Warehouse Overhead Crane,Bridge Crane & Eot Crane for Warehous

Warehouse overhead crane & crane system for sale. Customized overhead cranes, top running & underhung running crane for material handling in warehouse.

Category: Overhead Crane for Your Use

Your Trusted Warehouse Overhead Crane Manufacturer & Supplier

Warehouse Overhead Crane, Material Handling in Warehouse

Top running & underhung running crane for material handling in warehouse

Warehouse overhead crane & crane system for sale. Customized overhead cranes, single girder/double girder, top running / underhung running crane for material handling in warehouse.

We offer high-quality warehouse overhead cranes to customers in order to improve their working efficiency and safety. The warehouse crane is available in a variety of configurations to meet a variety of lifting needs, including single girder, double girder, top running, and underhung systems. Our bridge cranes are built to ensure long-term reliability and durability. We can provide you with a customized overhead material handling solution to meet your specific lifting requirements because we have a professional crane speaclist team and advanced manufacturing factory.

Warehouses are important places to store goods, but they are also the main location for goods turnover. Warehouse loading and unloading is frequent, and relying on manpower alone is inefficient and time-consuming, so warehouse operations have some operating equipment to assist. The warehouse crane is used to load, unload, and transport materials. Because it can replace human labor in carrying heavy loads, this overhead crane is especially popular in the manufacturing industry. This equipment allows for the lifting of goods across the entire warehouse floor.

Warehouse Crane Systems for Your Material Handling in Warehouse

The lifting mechanism, crane running mechanism, and trolley running mechanism are the three basic components of the warehouse crane system. The lifting mechanism is primarily made up of an electric hoist, wire rope, pulley, hook, or other spreader.

Which type of warehouse crane—an overhead crane, a gantry crane, or a hoist jib cane—do you require? A custom warehouse crane system is designed to meet particular needs.

- Warehouse overhead cranes include double-girder overhead cranes, single-girder overhead cranes, top running overhead crane and underhung bridge cranes, and others.

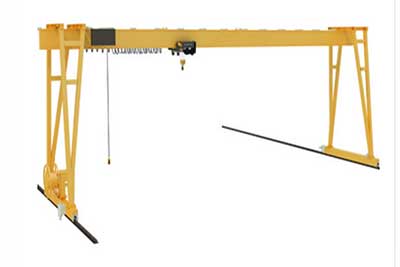

- Warehouse gantry cranes include semi-gantry cranes, single girder gantry cranes, and double girder gantry cranes, etc.

- Warehouse hoists include electric hoists, wire rope hoists, electric chain hoists, and so on.

Our warehouse crane and warehouse hoist can be used for a variety of lifting tasks, with lifting capacities ranging from 1ton to 100ton.

Warehouse overhead crane

The warehouse overhead crane is the most commonly used lifting device in the warehouse, and it can do a lot of large and heavy work that manpower cannot. As a result, users will benefit greatly from using this warehouse crane.

Single Girder Top Running Warehouse Overhead Cranes

The electric single girder warehouse overhead crane has a tonnage of 0.5 ton - 20t and is made up of a single girder beam, a monorail hoist, an end carriage with a motor, and total panels.

It can be mounted on steel columns. As a result, it is widely used in factories, mines, ports, warehouses, and other material handling locations to improve labor efficiency and working conditions for necessary machinery. It will take up the most space because it will be installed on the upper level of the factory.

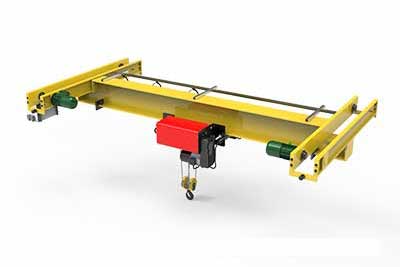

Double Girder Top Running Warehouse Overhead Cranes

A double girder warehouse overhead crane consists of a main beam, cross and long traveling mechanisms, and electrical equipment. It is divided into three working levels based on frequency of use: A5, A6, A7, and A8. It is widely used in steel mills, construction industries, warehouses, freight yards, cement plants, and other heavy-duty applications.

It relies on the bridge frame moving longitudinally along the workshop orbital direction, the trolley moving transversely along the main beam direction, and the hook lifting movement to function. Because it can lift up to 350 pounds, it can meet the majority of client requirements.

FEM Standard Top Runnning Warehouse Overhead Cranes with open winch trolley

The European style warehouse overhead crane is made to the FEM standard . It is renowned for having a small profile and a light dead weight.

As comparison to conventional bridge cranes, our European style overhead crane has a minimal hook-to-wall distance, the low headroom, which make it to operate closer to the front, and provide a higher lifting height, increasing your workshop space utilization.

Because of its low dead weight and low wheel pressure, new workshops can be built smaller and with more functionality.

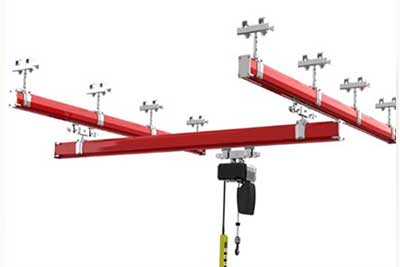

KBK single and double beam warehouse crane with hoist, as the trolley of this type is much smaller than other double girder overhead cranes, so it can be used when the distance from rail to roof is limited. It is used in mechanical processing workshops, metallurgical factories and subsidiary workshops, warehouses, material yards, and power plants for transferring, assembly, inspection maintenance, and load unload procedures due to its compact exterior dimension, low construction headroom, light dead weight, and light wheel load advantages. It can also be used to replace common double-girder overhead cranes found in light textile and food manufacturing workshops.

Underhung or Under Running Warehouse Overhead Cranes

Underhung or suspension warehouse overhead crane is a light duty crane. It can be suspended from a steel structure's girder or roof structure of your building and facility.

They are generally designed for light loads (up to 10000kg) in application and material handling operation, sush as, parts assembly, manufacturing and processing industries, pallet shipping, injection molding, warehousing loading and unloading, equipment maintenance, and so on.

Warehouse cranes allow workers to reduce their physical effort by eliminating the need for them to move loads between workstations. All they have to do is properly prepare it for transportation and supervise it. The latter is typically handled by a crane operator, who uses a radio system or a pendant control to control the crane from the workplace or a cabin.

Features of Warehouse Overhead Crane

Strong rigidity, low dead weight, and an outstanding structure design provide our warehouse crane with long service life and durability.

- Due to its small overall size, low clearance height, and light wheel load, our warehouse crane can save factory space and investment costs.

- Our warehouse crane stands out among similar hoisting products due to advanced technology and excellent professional knowledge.

- Perfect after-sales service and expert guidance relieve you of material handling concerns.

- With a competitive price and excellent quality, our warehouse crane is an excellent choice.

- The Warehouse crane is supplied with two distinct control forms: ground control with a rope handle and remote control. Our company would also manufacture a customized warehouse crane based on specific requirements.

What is overhead crane used for in a warehouse ?

An overhead crane is a very frequently used device not only in production halls, but also in logistics and storage halls. Provisions for it should be made at the design stage of the facility, and the type of equipment should be chosen according to the needs of the specific company that will use it. What exactly is an overhead crane used for? What are the types of cranes? Why and when should it be fitted?

Whether the hall will be used for production or as a storage and packaging area for goods, handling equipment needs to be planned into the hall. It facilitates and speeds up human labour and at the same time (these can be for example the cranes in question) and makes optimal use of the space inside the facility.Read on.

Functions of warehouse overhead cranes

Material handling overhead crane equipment, which is mechanical equipment designed to move, store, protect, and control materials throughout the manufacturing process, is critical for reliable distribution, consumption, and disposal processes.

Our crane company is pleased to offer a comprehensive range of material handling crane and hoist solutions for a variety of industries and applications.

Load transporting

The ability to transport loads over a variety of paths is critical to workflow and operational efficiency. Overhead bridge cranes, both freestanding and ceiling mounted, as well as workstation bridge cranes, are versatile. They are available in single and double girder builds, as well as top running and underhung bridge configurations. These systems can be customized to meet almost any transportation requirement.

Loads Positioning

A manufacturing shop's workflow depends on properly feeding, loading, unloading, and orienting materials. Monorails provide a unique overhead lifting solution, operating on tracks in the form of a complete route network or single circuits. Monorails, which are installed directly into a facility's ceiling, travel at high speeds from point to point based on preset counts or positions. Because of their fixed track systems, these tools are highly accurate and eliminate the risk of human error.

Loads Storage

Stacker cranes, like the popular bridge crane, provide an overhead solution with lifting forks or platforms instead of a hoist. This design enables efficient unit load handling, resulting in an optimal solution for storage and retrieval in shelving systems and high-rise racks.

Horizontal vs. Vertical Movement Control in Material Handling

Most warehouse overhead cranes are designed to move horizontal loads using trolley-and-bridge systems and vertical loads using hoist systems.

Vertical movers include gantry cranes, jib cranes, and bridge cranes. These are outfitted with hoists for safe load handling at a variety of heights. Electric hoists, the most common type, use efficient motor systems to lift capacities ranging from 250 pounds to hundreds of tons.

To ensure continuous material handling, an automatic overhead crane is used.

What are the benefits of investing in warehouse overhead crane?

What advantages of installation an overhead crane in warehouse? Warehouse cranes allow for the transport of extremely heavy components weighing several tons or more within a warehouse. Moving loads is simple, safe, and relatively quick with this type of equipment. Many warehouses would be unable to function or would perform significantly worse if the material was only transported using handling equipment such as forklifts.

What are other types of hoists and cranes for material handling in warehouses ?

A warehouse's efficiency and storage capacity are primarily determined by the material handling equipment it employs. Material handling equipment allows warehouse workers to lift, move, and store various items and commodities in the warehouse efficiently and safely, as well as position heavy objects with precision that cannot be achieved in other ways.

Overhead cranes, gantry cranes, jib cranes, hoists, and other equipment are included. Continue reading to learn about the various types of warehouse cranes that are currently in use.

Warehouse Cranes To Optimize Your Efficiency

If you want to use warehouse cranes to improve warehouse material handling efficiency, we can assist you in designing the best lifting solution for maximum efficiency, safety, and cost-effectiveness.

There are various types of warehouse cranes and lifting devices, each serving a different purpose. Some of the most common warehouse lifting solutions are as follows:

- Stacker cranes

- Ergonomic lifting devices

- High bay warehouse cranes

- Warehouse overhead cranes

- Bridge cranes

- Jib cranes

- Gantry cranes

- Hoists

- Workstation cranes

- Monorail cranes

How to Choose a Proper Warehouse Overhead Crane?

Because overhead lifting equipment is critical to the warehouse's efficiency, selecting the right crane is critical. The issue is determining how to select the best crane for your needs. One of the most important things is to carefully and clearly consider your specific need. Some points to consider include, but are not limited to:

- The materials you will be handling, as well as the specifications required for your overhead crane, such as lifting capacity, lifting height, and crane span.

- Suitable warehouse crane types include: overhead cranes, gantry cranes, and hoists.

- The frequency with which the crane is used. Some cranes are light duty and cannot be used in a busy and frequent working environment, whereas others are heavy duty and can do heavy work on a continuous basis. As a result, you should determine how frequently you will use the equipment.

- The price you intend to pay for a crane. How much money do you have set aside to buy a warehouse crane? Which of the two do you prefer? We can provide the best crane solution for your needs while staying within your budget.

- How you decide to use the overhead crane. There are three general methods: pendant control, remote control, and cab operation. You can select one of them or two combinations based on your needs.

We recommend that you carefully consider these factors, and then we will assist you in selecting the best warehouse crane solution. We also offer customized overhead lifting equipment.

Do you need steel buildings for warehouse construction ?

Our steel structures are of the highest quality and meet all building codes and regulations. We deliver steel buildings with various types of walls, such as sheet metal or sandwich panels, to both businesses and municipalities. Our entire portfolio is CE certified.

Planning a construction project takes time, and there are numerous regulations to follow. This is where a turnkey contract can come in handy. Our skilled fitters, assemblers, and designers will safely guide you through the project from start to finish.

For our warehouse overhead crane, we provide both gable and pulpit roof constructions. If necessary, we can also deliver

Your Trusted Warehouse Overhead Crane Manufacturer & Supplier

0.5 Ton- 2Ton Light & Simple Gantry Crane

Mastering Warehouse Overhead Cranes: A Comprehensive Guide for Users and Buyers

What is a Warehouse Overhead Crane?

Warehouse overhead cranes, often referred to as bridge cranes, are pivotal components in the world of material handling. These mechanical marvels are designed to efficiently lift, transport, and position heavy loads within a warehouse or industrial facility. Their name, "overhead," is derived from their unique positioning – these cranes are typically mounted on tracks or runways attached to the ceiling, allowing them to glide smoothly above the workspace.

The Role of Warehouse Overhead Cranes in Material Handling

The role of warehouse overhead cranes in material handling is paramount. They are the workhorses that streamline operations by lifting and moving heavy objects that would be impractical or impossible to handle manually. These cranes are akin to the backbone of many industries, offering unparalleled lifting capabilities and precision.

Warehouse overhead cranes excel in various tasks, such as transporting raw materials to production lines, moving finished products to storage areas, and aiding in the efficient loading and unloading of goods. Their flexibility, combined with their ability to operate within a confined space, makes them indispensable tools in modern warehouses and manufacturing plants.

The Advantages of Using Warehouse Overhead Cranes

There are numerous advantages to using warehouse overhead cranes, which contribute to their widespread adoption in the world of material handling:

- Enhanced Efficiency: Overhead cranes significantly expedite material handling processes, reducing production times and minimizing operational bottlenecks.

- Precise Positioning: These cranes offer exceptional precision in placing loads, ensuring items are precisely where they need to be with minimal margin for error.

- Improved Safety: With overhead cranes, the risks associated with manual lifting and transport are greatly reduced, promoting a safer working environment for employees.

- Optimized Space: The ability to move loads vertically and horizontally without taking up valuable floor space is a key benefit of overhead cranes, allowing for more efficient use of warehouse real estate.

- Versatility: Warehouse overhead cranes are available in various configurations to suit diverse industry needs, from handling small, delicate items to transporting heavy machinery.

As we delve deeper into the world of warehouse overhead cranes, we'll explore the various types, features, and applications that define these essential material handling tools. Join us on this journey to uncover the ins and outs of warehouse overhead cranes, empowering you to make informed decisions for your material handling requirements.

Hot Sale Warehouse Overhead Cranes

Warehouse overhead cranes come in a variety of types, each tailored to specific applications and needs within the material handling industry. Let's explore the diverse world of these cranes, uncovering their features, benefits, and typical uses:

Warehouse overhead cranes, also known as bridge cranes or overhead traveling cranes, are material handling machines that are used in warehouses and industrial facilities to lift and transport heavy loads horizontally and vertically. These cranes are typically mounted on tracks or runways on the ceiling of a building, allowing them to move back and forth along the length of the facility. Warehouse overhead cranes are essential for efficiently moving heavy and bulky items within a warehouse, manufacturing plant, or distribution center.

There are several types of overhead cranes commonly used in warehouses and industrial settings:

- Single Girder Overhead Crane: This type of crane has a single horizontal beam (girder) that spans the width of the building. It is often used for lighter lifting tasks and is cost-effective for smaller warehouses.

- - Typical Capacity of Overhead Crane in Warehouse: Up to 20 tons.

- - Features of Warehouse Cranes: Single girder overhead cranes are known for their simplicity, ease of installation, and lower cost compared to double girder cranes. They are suitable for warehouses with lower lifting requirements.

- - Benefits: Cost-effective, efficient for lighter loads, and suitable for smaller warehouses or spaces with restricted headroom.

- - Functions of Single Girder Warehouse Overhead Crane: Lifting, transporting, and positioning materials or goods within the warehouse. It can be used for tasks like moving pallets, machinery, or other moderate-weight items.

- - Industrial Warehouses: Single girder overhead cranes are commonly used in manufacturing facilities, distribution centers, and smaller warehouses where moderate lifting capacity is required.

- Double Girder Overhead Crane: These cranes have two horizontal beams (girders) that provide greater lifting capacity compared to single girder cranes. They are suitable for handling heavier loads.

- - Typical Capacity of Overhead Crane in Warehouse: Can range from 5 tons to over 100 tons.

- - Features of Warehouse Cranes: Double girder overhead cranes offer increased stability and higher lifting capacities compared to single girder cranes. They are ideal for warehouses with heavy-duty material handling needs.

- - Benefits: High lifting capacity, stability, and durability make them suitable for heavy-duty operations.

- - Functions of Double Girder Warehouse Overhead Crane: Lifting and moving heavy loads, machinery, or large items within the warehouse.

- - Industrial Warehouses: Double girder overhead cranes are commonly found in industrial settings, steel mills, and facilities with substantial material handling requirements.

- Top Running Overhead Crane: In a top running crane, the wheels run on top of the runway beams, which are attached to the building's support structure. These are commonly used for heavy-duty applications.

- - Typical Capacity of Overhead Crane in Warehouse: Varied, depending on the design and specifications.

- - Features of Warehouse Cranes: Top running overhead cranes provide excellent load-carrying capacity and can handle a wide range of loads.

- - Benefits: Ideal for heavy-duty tasks, suitable for warehouses requiring high-capacity lifting.

- - Functions of Top Running Warehouse Overhead Crane: Lifting and moving heavy loads, containers, and materials within the warehouse.

- - Industrial Warehouses: Top running overhead cranes are often used in manufacturing facilities, steel processing plants, and warehouses with large and heavy materials.

Under Running (Underhung) Overhead Crane:

Under Running (Underhung) Overhead Crane: In this type of crane, the wheels run on the bottom flange of the runway beams, which are suspended from the building's ceiling structure. Under running cranes are often used in facilities with limited overhead space.

- - Typical Capacity of Overhead Crane in Warehouse: Varied, depending on the design and specifications.

- - Features of Warehouse Cranes: Under running cranes are compact and suitable for warehouses with restricted headroom.

- - Benefits: Space-saving, ideal for warehouses with limited vertical clearance.

- - Functions of Under Running Warehouse Overhead Crane: Lifting and moving loads while maximizing available space within the warehouse.

- - Industrial Warehouses: Under running overhead cranes are commonly used in smaller warehouses, workshops, or facilities with low ceiling heights.

- Free Standing Bridge Crane: Free-standing bridge cranes are self-supporting overhead cranes that are not attached to the building's structure. They offer flexibility and versatility in material handling.

- - Typical Capacity of Overhead Crane in Warehouse: Can range from a few tons to several dozen tons.

- - Features of Warehouse Cranes: Free-standing bridge cranes do not rely on the building's structure, making them adaptable to various warehouse layouts and configurations.

- - Benefits: Flexibility, modularity, and suitability for warehouses where structural modifications are impractical.

- - Functions of Free Standing Bridge Crane: Lifting and transporting loads in warehouses with unique layouts or space constraints.

- - Industrial Warehouses: Free-standing bridge cranes are used in warehouses with specific layout needs or where traditional overhead cranes are not feasible.

- Grab Bucket Overhead Crane: These cranes are designed for handling loose bulk materials such as sand, gravel, coal, or agricultural products. They are commonly used in industries like mining, construction, and bulk material handling facilities.

- - Typical Capacity of Overhead Crane in Warehouse: Variable, depending on the design and requirements of the grab bucket.

- - Features of Warehouse Cranes: Equipped with a grab bucket or clamshell bucket attachment for efficient handling of loose bulk materials.

- - Benefits: Ideal for warehouses dealing with bulk materials and automated loading/unloading operations.

- - Functions of Grab Bucket Warehouse Overhead Crane: Scooping up, lifting, transporting, and releasing loose bulk materials within the warehouse.

- - Industrial Warehouses: Grab bucket overhead cranes are typically found in warehouses or facilities with bulk material storage and handling needs.

- Magnetic Overhead Cranes: These cranes are designed for handling ferrous (iron and steel) materials using a magnetic lifting attachment. They are commonly found in industries like steel mills, scrap yards, and metal recycling facilities.

- - Typical Capacity of Overhead Crane in Warehouse: Variable, depending on the size and strength of the magnetic attachment.

- - Features of Warehouse Cranes: Equipped with an electromagnet or permanent magnet that can attract and lift ferrous materials.

- - Benefits: Suitable for warehouses dealing with magnetic materials, such as metal sheets or scrap.

- - Functions of Magnetic Warehouse Overhead Crane: Lifting and transporting ferrous materials within the warehouse.

- - Industrial Warehouses: Magnetic overhead cranes are used in warehouses dealing with ferrous materials and metal processing.

- Single Girder Gantry Crane: This type of gantry crane has a single horizontal beam (girder) and is supported by legs that run on the floor. It is versatile and suitable for various warehouse applications.

- - Typical Capacity of Overhead Crane in Warehouse: Up to 20 tons or more.

- - Features of Warehouse Cranes: Single girder gantry cranes are cost-effective and can be used both indoors and outdoors.

- - Benefits: Versatile, adaptable to different environments, and suitable for moderate lifting tasks.

- - Functions of Single Girder Gantry Crane: Lifting and moving loads within the warehouse, often used in outdoor storage areas.

- - Industrial Warehouses: Single girder gantry cranes are used in warehouses, construction sites, and shipping yards for various material handling tasks.

- Double Girder Gantry Crane: These gantry cranes have two horizontal beams (girders) and provide higher lifting capacity compared to single girder gantry cranes. They are suitable for heavy-duty material handling.

- - Typical Capacity of Overhead Crane in Warehouse: Can range from 5 tons to over 100 tons.

- - Features of Warehouse Cranes: Double girder gantry cranes offer increased stability and high lifting capacity.

- - Benefits: Ideal for warehouses with heavy-duty material handling requirements.

- - Functions of Double Girder Gantry Crane: Lifting and moving heavy loads within the warehouse or outdoor storage areas.

- - Industrial Warehouses: Double girder gantry cranes are commonly used in warehouses and industrial facilities with substantial material handling needs.

- Portable Gantry Cranes: These are smaller gantry cranes designed to be mobile and easy to move. They are often used for temporary lifting tasks in warehouses or construction sites.

- - Typical Capacity of Overhead Crane in Warehouse: Up to 5 tons.

- - Features of Warehouse Cranes: Portable gantry cranes are lightweight and can be disassembled for easy transportation.

- - Benefits: Flexibility, easy setup, and mobility for temporary or occasional lifting tasks.

- - Functions of Portable Gantry Cranes: Lifting and moving loads in warehouses or construction sites, especially where a permanent crane is not required.

- - Industrial Warehouses: Portable gantry cranes are used for temporary lifting needs within warehouses or at job sites.

- Pillar Jib Crane: Jib cranes are fixed to a vertical mast or column and have a horizontal boom that can rotate. They are suitable for localized lifting and material handling tasks within a specific area of a warehouse.

- - Typical Capacity of Overhead Crane in Warehouse: Up to 5 tons.

- - Features of Warehouse Cranes: Pillar jib cranes offer a rotating boom for versatile load positioning.

- - Benefits: Ideal for localized lifting tasks in a specific area of the warehouse, providing efficient and precise material handling.

- - Functions of Pillar Jib Crane: Lifting and positioning materials within a confined workspace or near machinery.

- - Industrial Warehouses: Pillar jib cranes are often used in manufacturing facilities and warehouses with limited space for material handling.

- Wall-Mounted Crane: Wall-mounted cranes are fixed to a wall or column and are used for lifting and moving loads along a wall or within a specific work area.

- - Typical Capacity of Overhead Crane in Warehouse: Up to 5 tons.

- - Features of Warehouse Cranes: Wall-mounted cranes save floor space and offer efficient material handling along a specific path.

- - Benefits: Space-saving, suitable for localized material handling tasks along a wall, and can be positioned to maximize workspace.

- - Functions of Wall-Mounted Crane: Lifting and transporting materials along a wall or within a specific area of the warehouse.

- - Industrial Warehouses: Wall-mounted cranes are used in warehouses with limited floor space or where specific material handling paths are required.

- Monorail Crane: Monorail cranes consist of a single track or beam along which a trolley moves. They are used for linear material handling tasks and can be integrated into assembly lines and production processes.

- - Typical Capacity of Overhead Crane in Warehouse: Variable, depending on the design and specifications.

- - Features of Warehouse Cranes: Monorail cranes are ideal for repetitive linear material handling tasks.

- - Benefits: Efficient for assembly line applications, can move materials along a specific path, and integrate with production processes.

- - Functions of Monorail Crane: Transporting materials along a linear path, often used in manufacturing and production environments.

- - Industrial Warehouses: Monorail cranes are used in warehouses with assembly lines or specific linear material handling requirements.

The choice of an overhead crane type for a warehouse depends on the specific needs, space constraints, and materials handled within the facility. Warehouse managers and engineers should carefully assess their requirements to select the most suitable type of overhead crane for their operations.

Features and Benefits of Warehouse Overhead Cranes

Warehouse overhead cranes are renowned for their unique features and the multitude of benefits they bring to material handling operations. Let's explore the common features shared across crane types and the advantages of investing in these indispensable tools:

A. Common Features Across Crane Types

Warehouse overhead cranes, regardless of their specific type, share several common features that make them essential for modern material handling:

- Lifting Mechanism: All overhead cranes are equipped with a robust lifting mechanism, which may include hooks, hoists, or specialized attachments, designed to securely hold and transport loads.

- Bridge or Trolley: Overhead cranes operate on a bridge or trolley system that runs along a track or runway. This mobility allows for precise positioning of loads within the workspace.

- Remote Control: Many modern overhead cranes are equipped with remote control systems, enabling operators to manage lifting, movement, and positioning from a safe distance, enhancing safety and precision.

- Safety Features: Safety is paramount in overhead crane design. Features such as overload protection, emergency stop buttons, and warning systems ensure the well-being of personnel and prevent accidents.

- Versatility: Overhead cranes are versatile tools adaptable to various warehouse layouts and material handling needs. They can handle a wide range of loads, from small components to heavy machinery.

B. Benefits of Investing in Warehouse Overhead Cranes

The decision to invest in warehouse overhead cranes offers numerous advantages for businesses involved in material handling operations:

- Enhanced Efficiency: Overhead cranes significantly increase operational efficiency by streamlining material handling processes. They can quickly lift, move, and position loads, reducing production times and minimizing bottlenecks.

- Precise Positioning: Overhead cranes provide exceptional precision in placing loads exactly where they are needed. This precision minimizes errors and ensures efficient use of warehouse space.

- Improved Safety: Overhead cranes reduce the risks associated with manual lifting and transport. Operators can handle loads from a safe distance, reducing the potential for accidents and injuries.

- Optimized Space: The ability to move loads vertically and horizontally without consuming valuable floor space is a key benefit of overhead cranes. This optimization of space allows for more efficient warehouse layout and organization.

- Versatility: Warehouse overhead cranes are available in various configurations to suit diverse industry needs. Whether it's lifting delicate items or transporting heavy machinery, these cranes can adapt to various material handling tasks.

- Increased Productivity: By automating material handling processes, overhead cranes contribute to increased productivity and throughput. This translates to faster order fulfillment and improved customer satisfaction.

- Cost Savings: Over time, the efficiency and productivity gains achieved with overhead cranes can lead to cost savings. Reduced labor costs, minimized product damage, and enhanced operational speed all contribute to a positive return on investment.

Warehouse overhead cranes are not merely tools; they are indispensable partners in the quest for efficient and effective material handling. As we continue our journey through the world of warehouse overhead cranes, we'll explore their specific types, typical applications, and delve into real-world scenarios where these cranes make a significant impact. Stay with us to uncover more insights and knowledge to empower your material handling decisions.

Typical Industrial Applications of Warehouse Overhead Cranes

Warehouse overhead cranes find their applications across a diverse spectrum of industries, each harnessing the power of these versatile tools to optimize their material handling processes. In this section, we'll explore how various industries make use of warehouse overhead cranes and dive into some case studies and success stories.

A. How Different Industries Utilize Warehouse Overhead Cranes

- Manufacturing Industry: Overhead cranes play a pivotal role in manufacturing facilities, where they are used to move heavy machinery, components, and raw materials to different stages of the production process. Their precision and lifting capacity enhance manufacturing efficiency.

- Steel and Metal Industry: The steel and metal industry relies heavily on overhead cranes for tasks such as lifting and transporting steel coils, sheets, and other raw materials. These cranes are indispensable in steel mills and processing plants.

- Automotive Industry: In automotive manufacturing, overhead cranes are utilized to handle vehicle components, engines, and other heavy assemblies. Their ability to precisely position loads contributes to the assembly line's efficiency.

- Aerospace Industry: Aerospace manufacturers utilize overhead cranes to move aircraft parts, engines, and fuselage sections. The precise control provided by these cranes is crucial for ensuring the integrity of sensitive components.

- Warehousing and Logistics: Warehouses and distribution centers benefit from overhead cranes for efficient pallet handling, load stacking, and order fulfillment. They are particularly useful in high-bay storage facilities.

- Construction Industry: In construction, overhead cranes are employed for lifting and placing heavy construction materials such as concrete blocks, steel beams, and pre-fabricated structures. They improve the speed and safety of construction projects.

- Mining and Quarrying: The mining industry relies on overhead cranes for extracting minerals and transporting ore. Grab bucket overhead cranes, in particular, excel in these rugged environments.

B. Case Studies and Success Stories

- Automotive Assembly Line Optimization: A leading automotive manufacturer implemented double girder overhead cranes in their assembly line. This resulted in a 30% reduction in production time, improved workplace safety, and a notable increase in overall productivity.

- Steel Mill Efficiency Enhancement: A steel mill revamped its material handling processes by introducing magnetic overhead cranes. This innovation led to a 25% increase in the speed of loading and unloading operations, reducing downtime and boosting profitability.

- High-Bay Warehousing Excellence: A large e-commerce distribution center integrated top running overhead cranes into their high-bay storage facility. This move maximized vertical storage space and allowed for efficient retrieval of products, leading to faster order fulfillment.

- Aerospace Component Precision: An aerospace manufacturer's reliance on single girder overhead cranes for handling delicate aircraft components resulted in a remarkable reduction in part damage and improved assembly accuracy, enhancing their reputation for quality.

- Mining and Quarrying Cost Savings: A mining company adopted grab bucket overhead cranes for its ore handling processes. This switch led to a substantial reduction in manual labor, increased ore extraction rates, and significant cost savings.

These case studies underscore the transformative impact of warehouse overhead cranes across industries. They demonstrate how these versatile tools optimize material handling, enhance workplace safety, and contribute to substantial improvements in productivity and profitability.

Crane Cost and Pricing

Understanding the cost and pricing of warehouse overhead cranes is essential for businesses looking to invest in these valuable material handling tools. In this section, we will explore the factors that affect the cost of warehouse overhead cranes, various pricing models and options, and the significance of conducting a cost vs. benefits analysis.

A. Factors Affecting the Cost of Warehouse Overhead Cranes

The cost of warehouse overhead cranes can vary significantly based on several key factors:

- Crane Type: The specific type of crane you require will have a substantial impact on the cost. For instance, double girder overhead cranes with higher lifting capacities typically come at a higher price point than single girder cranes designed for lighter loads.

- Lifting Capacity: The crane's lifting capacity is a critical factor in determining its cost. Cranes with greater lifting capacities require more robust construction, which can increase the overall price.

- Span and Reach: The span, which is the distance between the runways or tracks, and the reach, which is how far the crane can extend its load, will affect the cost. Longer spans and greater reaches generally result in higher costs.

- Customization: Customized features and specialized attachments, such as magnets or grab buckets, will add to the crane's cost. These customizations are essential for meeting specific material handling needs.

- Installation Requirements: The complexity of installation can influence the overall cost. Factors such as ceiling height, structural modifications, and electrical work may impact the installation cost.

- Manufacturer and Supplier: Different manufacturers and suppliers offer overhead cranes at varying price points. The reputation, quality, and after-sales support of the supplier can impact pricing.

B. Pricing Models and Options

Warehouse overhead crane pricing typically follows one of these models:

- Purchase Price: This is the upfront cost of acquiring the crane. It includes the cost of the crane itself, installation, and any additional customizations or accessories.

- Leasing or Rental: Some businesses choose to lease or rent overhead cranes instead of purchasing them outright. This option may have lower initial costs but can result in higher overall expenses over time.

- Maintenance and Service Contracts: Ongoing maintenance and service contracts can be a significant part of the overall cost of owning an overhead crane. These contracts ensure the crane remains in optimal working condition.

C. Cost vs. Benefits Analysis

Conducting a cost vs. benefits analysis is crucial when considering an investment in warehouse overhead cranes. This analysis involves evaluating the long-term benefits of owning and operating a crane against the initial and ongoing costs. Key points to consider include:

- Return on Investment (ROI): Assess how quickly the crane's productivity gains and cost savings will offset the initial investment.

- Operational Efficiency: Consider how the crane will impact your operations. Will it lead to faster production times, reduced labor costs, and increased throughput?

- Safety Improvements: Evaluate the impact of the crane on workplace safety. Reduced manual handling can lead to fewer accidents and injuries.

- Maintenance Costs: Factor in ongoing maintenance and service costs. A well-maintained crane is more cost-effective in the long run.

- Scalability: Assess whether the crane can adapt to your changing material handling needs and future growth.

- Competitive Advantage: Consider how having an overhead crane can give you a competitive edge in your industry.

- Regulatory Compliance: Ensure that your crane investment aligns with industry regulations and safety standards.

By carefully weighing the costs and benefits, businesses can make informed decisions about the acquisition of warehouse overhead cranes, ensuring that the investment aligns with their goals and objectives.

Top Concerns of Warehouse Overhead Crane Users

Warehouse overhead crane users share common concerns related to safety, maintenance, training, efficiency, and keeping their equipment up to date. Understanding and addressing these concerns is vital for ensuring the safe and efficient operation of these essential material handling tools.

A. Safety Measures and Regulations

Safety is paramount in warehouse operations. Users of overhead cranes are concerned with:

- Compliance: Ensuring that their cranes adhere to industry safety standards and regulations to prevent accidents and injuries.

- Operator Safety: Implementing safety measures to protect crane operators from hazards during operation, such as falling loads and collisions.

- Load Security: Ensuring that loads are securely attached and properly balanced to prevent accidents or damage during lifting and transport.

B. Maintenance and Inspection

Proper maintenance and regular inspections are essential for crane longevity and safety. Users are concerned with:

- Preventive Maintenance: Implementing a robust preventive maintenance program to identify and address potential issues before they become serious problems.

- Inspection Schedules: Adhering to regular inspection schedules to detect wear and tear, corrosion, or other issues that may compromise crane performance.

- Downtime Minimization: Minimizing crane downtime during maintenance to avoid disruptions in warehouse operations.

C. Operator Training

Crane operators must be well-trained to operate equipment safely and efficiently. Concerns in this area include:

- Training Programs: Implementing comprehensive training programs to ensure operators have the skills and knowledge to handle the crane effectively.

- Operator Certification: Ensuring that crane operators receive proper certification and ongoing training to stay up-to-date with best practices and safety guidelines.

D. Maximizing Efficiency and Productivity

Users want to optimize their crane operations for maximum efficiency. Concerns include:

- Workflow Integration: Integrating overhead crane operations seamlessly into warehouse workflows to minimize idle time and improve overall productivity.

- Load Handling: Efficiently handling and positioning loads to reduce cycle times and increase throughput.

E. Upgrades and Modernization

Staying current with technological advancements and extending the life of crane equipment is a priority. Concerns encompass:

- Modernization Options: Exploring opportunities to upgrade and modernize existing crane systems to improve safety, efficiency, and functionality.

- Technology Integration: Embracing technologies such as automation, remote monitoring, and data analytics to enhance crane performance.

Frequently Asked Questions about Warehouse Overhead Cranes

Warehouse overhead cranes can be complex, and users often have questions about their selection, operation, and maintenance. Here are some common questions and their answers:

A. Answers to Common Questions Regarding Crane Selection

- Which type of overhead crane is suitable for my needs?

- The choice depends on factors like your lifting capacity, workspace layout, and the types of materials you handle. Consult with a crane expert to determine the best fit.

- What are the key safety features to look for in an overhead crane?

- Essential safety features include overload protection, emergency stop buttons, limit switches, and operator training programs.

B. Maintenance and Safety FAQs

- How often should I inspect my overhead crane?

- Regular inspections, typically on a monthly, quarterly, and annual basis, are recommended. The frequency may vary based on usage and industry regulations.

- What can I do to extend the lifespan of my crane equipment?

- Implement preventive maintenance, conduct timely repairs, and consider modernization or upgrades to keep your equipment in optimal condition.

C. Cost-Related Queries

- What is the typical cost range for purchasing an overhead crane?

- Costs vary widely depending on crane type, capacity, features, and customization. It's best to request quotes from manufacturers or suppliers to get accurate pricing.

- Are leasing or rental options available for overhead cranes?

- Yes, many suppliers offer leasing or rental options, which can be a cost-effective solution for short-term or temporary needs.

Conclusion: Making Informed Decisions for Warehouse Overhead Crane Investments

Warehouse overhead cranes are indispensable tools in material handling operations, offering unparalleled lifting capabilities and efficiency. To make informed decisions regarding their selection, operation, and maintenance, it is essential to address the top concerns of crane users and stay informed about safety regulations and advancements in crane technology.

By prioritizing safety measures, implementing effective maintenance programs, providing thorough operator training, maximizing efficiency, and considering upgrades, businesses can harness the full potential of warehouse overhead cranes while ensuring the well-being of their personnel and the longevity of their equipment.

In conclusion, a well-informed approach to warehouse overhead crane investments not only enhances workplace safety and productivity but also contributes to the overall success and competitiveness of your operations. We hope this comprehensive guide has provided valuable insights and knowledge to empower your material handling decisions. If you have any further questions or require assistance, do not hesitate to reach out to crane experts and suppliers who can offer tailored solutions to meet your specific needs.

interiors.If you have any need of warehouse overhead crane, please feel free to contact us.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch