Manual Overhead Crane: Top Running & Underhung Manual Overhead Crane

Manual overhead cranes for light loads lifting without electric power in single girder & double girder, top running & underhung manual overhead crane designs. 3- 10 ton manual overhead crane for sale.

Manual overhead crane

Manual overhead cranes are classified into two types: single-girder overhead cranes and double-girder overhead cranes. Gear and wheels are controlled by a drive chain, and the lifting and running power is provided by manpower. Suitable for overhauling and installing equipment in no-power warehouses, workshops, and other locations with low handling volumes and no consider for power or speed.

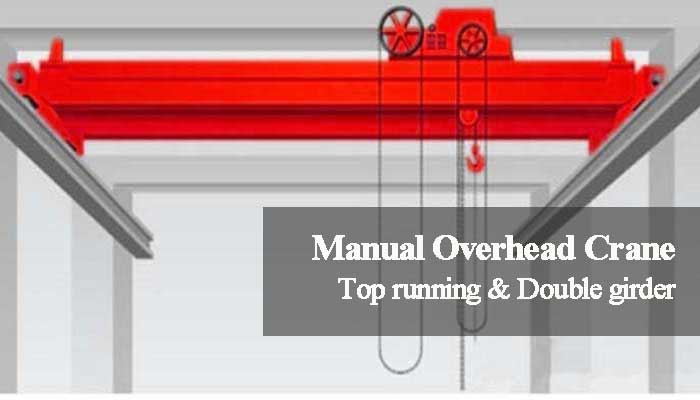

Top running manual overhead crane

Top running manual overhead cranes can be decided into single girder manual overhead crane & double girder manual overhead cranes, which can be selected as per your specific applications. As for the detailed specifications please feel free to contact us. WhatsApp/ WeChat: + 86 151 3981 1597.

Manual overhead crane - Double girder crane

Manual overhead crane main parameter

Lifting height |

Working system |

Trolley travelling speed(m/min) |

Crab travelling speed(m/min) |

Width of track |

|

1 ton manual overhead crane |

3-10 |

A1- A2( light) |

5.2 |

5.3 |

37-51 |

2 ton manual overhead crane |

3-10 |

A1- A2( light) |

5.2 |

5.9 |

37-51 |

3 ton manual overhead crane |

3-10 |

A1- A2( light) |

5.2 |

4.7 |

37-51 |

5 ton manual overhead crane |

3-10 |

A1- A2( light) |

4.3 |

4.7 |

37-51 |

10 ton manual overhead crane |

3-10 |

A1- A2( light) |

4.3 |

4.2 |

37-51 |

Aside from the above-mentioned manual overhead crane, custom manual crane designs are available depending on the crane requirements or your workshop drawing specifications; please contact us for additional information or leave a message below. We will provide you with a manual overhead crane that will completely meet your needs.

Features of top running manual overhead crane

Bridge frame, drive mechanism, trolley traveling and lifting section, and other components make up a manual overhead crane.The primary beam is welded to two end beams to form the bridge frame. The main beam is equipped with a trolley track.

There are two types of manual overhead crane drive mechanisms.

- The 5-10 ton transmission mechanism is a first-class transmission; each segment shaft is directly connected via coupling, drive sprocket, and driving wheel, which allows the crane to move back and forth.

- The 16-20 ton transmission mechanism is a second-class transmission that connects each segment by gears and couplings. The gear drives the driving wheel rotation, and the driven wheel rotates with it, causing the crane to move back and forth.

Trolley travel parts: the driving sprocket rotates the driving wheel, causing the trolley to move back and forth along the track.

Lifting components: a driving sprocket rotates the drum; a cable looped on the drum lifts the hook at the same time; the descending distance is controlled by a braking device.

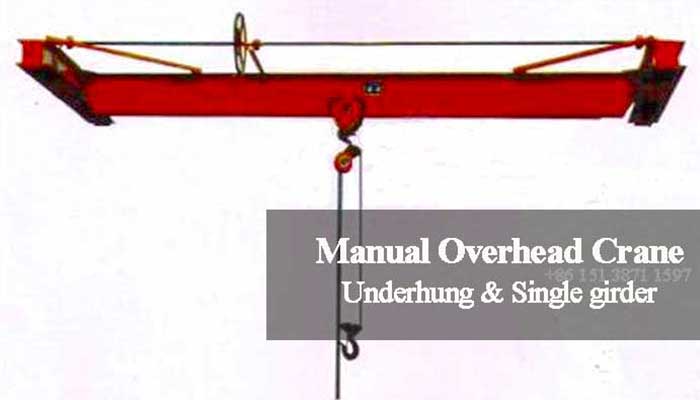

Under running manual overhead crane

Installed on the top of the plant, a manual suspension overhead crane is suited for no power plant of small and light load handling and does not pay more attention to efficiency and speed. The traveling track of a manual suspension crane differs from that of a top running manual overhead crane; the traveling track of a manual suspension crane is an I-steel fixed to the top of the plant. It features a modest travel speed, reliable operation, little noise, no pollution, a small footprint, and is simple to operate. It can be utilized in shops, warehouses, and other manufacturing, assembling, and repairing situations, and it can significantly reduce labor intensity and enhance job efficiency.

Manual suspension crane- Single girder crane

Manual suspension crane specification

Lifting height |

Working system |

Trolley travelling speed(m/min) |

Crab travelling speed(m/min) |

Width of track |

|

1 ton manual suspension crane |

3-10 |

A1- A2( light) |

5.2 |

5.3 |

37-51 |

2 ton manual suspension crane |

3-10 |

A1- A2( light) |

5.2 |

5.9 |

37-51 |

3 ton manual suspension crane |

3-10 |

A1- A2( light) |

5.2 |

4.7 |

37-51 |

5 ton manual suspension crane |

3-10 |

A1- A2( light) |

4.3 |

4.7 |

37-51 |

10 ton manual suspension crane |

3-10 |

A1- A2( light) |

4.3 |

4.2 |

37-51 |

Push/Pull Manual Overhead Cranes

The ability to manage the speed of push/pull type overhead bridge cranes is one of their major advantages. Operator-controlled push/pull cranes accelerate and decelerate at the same pace as the operator. In many circumstances, this is more efficient than using powered (motorized) cranes with preset speed points to handle the same loads.The most cost-effective bridge cranes are those with standard I-beam construction and underhung push/pull manual cranes.

Push / Push Manual Overhead Crane

Push/pull manual overhead cranes features:

- Manipulates modest loads in a cost-effective manner

- When crane operation is not too high, this is the best option.

- Some situations, such as slick floors and regions with many floor impediments, may not be suitable to this type of system due to the applied force required to move the bridge crane.

- Exceptional control of speed.

Hand Chain Drive Manual Underhung Cranes

Bridge cranes with chain drives are moved by pulling the hand chain that drives the geared wheels in one way or the other. While this gearing makes moving goods easier than a push/pull method, it also slows down the process. This makes it much easier to place a load at a precise area.Underhung manual overhead bridge cranes are generally less expensive than top-running cranes of same capacity, but they are also more robust and simple to operate.

Hand chain manual overhead crane

Features of manual overhead crane:

- Moves loads up to 15 tons for a low cost.

- Allows for precise spotting.

- Pumping stations, assembly applications, and maintenance bays are all good candidates.

Manual chain hoists, air hoists, electric hoists, and air balancers all operate well with manual overhead cranes. If you have any inquiry or question, please feel free to contact us to get your customized maual overhead crane.