2000KG KBK Rail Crane for Sale United Kingdom, 2 Ton Crane Designs

2 ton kbk rail crane for sale United Kingdom, light, flexible, modular design kbk crane, cost-effective material handling overhead crane for you.

| Crane type | kbk rail crane 2 ton |

| Crane capacity | 2 ton |

| Crane span | 5 m |

| Lifting height | 3.2 m |

| Power supply | 380v50hz3p |

Category: United Kingdom

Your Trusted Overhead KBK Rail Crane Manufacturer & Supplier

2000KG KBK Rail Crane for Sale United Kingdom, 2 Ton Crane Designs

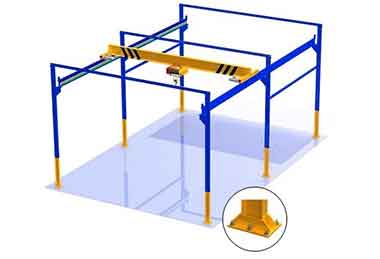

2 Ton kbk Rail Crane,cost-effective, Flexible & Modular Design kbk Crane

2 ton kbk rail crane for sale United Kingdom, light, flexible, modular design kbk crane, cost-effective material handling overhead crane for you.

Case Study- 2 Ton KBK Rail Crane for Sale in United Kingdom

A United Kingdom manufacturing company was in need of a reliable material handling solution for their facility. They required a crane with specific specifications to efficiently move and transport loads within their production area. After careful evaluation, they decided to invest in a 2-ton KBK Rail Crane to meet their lifting and handling needs. This case study outlines the main specifications of the crane and its successful implementation at the project location in United Kingdom.

Crane Specifications of kbk Rail Crane System

- Crane Capacity: 2 tons

- Crane Span: 5 meters

- Crane Lifting Height: 2 meters

- Power Supply: 380V, 50Hz, 3-phase

Lifting Requirments of 2000kg kbk Rail Crane System

The manufacturing facility had been facing several challenges in their material handling process, including inefficiency and potential safety risks. They needed a solution that would allow them to:

- Safely lift and transport heavy loads within the facility.

- Maximize space utilization in their production area.

- Improve overall productivity and reduce manual labor.

- Ensure reliability and durability of the lifting equipment.

Custom KBK Rail Crane Solution

After conducting a thorough evaluation of their needs, the company decided to invest in a 2-ton KBK Rail Crane. This solution offered several benefits:

- Lifting Capacity: With a 2-ton lifting capacity, the crane was well-suited for their requirements.

- Crane Span: The 5-meter crane span allowed for the efficient coverage of a significant area within their facility.

- Lifting Height: The 2-meter lifting height provided the necessary vertical reach for their specific applications.

- Power Supply: The crane's compatibility with the local power supply (380V, 50Hz, 3-phase) ensured seamless operation.

- KBK Rail System: The KBK Rail system was chosen for its flexibility and ease of movement. This system allows the crane to smoothly traverse the facility, making it suitable for various material handling tasks.

The installation and commissioning of the 2-ton KBK Rail Crane in United Kingdom were carried out by a team of qualified technicians. The crane was positioned strategically to cover the most critical work areas within the facility. Staff members received training on the safe operation of the crane to ensure the highest level of safety and productivity.

The implementation of the 2-ton KBK Rail Crane resulted in significant improvements for the United Kingdom manufacturing company:

- Increased Productivity: The crane facilitated faster and more efficient material handling, reducing production downtime.

- Enhanced Safety: The crane's precise control and safety features minimized the risk of accidents and injuries in the workplace.

- Space Optimization: The crane's ability to move loads horizontally and vertically allowed for better use of available space.

- Durability: The crane's robust construction and quality components ensured a long operational lifespan.

- Cost Savings: By reducing manual labor and increasing productivity, the company realized cost savings over time.

The investment in a 2-ton KBK Rail Crane proved to be a wise decision for the United Kingdom manufacturing company. The crane's specific specifications, including its lifting capacity, span, and lifting height, met their material handling needs efficiently. This solution improved overall productivity, safety, and space utilization, ultimately contributing to the company's success in its manufacturing operations.

Main Parts and Components of 2000kg KBK Rail Crane System

2000kg kbk rail crane main parts and component for for sale United Kingdom

KBK crane system for delivery to United Kingdom

2 ton electric chain hoist for kbk crane system

Electric motor driven trollley, the main parts of kbk crane system 2000kg

KBK crane motor nameplate, and the custom motor is provied based on your lifting requirement.

Small parts and spare parts of 2 ton kbk rail crane for sale UK at good price

KBK (Kundel Kranbau) Rail Crane: Main Parts and Features

KBK rail cranes are known for their flexibility, efficiency, and ease of use in material handling applications. They are modular systems consisting of several key parts and features that contribute to their effectiveness. Here are the main parts and features of KBK rail cranes:

- Rail System: - C-rail or I-beam design: KBK rail systems are typically configured as C-rail or I-beam tracks, which serve as the infrastructure for the crane's movement. These tracks are installed overhead and on the floor to create a path for the crane.

- Bridge or Trolley: - Bridge or trolley with hoist: The bridge or trolley is the mobile part of the crane that travels along the rail system. It is equipped with a hoisting mechanism for lifting and lowering loads.

- Hoisting Unit: - Electric wire rope or chain hoist: The hoisting unit is responsible for lifting and lowering the loads. It typically consists of an electric wire rope hoist or chain hoist with the necessary controls for precise handling.

- End Carriages: - End carriages with wheels: These are mounted on the ends of the bridge or trolley and contain wheels or rollers that run along the rails, ensuring smooth and controlled movement.

- Pendant Control or Radio Control: - Operator controls: KBK rail cranes come with operator controls, which can be in the form of a pendant control with buttons or a radio remote control. These controls enable the operator to maneuver the crane and control load handling.

- Motor Drives: - Electric motors: Electric motors drive the bridge and hoisting mechanisms. They are designed for efficient and precise movement.

- Load Handling Attachments: - Hooks, magnets, or specialized attachments: The crane can be equipped with various load handling attachments to suit different applications, such as hooks for general lifting, magnets for handling ferrous materials, or custom attachments for specialized tasks.

Key features of KBK rail crane sytem

- Modularity: - KBK rail cranes are highly modular, allowing for easy configuration and customization to meet specific requirements. You can add or remove components as needed.

- Smooth Movement: - The rail system and end carriages provide smooth and precise movement, reducing the risk of load sway and ensuring accurate positioning.

- Easy Installation: - KBK rail systems are relatively easy to install and can be adapted to existing structures, making them a cost-effective choice for material handling solutions.

- Space-Efficient: - KBK cranes are ideal for facilities with limited space, as they operate overhead and do not require a large footprint on the ground.

- Safety Features: - KBK rail cranes are equipped with safety features, such as limit switches, emergency stop buttons, and overload protection, to ensure safe operation.

- Versatility: - They can be used in various industries and applications, including manufacturing, warehousing, automotive, and assembly, making them highly versatile.

KBK rail cranes are widely used for their reliability, adaptability, and efficiency in material handling tasks, and their modular design allows for easy expansion and customization as the needs of the application change.

Advantages of KBK Rail Crane Over Traditional Bridge Crane

KBK rail cranes offer several advantages over traditional bridge cranes, making them a preferred choice for certain applications:

- Modularity and Flexibility: - KBK rail cranes are highly modular, allowing for easy configuration and adaptation to specific needs. This modularity makes them more flexible and customizable than traditional bridge cranes.

- Lightweight Design: - KBK cranes are generally lighter in weight compared to traditional bridge cranes. This results in reduced structural requirements and lower installation costs.

- Ease of Installation: - Installing KBK rail systems is relatively straightforward, and they can often be added to existing structures without extensive modifications. Traditional bridge cranes may require more significant construction work.

- Compact Footprint: - KBK rail systems run overhead and have a compact footprint, making them suitable for facilities with limited floor space. Traditional bridge cranes may take up more ground space due to their supporting structures.

- Precise and Smooth Movement: - KBK rail cranes offer precise and smooth movement, reducing the risk of load sway and enabling accurate positioning of loads.

- Cost-Effective: - Due to their modularity, ease of installation, and lower structural requirements, KBK rail cranes can be a cost-effective solution for many applications.

- Easy Expansion: - KBK rail systems can be expanded or modified with relative ease, allowing for future adjustments as business needs change.

Similarities between KBK Rail Cranes and Bridge Cranes

- Both are types of overhead cranes used for material handling.

- They are capable of lifting and moving heavy loads within a facility.

- Safety features are integrated into both types to prevent accidents.

- They can be used in various industries and applications, including manufacturing and warehousing.

Differences between KBK Rail Cranes and Bridge Cranes

Now let us to check the comparison of KBK rail cranes and traditional bridge cranes in a table format:

| Aspect | KBK Rail Crane | Bridge Crane |

|---|---|---|

| Modularity | Highly modular and flexible | Less modular and adaptable |

| Weight | Lighter in weight | Heavier and bulkier |

| Installation | Easier installation | May require more complex construction work |

| Footprint | Compact overhead footprint | Larger footprint, ground-based |

| Precise Movement | Offers precise and smooth movement, suitable for precise positioning of loads | Offers smooth movement but may have greater load sway |

| Expansion | Easy expansion and modification | Typically less flexible for expansion |

| Cost-Effectiveness | Often more cost-effective due to modularity and lower installation costs | May have higher installation and structural costs |

| Suitable Applications | Assembly lines, workstations, light manufacturing, warehousing, maintenance | Heavy lifting, long spans, and applications requiring high lifting capacities |

| Maintenance and Cleanliness | Easier maintenance and suitability for clean environments | May have more exposed components and may not be as suitable for clean environments |

| Usage in Specific Industries | Common in industries with precision workstations and lighter loads | Used in a wide range of industries, including heavy manufacturing and heavy lifting applications |

This table summarizes the key similarities and differences between KBK Rail Cranes and traditional Bridge Cranes, helping you understand their respective strengths and applications. The choice between the two depends on the specific needs of your material handling tasks and the characteristics of your facility.

Typical Applications Where KBK Rail Cranes Outperform Other Types of Overhead Cranes

KBK rail cranes are well-suited for various applications where their advantages are particularly beneficial:

- Assembly Lines: KBK rail cranes are commonly used in assembly lines, where their smooth movement and ability to cover specific workstations make them ideal for repetitive manufacturing processes.

- Workstations and Production Cells: They are often used in production cells for efficient and ergonomic load handling, such as in the automotive industry for engine assembly.

- Warehousing: KBK rail cranes can efficiently move and stack items in warehouses, especially in situations where space is limited, and precise load placement is crucial.

- Light Manufacturing: Industries involved in light manufacturing, such as electronics and small parts assembly, find KBK rail cranes suitable due to their ability to handle smaller loads with precision.

- Maintenance and Repair: KBK rail systems are used in maintenance facilities to handle equipment, components, and machinery during repairs or maintenance tasks.

- Clean Environments: Environments where cleanliness and contamination control are essential, such as in the pharmaceutical or food industries, benefit from KBK cranes because they have fewer exposed components and are easier to clean.

- Textile Industry: KBK rail cranes are commonly used in textile factories for transporting rolls of fabric efficiently.

- Painting and Finishing Lines: Their precise movement and adaptability make KBK rail cranes suitable for use in painting and finishing lines where accurate workpiece positioning is crucial.

It's important to note that while KBK rail cranes offer many advantages, traditional bridge cranes are still preferred for heavy-duty lifting tasks and applications that require high lifting capacities and long spans. The choice between these crane types depends on the specific needs of the application.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch