Industrial Electric Hoist & Industrial Overhead Cranes 1 to 80 Ton

Industrial electric hoist & industrial overhead cranes overview: custom industrial hoists and cranes1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 15 ton up to 80 ton.

Category: Overhead Hoist

Your Trusted Industrial Cranes and Hoists Manufacturer & Supplier

Industrial Electric Hoist & Industrial Overhead Cranes 1 to 80 Ton

Industrial electric hoist & industrial overhead cranes overview: custom industrial hoists and cranes1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 15 ton up to 80 ton.

Maximizing Efficiency and Safety with Industrial Electric Hoist and Crane Solutions

Industrial operations heavily rely on the efficiency and precision of lifting equipment, among which industrial electric hoists stand as indispensable assets. These industrial hoists come in two primary types: wire rope hoists and electric chain hoists. Wire rope hoists utilize a sturdy mechanism with a steel cable wound around a drum, excelling in handling heavy loads with endurance and reliability. On the other hand, electric chain hoists operate through a powered chain system, offering versatility and ease of use across various load capacities. Both variants prioritize safety with features like limit switches and overload protection, ensuring secure lifting operations within industrial settings.

Expanding beyond electric hoists, industrial cranes, including overhead cranes, gantry cranes, and jib cranes, constitute crucial lifting solutions in diverse industries. Industrial overhead cranes are omnipresent, spanning factory floors with their robust structures and diverse configurations, facilitating heavy-duty lifting and material transport. Gantry cranes, equally essential, offer mobility with their movable support legs, suited for outdoor applications or flexible material handling needs. Meanwhile, jib cranes, known for their wall or floor-mounted designs, serve localized lifting, ideal for small workshops or machining areas.

For industries operating in hazardous environments, the need for explosion-proof hoists becomes paramount. These specialized hoists are engineered with materials and components resistant to volatile atmospheres, ensuring safety in sectors like chemical processing or oil and gas industries. Together, these diverse lifting solutions, from wire rope hoists to jib cranes, form the backbone of industrial efficiency, providing tailored options for lifting, transporting, and ensuring the safe handling of heavy materials across a wide spectrum of industrial operations.

Overview of Industrial Electric Hoist and Crane Services

In the realm of industrial electric hoists and cranes, specialized services form the backbone of reliable and efficient operations. These services encompass a spectrum of crucial tasks, ranging from installation and maintenance to repair and compliance checks. Understanding the role of these specialized services is pivotal for maximizing the longevity, performance, and safety of hoist and crane systems.

Installation, Maintenance, and Repair

- Installation: The installation phase marks the foundation of a robust and functional hoist or crane system. Expert technicians ensure precise assembly and calibration, considering factors like load capacities, structural integrity, and environmental conditions. This phase lays the groundwork for seamless operations.

- Maintenance: Regular maintenance is the lifeline that sustains the efficiency and reliability of industrial hoists and cranes. Scheduled inspections, lubrication, and part replacements are integral to preventing breakdowns and optimizing performance. Maintenance routines are tailored to specific equipment and industry requirements.

- Repair: Despite meticulous maintenance, wear and tear or unforeseen issues can occur. Prompt and proficient repair services are essential to swiftly address malfunctions or damages. Skilled technicians equipped with in-depth knowledge perform diagnostics and carry out repairs to restore the systems to optimal functioning.

Safety is non-negotiable in industrial settings, especially when it comes to lifting equipment. Regular inspections are imperative to identify potential risks or malfunctions before they escalate into hazardous situations. Compliance with safety regulations and standards set by governing bodies ensures a secure working environment and adherence to legal requirements.

Key Services Offered by Expert Providers

Expert providers in the field of industrial electric hoist and crane services offer a comprehensive array of specialized solutions. These services encompass:

- Installation Services: Precise setup and configuration of hoist and crane systems tailored to specific industrial needs.

Maintenance Contracts: Scheduled maintenance routines and inspections to uphold optimal performance and extend equipment lifespan. - Repair Services: Swift and efficient repair solutions to minimize downtime and ensure continuous operations.

- Compliance Inspections: Thorough checks and adherence to safety regulations and industry standards to maintain a safe working environment.

Choosing a reputable service provider with a track record of excellence in these areas is crucial for ensuring the longevity and reliability of industrial electric hoists and cranes.

Types of Industrial Hoist and Crane Systems

Industrial lifting and material handling tasks vary widely across different industries, necessitating diverse types of hoist and crane systems.

Basic Types of industrial Cranes

Industrial Overhead Cranes: These are versatile systems comprising a bridge, runway, and hoist mechanism, providing horizontal movement along a fixed path. Overhead cranes excel in lifting heavy loads and are commonly found in manufacturing, warehouses, and construction sites.

Industrial Gantry Cranes: Offering mobility and flexibility, gantry cranes feature legs or supporting frames fitted with wheels or tracks. They're suitable for outdoor applications and are widely used in shipyards, construction sites, and transportation hubs.

Industrial Jib Cranes: Ideal for localized lifting tasks within a limited radius, jib cranes consist of a horizontal arm (jib) mounted to a vertical pillar or wall. They find application in workshops, assembly lines, and smaller workstations.

Hot sale types of industrial cranes

Top Running Industrial Overhead Crane

Features:

Bridge travels on rails mounted on the top of runway beams.

Offers greater hook height and lift capacity.

Benefits:

Ideal for heavy-duty applications.

Excellent hook height and lift capacity.

Suitable for large facilities with high ceilings.

Typical Industrial Sectors:

Manufacturing, heavy machinery, steel mills.

Applicable Workshops/Facilities:

Foundries, metalworking shops, manufacturing plants.

Load Handling:

Handles heavy loads efficiently.

Underhung Industrial Overhead Crane

Features:

Bridge travels on rails mounted beneath runway beams.

Saves floor space by utilizing overhead space.

Benefits:

Maximizes floor space utilization.

Well-suited for workshops with space constraints.

Efficient for lighter load applications.

Typical Industrial Sectors:

Small manufacturing units, assembly lines.

Applicable Workshops/Facilities:

Small workshops, production lines with limited space.

Load Handling:

Suitable for handling lighter loads efficiently.

Single Girder Industrial Overhead Crane

Features:

Consists of a single girder supporting the hoist mechanism.

Offers cost-effective solutions for light to moderate loads.

Benefits:

Cost-effective installation and operation.

Suitable for light to moderate lifting applications.

Efficient for limited headroom facilities.

Typical Industrial Sectors:

Warehousing, logistics, light manufacturing.

Applicable Workshops/Facilities:

Small manufacturing units, warehouses, maintenance workshops.

Load Handling:

Handles moderate loads efficiently.

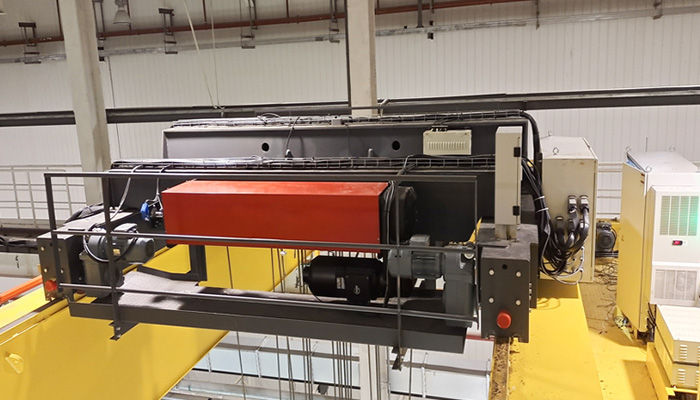

Double Girder Industrial Overhead Crane

Features:

Incorporates two girders supporting the hoist mechanism.

Offers higher lifting capacities and greater stability.

Benefits:

High lifting capacities and longer spans.

Suitable for heavy-duty applications.

Enhanced stability and precision.

Typical Industrial Sectors:

Steel industry, heavy manufacturing, shipbuilding.

Applicable Workshops/Facilities:

Heavy machinery plants, foundries, large-scale production.

Load Handling:

Handles heavy loads efficiently.

Freestanding Industrial Overhead Crane

Features:

Self-supporting crane structure without the need for support from building columns or overhead structures.

Benefits:

Offers flexibility in placement.

Does not require additional support structures.

Suitable for locations lacking overhead support.

Typical Industrial Sectors:

Warehousing, assembly lines, workshops.

Applicable Workshops/Facilities:

Facilities lacking overhead support or columns.

Load Handling:

Depends on the crane specifications and configuration.

These represent different configurations and specialized types of industrial overhead cranes, each offering specific benefits tailored to different industrial sectors, workshops, and load handling requirements.

Grab Bucket Industrial Overhead Crane

Features:

Equipped with a grab bucket for handling bulk materials.

Ideal for lifting and moving loose materials like sand, gravel, or scrap.

Benefits:

Efficient handling of bulk materials.

Minimizes manual labor for bulk material transfer.

Suitable for industries requiring continuous material handling.

Typical Industrial Sectors:

Mining, construction, waste management.

Applicable Workshops/Facilities:

Quarry sites, waste recycling plants, mining operations.

Load Handling:

Designed for bulk material handling.

Magnetic Industrial Overhead Crane

Features:

Equipped with an electromagnet for lifting ferrous materials.

Designed for handling metal scraps, sheets, or rods.

Benefits:

Efficient handling of ferrous materials.

Reduces manual labor in metal handling.

Suitable for industries dealing with ferrous metals.

Typical Industrial Sectors:

Metal fabrication, recycling, scrapyards.

Applicable Workshops/Facilities:

Metal recycling facilities, steel mills, scrapyards.

Load Handling:

Specifically for lifting ferrous materials using magnetic force.

Explosion-Proof Overhead Cranes

Features:

Constructed with explosion-proof components.

Designed to operate in hazardous or explosive environments.

Benefits:

Ensures safety in volatile environments.

Prevents sparks or ignition in explosive atmospheres.

Suitable for industries with strict safety requirements.

Typical Industrial Sectors:

Chemical processing, oil & gas, pharmaceuticals.

Applicable Workshops/Facilities:

Hazardous areas where safety standards are critical.

Load Handling:

Depends on the specifications and requirements of the hazardous environment.

Features:

Designed with lightweight components.

Suitable for lighter load handling applications.

Benefits:

Cost-effective for lighter load applications.

Easy to install and maneuver.

Suitable for workshops with limited load requirements.

Typical Industrial Sectors:

Small-scale manufacturing, workshops, laboratories.

Applicable Workshops/Facilities:

Laboratories, small-scale production units, workshops.

Load Handling:

Handles light to moderate loads efficiently.

Features:

Operates along a single track or beam.

Utilizes a hoist and trolley system for material movement.

Benefits:

Efficient for linear material handling processes.

Maximizes space utilization along the track route.

Ideal for assembly lines and repetitive material movement.

Typical Industrial Sectors:

Automotive, assembly line production, manufacturing.

Applicable Workshops/Facilities:

Production lines, assembly stations, automotive manufacturing units.

Load Handling:

Suitable for continuous or repetitive material handling within a specific route.

Features:

Installed within a limited area for localized lifting tasks.

Provides flexibility for workstations or specific work areas.

Benefits:

Ideal for precise and localized lifting needs.

Saves floor space by covering specific workstations.

Enhances ergonomics and efficiency in workstations.

Typical Industrial Sectors:

Workshops, assembly lines, maintenance areas.

Applicable Workshops/Facilities:

Specific workstations, assembly areas, maintenance bays.

Load Handling:

Handles light to moderate loads within a limited radius.

Each of these specialized types of industrial overhead cranes caters to unique requirements, offering tailored solutions for specific industrial sectors, workshops, or facilities, optimizing material handling processes and ensuring efficient and safe operations.

Main Types of Industrial Gantry Cranes

Here's an overview of various types of industrial gantry cranes, highlighting their typical features, benefits, suitable industrial sectors, applicable workshops/facilities, and load handling capabilities:

Single Girder Industrial Gantry Cranes

Features:

Single beam supporting the hoist mechanism.

Lightweight design and cost-effective.

Benefits:

Cost-effective solution for light to moderate loads.

Easy to install and operate.

Suitable for limited headroom facilities.

Typical Industrial Sectors:

Warehousing, small manufacturing units, workshops.

Applicable Workshops/Facilities:

Small-scale production units, warehouses, maintenance areas.

Load Handling:

Handles light to moderate loads efficiently.

Double Girder Industrial Gantry Cranes

Features:

Two girders supporting the hoist mechanism.

Offers higher lifting capacities and stability.

Benefits:

High lifting capacities and longer spans.

Suitable for heavy-duty applications.

Enhanced stability and precision.

Typical Industrial Sectors:

Heavy manufacturing, shipbuilding, steel industry.

Applicable Workshops/Facilities:

Heavy machinery plants, foundries, large-scale production.

Load Handling:

Handles heavy loads efficiently.

Features:

Utilizes one end supported by a gantry system and the other end supported by a building structure.

Offers a cost-effective solution with some mobility.

Benefits:

Cost-effective with partial mobility.

Suitable for workshops with limited space.

Typical Industrial Sectors:

Construction, workshops with limited space.

Applicable Workshops/Facilities:

Construction sites, small-scale workshops.

Load Handling:

Depends on the specifications and intended use.

Fixed Height Portable Gantry Cranes

Features:

Easily transportable due to their lightweight and modular design.

Can be disassembled and reassembled quickly.

Benefits:

Highly portable for versatile use.

Suitable for temporary lifting needs.

Easy to transport between different work areas.

Typical Industrial Sectors:

Maintenance, workshops, temporary job sites.

Applicable Workshops/Facilities:

Maintenance bays, temporary construction sites.

Load Handling:

Handles moderate loads with mobility.

Features:

Designed with adjustable height or span settings.

Offers flexibility in adapting to different load sizes.

Benefits:

Adjustable for varied load sizes.

Provides versatility in handling different materials.

Fits various work environments.

Typical Industrial Sectors:

Warehousing, manufacturing, assembly lines.

Applicable Workshops/Facilities:

Versatile across different industrial settings.

Load Handling:

Handles varied load sizes efficiently.

Features:

Constructed with lightweight aluminum materials.

Corrosion-resistant and easily maneuverable.

Benefits:

Lightweight and easy to move.

Resistant to corrosion in various environments.

Ideal for cleanroom or outdoor use.

Typical Industrial Sectors:

Aerospace, cleanroom environments, outdoor applications.

Applicable Workshops/Facilities:

Cleanroom facilities, outdoor workshops.

Load Handling:

Handles light to moderate loads efficiently.

These various types of industrial gantry cranes offer specialized features and benefits catering to diverse industrial sectors and specific application needs, providing efficient and safe material handling solutions.

Main types of industrial jib cranes

Features:

Mounted on a vertical pillar or column and can rotate/swivel horizontally.

Offers a wide range of movement and coverage.

Benefits:

Provides extensive coverage area.

Versatile for handling loads in different directions.

Efficient for material transfer within a defined radius.

Typical Industrial Sectors:

Manufacturing, assembly lines, workshops.

Applicable Workshops/Facilities:

Assembly stations, machining centers, production lines.

Load Handling:

Handles moderate loads within its radius efficiently.

Floor Jib Cranes

Features:

Mounted on a freestanding base directly on the floor.

Provides localized lifting within a specific area.

Benefits:

No need for structural attachment to the building.

Easy to install and reposition.

Efficient for localized material handling.

Typical Industrial Sectors:

Warehousing, small-scale manufacturing, workshops.

Applicable Workshops/Facilities:

Small workshops, material loading areas, warehouses.

Load Handling:

Handles light to moderate loads within its coverage area.

Features:

Mounted on a wall or building structure.

Provides localized lifting adjacent to the mounting wall.

Benefits:

Utilizes minimal floor space.

Leaves the floor area unobstructed.

Efficient for lifting and positioning near walls or machinery.

Typical Industrial Sectors:

Machining shops, production lines, tool rooms.

Applicable Workshops/Facilities:

Machining cells, tool areas, production floors.

Load Handling:

Handles moderate loads adjacent to the wall or machinery.

Features:

Can move horizontally along a fixed track or rail.

Provides lateral movement capabilities.

Benefits:

Extends coverage area beyond fixed jib cranes.

Offers flexibility in material handling.

Suitable for longitudinal material transfer.

Typical Industrial Sectors:

Large manufacturing facilities, assembly lines.

Applicable Workshops/Facilities:

Long assembly lines, material transfer routes.

Load Handling:

Handles moderate loads along its travel path.

Portable Jib Cranes

Features:

Designed for easy transport and mobility.

Can be disassembled and moved between different locations.

Benefits:

Highly portable for versatile use.

Suitable for temporary lifting needs.

Easy to transport between different work areas.

Typical Industrial Sectors:

Maintenance, workshops, temporary job sites.

Applicable Workshops/Facilities:

Maintenance bays, temporary construction sites.

Load Handling:

Handles light to moderate loads with mobility.

These various types of industrial jib cranes cater to specific material handling needs within different industrial sectors, offering versatility, efficiency, and precision for lifting tasks within defined areas or ranges.

Specialized industrial cranes for different sectors

Specialized industrial overhead cranes are tailored to meet specific needs across various sectors, offering custom solutions that cater to unique requirements. Here are some examples of specialized industrial overhead cranes designed for different sectors:

Automotive Industry

Automated Assembly Line Cranes: Overhead cranes in automotive plants are often designed for high-speed operations, efficiently moving vehicle components along assembly lines. They incorporate advanced automation and precision controls for accurate positioning and assembly.

Aerospace Sector

Cleanroom Cranes: Aerospace industries require stringent cleanliness standards. Cleanroom cranes are designed to minimize particulate contamination in manufacturing facilities where precision and cleanliness are paramount, ensuring the safe handling of sensitive aerospace components.

Steel and Metal Fabrication

Foundry Cranes: In steel and metal fabrication, foundry cranes are specialized for handling molten metal, heavy-duty loads, and extreme temperatures. They are equipped with heat-resistant features and robust designs to withstand harsh environments.

Ports and Shipping

Container Handling Cranes: Ports and shipping facilities use specialized cranes like container handling cranes for efficiently loading and unloading shipping containers from vessels. These cranes are designed for high lifting capacities and precision movements in a maritime environment.

Energy and Power Generation

Nuclear Plant Cranes: Nuclear power plants require overhead cranes designed to handle heavy components in a highly controlled environment. These cranes adhere to strict safety standards and often have radiation-resistant features.

Pharmaceutical and Chemical Industries

Explosion-Proof Cranes: In environments where flammable or hazardous materials are handled, explosion-proof overhead cranes are utilized. These cranes are designed with features that mitigate the risk of sparks or ignition in potentially explosive atmospheres.

Mining and Quarrying

Heavy-Duty Mining Cranes: Mining operations often require robust overhead cranes capable of handling extremely heavy loads and enduring harsh mining conditions. These cranes are designed with high lifting capacities and durability to withstand the rigors of mining environments.

Food and Beverage Sector

Hygienic Cranes: In food processing and beverage industries, cranes are designed with stainless steel components and easy-to-clean surfaces to maintain hygiene standards. These cranes prevent contamination and ensure safe material handling.

Each sector's specialized overhead cranes are engineered with industry-specific features, materials, and safety standards to address the unique challenges and requirements of the respective industries, enabling efficient and safe material handling operations.

Absolutely, several other industrial sectors have specific needs that require custom overhead cranes or gantry cranes tailored to their operations. Here are more examples:

Renewable Energy

Wind Turbine Installation Cranes: Custom cranes designed for assembling wind turbines in wind farms require specialized configurations and lifting capacities to handle turbine components at various heights. These cranes are crucial for installing and maintaining wind turbines efficiently.

Agriculture and Farming

Barn and Silo Cranes: In agricultural settings, cranes assist in handling and storing feed, equipment, and livestock. Barn and silo cranes are customized for lifting and moving heavy loads within farm buildings, aiding in storage and material handling.

Entertainment and Events

Entertainment Rigging Cranes: In the entertainment industry, specialized cranes are utilized for setting up stage equipment, lighting, and audio-visual components for events or concerts. These cranes are designed to facilitate the safe and efficient installation of equipment.

Aerospace Manufacturing

Aircraft Maintenance Cranes: In aerospace manufacturing and maintenance facilities, specialized cranes are used for the assembly, maintenance, and repair of aircraft. These cranes are designed to lift aircraft components for maintenance or engine installation.

Textile Industry

Textile Mill Cranes: Custom cranes for textile mills aid in the movement and handling of heavy textile machinery or materials used in the textile manufacturing process. They are adapted to the specific needs of the textile industry for efficient material handling.

Research and Laboratories

Cleanroom and Laboratory Cranes: Laboratories, especially in scientific research and pharmaceutical sectors, require cranes designed to work in cleanroom environments or laboratories handling sensitive equipment or materials. These cranes maintain cleanliness and precision in handling delicate items.

Railway Maintenance

Railcar Maintenance Cranes: Facilities involved in railway maintenance use specialized cranes for lifting and servicing railcars. These cranes are designed to navigate rail tracks and efficiently handle maintenance tasks on trains or railcars.

Custom overhead cranes or gantry cranes for these industrial sectors are tailored to specific operational needs, ensuring efficiency, safety, and compliance with industry standards. These custom solutions play a pivotal role in optimizing material handling processes in their respective fields.

Industrial Electric Hoists: Wire Rope vs. Chain Hoists

Industrial electric hoists represent a fundamental component in modern material handling and lifting operations within various industries. These devices are designed to efficiently and safely lift, lower, and move heavy loads, streamlining workflow processes and enhancing productivity. Operating on electric power, these hoists utilize motor-driven mechanisms to elevate loads, offering precise control and reliability in diverse industrial settings.

One of the key advantages of industrial electric hoists lies in their versatility. They come in various configurations, such as wire rope hoists or chain hoists, each tailored to specific load capacities, lifting heights, and operational requirements. Their adaptable nature allows for seamless integration into different environments, whether within manufacturing plants, warehouses, construction sites, or other industrial facilities.

Moreover, industrial electric hoists are engineered with advanced safety features, including overload protection, emergency braking systems, and limit switches. These safety mechanisms are crucial, ensuring the protection of personnel, materials, and equipment during lifting operations. The integration of these safety measures aligns with stringent industry standards and regulations, prioritizing workplace safety.

In essence, industrial electric hoists play an integral role in optimizing material handling processes, promoting operational efficiency, and upholding safety standards within a wide spectrum of industries. Their precision, adaptability, and commitment to safety make them indispensable tools, significantly contributing to the seamless movement and management of heavy loads in industrial operations.

- Wire Rope Hoists: These hoists utilize a system of wire ropes wound around a drum connected to a motor. They offer high lifting capacities, smooth operation, and durability, making them suitable for heavy-duty applications in industries such as manufacturing, mining, and construction.

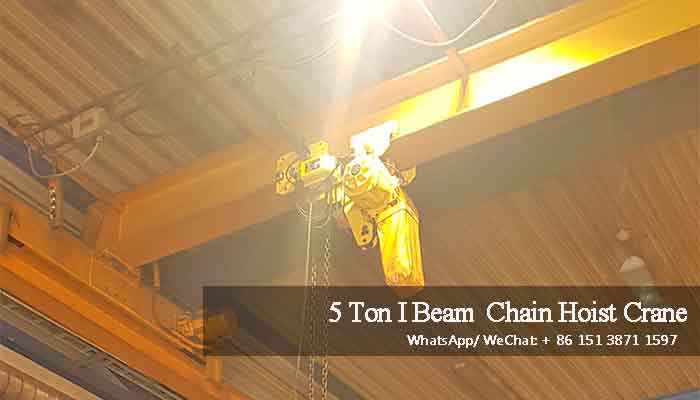

- Chain Hoists: Operating by lifting loads using a chain looped around a pulley, chain hoists are known for their simplicity, portability, and versatility. They're commonly used in smaller-scale operations, workshops, and maintenance tasks.

Industrial wire rope hoists

Industrial wire rope hoists are essential lifting devices widely used in various industrial settings for their robustness, reliability, and versatility. These hoists are specifically designed to handle heavy loads efficiently and safely by utilizing wire ropes wound around a drum and a motor-driven mechanism for lifting and lowering operations.

Main types of industrial wire rope hoists

The different types of industrial wire rope hoists, outlining their typical features, benefits, typical industrial sectors, applicable workshops/facilities, and load handling capabilities:

Standard Industrial Wire Rope Hoists

Features:

Reliable and commonly used in various industries.

Available in different load capacities and lifting heights.

Typically operate at a single fixed lifting speed.

Benefits:

Simple operation and maintenance.

Suitable for general material handling tasks.

Cost-effective solution for standard lifting needs.

Typical Industrial Sectors:

Warehousing, manufacturing, construction.

Applicable Workshops/Facilities:

Production lines, assembly stations, material storage areas.

Load Handling:

Handles a wide range of loads within its capacity.

Low Headroom Industrial Wire Rope Hoists

Features:

Designed with a compact profile for limited vertical space.

Maximizes lifting height in areas with low headroom.

Allows efficient usage in confined spaces.

Benefits:

Ideal for installations where vertical space is restricted.

Ensures maximum lifting height within limited headroom.

Suitable for facilities with overhead space constraints.

Typical Industrial Sectors:

Workshops, manufacturing facilities with restricted overhead space.

Applicable Workshops/Facilities:

Areas with limited vertical clearance, maintenance bays.

Load Handling:

Handles loads efficiently within confined spaces.

Explosion-Proof Industrial Wire Rope Hoists

Features:

Constructed with explosion-proof components.

Designed for safe operation in hazardous environments.

Meets stringent safety standards and certifications.

Benefits:

Ensures safety in volatile or hazardous industrial settings.

Prevents sparks or ignition in explosive atmospheres.

Suitable for industries with strict safety requirements.

Typical Industrial Sectors:

Chemical processing, oil & gas, pharmaceutical industries.

Applicable Workshops/Facilities:

Environments where safety standards are critical.

Load Handling:

Handles various loads while ensuring safety in hazardous areas.

Wire Rope Variable Speed Hoists

Features:

Offers multiple lifting speeds for diverse load handling.

Allows precise and controlled lifting operations.

Provides versatility for handling different load types.

Benefits:

Versatile in handling various loads at different speeds.

Enhanced control and precision in lifting operations.

Suitable for applications requiring different lifting speeds.

Typical Industrial Sectors:

Manufacturing facilities with diverse load handling needs.

Applicable Workshops/Facilities:

Production lines, machining centers, assembly stations.

Load Handling:

Handles different loads at varying speeds with precision.

CD/MD Wire Rope Hoists

Features:

Cost-effective wire rope hoists with basic functionalities.

Designed for standard lifting applications.

Offered at competitive prices.

Benefits:

Budget-friendly option for general lifting needs.

Provides reliable lifting solutions at lower costs.

Suitable for applications with standard load requirements.

Typical Industrial Sectors:

Warehousing, light manufacturing, small-scale industries.

Applicable Workshops/Facilities:

General material handling areas, smaller workshops.

Load Handling:

Handles standard loads within its capacity efficiently.

These different types of industrial wire rope hoists cater to specific industrial needs, offering diverse features, safety measures, and load handling capabilities to meet various lifting requirements across different sectors and facilities.

Key components of industrial wire rope hoists include the wire rope itself, wound around a drum, and a lifting mechanism that consists of a motor, gearbox, and braking system. The motor provides the necessary power to drive the lifting operation, while the gearbox ensures smooth and controlled movement. Additionally, the braking system plays a critical role in securing the load and preventing accidental drops.

One of the primary advantages of wire rope hoists is their ability to handle substantial loads with precision and stability. They are available in various configurations, offering different load capacities, lifting speeds, and lift heights to suit diverse industrial applications. This adaptability makes them suitable for tasks ranging from light-duty material handling in warehouses to heavy-duty lifting in manufacturing or construction sites.

Furthermore, wire rope hoists are known for their durability and resilience, making them ideal for demanding industrial environments. The wire ropes are constructed with multiple strands of high-strength steel wire, providing exceptional tensile strength and resistance to wear and tear over extended periods of use.

In essence, industrial wire rope hoists are integral components in material handling operations, offering robust lifting capabilities, reliability, and adaptability across a wide range of industries. Their ability to handle heavy loads safely and efficiently makes them indispensable tools in optimizing workflow processes and ensuring productivity within industrial settings.

Industrial electric chain hoists

Give me an brief introduction of industrial electric chain hoists into paragraphs

Industrial electric chain hoists represent a pivotal component in the landscape of material handling solutions across diverse industrial sectors. These hoists are meticulously designed to facilitate the efficient lifting and lowering of heavy loads using an electrically powered chain mechanism. Renowned for their compact build, electric chain hoists boast a lightweight design, making them easily maneuverable and adaptable to a myriad of lifting applications within industrial environments.

One of the defining characteristics of electric chain hoists is their robustness coupled with a user-friendly operation. Their mechanism revolves around a chain-driven system powered by an electric motor, offering precise and controlled lifting operations. Equipped with safety features such as limit switches, overload protection, and emergency stop functions, these hoists prioritize operational safety, safeguarding both personnel and materials during lifting procedures.

Electric chain hoists exhibit remarkable versatility, suitable for various load capacities and lifting requirements. From standard lifting tasks in warehousing and assembly lines to precision manufacturing in automotive and aerospace industries, these hoists offer a range of options tailored to specific industrial needs. Their reliability, ease of use, and consistent performance make them an indispensable tool across numerous industrial settings, optimizing material handling processes and enhancing overall productivity.

In addition to their adaptability, electric chain hoists come in specialized variations catering to distinct industrial demands. Varieties such as European style hoists, low headroom designs, and explosion-proof configurations serve specific sectors like precision manufacturing, confined-space workshops, and hazardous environments respectively, ensuring a tailored solution for each application's unique requirements. In essence, electric chain hoists stand as a cornerstone of efficiency and reliability in industrial lifting operations, contributing significantly to seamless material handling and operational excellence.

Types of Electric Chain Hoists:

European Style Electric Chain Hoists:

Features: Follow a design and construction conforming to European standards.

Benefits: Known for their precision, durability, and compliance with stringent safety regulations.

Typical Industrial Sectors: Automotive, aerospace, precision manufacturing.

Applicable Workshops/Facilities: Assembly lines, machining centers, industrial manufacturing plants.

General Use Electric Chain Hoists:

Features: Versatile hoists suitable for various general lifting applications.

Benefits: Offer cost-effective solutions for standard lifting needs with reliable performance.

Typical Industrial Sectors: Warehousing, light manufacturing, assembly operations.

Applicable Workshops/Facilities: Material handling areas, small-scale workshops.

Low Headroom Electric Chain Hoists:

Features: Designed with a compact profile for limited headroom spaces.

Benefits: Optimizes vertical space usage while providing efficient lifting in confined areas.

Typical Industrial Sectors: Workshops with limited overhead space, maintenance bays.

Applicable Workshops/Facilities: Areas with restricted vertical clearance, where space optimization is crucial.

Explosion-Proof Electric Chain Hoists:

Features: Constructed with components suitable for hazardous environments.

Benefits: Ensures safety in explosive or volatile industrial settings.

Typical Industrial Sectors: Chemical processing, oil & gas, pharmaceutical industries.

Applicable Workshops/Facilities: Environments with strict safety requirements, where explosion-proof equipment is essential.

Electric chain hoists are integral in various industries for their reliability, versatility, and safety features, catering to specific lifting needs across different sectors while enhancing efficiency and safety in material handling operations.

Comparative Advantages

The choice between wire rope and chain hoists typically depends on load capacities, operational requirements, and environmental conditions. While wire rope hoists excel in handling heavier loads and enduring rugged environments, chain hoists offer greater flexibility and portability for lighter loads and varied applications.

Wire Rope Hoists:

Advantages:

Heavy Load Handling: Wire rope hoists are known for their capability to handle heavier loads compared to chain hoists. They excel in lifting larger capacities while maintaining stability and strength.

Durability and Longevity: Wire ropes, typically constructed from multiple strands of high-strength steel wire, are highly durable and resistant to wear and tear. This durability makes wire rope hoists well-suited for rugged and demanding environments.

Vertical Lifting Height: They offer increased vertical lifting height and are efficient in applications where a higher lift is required within limited headroom spaces.

Suitable for Harsh Environments: Wire rope hoists are more adept at withstanding harsh environmental conditions, such as extreme temperatures, dust, or moisture, making them ideal for outdoor or heavy industrial applications.

Smooth Operation: They offer smoother and quieter operation compared to chain hoists due to the nature of the wire rope system, providing precise and controlled lifting.

Chain Hoists:

Advantages:

Portability and Flexibility: Chain hoists are more portable and offer greater flexibility in handling lighter loads and varied applications. Their lightweight design and ease of mobility make them suitable for different work environments.

- Ease of Installation: They are generally easier to install and set up compared to wire rope hoists, making them a convenient choice for temporary or mobile lifting needs.

- Versatility in Confined Spaces: Chain hoists are more adaptable to confined spaces due to their compact size and can operate efficiently in areas with limited headroom.

- Simple Maintenance: They typically have simpler mechanisms, which often translates to easier maintenance and repair compared to wire rope hoists.

- Cost-Effectiveness: Chain hoists are often more cost-effective, making them a preferred choice for applications where heavy lifting capacities are not required, and budget considerations are paramount.

Consideration for Selection:

The choice between wire rope and chain hoists hinges on various factors such as load capacities, operational requirements, and environmental conditions. In scenarios where heavy lifting capacities, durability in rugged environments, or increased vertical lift are crucial, wire rope hoists are preferred. Conversely, for applications demanding portability, flexibility in handling lighter loads, and ease of installation in confined spaces, chain hoists present a more suitable solution. The decision ultimately depends on assessing the specific needs and conditions of the lifting task at hand.

Benefits of Customized Solutions

Customization plays a pivotal role in optimizing hoist and crane systems for specific industrial needs. Tailoring these systems to meet unique operational demands ensures enhanced efficiency, minimized downtime, and improved safety. Factors like load capacities, lifting heights, environmental conditions, and space constraints are meticulously considered in custom solutions.

Tailored Specifications:

- Enhanced Efficiency: Customization allows for precise alignment of the hoist and crane systems with specific operational requirements. By tailoring these systems to fit the exact needs of the industry or facility, efficiency is maximized in material handling processes.

- Optimized Performance: Customized solutions ensure that hoist and crane systems are optimized for their intended applications. This optimization results in smoother operations, reducing unnecessary strain on the equipment and prolonging its lifespan.

- Minimized Downtime: Addressing specific operational demands through customization helps in reducing downtime. Systems designed to meet exact specifications are less likely to encounter compatibility issues or inefficiencies, leading to fewer breakdowns or interruptions in workflow.

Consideration of Various Factors:

- Load Capacities: Tailoring hoist and crane systems to handle specific load capacities ensures that the equipment operates optimally, preventing overloading or underutilization issues.

- Lifting Heights: Custom solutions factor in precise lifting heights required for the task. This consideration ensures that the systems deliver accurate and efficient lifting operations within the necessary height range.

- Environmental Conditions: Customization takes into account the environmental conditions where the hoist and crane systems will operate. This includes considerations for factors such as extreme temperatures, dust, moisture, or corrosive atmospheres, ensuring the equipment is suitable for the environment.

- Space Constraints: Adapting hoist and crane systems to fit within limited space constraints optimizes their functionality. Customized designs ensure that the equipment fits the available space without compromising its performance or safety.

Safety and Compliance:

- Enhanced Safety: Customized solutions focus on aligning the hoist and crane systems with strict safety protocols and standards. This ensures that safety features and mechanisms are tailored to specific needs, promoting a safer work environment.

- Compliance: Custom solutions are designed to meet industry regulations and safety standards. This compliance ensures that the equipment adheres to all necessary guidelines, reducing the risk of accidents or regulatory issues.

Customization of hoist and crane systems allows for the creation of tailored solutions that precisely fit the operational needs of various industries. These custom solutions not only improve efficiency and safety but also reduce downtime, ensuring that the equipment operates optimally in the designated environment. Ultimately, customized hoist and crane systems provide a strategic advantage by addressing specific requirements and challenges within industrial settings.

Features and Capabilities of Industrial Electric Hoists

Industrial electric hoists are at the forefront of material handling equipment, offering a wide array of features that enhance efficiency, precision, and safety in lifting operations.

Characteristics of High-Quality Electric Hoists

- Load Capacity: The load capacity of electric hoists varies based on different models and designs, catering to a range of lifting requirements, from light-duty to heavy-duty operations.

- Lifting Speed: The lifting speed dictates the efficiency of hoisting tasks. Modern electric hoists are designed with adjustable lifting speeds to accommodate varying load sizes and operational demands.

- Precision Controls: Advanced control mechanisms allow operators to maneuver loads with precision and accuracy, ensuring smooth and controlled movements during lifting and positioning.

Advanced Safety Features

- Overload Protection: Electric hoists incorporate mechanisms to prevent overloading, automatically stopping the hoist when the load exceeds the specified capacity, thus averting potential accidents.

- Emergency Braking Systems: In the event of power failure or malfunction, emergency braking systems swiftly halt operations to prevent uncontrolled movements or accidents.

- Limit Switches: These switches act as safety measures by restricting the movement of the hoist or crane beyond predetermined limits, preventing collisions or damage to the equipment.

Modern electric hoists integrate seamlessly with IoT (Internet of Things) and automation technologies, revolutionizing industrial operations. By leveraging IoT, hoists can be remotely monitored and managed, allowing for predictive maintenance, real-time diagnostics, and performance optimization.

Advantages of Industrial Hoist Crane Integration

The seamless integration of hoists with crane systems offers a multitude of advantages that significantly enhance efficiency, streamline operations, and positively impact the bottom line for businesses.

Efficiency and Productivity Improvements

- Streamlined Workflow: Integration allows for the efficient movement of materials within a facility or worksite. Hoist crane systems work harmoniously, reducing time spent on manual handling and improving overall workflow efficiency.

- Enhanced Material Handling: The combined capabilities of hoists and cranes enable the swift and precise handling of materials, minimizing delays and optimizing production processes.

- Operational Processes Optimization: Integration leads to smoother operational processes, allowing for quicker loading/unloading, assembly, and logistics, thereby improving overall operational efficiency.

Cost-effectiveness and Return on Investment (ROI)

- Reduced Labor Costs: By automating lifting tasks, businesses can minimize the need for manual labor, reducing associated costs and potential risks of workplace injuries.

- Increased Productivity: The improved efficiency and reduced downtime achieved through integration result in increased output, contributing to better ROI over time.

- Equipment Longevity: Properly integrated hoist crane systems often experience reduced wear and tear due to optimized operations, leading to prolonged equipment lifespan and decreased maintenance costs.

Safety and Risk Mitigation

- Accident Prevention: Integration ensures coordinated movements, reducing the risk of accidents caused by human error during material handling processes.

- Compliance with Regulations: Efficiently integrated systems often adhere to safety standards and regulations, mitigating potential penalties or liabilities due to non-compliance.

Businesses that invest in integrated hoist crane systems position themselves for future advancements in technology and operational practices. These systems can be easily adapted to incorporate emerging technologies, ensuring continued efficiency and relevance in evolving industrial landscapes.

Safety Measures and Compliance

Safety stands as the cornerstone of industrial hoisting operations, requiring stringent adherence to industry standards, protocols, and a proactive approach towards training and best practices.

Paramount Importance of Safety

- Personnel Protection: Ensuring the safety of personnel involved in hoisting operations is of utmost priority. Adequate safety measures mitigate the risks of accidents or injuries, safeguarding the workforce.

- Protection of Materials: Beyond human safety, ensuring the secure handling of materials prevents damage, loss, or contamination during lifting and movement processes.

- Liability and Reputation: Adhering to safety standards not only prevents accidents but also safeguards a company's reputation and minimizes legal liabilities.

Compliance with Standards and Regulations

- Industry Standards: Compliance with established industry standards such as ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) ensures that hoist crane systems meet safety and performance criteria.

- Safety Protocols: Implementing comprehensive safety protocols and guidelines within the organization ensures uniformity in safety practices across all operational levels.

- Regulatory Requirements: Adhering to local, national, and international regulations concerning workplace safety and equipment usage is crucial to avoid legal complications.

Training Programs and Best Practices

- Operator Training: Proper training for operators and workers handling hoist crane systems is indispensable. Training programs cover operational procedures, safety protocols, emergency responses, and equipment-specific knowledge.

- Regular Reviews and Updates: Continuous review and updating of safety procedures and protocols to accommodate new technologies or changing regulations are essential to maintain a safe working environment.

- Safety Audits: Periodic safety audits help assess compliance, identify potential hazards, and implement corrective measures to enhance safety standards continually.

Selecting the Right Industrial Hoist Crane Solution

Choosing the most suitable hoist crane solution involves a meticulous evaluation of various factors to ensure it aligns with specific industry requirements, operational demands, and environmental conditions.

Considerations for Selection

- Load Capacities: Understanding the weight and nature of the loads to be lifted is crucial. Different systems cater to varying load capacities, and selecting one that matches the operational requirements is essential.

- Lifting Heights and Spans: Evaluating the required lifting heights and spans helps in determining the appropriate crane type and specifications, ensuring that it meets the vertical and horizontal reach needed for tasks.

- Environmental Conditions: Factors like indoor or outdoor use, temperature variations, presence of hazardous materials, and exposure to corrosive elements influence the choice of materials and specifications for the hoist crane system.

- Space Constraints: Available space within the facility or worksite determines the size, configuration, and mobility requirements of the hoist crane system.

Wrap it Up,

Industrial electric hoists and cranes stand as indispensable assets, revolutionizing material handling and lifting operations across diverse industries. Their critical role in enhancing operational efficiency, ensuring safety, and optimizing workflows cannot be overstated.

- Enhancing Operational Efficiency and Safety -These sophisticated lifting solutions contribute significantly to the optimization of industrial operations. From streamlining workflows, reducing manual labor, and enabling precise material handling to ensuring compliance with safety standards, industrial electric hoists and cranes play a pivotal role in enhancing productivity and safety.

- The Need for Reliable, High-Quality Hoisting Solutions -Investing in reliable and high-quality hoisting solutions is paramount for businesses aiming for sustainable growth. These solutions not only bolster efficiency and productivity but also reduce downtime, minimize risks, and enhance workplace safety.

- Continual Advancements in Hoist and Crane Technology -As technology evolves, the landscape of industrial hoisting solutions continues to advance. The integration of IoT, automation, and innovative safety features propels these systems towards greater efficiency, reliability, and adaptability in meeting the evolving demands of modern industries.

In conclusion, the strategic integration of industrial electric hoists and cranes into operational setups yields multifaceted benefits, ultimately contributing to enhanced efficiency, improved safety standards, and sustainable growth for businesses across various sectors.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch