance crane safety. These features can prevent accidents and equipment damage in case of unexpected situations.

By carefully considering weight capacity, space limitations, and environmental factors while adhering to safety measures and regulations, you can create a safe and efficient pump handling environment using a gantry crane.

Applications of 2 Ton Aluminum Gantry Crane for Pump Handling

Overview of Industries and Applications Where 2 Ton Aluminum Gantry Crane Is Commonly Used

The 2-ton aluminum gantry crane designed for pump handling finds its application across various industries and scenarios where precision, mobility, and corrosion resistance are paramount. Common industries and settings include:

- Manufacturing: In manufacturing facilities, the crane assists in the installation, maintenance, and replacement of pumps used in production processes. Its adaptability to varying pump sizes makes it a versatile choice.

- Oil and Gas: Within the oil and gas industry, this gantry crane proves invaluable for handling pumps used in drilling operations, refineries, and offshore platforms. Its corrosion resistance is particularly advantageous in harsh environments.

- Construction: Construction sites often require the movement and installation of water pumps, concrete pumps, and other heavy equipment. The crane's mobility and lifting capacity facilitate these tasks efficiently.

- Water Treatment: Municipal water treatment plants rely on pumps to manage water distribution and purification. The gantry crane ensures that these pumps are positioned and maintained accurately.

- Chemical Processing: Chemical plants dealing with corrosive substances benefit from the corrosion-resistant properties of the aluminum gantry crane. It assists in handling pumps used in chemical manufacturing processes.

- Utilities: Utility companies use pumps extensively for various purposes, including sewage management and power generation. The gantry crane simplifies the installation and maintenance of these critical pumps.

Pump Handling Tasks That Benefit From This Crane

- Water Treatment Facility: In a municipal water treatment plant, the 2-ton aluminum gantry crane is used to position large pumps responsible for water purification. Its corrosion-resistant construction ensures longevity in the moist environment.

- Oil Rig Maintenance: Offshore oil rigs often require the replacement of pumps used in drilling operations. The crane's mobility allows it to be easily transported to different locations on the rig, ensuring timely maintenance.

- Manufacturing Plant: Within a manufacturing facility, the crane assists in the installation of pumps for hydraulic systems. Its adjustable height and adaptability to varying pump sizes streamline the process.

- Chemical Processing: In a chemical processing plant, the crane is utilized to handle pumps used in the transportation of corrosive chemicals. Its clean and corrosion-resistant nature aligns with strict safety and hygiene requirements.

- Construction Site: At a construction site, the crane facilitates the installation of concrete pumps, ensuring precise positioning and minimizing construction delays.

These real-world examples demonstrate the versatility and practicality of the 2-ton aluminum gantry crane for pump handling in various industries and scenarios. Its ability to handle heavy loads while maintaining corrosion resistance and mobility makes it an asset in critical pump-related tasks.

Installation and Operation

Steps Involved in Setting Up the Aluminum Gantry Crane

Proper installation of the aluminum gantry crane is essential to ensure its safe and efficient operation. Here are the key steps involved in setting up the crane:

- Select a Suitable Location: Choose a level and stable surface for crane setup, ensuring it can support the crane's weight and the loads it will handle.

- Assemble the Frame: Assemble the aluminum frame components according to the manufacturer's instructions. Ensure that all bolts and connections are tightened securely.

- Attach the Wheels: If not already attached, install the wheels on the crane's legs. Ensure they are securely fastened and locked to prevent unintended movement.

- Adjust Height: Adjust the telescopic legs to the desired height, taking into account the specific pump handling task and load height requirements.

- Position the Crane: Move the crane into its operating position, ensuring it is aligned correctly with the pump or load to be handled.

- Secure the Load: Attach the lifting equipment, such as hooks or slings, to the crane's trolley. Ensure that the load is properly secured before lifting.

- Test Run: Perform a test run without a load to ensure that all functions, including hoisting and traversing, are working smoothly and that there are no issues with the setup.

Safety Precautions During Installation and Operation

Safety is paramount when installing and operating the gantry crane:

- Safety Equipment: Ensure that appropriate safety equipment, such as hard hats, gloves, and safety glasses, is worn by all personnel involved in the installation and operation.

- Load Inspection: Before lifting any load, conduct a thorough inspection to ensure it is in good condition and properly attached to the crane's lifting equipment.

- Clear Workspace: Keep the workspace clear of obstacles and personnel not involved in the operation to prevent accidents and collisions.

- Load Capacity: Never exceed the crane's specified load capacity. Overloading can lead to equipment damage and safety hazards.

- Communication: Establish clear communication between the crane operator and ground personnel during operation. Use hand signals or two-way radios for effective communication.

- Emergency Stop: Ensure that the crane is equipped with an emergency stop button or switch that can quickly halt all crane movements in case of an emergency.

- Regular Inspections: Conduct regular inspections of the crane's components, including the frame, wheels, and lifting equipment, to identify and address any wear or damage promptly.

Maintenance Guidelines to Ensure Longevity and Performance

To maintain the longevity and optimal performance of the aluminum gantry crane:

- Lubrication: Regularly lubricate moving parts, such as wheels and trolley wheels, to reduce friction and wear.

- Cleaning: Keep the crane clean and free from debris or corrosive materials that could affect its structural integrity.

- Inspections: Schedule routine inspections to identify and address any wear, damage, or loose components promptly.

- Training: Ensure that personnel responsible for crane operation and maintenance are adequately trained in safe and proper practices.

- Documentation: Maintain records of inspections, maintenance activities, and any repairs performed on the crane.

By following these installation, safety, and maintenance guidelines, you can ensure the safe operation and prolonged lifespan of the aluminum gantry crane, making it a reliable asset for pump handling tasks.

Case Studies

In-Depth Analysis of Specific Projects or Instances Where the 2-Ton Aluminum Gantry Crane Was Employed for Pump Handling

Municipal Water Treatment Plant

- Project Description: A municipal water treatment plant faced the challenge of replacing large water pumps used in the purification process. The cramped workspace and the need for corrosion-resistant equipment made the 2-ton aluminum gantry crane an ideal choice.

- Implementation: The aluminum gantry crane was set up near the pump installation site. Its adjustable height allowed for precise positioning of the replacement pump. The crane's corrosion resistance was crucial due to the water treatment environment.

Offshore Oil Rig Maintenance

- Project Description: An offshore oil rig required routine maintenance of pumps used in drilling operations. The gantry crane's mobility and corrosion resistance were essential for this project, given the harsh marine environment.

- Implementation: The aluminum gantry crane was transported to different locations on the rig using its wheels. It facilitated the removal and replacement of pumps efficiently, reducing downtime and maintenance costs.

Outcomes and Efficiency Improvements Achieved Through Its Use

Municipal Water Treatment Plant

- Efficiency: The use of the aluminum gantry crane significantly reduced the time required for pump replacement, minimizing disruptions to the water treatment process.

- Safety: Precise positioning of the replacement pump enhanced safety, reducing the risk of accidents during installation.

- Cost Savings: The crane's corrosion resistance contributed to its longevity, resulting in cost savings over time due to reduced equipment replacement.

Offshore Oil Rig Maintenance

- Downtime Reduction: The mobility of the gantry crane allowed for quick access to pumps in various locations on the rig, reducing downtime and enhancing operational efficiency.

- Corrosion Resistance: The crane's corrosion resistance proved crucial in the saltwater environment, extending its lifespan and minimizing maintenance requirements.

- Safety: Efficient pump handling enhanced safety on the rig, reducing the risk of incidents during maintenance operations.

These case studies highlight the practical benefits of the 2-ton aluminum gantry crane for pump handling in diverse industrial settings. Its adaptability, mobility, and corrosion resistance contribute to improved efficiency, safety, and cost-effectiveness in such critical tasks.

Aluminum Gantry Cranes vs Steel Gantry Cranes

Brief Comparison with Steel Gantry Cranes

When evaluating the choice between an aluminum gantry crane and alternative crane types, such as steel gantry cranes, several factors come into play:

- Durability: Steel gantry cranes are known for their durability and high load capacity, making them suitable for heavy-duty applications in manufacturing and construction.

- Corrosion Resistance: While steel gantry cranes can be galvanized for enhanced corrosion resistance, they may not match the inherent corrosion resistance of aluminum.

- Weight: Steel gantry cranes are heavier and often require more effort to transport and assemble compared to aluminum gantry cranes.

- Cost: Steel gantry cranes may have a lower initial purchase cost compared to aluminum gantry cranes, but their installation and transportation costs can be higher due to their weight.

Highlighting the Advantages of Aluminum Gantry Cranes in Specific Scenarios

The advantages of aluminum gantry cranes become particularly evident in specific scenarios:

- Cleanroom Environments: Aluminum gantry cranes are preferred in industries like pharmaceuticals and electronics, where cleanroom conditions are crucial. Their clean and corrosion-resistant properties make them an ideal choice.

- Outdoor Use: When exposed to the elements, aluminum gantry cranes outperform steel counterparts due to their natural resistance to corrosion.

- Mobility: For applications that require frequent movement within a workspace, the lightweight and wheeled design of aluminum gantry cranes provide unmatched mobility.

- Adaptability: Aluminum gantry cranes with telescopic legs offer adaptability to varying load heights, making them versatile in handling pumps and equipment of different sizes.

- Cost-Effectiveness: Over the long term, the reduced maintenance and longer lifespan of aluminum gantry cranes can make them cost-effective, especially in corrosive environments.

In summary, while steel gantry cranes excel in heavy-duty applications, aluminum gantry cranes shine in scenarios where mobility, corrosion resistance, and adaptability to specific environments are paramount. The choice between the two depends on the unique requirements of the task at hand and the operating conditions in which they will be used.

Cost Considerations

Factors Affecting the Cost of Acquiring and Operating a 2-Ton Aluminum Gantry Crane

Several factors contribute to the overall cost associated with acquiring and operating a 2-ton aluminum gantry crane:

- Initial Purchase Price: The upfront cost of purchasing the gantry crane, which varies based on the crane's specifications, brand, and features.

- Installation Costs: Expenses related to setting up the crane, including any additional equipment needed for assembly and installation.

- Transportation Costs: If the crane needs to be transported to different locations, expenses for transportation, including fuel and logistics, can add to the overall cost.

- Maintenance and Repairs: Ongoing maintenance costs, including lubrication, inspections, and any necessary repairs, should be factored in.

- Operational Costs: These include energy costs if the crane is electric, as well as labor costs associated with crane operation.

- Training: Costs related to training personnel to operate and maintain the crane safely and effectively.

- Insurance: Depending on the facility and regulations, insurance costs for liability and equipment coverage may apply.

- Resale or Depreciation: Consideration of potential resale value or depreciation of the crane over time.

Return on Investment (ROI) Analysis for Potential Users

To evaluate the ROI of a 2-ton aluminum gantry crane, potential users should consider the following:

- Productivity Gains: Assess how the crane's efficiency and mobility contribute to increased productivity and reduced downtime in pump handling tasks.

- Cost Savings: Calculate the potential cost savings resulting from reduced maintenance, extended equipment lifespan, and minimized equipment replacement.

- Safety Improvements: Factor in the value of improved safety, including reduced accidents and associated costs.

- Environmental Impact: Evaluate any environmental benefits, such as reduced material waste, energy savings, or compliance with environmental regulations.

- Opportunity Costs: Consider the opportunity cost of not using the crane—what other tasks or projects could be undertaken with the time and resources saved?

- Long-Term Viability: Assess the long-term viability of the crane in your facility or industry, considering factors like changing regulations, technological advancements, and evolving business needs.

A comprehensive ROI analysis will help potential users determine whether the investment in a 2-ton aluminum gantry crane aligns with their specific needs and provides a favorable return on investment over time.

Conclusion

Throughout this comprehensive article, we've delved into the world of material handling, specifically focusing on the 2-ton aluminum gantry crane designed for pump handling. Here's a brief recap of the key points we've covered:

- We began with an introduction to the importance of gantry cranes in material handling, highlighting the significance of our specific focus on the 2-ton aluminum gantry crane for pump handling.

- We explored the fundamental concepts of gantry cranes, their types, and the advantages of using aluminum gantry cranes.

- We delved into the critical industrial process of pump handling, emphasizing its significance, challenges, and the need for efficient and safe operations.

- An in-depth overview of the 2-ton aluminum gantry crane provided insights into its design, features, and benefits, including corrosion resistance, mobility, and adaptability.

- We discussed factors to consider when selecting a gantry crane for pump handling, along with safety measures and regulations essential for safe operations.

- Real-world case studies demonstrated the crane's practical applications and the efficiency improvements achieved in various industries.

- A comparison with alternative crane types, such as steel gantry cranes, highlighted the advantages of aluminum gantry cranes in specific scenarios.

- Cost considerations covered factors affecting the cost of acquisition and operation, along with an ROI analysis for potential users.

Emphasis on the Suitability and Benefits of the 2-Ton Aluminum Gantry Crane for Pump Handling

The 2-ton aluminum gantry crane has proven to be an exceptional asset in pump handling tasks across diverse industries. Its lightweight yet durable construction, corrosion resistance, and mobility make it ideally suited for cleanroom environments, outdoor use, and applications where precise positioning of pumps of varying sizes is crucial. Its benefits include improved efficiency, cost-effectiveness, and enhanced safety in critical pump handling operations.

Encouragement for Informed Decision-Making When Selecting Gantry Cranes for Specific Applications

In the world of material handling, selecting the right equipment is paramount. We encourage informed decision-making when choosing gantry cranes for specific applications. Evaluate your unique requirements, consider factors such as mobility, corrosion resistance, and adaptability, and conduct ROI analyses to ensure that your choice aligns with your operational needs and objectives.

The 2-ton aluminum gantry crane for pump handling stands as a testament to innovation in material handling equipment, offering efficiency, versatility, and safety. With careful consideration and informed choices, you can elevate your material handling solutions and enhance productivity in your industrial operations.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch