Double Girder Eot Crane Specifications 5 Ton - 450 Ton

Double girder eot crane, heavy duty double girder crane design, open winch trolley with capacity from 5 ton to 450 ton. Check eot crane specifications.

| Crane Type | Double Girder Eot Crane with Open Winch Trolley |

| Crane specifications | 5 ton -550 ton |

| Lifting Height | Customized as your request |

| Working Class | A5, A6, A7 |

Category: Hoist and Crane Specifications

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Double Girder Eot Crane Specifications 5 Ton - 450 Ton

Heavy Duty Double Girder Crane Design with Dpen Winch Trolley

Electric open winch heavy duty double girder eot crane is a type of lifting equipment used to lift materials or loads in a workshop, warehouse, or yard. The overhead crane's hoisting system is a built-up open winch trolley that runs along the beam of the double girder crane. The built-up open winch overhead crane can make full use of the space above the bridge to lift loads and is not hindered by ground equipment. As a result, the electric open winch crane is one of the most commonly used for heavy duty and large capacity handling applications.

Supply Scope of QD Type Double Girder Eot Cranes

The general use QD type of double girder overhead cranes are available with the lifting capacity of 5 ton -550 ton, span of 10.5m-31.5m, lifting height of 1m-30m, working duty is medium (A5, A6). Also supply non-standard overhead cranes are available based on your requirements and applications conditions.

Lifting Capacity:

- 5 ton, 10 ton, 16/3.2 ton, 20/5 ton, 32/5 ton, 50/10 ton,

- 75/20 ton, 100/20 ton, 125/32 ton, 150/30 ton, 160/32 ton, 200/50 ton, 250/50 ton, 300/75 ton, 350/80 ton, 400/80 ton, 450/100 ton, 500/100 ton, 550/100 ton,etc.

Span:

- 10.5M , 13.5M , 16.5M , 19.5M , 22.5M , 25.5M , 28.5M , 31.5M

Working Duty:

- A5(The eot crane is usually used in working not so frequency, such as general machining and assembly workshop)

- A6 (The eot crane is usually used in much more frequency work, such as auxiliary hoisting in metallurgy and casting workshop)

- A7 (The eot crane is usually used in busy working and the hoisting of melted hot metal)

Applications of Double Girder EOT Crane

- It is one of the most frequently used double girder eot cranes and has the most different specifications available when it used for heavy material handling.

- Widely used for loads operations including the carrying, assemble and unassemble of general weights. It can also be equipped with particular designed open winch hoists for specialized operations.

- As it is prohibited to be used in hazardous application with the features of easily combustible, explosive, and corrosive, acid, alkali, plating, steam, etc.

- Working conditions include temperatures between -25#176;C and +40#176;C, humidity below 85%, altitudes under 1000 meters, and a power supply of 380V, 50Hz, 3phases, which is adjustable in accordance with various customer requirements.

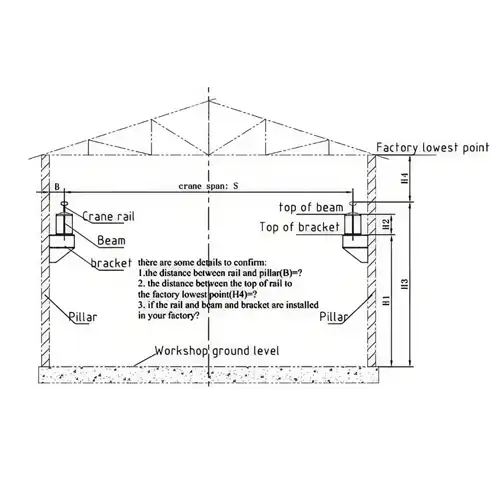

QD type double girder eot crane drawing with the specifications of 15 ton /5 ton capacity -31.48m spane -8.25m lifting height, A5 working duty with driver's cabin + remote control, for Philippines client. Click to download 15 ton/5 ton overhead crane drawing.

QD types of double girder overhead crane drawing with specifications of 35 ton /15 ton -22.5m span-20m lfiitng height, A7 woriking duty with driver's cabin for clients in Uzbekistan. Check 35 ton /5 ton double girder overhead crane drawing.

Structure and Characteristics of Double Girder EOT Crane

- The double girder eot crane is mainly consists of bridge, trolley, crane traveling mechanism and electrical system, etc.

- There are three main operating mechanisms for the overhead crane: lifting mechanism, trolley traveling mechanism and crane traveling mechanism. And each of them is equipped with separate motors for their own drive.

- For 5 ton and 10 ton, the double girder bridge cranes is normally designed with single hook crane and only have one set of lifting mechanism.

- For 16/3.2 ton ~50/10 ton eot cranes, there are two separate main and auxiliary lifting mechanism with two hook, equipped on the double girder overhead crane.

- The main hook is used to lift heavy objects, while the auxiliary hook is used to lift lighter ones. Furthermore, the auxiliary hook can be used to assist the main hook in tipping and turning over the workpiece.

- It is important to remember that two hooks should never be used to lift two objects at the same time. When they work together, the weight of the object cannot exceed the rated lifting capacity of the main hook.

Bridge of Double Girder EOT Crane

- Consists of main girder, end beam, walkway, railing, overhaul crane cage, cab and its platform, etc.

Main Girder

- The double main girder, welded box girder, and camber all meet national specifications.

- Q235B or Q345B steel is used.Equivalentto foreign steel type Fe37 or Fe52.

- Lincoln welding and nondestructive testing are used for the main weld.

End Beam

- The main girder andend beam is a rigid connection. The middle of the two end beams is detachable and bolted together.

- For crane bridge with a long spenis divided into two sections foreasytransportation and installation.

Main girder of double girder overhead crane

Trolley

Trolley Frame

- Welded of steel plate with high intensity and strong rigidity.

- Equipped with lifting mechanism and trolley traveling mechanism.

Lifting Mechanism

- One independent driving device set for a single hook and two separate driving devices for a double hook (main and auxiliary).

- The lifting mechanism operates on the basis of a high-speed rotating YZR type crane special motor and a gear coupling drive involute gear reducer. The wire rope drum is then turned by the reducer's low speed shaft. The lifting function of the hook can be achieved as long as the control of motors and their positive and negative rotation is maintained.

- The brake is installed on the high speed shaft of the reducer to ensure the security and reliability of the lifting mechanism. To prevent overload, a load limiter is installed on the bearing pedestal that supports the drum.

- The mechanical drawing as follows:

- 1. Main overload limitation;

- 2. Main lifting motor;

- 3. Main lifting gear coupling;

- 4. Main lifting drum;

- 5. Main lifting brake wheel coupling;

- 6. Main lifting brake;

- 7. Main lifting reducer

Trolley Traveling Mechanism

- The vertical gear reducer is driven by a motor in the trolley traveling mechanism. In centralized driving, the reducer's low speed shaft connects to the active wheel of the trolley frame. The motor uses a double-output gear and has a brake on one end.

- The trolley is equipped with four wheels. Two of them are driven wheels, while the others are active wheels.

Trolley Driving devices include 1. Motor; 2. Brake; 3. Reducer; 4. Compensating shaft; 5. Coupling; 6. Wheels, etc.

Crane Driving devices include 1. Reducer; 2. Motor; 3. Brake; 4. Coupling; 5.Coupling; 6. Wheels, etc.

Crane Traveling Mechanism

- On each side of the two end beams, four traveling wheels are installed. Two of them are active, while the others are driven. The active wheel driving device is installed on the walkway. Here adopt two sets of symmetrical independent driving devices and we call it respectively driven.

- The reducer uses a circular-arc gear, which has a higher load capacity than an gear reducer of the same type. All mechanisms use rolling bearings and an A.C. electromagnetic block brake.

- All parts of the mechanism are connected by gear coupling. This allows it to function effectively even if there is a manufacturing or installation error or deflection between the parts brought on by a bridge that deforms under load.

- Support for driven and active wheel axles on the angular bearing box for simple installation and maintenance.

Other Equipment

Bumper

- The ends of the two end beams have crane bumpers installed on them. The trolley bumpers, which are typically polyurethane buffers, are mounted underneath the trolley frame. Additionally, options are available based on customer needs.

- Use to lessen the likelihood of a collision between two cranes operating across the same span or the impact that results when a trolley reaches its limit at both ends.

- Crane Conductor Wire Frame

To prevent the hook or wire rope from colliding with the high voltage supply when the trolley is in the limiting position, the crane conductor wire frame is installed on the end close to the power supply under the bridge's two main girders.

Crane Pantograph

The pantograph is mounted at the bottom of the main girder. The power line is installed in three sets of current collectors to power the entire double girder eotcrane.

Electrical System

- The layout of the electric control box is reasonable and simple to repair.

- Security trolley line or angle steel trolley line

- External cables are labeled with the line number.

- Flat cable provides trolley moving power.

- The conductor is made of I steel or a C-shaped sliding line.

- Safety sliding touch line with high conductive rate and low pressure drop; high-speed current collector.

- The hoisting trolleyand overheadcrane can be controlled completely separately; they can also work together.

Limit and Safety Switch

- Limit switches are installed in the crane traveling, trolley traveling, and lifting mechanisms to limit the travel distance of each mechanism.

- When the limit switch is activated, the circuit is closed, and the mechanism is turned off. When you turn on the power again, it will move in the opposite direction. As a result, double girder eot crane safty is guranteed.

- To protect the operators and maintenance personnel from an accident, a safety switch is installed on the access door of the walkway that leads from the cab to the bridge, as well as on the railing that leads to the end beam

Operation Mode

- Cab control and ground control.

- Special driver's cabin for bridge crane or capsule driver room, open vision, comfortable operation.

- The cable have open style, close style, can fixed on left or right, based on your requirements and applications.

- The cab hangs under the side walkway of crane bridge close to end beam. Inside of it include control equipment of each mechanism, distribution board, emergency switch and bell push button, etc.

- Ground control (wire or remote), without professional driver.

- Choose according to customer's different requirements.

Optional Functions

- Every operating mechanism's speed regulation (1:10 or more).

- Load weighing and display, overload limiter, and alarm display.

- Height limiter.

- Main and auxiliary hook changes for a single trolley.

- Central lubrication.

- PLC control, fault detection, display records and print system.

Crane Specifictions of Double Girder Eot Crane QD series

Main parameters of QD series of double girder eot crane with open winch trolley

The general use QD type of double girder overhead cranes are available with the lifting capacity of 5 ton -550 ton, span of 10.5m-31.5m, lifting height of 1m-30m, working duty is medium (A5, A6). Also supply non-standard overhead cranes are available based on your requirements and applications conditions. More about QD types double girder eot overhead cranes.

General crane specification of double girder eot crane 5 ton-50 ton

General crane specification of double girder eot crane 5 ton-50 ton

Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 |

Lifting speed | m/min | 11.5 | 8.5 | 7.9 | 7.2 | 6 | 6 |

Trolley speed | m/min | 37.2 | 37.4 | 40.1 | 40 | 37 | 31.3 |

Crane speed | m/min | 70.6 | 70.6 | 74.3 | 75.1 | 64.9 | 58.5 |

Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

Track type | P38 | P38 P43 | P43 | P43 | QU70 | QU8 |

General crane specification of double girder eot crane 75 ton -250 ton

General crane specification of double girder eot crane 75 ton -250 ton

apacity | t | 75 | 100 | 125 | 160 | 200 | 250 |

Span | S(m) | 10.5~31.5 | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 |

Lifting height | m | 6~20 | 6~20 | 6~20 | 6~22 | 6~20 | 6~20 |

Lifting speed | m/min | 3.9 | 3.1 | 3.9 | 3.5 | 2.6 | 2.2 |

Trolley speed | m/min | 31.3 | 33.6 | 33 | 40 | 32 | 32 |

Crane speed | m/min | 61 | 61.8 | 62.3 | 68 | 48 | 50 |

Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

Track type | QU100 | QU100 | QU100 | QU120 | QU120 |

General crane specification of double girder eot crane 300 ton- 450 ton

General crane specification of double girder eot crane 300 ton- 450 ton

| Capacity | t | 300 | 350 | 400 | 450 |

| Span | S(m) | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | m | 6~24 | 6~24 | 6~24 | 6~24 |

| Lifting speed | m/min | 2.4 | 2.2 | 2.6 | 2.1 |

| Trolley speed | m/min | 28 | 28 | 31 | 27 |

| Crane speed | m/min | 42 | 42 | 45 | 42 |

| Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

| Track type | QU120 | QU120 | QU120 | QU120 |

Detailed crane specification of double girder eot crane 5 ton

Detailed crane specification of double girder eot crane 5 ton

QD Electric Double Girder Eot Crane with Hook Crane Specification of 5 Ton | |||||||||

Span (S) | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 |

| |||||||||

Lifting speed | m/min | 12.5(A5)、15.5(A6) | |||||||

Trolley speed | m/min | 37.2 | |||||||

Crane speed | m/min | 90.7(A5)、115.6(A6) | 91.9(A5)、116.8(A6) | ||||||

Lifting motor | kw | 13(A5)、15(A6) | |||||||

Trolley motor | kw | 1.8 | |||||||

Overall weight(A5) | kg | 11830 | 13670 | 15565 | 18200 | 20650 | 25040 | 28130 | 31080 |

Overall weight(A6) | kg | 12130 | 13980 | 15860 | 18500 | 20950 | 25240 | 28330 | 31280 |

Max. wheel load(A5) | KN | 72 | 78 | 84 | 92 | 97 | 109 | 117 | 125 |

Max. wheel load(A6) | KN | 73 | 79 | 85 | 93 | 98 | 110 | 118 | 125 |

Rail recommended | P43 | ||||||||

Main dimension | mm | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 |

Wheel tread to trolley top | H | 1763 | 1763 | 1763 | 1763 | 1763 | 1763 | 1763 | 1763 |

Wheel tread to main girder bottom | H2 | -24 | 126 | 226 | 376 | 526 | 676 | 826 | 976 |

Wheel tread to hook center | H4 | 71 | 71 | 71 | 71 | 71 | 71 | 71 | 71 |

End beam wheel's distance | W | 3400 | 3400 | 3550 | 3550 | 3550 | 5000 | 5000 | 5000 |

End beam length | B | 5054 | 5054 | 5204 | 5204 | 5204 | 5948 | 5948 | 5948 |

Trolley wheels' distance | L | 1400 | |||||||

Hook left limitation | S2 | 800 | |||||||

Hook right limitation | S3 | 1250 | |||||||

Detailed crane specification of double girder eot crane 10 ton

QD Electric Double Girder Eot Crane with Hook Crane Specification of 10 Ton | |||||||||

Span (S) | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 |

| |||||||||

Lifting speed | m/min | 8.5(A5)、13.3(A6) | |||||||

Trolley speed | m/min | 43.8 | |||||||

Crane speed | m/min | 90.7(A5)、115.6(A6) | 91.9(A5)、116.8(A6) | 84.7(A5)、112.5(A6) | |||||

Lifting motor | kw | 17(A5)、22(A6) | |||||||

Trolley motor | kw | 2.5 | |||||||

Overall weight(A5) | kg | 13640 | 15520 | 18350 | 20340 | 22750 | 27140 | 30530 | 33620 |

Overall weight(A6) | kg | 13980 | 15870 | 18685 | 20385 | 22990 | 27470 | 30870 | 33960 |

Max. wheel load(A5) | KN | 101 | 108 | 117 | 122 | 130 | 140 | 150 | 160 |

Max. wheel load(A6) | KN | 102 | 109 | 118 | 123 | 132 | 143 | 152 | 162 |

Rail recommended | P43 | ||||||||

Main dimension | mm | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 |

Wheel tread to trolley top | H | 1876 | 1876 | 1876 | 1876 | 1876 | 1926 | 1926 | 1926 |

Wheel tread to main girder bottom | H2 | -24 | 126 | 226 | 376 | 526 | 628 | 778 | 928 |

Wheel tread to hook center | H4 | 602 | 602 | 602 | 602 | 602 | 552 | 552 | 552 |

End beam wheel's distance | W | 4050 | 4050 | 4050 | 4050 | 4050 | 5000 | 5000 | 5000 |

End beam length | B | 5704 | 5704 | 5704 | 5882 | 5882 | 5948 | 5948 | 5948 |

Trolley wheels' distance | L | 2000 | |||||||

Hook left limitation | S2 | 1300 | |||||||

Hook right limitation | S3 | 2000 | |||||||

Remark: H2 means hook is above the rail. Besides of qd types of double girder eot cranes, there are various types of double girder overhead cranes for different applications and uses. Contact us today to get your customized overhead crane specifications and drawing!

Main Types of Double Girder Overhead Cranes

Double girder overhead cranes, as the name suggests, incorporate two horizontal girders instead of one. These cranes are designed to handle heavier loads and longer spans. Their robust construction and higher load capacity make them indispensable in heavy industries like steel production and shipbuilding.

Double girder cranes excel in heavy-duty applications, such as lifting steel coils, large machinery, and shipping containers. They are commonly used in environments where precision and strength are paramount.

Hot Sale Double Girder Overhead Crane Specifications

QD Hook Double Girder Overhead Crane China

QD type double girder overhead crane is a large and powerful heavy duty lifting equipment used for various fields and sectors, such as workshop of manufacturing and assembly lines, chemical plant and freight yard. The double beam overhead crane with hook can handle a considerable amount of weight within your facilities, ranging from 5 ton to 550 ton. To meet your heavier lifting applications or special requirements, the double girder crane can be custom designed and built.

Double girder crane can realize a greater lifting height, speed and work duty than single girder overhead crane, thus it can be employed for a variety of usage from intermittent use to frequent service. With regard to heavy duty overhead crane, the lifting operation is typically controlled within the cabin, whereas wireless remote control is a cost-effective option for lightweight lifting operations.

QD hook double girder overhead crane parameters:

- Load capacity: 5-450t

- Span: 10.5-31.5m

- Lifting height: 6-24m

- Lifting speed: 2.1-11.5m/min

- Trolley running speed: 27-40m/min

- Crane running speed: 42-75m/min

- Work duty: A3-A7

| Technical Parameter of QD Double Girder Overhead Crane | |||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 |

| Lifting speed | m/min | 11.5 | 8.5 | 7.9 | 7.2 | 6 | 6 |

| Trolley speed | m/min | 37.2 | 37.4 | 40.1 | 40 | 37 | 31.3 |

| Crane speed | m/min | 70.6 | 70.6 | 74.3 | 75.1 | 64.9 | 58.5 |

| Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

| Track type | P38 | P38 P43 | P43 | P43 | QU70 | QU80 |

| Capacity | t | 75 | 100 | 125 | 160 | 200 | 250 |

| Span | S(m) | 10.5~31.5 | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | m | 6~20 | 6~20 | 6~20 | 6~22 | 6~20 | 6~20 |

| Lifting speed | m/min | 3.9 | 3.1 | 3.9 | 3.5 | 2.6 | 2.2 |

| Trolley speed | m/min | 31.3 | 33.6 | 33 | 40 | 32 | 32 |

| Crane speed | m/min | 61 | 61.8 | 62.3 | 68 | 48 | 50 |

| Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

| Track type | QU100 | QU100 | QU100 | QU120 | QU120 | QU120 |

| Capacity | t | 300 | 350 | 400 | 450 |

| Span | S(m) | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | m | 6~24 | 6~24 | 6~24 | 6~24 |

| Lifting speed | m/min | 2.4 | 2.2 | 2.6 | 2.1 |

| Trolley speed | m/min | 28 | 28 | 31 | 27 |

| Crane speed | m/min | 42 | 42 | 45 | 42 |

| Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

| Track type | QU120 | QU120 | QU120 | QU120 |

LH Electric Hoist Overhead Crane Hot Sale in Chia 10 Ton 20 Ton 30 Ton 50 Ton

The LH electric hoist overhead crane is a sort of double girder crane primarily used in mechanical processing workshops, metallurgical plants, warehouses, storage yards and power stations to fulfill a variety of lifting requirements, such as assembly, loading, unloading, overhaul and transferring operations. The overhead crane can also replace a conventional double girder bridge crane for workshops of textile industry and food industry.

LH type overhead crane is able to handle loads that range from 5 ton to 50 ton, and it is specifically designed for light and moderate service. The cranes cannot be used in flammable, explosive or corrosive environments.

LH electric hoist overhead crane parameters:

- Load capacity: 5-50t

- Span: 10.5-31.5 m

- Lifting height: 6-30m

- Lifting speed: 0.18-8m/min

- Trolley running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

| Technical Parameter of LH Model Electric Hoist Bridge Crane | |||||

| Capacity | t | 5 | 10 | 16 | 20 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~30 | 9~30 | 9~30 | 9~30 |

| Lifting speed | m/min | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) |

| Crane speed | m/min | 20(43) | 20(43) | 20(43) | 20(43) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P30 | P30 P38 | P38 | P38 P43 |

| Capacity | t | 25 | 32 | 40 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 9~24 | 9~24 | 9~20 | 9~20 |

| Lifting speed | m/min | 3(0.3/3) | 3(0.3/3) | 2.3(0.23/2.3) | 1.8(0.18/1.8) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) |

| Crane speed | m/min | 20(43) | 20(43) | 20(43) | 20(43) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P43 | P43 | P43 QU70 | P43 QU70 |

NLH European Double Girder Bridge Crane 3 Ton to 80 Ton, Hot Sale 10 Ton, 50 Ton

NLH double girder bridge crane is an European standard overhead lifting equipment. It is distinct from other conventional double girder cranes as it has low headroom, compact structure and delicate appearance. The European standard double girder overhead crane adopts advanced technology and design concept, making it a perfect option for lifting occasions where they require a high-level efficiency and reliability.

The advanced double girder bridge crane can lift 5 ton to 80 ton weight, and the working duty is A5. It is equipped ND type wire rope electric hoist. According to your special requirement, we provide custom design.

NLH European double girder bridge crane parameters:

- Load capacity: 5-80t

- Span: 10.5-31.5m

- Lifting height: 6-18m

- Lifting speed: 0.4-5m/min

- Trolley running speed: 2-20m/min

- Crane running speed: 3-30m/min

- Work duty: A5

| Technical Parameter of NLH European Type Electric Hoist Overhead Crane | |||||

| Capacity | t | 5 | 10 | 16 | 20 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 0.8/5 | 0.8/5 | 0.66/4 | 0.53/3.4 |

| Trolley speed | m/min | 2~20 | 2~20 | 2~20 | 2~20 |

| Crane speed | m/min | 3~30 | 3~30 | 3~30 | 3~30 |

| Work duty | A5 | A5 | A5 | A5 | |

| Track type | P30 | P30 P38 | P38 | P38 P43 |

| Capacity | t | 32 | 50 | 63 | 80 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 0.6/2.6 | 0.4~2.4 | 0.4~2.4 | 0.4~2.4 |

| Trolley speed | m/min | 2~20 | 2~20 | 2~20 | 2~20 |

| Crane speed | m/min | 3~30 | 3~30 | 3~30 | 3~30 |

| Work duty | A5 | A5 | A5 | A5 | |

| Track type | P43 | P43 QU70 | QU70 | QU80 |

European standard 320 Ton overhead cranes China

QDX European 320ton bridge crane parameters:

- Span: 10.5-31.5 m

- Lifting height: 6-24m

- Lifting speed: 0.2-10.7m/min

- Trolley running speed: 2.4-33m/min

- Crane running speed: 4.2-68m/min

- Work duty: A3-A5

| Technical Parameter of QDX European style Double Girder Overhead Crane | |||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 | 6~16 | 6~16 |

| Lifting speed | m/min | 1.07~10.7 | 0.81~8.1 | 0.73~7.3 | 0.58~5.8 | 0.49~4.9 | 0.4~4 |

| Trolley speed | m/min | 3.3~33 | 3.3~33 | 3.2~32 | 3.2~32 | 3.36~33.6 | 2.9~29 |

| Crane speed | m/min | 6.8~68 | 6.8~68 | 5.4~54 | 5.4~54 | 5.6~56 | 5.4~54 |

| Work duty | A3~A5 | A3~A5 | A3~A5 | A3~A5 | A3~A5 | A3~A5 | |

| Track type | P38 | P38 P43 | P43 | P43 | QU70 | QU80 |

| Capacity | t | 75 | 100 | 160 | 200 | 250 | 320 |

| Span | S(m) | 10.5~31.5 | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | m | 6~24 | 6~24 | 6~24 | 6~20 | 6~20 | 6~24 |

| Lifting speed | m/min | 0.37~3.7 | 0.32~3.2 | 0.25~2.5 | 0.24~2.4 | 0.21~2.1 | 0.2~2 |

| Trolley speed | m/min | 2.92~29.2 | 2.9~29 | 2.65~26.5 | 2.5~25 | 2.5~25 | 2.4~24 |

| Crane speed | m/min | 4.8~48 | 5.26~52.6 | 4.67~46.7 | 5.2~52 | 5.2~52 | 4.15~41.5 |

| Work duty | A3~A5 | A3~A5 | A3~A5 | A3~A5 | A3~A5 | A3~A5 | |

| Track type | QU100 | QU100 | QU120 | QU120 | QU120 | QU120 |

QB Double Girder Explosion Proof Crane 5 Ton to 75 Ton for Sale

QB type double girder explosion proof crane is designed for general hoisting operations in explosive or flammable atmospheres, usually equipped with explosion-proof hoist and motor. It is widely used in chemical workshop, petrochemical plant, wastewater treatment plant, gas power plant and other industrial plants for light duty to moderate service. The lifting capacity of this particular double girder crane is generally in a range of 5 ton to 75 ton, and the work duty is A3-A4.

The design and explosion-proof performance of the entire crane are in line with JB/T5897-2006 standard, and that of all motors and electrical devices are in conformity with GB3836.2-2000 standard. The explosion proof signs on the lifting equipment are ExdII BT4 and ExdII CT4.

QB explosion proof crane parameters:

- Load capacity: 5-75t

- Span: 10.5-31.5 m

- Lifting height: 6-20m

- Lifting speed: 1.9-5m/min

- Trolley running speed: 10.5-20.5m/min

- Crane running speed: 15.4-22.3m/min

- Explosion-proof grade: ExdⅡBT4、ExdⅡCT4

- Work duty: A3-A4

| Technical Parameter of QB Explosion Proof Overhead Crane | ||||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 | 75 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 | 6~20 |

| Lifting speed | m/min | 5 | 5 | 4.2 | 4.2 | 4.1 | 3 | 1.9 |

| Trolley speed | m/min | 19.6 | 20.5 | 20.5 | 20.5 | 20 | 19.1 | 10.5 |

| Crane speed | m/min | 22.3 | 22.3 | 19 | 19 | 17 | 19.4 | 15.4 |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Explosion-proof Grade | ExdⅡBT4、ExdⅡCT4 | |||||||

| Track type | P38 | P38 P43 | P43 | P43 | P43 QU70 | QU80 | QU100 |

QC Double Girder Magnetic Overhead Crane Hot Sale 5 Ton to 32 Ton

QC magnetic overhead crane is a sort of double girder crane specifically designed to handle metal sheets, scraps and other metallic materials since it is able to generate powerful magnetic forces by utilizing a detachable electromagnetic chuck. The crane is designed for heavy duty service that can lift loads with large capacity, typically in a range of 5 ton to 50 ton.

QC magnetic overhead crane parameters:

- Load capacity: 5-50t

- Span: 10.5-31.5 m

- Lifting height: 6-16m

- Lifting speed: 7.8-15.5m/min

- Trolley running speed: 31.3-40.1m/min

- Crane running speed: 58.5-70.6m/min

- Work duty: A5-A7

| Technical Parameter of QC Electromagnetic Overhead Crane | |||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 |

| Lifting speed | m/min | 15.5 | 13.3 | 13 | 9.7 | 9.5 | 7.8 |

| Trolley speed | m/min | 37.2 | 37.4 | 40.1 | 40 | 37 | 31.3 |

| Crane speed | m/min | 70.6 | 70.6 | 74.3 | 75.1 | 64.9 | 58.5 |

| Work duty | A5~A7 | A5~A7 | A5~A7 | A5~A7 | A5~A7 | A5~A7 | |

| Track type | P38 | P38 P43 | P43 | P43 | QU70 | QU80 |

YZ Double Girder Overhead Casting Crane, Star Steel Mill Crane

YZ type double girder casting crane is the main overhead lifting equipment used for steelmaking and continuous casting process. The crane offers great protection and high-level efficiency in areas where the high temperature and dust present. It can lift and transport liquid steel ladle in a greater speed and efficiency than its single girder counterpart, making it ideal for heavy duty or severe lifting requirements.

The crane is capable of lifting a substantial amount of weight, usually is a range of 5 tons to 320 tons, and the work duty is A6-A8. Thus the double girder casting crane can adapt to a much worse working environment.

YZ overhead casting crane parameters:

- Load capacity: 5-320t

- Span: 10.5-31.5 m

- Lifting height: 6-24m

- Lifting speed: 6-13m/min

- Trolley running speed: 36-45.9m/min

- Crane running speed: 63-118.6m/min

- Work duty: A6-A8

| Technical Parameter of YZ Hook Casting Overhead Crane | |||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~16 | 6~16 |

| Lifting speed | m/min | 12.5 | 13 | 10.8 | 9.9 | 9.7 | 7.6 |

| Trolley speed | m/min | 39.5 | 44.9 | 44.6 | 45.9 | 43.5 | 39.3 |

| Crane speed | m/min | 118.6 | 114.9 | 103.5 | 103.5 | 88 | 77.5 |

| Work duty | A6~A8 | A6~A8 | A6~A8 | A6~A8 | A6~A8 | A6~A8 | |

| Track type | P38 | P38 P43 | P43 QU70 | P43 QU70 | QU70 | QU80 |

| Capacity | t | 74 | 100 | 125 | 140 | 160 | 180 |

| Span | S(m) | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | m | 6~20 | 6~20 | 6~20 | 6~22 | 6~22 | 6~24 |

| Lifting speed | m/min | 6.4 | 7.5 | 7.5 | 6.84 | 6 | 7.2 |

| Trolley speed | m/min | 37.2 | 38 | 38 | 38 | 37 | 38 |

| Crane speed | m/min | 77 | 77 | 79.7 | 73 | 77.8 | 86 |

| Work duty | A6~A8 | A6~A8 | A6~A8 | A6~A8 | A6~A8 | A6~A8 | |

| Track type | QU100 | QU120 | QU120 | QU120 | QU120 | QU120 |

| Capacity | t | 200 | 225 | 240 | 280 | 320 |

| Span | S(m) | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 |

| Lifting height | m | 6~24 | 6~24 | 6~24 | 6~24 | 6~24 |

| Lifting speed | m/min | 8 | 8 | 10 | 10 | 9 |

| Trolley speed | m/min | 40 | 40 | 38 | 36 | 36 |

| Crane speed | m/min | 86 | 87 | 87 | 76 | 63 |

| Work duty | A6~A8 | A6~A8 | A6~A8 | A6~A8 | A6~A8 | |

| Track type | QU120 | QU120 | QU120 | QU120 | QU120 |

QE Double Trolley Overhead Crane

The QE type double trolley overhead crane, as the name implies, is equipped with two hoist trolleys of equal lifting capacity, both of which can be used independently and simultaneously. The trolley overhead crane is capable of lifting hundreds of tons, and it performs the lifting work more efficiently and safely. The overhead trolley crane design is in line with GB / T3811 standard.

QE double trolley overhead crane parameters:

- Load capacity: 5+5t-320+320t

- Span: 10.5-34m

- Lifting height: 6-24m

- Lifting speed: 2.3-11.5m/min

- Trolley running speed: 22.5-40.1m/min

- Crane running speed: 40-75.1m/min

- Work duty: A3-A7

| Technical Parameter of QE Double Trolley Overhead Crane | |||||||

| Capacity | t | 5+5 | 10+10 | 16+16 | 20+20 | 32+32 | 50+50 |

| Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 |

| Lifting speed | m/min | 11.5 | 8.5 | 7.9 | 7.2 | 6 | 5.9 |

| Trolley speed | m/min | 37.2 | 37.4 | 40.1 | 40 | 37 | 31.3 |

| Crane speed | m/min | 70.6 | 75.1 | 64.9 | 59.1 | 59.1 | 61.8 |

| Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

| Track type | P38 P43 | P43 | P43 QU70 | P43 QU70 | QU80 | QU100 |

| Capacity | t | 75+75 | 100+100 | 160+160 | 200+200 | 250+250 | 320+320 |

| Span | S(m) | 13~34 | 13~34 | 13~34 | 13~34 | 13~34 | 13~34 |

| Lifting height | m | 6~20 | 6~20 | 6~22 | 6~20 | 6~20 | 6~24 |

| Lifting speed | m/min | 4.7 | 3.9 | 3.5 | 3.5 | 2.2 | 2.3 |

| Trolley speed | m/min | 38.2 | 33.9 | 22.5 | 29 | 28 | 28 |

| Crane speed | m/min | 68 | 48 | 42 | 45 | 42 | 40 |

| Work duty | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | |

| Track type | QU120 | QU120 | QU120 | QU120 | QU120 | QU120 |

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch