2 Ton Overhead Hoist and Crane Equipment, Your Choices for 2 Ton Load Handling

2 ton overhead hoists and cranes for sale, including electric, manual, bridge crane, jib, gantry, & specialized hoisting options for efficient load handling.

Category: Light Duty Crane 1, 2, 3 Ton

Your Trusted 2 Ton Overhead Crane Manufacturer & Supplier

2 Ton Overhead Hoist and Crane Equipment, Your Choices for 2 Ton Load Handling

Explore versatile 2 ton overhead hoists and cranes, including electric, manual, bridge crane, jib, gantry, and specialized options for efficient load handling.

Overview of 2 Ton Load Capacity and Its Importance

A 2 ton load capacity is commonly used in a range of industries, offering a practical balance between lifting power and space efficiency. It's suitable for tasks like moving heavy machinery in manufacturing, lifting materials in warehouses, or transporting components in construction. The 2 ton crane provides versatility while being cost-effective and reliable for medium-duty applications.

Why Proper Crane and Hoist Selection Matters

Selecting the right crane or hoist for 2 ton loads is crucial for safety, efficiency, and cost-effectiveness. The right equipment ensures smooth operation, reduces risks of accidents, and minimizes wear and tear. It also helps optimize productivity, particularly in high-volume environments, by matching the lifting capability to the task at hand.

Key Factors to Consider When Choosing Equipment

- Load Type: Different loads—such as engines, parts, or raw materials—require specialized handling. Choose equipment that offers control and stability for the type of load you handle.

- Space and Layout: Consider your available space. For limited headroom, a single girder underhung crane may be more suitable, while freestanding cranes or gantries work better in larger areas.

- Environment: For cleanroom or hazardous environments, select explosion-proof cranes or cleanroom cranes that meet specific safety standards.

- Duty Cycle: Choose based on how frequently the crane will be used. Light-duty workstation cranes or KBK cranes are ideal for less frequent tasks, while heavier-duty options are better for continuous operation.

- Power Source: Consider whether an electric, battery-powered, or manual crane best fits your needs, depending on mobility and available power sources.

- Safety and Maintenance: Ensure that safety features like overload protection and reliable braking systems are included. Long-term maintenance needs should also be considered to reduce operational costs.

By understanding these key factors, you can select the appropriate 2 ton crane or hoist that ensures smooth, safe, and efficient material handling in your facility.

Requirements for 2 Ton Load Handling

Defining Load Types: General Industrial Loads vs. Delicate or Specialized Materials

When selecting the right crane for handling 2 ton loads, the nature of the load is a critical factor. General industrial loads, like metal components or equipment parts, typically require standard lifting solutions. These loads are more robust, and a range of crane options can accommodate them. However, when dealing with delicate or specialized materials, such as electronics, glass, or other precision equipment, the handling requirements become more stringent. These loads require cranes that offer precise control, stability, and protection from damage during lifting, which may necessitate cranes like cleanroom cranes or explosion-proof cranes.

Key Factors to Consider: Load Weight, Shape, and Size

Apart from the weight, which is the most straightforward factor, the shape and size of the load are important considerations. Irregularly shaped or oversized items require additional planning to ensure they are lifted safely and without risk of tipping or damage. For example, lifting long, narrow items such as pipes or beams may require spreader bars or specialized hooks. Understanding the full dimensions and shape of your load will guide the selection of the appropriate crane and lifting accessories.

Frequency of Use and Duty Cycle

How often the crane will be used is another key consideration. If the crane is required for frequent or continuous use, such as in high-volume manufacturing or assembly environments, a more durable, high-duty crane, such as a single girder top-running crane, might be ideal. For less frequent or lighter-duty tasks, options like a KBK workstation crane or portable gantry crane may be more cost-effective while still meeting your requirements for occasional lifting.

Environmental Conditions (Temperature, Humidity, Chemicals, etc.)

Environmental factors can significantly affect crane performance. If you are working in extreme temperatures or areas with high humidity or corrosive chemicals, special considerations must be made. Cranes exposed to these conditions may require anti-corrosion coatings or be built from materials that resist the harsh environment. For instance, explosion-proof cranes are designed for areas with explosive risks, while cleanroom cranes are made from materials that are easy to clean and won't contaminate the environment. These cranes help ensure safe and efficient operations, even in challenging conditions.

Safety Standards and Regulatory Compliance

Safety is paramount when selecting any material handling equipment. All cranes and hoists must comply with local safety regulations and industry standards. This includes having proper overload protection, emergency stops, and braking systems to ensure the crane operates safely under all conditions. Depending on the application, additional safety features such as anti-collision systems, radio controls, or redundant safety mechanisms might be necessary. Compliance with international safety standards, such as OSHA in the U.S. or CE in Europe, is essential to ensure that both the equipment and the operation meet required safety protocols.

In conclusion, selecting the right equipment for 2 ton load handling requires careful consideration of the load characteristics, the frequency of use, environmental conditions, and safety standards. Understanding these factors will help ensure that you choose the right crane to meet your operational needs while maintaining safety and efficiency.

Types of Overhead Hoists and Cranes for 2 Ton Load Handling

When selecting equipment for 2 ton load handling, it's important to choose the right hoist or crane based on the specific needs of your facility. Below are some of the most common types of hoists and cranes used for this capacity range:

Electric Chain Hoist Crane 2 Ton

- Overview: Electric chain hoists are a popular choice for lifting small to medium loads with precision. They offer reliable performance and are especially suited for environments where space is limited.

- Design Considerations: These hoists are designed for high lifting speeds, a compact size, and ease of use, making them ideal for quick, controlled lifting.

- Best Applications: They are well-suited for indoor environments such as manufacturing plants, workshops, warehouses, and assembly lines.

- Advantages: Electric chain hoists are cost-effective, easy to install, and highly versatile. They require minimal maintenance and offer flexibility in various industrial settings.

Electric Wire Rope Hoist Crane 2 Ton

- Overview: Electric wire rope hoists are designed for heavier-duty lifting tasks, particularly when high lifting heights and long spans are required. These hoists provide stronger and more durable lifting solutions.

- Design Considerations: Built for robustness, electric wire rope hoists are efficient at handling larger lifting heights and longer spans, offering strong performance in demanding environments.

- Best Applications: These hoists are ideal for automotive assembly lines, heavy manufacturing plants, and large warehouses where heavy loads and high lifts are common.

- Advantages: They are more durable, can lift higher loads, and are designed to handle larger operational demands, making them perfect for more challenging tasks.

Manual Chain Hoist Crane 2 Ton

- Overview: Manual chain hoists offer a simple and cost-effective solution for smaller-scale operations where power-driven lifting is unnecessary. They rely on manual operation via a hand chain.

- Best Applications: These hoists are typically used for light lifting in areas with limited space or when lifting is infrequent. They are ideal for workshops, small manufacturing facilities, and maintenance tasks.

- Advantages: Manual chain hoists are affordable, portable, and require low maintenance. They are easy to use and are ideal for environments where occasional lifting is needed.

- Limitations: These hoists are slower than electric options and limited to smaller lifts, making them unsuitable for continuous or high-speed lifting operations.

When selecting hoists and cranes for 2 ton load handling, understanding the specific requirements of your operation—such as load type, frequency of use, and space constraints—is essential. Electric chain hoists offer versatility and speed, electric wire rope hoists provide strength and durability for demanding tasks, while manual chain hoists are perfect for occasional light lifting. Your decision should align with both operational needs and budget considerations.

Overhead Bridge Cranes for 2 ton Load Handling

When selecting overhead bridge cranes for handling 2 ton loads, different types of cranes offer unique advantages based on space requirements, flexibility, and specific operational needs. Below is an overview of the most common types:

Single Girder Top Running Crane 2 Ton

- Overview: These cranes feature a lightweight and cost-effective design that is suitable for smaller workshops. The crane runs on rails installed at the top of the structure, providing efficient overhead lifting.

- Best Applications: Ideal for light manufacturing, assembly lines, and warehouses where space and load requirements are moderate.

- Advantages: These cranes are less expensive, have a simpler design, and are easy to install. They are perfect for businesses with budget constraints but still need reliable lifting solutions.

- Limitations: Single girder top running cranes are limited by their span and lifting height, making them unsuitable for heavy-duty or high-lift operations.

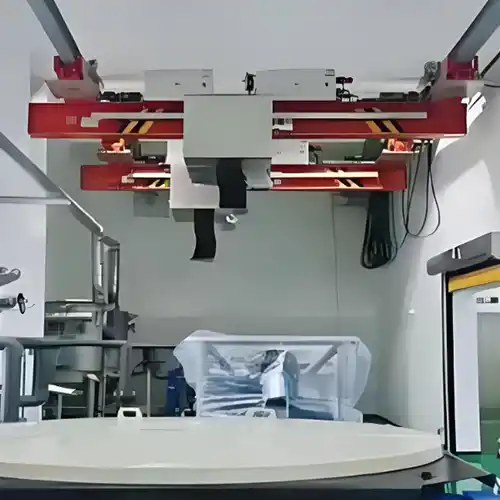

Single Girder Underhung Crane 2 Ton

- Overview: In single girder underhung cranes, the crane runs beneath the rail system. This compact design is perfect for applications where headroom is limited.

- Best Applications: Suitable for environments with limited vertical space, such as smaller workshops, assembly lines, or warehouses.

- Advantages: The low profile of underhung cranes makes them highly efficient in confined spaces. They offer excellent maneuverability and are well-suited for areas with tight headroom.

- Limitations: These cranes have shorter spans and lower lifting heights, which can be a limitation in larger operations or areas with more demanding lifting needs.

- Overview: Telescoping cranes have extendable arms, allowing them to adjust their reach based on the task at hand. This flexibility makes them versatile in a variety of applications.

- Best Applications: Ideal for use in areas where adjustable reach and flexibility in load handling are required, such as construction sites or maintenance work.

- Advantages: These cranes provide versatile, adjustable reach for handling various loads over different distances. Their extendable design is beneficial when working with unpredictable or changing load requirements.

- Limitations: The more complex design of telescoping cranes can result in higher costs and maintenance needs. They are also typically less compact than other types.

Freestanding Bridge Crane 2 Ton

- Overview: Freestanding bridge cranes are designed for situations where no existing structural support is available. These cranes stand on their own, making them ideal for temporary or standalone lifting needs.

- Best Applications: Perfect for small factories, warehouses, and areas that need flexibility in crane placement, such as workshops with no overhead structural support.

- Advantages: These cranes offer flexibility in installation, providing a cost-effective solution for spaces without pre-existing support structures. They are easy to move and reconfigure if needed.

- Limitations: They require more floor space for installation and may incur additional costs due to the need for their own support structure.

- Overview: Cleanroom cranes are specifically designed for use in sterile environments where contamination must be avoided. They are often used in industries like pharmaceuticals, electronics, and biotech.

- Best Applications: Ideal for cleanroom-sensitive industries that require controlled environments, such as pharmaceuticals, electronics manufacturing, and research labs.

- Advantages: These cranes are designed to prevent contamination and maintain the sterile environment, making them crucial in industries where cleanliness is critical.

- Limitations: Due to the specialized materials and design required for cleanroom environments, these cranes tend to have higher upfront costs and require strict maintenance protocols.

- Overview: Explosion-proof cranes are specifically built for use in hazardous environments where there is a risk of explosion, such as in chemical plants, mining, or oil and gas industries.

- Best Applications: These cranes are essential in environments that involve flammable materials, such as chemical plants, refineries, and gas plants, where safety is a top priority.

- Advantages: Explosion-proof cranes are built to ensure safety in volatile environments, reducing the risk of sparks or ignition in hazardous locations. They are designed to meet strict safety standards.

- Limitations: The primary drawbacks of explosion-proof cranes are their high cost and the need for special certifications to ensure they meet safety standards for use in hazardous environments.

Selecting the appropriate type of overhead bridge crane for 2 ton load handling depends on your operational needs, environmental conditions, and budget. While single girder cranes offer a cost-effective solution for smaller spaces, options like telescoping or freestanding cranes provide greater flexibility. Cleanroom and explosion-proof cranes are specialized designs for handling sensitive materials and hazardous environments, respectively. Understanding the unique features and applications of each crane type will help ensure you choose the right equipment for your business.

Light Duty Cranes for 2 ton Load Handling

Light-duty cranes are designed for applications that require lifting and moving lighter loads, typically in environments where space is limited or the load capacity is relatively low. These cranes are ideal for tasks that involve smaller, repetitive movements and require easy installation and maintenance. Below is an overview of some popular light-duty cranes suitable for handling 2 ton loads:

Light Workstation Crane 2 Ton

- Overview: Light workstation cranes are designed for ergonomic, small-scale workstations, making them ideal for handling light loads in confined spaces.

- Best Applications: Perfect for assembly tasks, packaging, material handling, and other operations in manufacturing facilities or workshops that require easy access to various points in the workspace.

- Advantages: Compact and easy to install, light workstation cranes improve productivity by reducing manual lifting and offering ergonomic benefits. Their flexibility and ease of use allow for faster handling of materials.

- Limitations: Their main limitation is their lower load capacity, typically designed for loads under 2 tons, making them unsuitable for heavier tasks.

- Overview: KBK cranes are modular, flexible crane systems that can be adapted for a variety of applications, offering excellent scalability and customization options.

- Best Applications: These cranes are commonly used in small workshops, light manufacturing environments, and warehouses where versatility and adaptability are key.

- Advantages: The highly customizable nature of KBK systems means they can be easily tailored to meet specific operational needs. They are simple to install and reconfigure, making them a great solution for dynamic environments.

- Limitations: While versatile, KBK cranes have lower load capacities and more limited span compared to other cranes, making them less suitable for heavier or more expansive lifting tasks.

Truss Girder KBK Crane 2 Ton

- Overview: A more robust version of the standard KBK crane, the truss girder KBK crane is designed for slightly heavier light-duty tasks, providing greater strength and stability.

- Best Applications: Truss girder KBK cranes are ideal for environments requiring flexibility with heavier loads than a standard KBK crane can handle, such as light manufacturing and assembly operations that occasionally need more strength.

- Advantages: The truss design provides added stability and strength, making it suitable for applications where higher loads need to be lifted. It retains the modularity and ease of installation of the standard KBK crane while offering greater durability.

- Limitations: Truss girder KBK cranes tend to have a higher cost than standard KBK systems due to their enhanced capabilities. They are also more specialized and may not be necessary for operations with lighter load requirements.

Monorail Crane 2 Ton

- Overview: Monorail cranes feature a single rail on which the crane moves, making them ideal for transporting materials along a fixed path in a straight line.

- Best Applications: Best suited for applications where materials need to be moved along a consistent, straight path. This could include transporting components across an assembly line, or moving goods in and out of a warehouse.

- Advantages: Monorail cranes are efficient for repetitive tasks and help save floor space, as they utilize overhead tracks. Their linear movement is ideal for streamlined material handling operations in confined areas.

- Limitations: Their movement capabilities are limited to the fixed rail system, meaning they are less flexible than other crane types. Monorails also have a limited lifting range and cannot handle complex movements or multi-directional lifts.

Light-duty cranes, including workstation cranes, KBK cranes, truss girder KBK cranes, and monorail systems, offer flexible, cost-effective solutions for handling 2 ton loads. Each type of crane is designed with specific applications in mind, and choosing the right option depends on factors such as space constraints, load handling requirements, and the type of work being performed. Whether you're looking for a compact solution for small-scale tasks or a more robust crane for slightly heavier loads, light-duty cranes can provide an efficient way to increase productivity and streamline operations.

Small Gantry Cranes and Portale Crane for 2 ton Load Handling

Small gantry cranes are compact and versatile, offering effective solutions for lifting and transporting lighter loads in environments with space constraints or where portability is essential. These cranes are ideal for smaller-scale operations that require mobility, easy setup, and flexibility. Below is an overview of various small gantry cranes suitable for handling 2 ton loads:

Single Girder Gantry Crane 2 Ton

- Overview: Single girder gantry cranes are characterized by a simple design, with a single beam running across the workspace to support the lifting mechanism.

- Best Applications: These cranes are best suited for small workshops, manufacturing lines, or outdoor environments where cost-effectiveness and space-saving are important.

- Advantages: They are highly cost-effective, easy to install, and provide straightforward solutions for light-duty lifting tasks.

- Limitations: While practical, these cranes are limited by smaller spans and can only handle lighter loads compared to more complex gantry systems.

- Overview: Semi-gantry cranes are a hybrid design, with one support fixed on the ground and the other mounted on a rail system. This design allows for a combination of overhead and ground-level movement.

- Best Applications: Semi-gantry cranes are ideal for smaller industrial spaces where full overhead track systems are not feasible, making them useful in areas with space constraints.

- Advantages: These cranes provide flexibility in movement and are a space-saving solution, offering a more efficient use of the available floor area.

- Limitations: The lifting capacity is limited compared to double girder gantries, and their use is best suited for lighter loads and shorter spans.

- Overview: Portable gantry cranes are lightweight and designed for easy relocation. These cranes are typically used in temporary setups or mobile applications.

- Best Applications: Commonly used on construction sites, for small maintenance tasks, or in situations where a crane needs to be moved frequently between work locations.

- Advantages: Their high portability makes them ideal for use in areas where the crane needs to be relocated frequently. They are also relatively low in cost, making them a budget-friendly option for temporary lifting needs.

- Limitations: Portable gantry cranes are limited by their lifting height and span, making them suitable only for lighter, more localized lifting tasks.

- Overview: Aluminum gantry cranes are lightweight, corrosion-resistant, and designed for non-industrial environments where portability and ease of movement are key.

- Best Applications: These cranes are well-suited for workshops, light lifting tasks, and mobile operations where weight and portability are essential.

- Advantages: The key benefit of aluminum gantry cranes is their lightweight construction, which allows for easy transport and handling. Their corrosion resistance makes them ideal for use in environments where rust and degradation are concerns.

- Limitations: Due to the material's strength limitations, aluminum gantry cranes are typically suited only for smaller lifting capacities, which makes them less suitable for heavy-duty industrial applications.

Battery-Powered Gantry Crane 2 Ton

- Overview: Battery-powered gantry cranes are designed for applications that require mobility without the need for fixed power sources. These cranes are powered by rechargeable batteries, offering increased flexibility in temporary or remote settings.

- Best Applications: Battery-powered gantry cranes are ideal for use in temporary work sites, outdoor environments, or remote locations where electricity is not readily available.

- Advantages: These cranes are highly mobile and provide flexibility in remote or off-grid locations. Since they do not require fixed electrical infrastructure, they are well-suited for temporary lifting applications.

- Limitations: Battery life can limit the operational time of these cranes, and their lifting capacity is often lower than that of traditional gantry cranes with permanent power sources.

Small gantry cranes offer a range of options for handling 2 ton loads in space-constrained or mobile work environments. From cost-effective single girder designs to highly portable aluminum or battery-powered options, these cranes provide versatile and efficient lifting solutions for smaller operations. While each type has its strengths, the choice of crane should align with the specific needs of the workplace, considering factors such as mobility, lifting capacity, and environmental conditions.

Jib Cranes for 2 ton Load Handling

Jib cranes are versatile lifting devices that provide localized lifting solutions in confined spaces or specific areas within a workshop or industrial environment. These cranes are designed for efficient operation in smaller areas, offering flexibility, mobility, and ease of installation. Below are the key types of jib cranes suitable for handling 2 ton loads:

Pillar-Mounted Jib Crane 2 Ton

- Overview: Pillar-mounted jib cranes are fixed cranes with a rotating arm, mounted on a stationary pillar. The arm can rotate around the pillar to provide a wide working range within its radius.

- Best Applications: Ideal for workstations or areas where localized lifting is required, such as assembly lines, repair stations, and heavy material handling.

- Advantages: These cranes are space-efficient and provide ergonomic solutions for workers by minimizing manual lifting efforts. They are easy to install and require minimal space.

- Limitations: The main limitation is the rotation radius, which restricts the reach of the crane and makes it unsuitable for handling loads outside of its designated coverage area.

- Overview: Wall-mounted jib cranes are attached to an existing wall or structural support, with a rotating arm extending from the wall to handle materials within its radius.

- Best Applications: Best suited for small workstations, areas where floor space is limited, or when you need to take advantage of existing structural supports.

- Advantages: These cranes save valuable floor space and are relatively easy to install. They are a cost-effective solution for facilities with limited space or in existing buildings without the need for additional structural support.

- Limitations: Wall-mounted jib cranes are limited by the structural integrity of the wall they are mounted on. If the wall is not strong enough to bear the load or if there is insufficient clearance, the crane may not be feasible.

Wall-Traveling Jib Crane 2 Ton

- Overview: Wall-traveling jib cranes are similar to wall-mounted jib cranes, but with the added functionality of being able to travel along the length of the wall.

- Best Applications: These cranes are ideal for large industrial spaces with multiple workstations or areas where flexibility in coverage across a longer distance is required.

- Advantages: Wall-traveling jib cranes offer increased mobility along the wall, providing flexibility in use across different workstations. They are still space-efficient and improve the overall workflow.

- Limitations: The primary limitation is the length of the wall or the space in which the crane can travel. The crane's range is confined to the structural length of the wall it is mounted on.

Electric Portable Jib Crane 2 Ton

- Overview: Electric portable jib cranes are compact, mobile units equipped with electric hoists for easier lifting and transportation of materials.

- Best Applications: These cranes are ideal for small-scale lifting tasks, maintenance, or temporary setups in environments where mobility and electric-powered lifting are required.

- Advantages: These cranes offer the benefit of portability, allowing users to move them between workstations or areas within a facility. The electric hoist makes lifting tasks easier and less physically demanding.

- Limitations: Although they provide mobility, these cranes are limited in lifting capacity and span, making them suitable only for smaller, localized tasks.

Battery-Powered Portable Jib Crane 2 Ton

- Overview: Battery-powered portable jib cranes operate similarly to electric portable jib cranes, but they are powered by rechargeable batteries, allowing for more freedom of movement.

- Best Applications: These cranes are ideal for remote work environments, outdoor construction sites, or temporary installations where access to electrical outlets is not available.

- Advantages: The key advantage is the mobility offered by the battery-powered design, which eliminates the need for electrical outlets. These cranes are versatile and can be used in a variety of settings.

- Limitations: Battery-powered cranes are limited by the battery life and load capacity. The time between charges may affect their performance on longer tasks, and the lifting capacity may be lower compared to other crane types.

Jib cranes offer flexible, localized lifting solutions for a range of industrial environments. For handling 2 ton loads, these cranes provide a mix of portability, space-efficiency, and ergonomic benefits. Whether you need a fixed solution like pillar-mounted cranes or a more mobile option like battery-powered portable cranes, jib cranes offer a versatile approach to lifting in confined or dynamic workspaces. The key to selecting the right jib crane lies in understanding the specific needs of your workspace, including mobility, available structural support, and the range of lift required.

Key Considerations for Equipment Selection

When selecting overhead cranes, hoists, or other material handling equipment for 2 ton load capacity, it's crucial to take a comprehensive approach that considers various operational, environmental, and safety factors. Each factor plays a significant role in ensuring efficient, safe, and effective load handling. Below are the key considerations you should factor into your selection process:

Load Handling Capacity

Understanding the weight, size, and shape of the materials to be lifted is the most critical aspect of crane selection. The load capacity of the crane must exceed the weight of the heaviest material you plan to lift, while also accommodating the size and shape of the load. In addition, certain materials may require specialized lifting attachments (e.g., lifting beams, grabs, slings), which can affect how the load is handled and distributed.

- Considerations: Ensure the crane's capacity is within the required range for 2 ton loads. Account for load distribution and handling method.

- Examples: Lifting heavy equipment, large containers, or assembly components in factories and warehouses.

Lifting Height and Span

Lifting height refers to the distance a load needs to be raised, while span refers to the distance the crane needs to cover horizontally. Both parameters influence crane design and selection, as different crane types are suited for varying heights and spans.

- Lifting Height: Assess the vertical distance the crane needs to travel. Cranes for higher lifting requirements will have longer hoists and lifting mechanisms.

- Span: Evaluate the horizontal distance between the crane's support points (such as beams or columns). Longer spans require more robust crane structures and more powerful motors.

- Considerations: Ensure that the crane design fits the available headroom and the intended span within your facility or workspace. This is especially important in environments with limited space, such as small workshops or areas with existing infrastructure.

Environmental Conditions

Different environments present different challenges that affect crane performance. Outdoor, industrial, or specialized environments such as cleanrooms or hazardous areas will dictate the type of crane and hoist system needed.

- Indoor vs. Outdoor: Outdoor cranes may require weather-resistant coatings or special materials to protect against the elements, whereas indoor cranes may need to accommodate specific building constraints.

- Cleanrooms: Cranes used in cleanroom environments require strict contamination controls, often built with non-shedding materials and smooth surfaces.

- Hazardous Locations: Cranes operating in hazardous environments (e.g., explosive, flammable, or toxic areas) must be built to meet stringent safety standards and equipped with explosion-proof features.

- Considerations: The operating environment will influence materials used, the crane's design, and any additional protective coatings or safety certifications required.

Power Source

The power source for cranes can vary depending on the application, mobility needs, and power availability. The most common options include manual, electric, battery-powered, and pneumatic cranes.

- Manual: Simple, cost-effective, and often used for light lifting or occasional tasks.

- Electric: Ideal for continuous operation and higher lifting speeds. Electric cranes are more efficient and can be used in various environments.

- Battery-Powered: Suitable for locations without easy access to a power grid, offering mobility without the need for a constant power supply.

- Pneumatic: Used in applications where electrical equipment cannot be used, such as in certain explosive environments.

- Considerations: Choose the power source based on the operational scale, worksite mobility, and power availability in your facility.

Safety Features

Safety is paramount when selecting material handling equipment. Overload protection, emergency stops, brakes, and anti-collision systems help prevent accidents, damage to the crane, and injury to workers.

- Overload Protection: Prevents the crane from lifting loads heavier than its rated capacity, ensuring safety and preventing damage to the crane.

- Emergency Stops: An essential safety feature that allows the crane to be stopped immediately in the event of an emergency.

- Brakes: Ensure the crane's load is securely held in place when not in motion and can be safely lowered when necessary.

- Anti-Collision Systems: Especially useful for multiple cranes operating in the same space. These systems prevent crane collisions and ensure smooth operation in confined spaces.

- Considerations: Always ensure your crane meets local safety standards and industry regulations, such as ISO, OSHA, or CE requirements. Additional safety features, like visual or auditory alarms, might be necessary depending on the environment.

Selecting the right crane or hoist for handling 2 ton loads involves a careful evaluation of several factors, including load capacity, lifting height, environmental conditions, power sources, and safety features. By understanding the specific needs of your operation, you can choose equipment that maximizes productivity while ensuring safety and compliance with industry standards. Keep these considerations in mind to make an informed decision and ensure the efficient and safe handling of materials within your workspace.

Applications of 2 ton Hoists and Cranes

Overhead hoists and cranes with a 2 ton load capacity are highly versatile and widely used across various industries. They are designed to meet specific needs depending on the type of material, equipment, and tasks involved. Below are the key applications for 2 ton hoists and cranes:

Automotive Manufacturing

In automotive manufacturing, 2 ton hoists and cranes are commonly used to handle various components during the assembly process.

- Applications: Lifting engine components, transmissions, drive shafts, suspension parts, and other large automotive components.

- Benefits: These cranes facilitate smooth and precise movement of heavy automotive parts, allowing for efficient assembly line operations. They are often used for both assembly and maintenance tasks, reducing manual handling and improving safety.

Electronics and Semiconductors

The electronics and semiconductor industries require careful handling of sensitive and often fragile components, making 2 ton hoists and cranes essential for moving delicate materials without causing damage.

- Applications: Lifting and transporting sensitive materials such as circuit boards, microchips, semiconductor components, and delicate machinery.

- Benefits: The ability to handle these lightweight yet fragile components with precision reduces the risk of damage during transport. Cleanroom cranes, in particular, are critical in these environments to maintain contamination-free conditions.

Warehouses and Distribution

In warehouse and distribution centers, 2 ton hoists and cranes are invaluable for material handling, allowing workers to move goods quickly and safely.

- Applications: Moving stock, lifting packaged goods, handling storage bins, and organizing inventory.

- Benefits: With high lifting capacities and precision, these cranes help optimize warehouse workflows by streamlining material movement and reducing manual labor. Their compact design allows them to fit in narrow aisles and tight spaces.

Aerospace and Defense

Aerospace and defense industries require cranes that can handle large and heavy components while adhering to strict safety and regulatory standards.

- Applications: Lifting aircraft parts such as wings, fuselages, landing gear, and other aerospace components.

- Benefits: 2 ton hoists and cranes are ideal for moving critical components with precision. These cranes ensure that parts are handled safely and securely in the delicate and high-stakes environments of aerospace manufacturing, repair, and maintenance.

Heavy Manufacturing

Heavy manufacturing plants, such as those producing large industrial machinery, also rely on 2 ton hoists and cranes for lifting and moving machine parts and components.

- Applications: Lifting heavy machine components, subassemblies, and large parts used in industrial machinery production.

- Benefits: These cranes enable efficient handling of bulky components, facilitating smoother workflows in factories where large-scale equipment and heavy machinery need to be moved, assembled, or disassembled. They improve productivity and ensure safety during the manufacturing process.

From the automotive industry to aerospace and heavy manufacturing, 2 ton hoists and cranes play a critical role in improving the efficiency and safety of material handling. By addressing the unique needs of each application, these cranes help ensure smooth and reliable operations, contributing to enhanced productivity across diverse industrial environments.

How to Choose the Right Crane or Hoist for Your Facility

Selecting the right crane or hoist for handling 2 ton loads is crucial for optimizing your operations, ensuring safety, and enhancing productivity. Here's a structured approach to help guide you through the decision-making process:

Evaluate Your Needs

Before choosing a crane or hoist, it's essential to assess the specific needs of your facility. Understanding the type of loads, operational goals, and space constraints will guide you in selecting the best solution.

- Load Types: Consider the weight, size, and shape of the materials you need to lift. For example, if you are handling bulky and irregularly shaped loads, a crane with more precise control, such as an electric chain hoist or a monorail system, may be necessary.

- Facility Layout: Review the available space in your facility, including ceiling height, aisle width, and floor space. A narrow or constrained layout may require a compact design, such as a single girder top running crane or a wall-mounted jib crane, while a larger open area might accommodate a freestanding bridge crane or a gantry crane.

- Lifting Requirements: Define the required lifting height and span for your operations. Overhead bridge cranes are typically better for handling large spans, while smaller areas with limited headroom may benefit from underhung cranes or jib cranes.

Determine Crane Type

Choosing the correct type of crane will depend on the specific tasks and workspace conditions.

- Overhead Bridge Cranes: If your facility requires lifting over large spans and high loads, an overhead bridge crane (single girder or double girder) is ideal. It offers flexibility in lifting height and load capacity, making it suitable for most industrial environments, including manufacturing and warehouses.

- Gantry Cranes: For environments with limited overhead support or where portability is required, a gantry crane (single girder or semi-gantry) provides a solid option. These cranes can be used outdoors or in areas where fixed support structures are unavailable.

- Jib Cranes: When localized lifting is needed, especially for smaller, lighter loads, jib cranes (pillar-mounted or wall-mounted) offer ergonomic and efficient solutions. They are excellent for handling tasks at workstations where materials need to be rotated or positioned in tight spaces.

- Monorail Systems: Monorail cranes are suitable for repetitive, linear lifting tasks along a fixed path. They are ideal for transporting goods along a dedicated route in a warehouse or distribution center.

Consider Environmental Factors

Environmental conditions play a significant role in crane selection. Cranes must be suited to the working environment to ensure safe and reliable performance.

- Cleanrooms: If your operations require cleanroom conditions (such as in pharmaceuticals or electronics), a cleanroom crane is essential. These cranes are designed to prevent contamination and meet specific hygiene standards.

- Explosive or Hazardous Environments: For industries such as oil and gas, chemical manufacturing, or mining, cranes built with explosion-proof features are necessary. These cranes are designed to prevent sparks and ensure safety in volatile environments.

- Outdoor Use: If your crane needs to operate outdoors or in exposed environments, consider materials and designs that can withstand weather conditions. A gantry crane or a crane with corrosion-resistant features may be required for durability in harsh conditions.

Selecting the right crane or hoist for your facility involves careful consideration of the load types, layout, environmental factors, and lifting requirements. By evaluating your needs, determining the appropriate crane type, and factoring in environmental conditions, you can ensure that your facility is equipped with the best material handling solution for efficient and safe operations.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch