Top 6 Hot Sale Single Girder Cranes & Specifications 1 to 20Ton

Hot sale single girder overhead cranes & specifications for reference. Get your 5 ton, 10 ton, 16 ton & 20 ton single girder crane at good crane price.

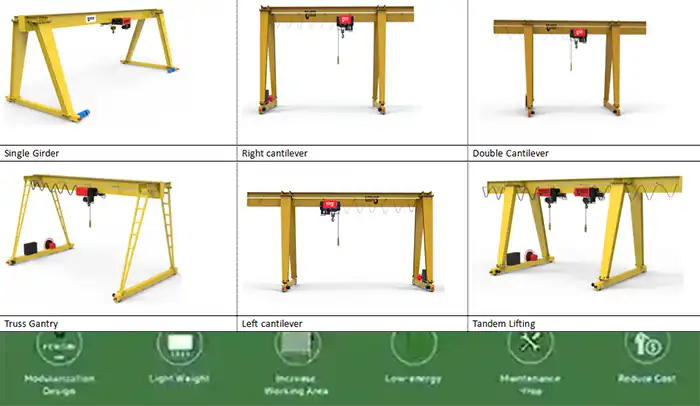

| Crane Type | single girder crane with different designs |

| Crane Capacity | 1-20 ton |

| Lifting Height | As your request |

| Crane Span | As your request |

Category: Hoist and Crane Specifications

Your Trusted Single Girder Overhead Crane Manufacturer & Supplier

Top 5 Hot Sale Single Girder Cranes & Specifications 1 to 20 Ton

Single girder overhead cranes are a crucial component in various industrial settings, offering an efficient and reliable solution for material handling. These cranes are characterized by their single girder design, which supports the trolley and hoist, making them a versatile and cost-effective choice for many operations. Their design allows for optimal space utilization, as the crane's structure is compact yet capable of handling substantial loads, making them ideal for facilities with limited headroom or space constraints.

In industrial applications, single girder overhead cranes play a vital role in improving workflow efficiency, reducing manual labor, and enhancing safety. They are commonly used in manufacturing plants, warehouses, assembly lines, and maintenance facilities, where lifting and transporting heavy loads are frequent tasks. The single girder design is particularly beneficial for medium-duty to heavy-duty applications, where reliability and ease of operation are essential.

Key Features of Single Girder Overhead Cranes

Robust Construction and Design

Single girder overhead cranes are engineered with durability and strength in mind, making them suitable for a wide range of industrial applications. The robust construction ensures that these cranes can withstand the rigors of daily use in demanding environments. The single girder design optimizes the balance between structural integrity and weight, resulting in a crane that is both strong and lightweight. This design not only allows for easier installation and reduced stress on the building structure but also ensures long-term performance with minimal wear and tear. The materials used in constructing the girder and supporting components are typically high-grade steel, which provides excellent resistance to fatigue and deformation, even under heavy loads.

Efficiency and Reliability in Various Environments

Efficiency is a hallmark of single girder overhead cranes. They are designed to streamline material handling processes, reducing the time and effort required to move heavy loads across the workspace. The cranes operate with smooth and precise movements, allowing for accurate positioning of materials, which is crucial in assembly lines, warehouses, and manufacturing plants. The reliability of these cranes is another key feature, with components designed to minimize the risk of breakdowns and ensure consistent performance over time. Whether operating in a controlled indoor environment or a more challenging industrial setting, such as a foundry or chemical plant, single girder overhead cranes are built to deliver reliable service, even in harsh conditions. This includes environments with high temperatures, dust, or exposure to chemicals, where the crane's resilience and dependability are critical.

Ease of Operation and Maintenance

Single girder overhead cranes are user-friendly, designed for ease of operation even by operators with minimal training. The controls are typically straightforward, allowing operators to manage the crane's movements with precision and confidence. Many models come equipped with ergonomic control systems, including pendant controls, wireless remote controls, or cabin controls, depending on the specific requirements of the operation. The ease of operation extends to the crane's maintenance as well. Routine maintenance tasks, such as lubrication, inspection, and part replacements, are designed to be simple and quick, reducing downtime and ensuring that the crane remains in optimal working condition. The design also facilitates easy access to critical components, which simplifies maintenance and inspection processes, leading to lower maintenance costs and extended service life. Additionally, many modern single girder cranes include diagnostic systems that alert operators to potential issues before they become serious problems, further enhancing the ease of maintenance and contributing to the crane's overall reliability.

General Specifications for Single Girder Capacity

1-5-Ton Single Girder Overhead Crane

Technical Specifications:

- Capacity Range: 1 to 5 tons

- Span Length: Customizable up to 30 meters

- Lifting Height: Typically up to 12 meters, customizable based on site requirements

- Lifting Speed: 0.8 to 8 m/min, variable speed options available

- Hoist Type: Electric wire rope or chain hoist

- Power Supply: 380V/50Hz/3Ph (customizable for different regions)

- Control System: Pendant control, wireless remote control, or cabin control

Typical Applications:

- Warehousing: Efficiently handling palletized goods and materials in warehouses.

- Manufacturing: Supporting assembly lines and moving materials between workstations.

- Maintenance Shops: Ideal for small to medium-sized repair tasks, lifting engines, and machinery.

- Automotive Industry: Used in the production and maintenance of automotive components.

10-Ton Single Girder Overhead Crane

Technical Specifications:

- Capacity: 10 tons

- Span Length: Up to 28 meters

- Lifting Height: Typically up to 12 meters, adjustable to meet specific needs

- Lifting Speed: 0.8 to 8 m/min with precision control

- Hoist Type: Electric wire rope hoist

- Power Supply: 380V/50Hz/3Ph (customizable)

- Control System: Available with pendant control, wireless remote, or cabin control

Typical Applications:

- Steel Mills: Transporting steel plates, coils, and bars within the facility.

- Construction Sites: Assisting in lifting heavy construction materials like beams and columns.

- Fabrication Shops: Moving heavy metal parts during fabrication processes.

- Heavy Machinery: Ideal for handling heavy equipment and machinery components.

15 Ton 16 Ton Single Girder Overhead Crane

Technical Specifications:

- Capacity: 16 tons

- Span Length: Up to 25 meters

- Lifting Height: Typically up to 12 meters, customizable as required

- Lifting Speed: 0.5 to 5 m/min for precise load handling

- Hoist Type: Heavy-duty electric wire rope hoist

- Power Supply: 380V/50Hz/3Ph (customizable)

- Control System: Options include pendant control, wireless remote, or cabin control

Typical Applications:

- Heavy Manufacturing: Supporting production lines in heavy manufacturing industries.

- Shipyards: Moving large ship components during construction and repair.

- Power Plants: Handling heavy turbines, generators, and other large components.

- Mining Operations: Lifting heavy machinery and mined materials.

20 Ton Single Girder Overhead Crane

Technical Specifications:

- Capacity: 20 tons

- Span Length: Up to 22 meters

- Lifting Height: Typically up to 12 meters, customizable for specific projects

- Lifting Speed: 0.5 to 5 m/min with high precision

- Hoist Type: Industrial-grade electric wire rope hoist

- Power Supply: 380V/50Hz/3Ph (customizable)

- Control System: Available in pendant control, wireless remote control, or cabin control configurations

Typical Applications:

- Aerospace Industry: Lifting and handling large aircraft parts during assembly and maintenance.

- Oil and Gas: Managing heavy components in refineries and offshore facilities.

- Large-scale Fabrication: Moving large and heavy components in large-scale fabrication shops.

- Infrastructure Projects: Supporting construction of bridges, tunnels, and other major infrastructure projects.

Hot Sale Single Girder Overhead Crane Specifications

HD Electric Single Girder Bridge Crane for Sale 3 Ton , 5 Ton, 10 Ton, 12.5Ton, 16 Ton, 20 Ton

HD electric single girder bridge crane represents a high-level lifting equipment that adopts unique design concept and the latest technology. This advanced overhead crane can be applied in mechanical manufacturing, metallurgy, power plant and other industries to handle large and heavy materials, especially suitable for occasions that require accurate positioning or precision assembly for large parts.

The European standard single girder crane is equipped with ND wire rope hoist to lift a large amount of weight, usually in a range of 1 ton to 20 ton. The bridge crane design conforms to international standards including DIN, FEM and ISO.

HD European single girder bridge crane parameters:

- Load capacity: 1-20t

- Span: 7.5-28.5m

- Lifting height: 6-18m

- Lifting speed: 0.8/5m/min

- Hoist running speed: 2-20m/min

- Crane running speed: 3-30m/min

- Work duty: A5

| Technical Parameter of HD European Type Single Girder Overhead Crane | |||||

| Capacity | t | 1 | 2 | 3.2 | 5 |

| Span | S(m) | 7.5~28.5 | 7.5~28.5 | 7.5~28.5 | 7.5~28.5 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 0.8/5 | 0.8/5 | 0.8/5 | 0.8/5 |

| Trolley speed | m/min | 2~20 | 2~20 | 2~20 | 2~20 |

| Crane speed | m/min | 3~30 | 3~30 | 3~30 | 3~30 |

| Work duty | A5 | A5 | A5 | A5 | |

| Track type | P18 P24 | P18 P24 | P24 | P24 |

| Capacity | t | 10 | 12.5 | 16 | 20 |

| Span | S(m) | 7.5~28.5 | 7.5~28.5 | 7.5~28.5 | 7.5~28.5 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 0.8/5 | 0.66/4 | 0.66/4 | 0.53/3.4 |

| Trolley speed | m/min | 2~20 | 2~20 | 2~20 | 2~20 |

| Crane speed | m/min | 3~30 | 3~30 | 3~30 | 3~30 |

| Work duty | A5 | A5 | A5 | A5 | |

| Track type | P30 | P30 | P30 P38 | P30 P38 |

LD Electric Single Girder Overhead Crane for Sale 1 Ton, 3 Ton, 5 Ton, 10 Ton, 16 Ton, 20 Ton, 25 Ton

LD model single girder overhead crane is the most common type of overhead cranes used for small to moderate lifting applications. It is extensively applied in workshops of manufacturing, repairing and assembly lines, warehouses and storage yards to carry out different lifting tasks. This typical single beam overhead crane cannot be used in flammable, explosive or corrosive environments.

LD single girder overhead crane parameters:

- Load capacity: 1-20t

- Span: 7.5-31.5m

- Lifting height: 6-30m

- Lifting speed: 0.3-8m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

| Technical Parameter of LD Single Girder Overhead Crane | |||||||||

| Capacity | t | 1 | 2 | 3 | 5 | 10 | 16 | 20 | 25 |

| Span | S(m) | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~25.5 |

| Lifting height | m | 6~30 | 6~30 | 6~30 | 6~30 | 9~30 | 9~30 | 9~30 | 9~30 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) | 3(0.3/3) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 18 | 14 | 16 |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P18 | P18 P24 | P24 | P24 | P24 P30 | P30 P38 | P38 P43 | P38 P43 |

LB Explosion Proof Overhead Crane, hot sale 3 Ton, 5 Ton, 10 Ton, 15 Ton

LB model explosion proof overhead crane is a kind of single girder crane specifically designed for hazardous lifting environments, usually equipped with HB explosion proof electric hoist. The motor and electrical devices of this crane are also explosion-proof type to ensure a high level of safety required for explosive atmospheres.

The single girder explosion proof crane is widely applied in power plant, chemical plant, sewage treatment plant and other industries to load, unload and transfer heavy items. It can lift a large amount of weight, ranging from 1 ton to 20 ton, and the working class is A3, A4.

LB explosion proof overhead crane parameters:

- Load capacity: 1-20t

- Span: 7.5-31.5m

- Lifting height: 6-30m

- Lifting speed: 0.33-8m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Explosion-proof grade: ExdⅡBT4、ExdⅡCT4

- Work duty: A3, A4

| Technical Parameter of LB Model Explosion-proof Electric Single Girder Crane | ||||||||

| Capacity | t | 1 | 2 | 3 | 5 | 10 | 16 | 20 |

| Span | S(m) | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 |

| Lifting height | m | 6~30 | 6~30 | 6~30 | 6~30 | 9~30 | 9~30 | 9~30 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 18 | 14 |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Explosion-proof Grade | ExdⅡBT4、ExdⅡCT4 | |||||||

| Track type | P18 | P18 P24 | P24 | P24 | P24 P30 | P30 P38 | P30 P38 |

LX Single Girder Suspension Crane Hot Sale 1 Ton, 2 Ton 3 Ton, 5 Ton in China

Suspension crane is a kind of small and lightweight underhung overhead crane, also known as under running crane or underhung crane. It is widely applied in workshop of production and assembly lines, warehouse and other places to lift and move heavy loads. The underhung crane, as its name implies, is suspended from building roof structure and runs at the bottom flange of runway beam.

Single girder suspension crane is designed and manufactured in strict accordance with industrial standard JB2603-94, usually equipped with CD and MD electric hoists. Due to its distinct structure, the under running overhead crane usually comes in single girder design, thus it cannot lift a considerable amount of weight. The capacity ranges from 0.5 ton to 10 ton, the span of is 3-22.5m, working classification is A3-A4.

LX suspension crane parameters:

- Load capacity: 0.5-10t

- Span: 3-22.5m

- Lifting height: 6-30m

- Lifting speed: 0.7-8m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

| Technical Parameter of LX Single Girder Suspension Crane | |||||||

| Capacity | t | 0.5 | 1 | 2 | 3 | 5 | 10 |

| Span | S(m) | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 |

| Lifting height | m | 6~30 | 6~30 | 6~30 | 6~30 | 6~30 | 9~30 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 |

LDY Single Girder Foundry Crane 3 Ton, 5 Ton, 10 Ton Hot Sale in China

LDY model electric single girder foundry crane is specially designed for lifting and transferring molten metal in metallurgy and casting places. It can also be used for handling molten non-metallic materials and hot solid metal. The overhead crane is generally outfitted with YH type metallurgical electric hoist, and its lifting capacity is not more than 10 tons. This crane is designed according to JB/T 1306-2008 standards.

LDY single girder foundry crane parameters:

- Load capacity: 1-10t

- Span: 7.5-31.5m

- Lifting height: 6-20m

- Lifting speed: 1.75-8m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A6

| Technical Parameter of LDY Metallurgy Electric Single Girder Overhead Crane | ||||||

| Capacity | t | 1 | 2 | 3 | 5 | 10 |

| Span | S(m) | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 | 7.5~31.5 |

| Lifting height | m | 6~20 | 6~20 | 6~20 | 6~20 | 6~20 |

| Lifting speed | m/min | 8(2/8) | 8(2/8) | 8(2/8) | 8(2/8) | 7(1.75/7) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A6 | A6 | A6 | A6 | A6 | |

| Track type | P18 P24 | P18 P24 | P24 | P24 | P24 P30 |

LDZ Single Girder Grab Crane 3 Ton, 5 Ton, 10 Ton China

LDZ single girder grab crane is generally the same with LD electric single girder crane except for its grabbing mechanism. Equipped with grab hoist trolley, the crane is suitable for handling almost all kinds of loose and bulk materials, such as garbage, industrial materials and sand. The lifting capacity of overhead crane ranges from 2 ton to 10 ton, and the working class is A4. This crane cannot be used in flammable, explosive or corrosive atmosphere.

The crane system is usually controlled by an operator from the ground or by a driver sitting in the cabin to realize a safe and easy lifting operation. This bridge crane features high working efficiency, wide application, sturdy construction and reliable performance, making it perfect for lifting in mining, garbage disposal plant, steel plant and power plant.

LDZ single girder grab crane parameters:

- Load capacity: 2-10t

- Span: 4.5-28.5m

- Lifting height: 6-16m

- Lifting speed: 14-16m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

| Technical Parameter of LDZ Electric Single Girder grab Crane | |||||

| Capacity | t | 2 | 3 | 5 | 10 |

| Span | S(m) | 4.5-28.5 | 4.5-28.5 | 4.5-28.5 | 4.5-28.5 |

| Lifting height | m | 6~16 | 6~16 | 6~16 | 6~13 |

| Lifting speed | m/min | 16 | 16 | 16 | 14 |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) |

| Grab volume | m³ | 0.5 | 0.5 | 0.75 | 1 |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P18 P24 | P24 | P24 | P24 P30 |

Customization Options

Tailoring Single Girder Crane Features to Specific Needs

Our single girder overhead cranes can be meticulously customized to align with the unique requirements of your operation. Here's how we tailor the crane to meet your specific needs:

Custom Lifting Heights and Spans:

- Lifting Heights: Choose from a range of lifting heights to ensure the crane operates efficiently within the vertical constraints of your facility. This customization helps maximize usable space and accommodate various load types.

- Tailored Spans: Select the appropriate span length to fit the width of your workspace. Custom spans ensure the crane covers the required area, improving material handling efficiency and workspace utilization.

Specialized Hoist Types:

- Hoist Types: Choose from different types of hoists, including electric chain hoists, wire rope hoists, or specialized hoists designed for specific applications. This ensures the crane is equipped with the right hoist for your load types and operational requirements.

Lifting Speeds and Control Systems:

- Lifting Speeds: Opt for various lifting speeds to match the speed requirements of your operations. Faster lifting speeds can increase productivity, while slower speeds offer better control for delicate loads.

- Control Systems: Customize the control system to include options such as manual controls, radio remote controls, or sophisticated automated systems. This enhances ease of use and operational flexibility.

Power Supplies and Motor Options:

- Power Supplies: Select from different power supply configurations to ensure compatibility with your facility's electrical system. Options include standard AC power, low voltage, or specialized power requirements.

- Motor Options: Choose from various motor types and configurations to match the operational demands of your crane. This includes options for energy efficiency and performance optimization.

Anti-Sway Technology and Variable Frequency Drives (VFDs):

- Anti-Sway Technology: Incorporate anti-sway systems to minimize load swinging and improve precision during operation. This is particularly beneficial for handling sensitive or high-value materials.

- Variable Frequency Drives (VFDs): Implement VFDs to control the crane's speed and acceleration, enhancing operational smoothness and energy efficiency. VFDs contribute to better load handling and reduced mechanical wear.

Enhanced Safety Features:

- Safety Features: Integrate advanced safety features such as overload protection, emergency stop systems, and collision avoidance sensors. These features ensure the safe operation of the crane and protect both personnel and equipment.

By customizing these features, we ensure that your single girder overhead crane is perfectly suited to your operational needs, enhancing performance, safety, and efficiency in your facility.

Options for Different Industries and Environments

We understand that different industries and environments have distinct challenges, and our cranes are designed with this in mind. For instance, in environments with extreme temperatures or exposure to corrosive materials, we offer cranes with specialized coatings and materials to ensure durability and longevity. Industries like food processing, where hygiene is critical, can opt for cranes made from stainless steel or with special finishes that resist contamination. For hazardous environments, such as chemical plants or oil and gas facilities, we provide explosion-proof components and enhanced safety features that comply with industry standards. No matter the industry, our customization options ensure that your single girder overhead crane is optimally designed for your specific working conditions and operational needs.

We recognize that different industries and environments pose unique challenges, and our single girder overhead cranes are engineered to address these specific needs. Here's how our cranes can be customized for various industries and environmental conditions:

Extreme Temperatures and Corrosive Environments

- Specialized Coatings and Materials: For environments with extreme temperatures, whether hot or cold, we offer single girder cranes with specialized coatings and materials designed to withstand thermal stress and maintain performance. These include heat-resistant paints and cold-weather lubricants that ensure reliable operation under harsh conditions.

- Corrosion-Resistant Design: In environments exposed to corrosive materials, such as coastal areas or chemical processing plants, our cranes are built with corrosion-resistant materials and coatings. Options include galvanized steel, epoxy coatings, and stainless steel components to enhance durability and extend the lifespan of the crane.

Food Processing and Hygiene-Sensitive Industries

- Stainless Steel and Special Finishes: For industries like food processing where hygiene is paramount, we offer cranes made from stainless steel or with specialized finishes that resist contamination and facilitate easy cleaning. These cranes are designed to meet stringent hygiene standards, preventing the accumulation of contaminants and ensuring compliance with industry regulations.

- Hygienic Design: Features such as smooth, non-porous surfaces and sealed joints are included to minimize the risk of bacterial growth and facilitate regular sanitation. This design consideration ensures that the crane supports a clean and safe working environment.

Hazardous Environments

- Explosion-Proof Components: In hazardous environments such as chemical plants, oil refineries, or gas facilities, we provide single girder cranes equipped with explosion-proof components. These include explosion-proof motors, control panels, and electrical fittings that comply with industry standards for safety and reliability.

- Enhanced Safety Features: Additional safety features such as flameproof enclosures, emergency shutdown systems, and advanced monitoring technology are incorporated to ensure the crane operates safely in high-risk environments. These features help mitigate risks associated with flammable or hazardous materials.

General Industrial Applications

- Custom Features for Specific Needs: Regardless of the industry, our cranes can be tailored with features to meet general industrial requirements. This includes options for varying lifting capacities, speeds, and control systems to optimize the crane's performance for your specific operational needs.

By offering these customization options, we ensure that our single girder overhead cranes are not only capable of meeting the diverse demands of different industries but also provide reliable, safe, and efficient performance in any working environment.

Competitive Pricing and Value

Our pricing strategy is designed to offer the best value for your investment in single girder overhead cranes. We focus on providing high-quality cranes at competitive prices, ensuring that you get a reliable, efficient lifting solution without overextending your budget. Our pricing is transparent, with no hidden costs, and is tailored to accommodate different capacities and custom features. Whether you are purchasing a 5-ton or a 20-ton crane, we strive to deliver a cost-effective solution that meets your specific requirements.

Cost-Benefit Analysis for Different Capacities

When considering the purchase of a single girder overhead crane, it's essential to evaluate the cost-benefit ratio for each capacity. For lighter loads, such as 5-ton and 10-ton cranes, the initial investment is lower, but these cranes still offer robust performance and reliability for smaller-scale operations. As you move up to 16-ton and 20-ton capacities, the upfront cost increases, but the benefits of handling heavier loads with ease and efficiency can lead to significant operational savings. These larger cranes are particularly valuable in industries where heavy lifting is frequent, as they reduce the need for multiple lifts and minimize downtime, ultimately leading to cost savings over time.

Long-Term Value and Investment in Quality

Investing in a high-quality single girder overhead crane offers long-term value that extends beyond the initial purchase price. Our cranes are built to last, with durable components and advanced engineering that reduce the need for frequent repairs and replacements. This longevity means that your crane will continue to deliver reliable performance for many years, making it a cost-effective investment. Additionally, the enhanced safety features, ease of maintenance, and potential for customization ensure that your crane adapts to your evolving operational needs, further increasing its value. In the long run, choosing a quality crane from our range not only optimizes your material handling processes but also provides a solid return on investment, as it enhances productivity, reduces operational risks, and supports the overall efficiency of your facility.

Why Choose Our Single Girder Overhead Cranes?

Advantages Over Competitors

Our single girder overhead cranes stand out in the market due to their superior design, quality, and customization options. Unlike many competitors, we prioritize both durability and efficiency, ensuring that our cranes perform reliably in even the most demanding industrial environments. Our cranes are engineered with advanced technology that enhances safety, reduces operational costs, and maximizes productivity. Additionally, our flexible customization options allow you to tailor the crane to your specific needs, from lifting capacity to control systems, providing you with a solution that is perfectly suited to your operation. The competitive pricing we offer also means you receive top-tier quality without compromising on your budget.

Proven Performance and Customer Satisfaction

Our single girder overhead cranes have a proven track record of delivering exceptional performance across various industries. Clients consistently report increased efficiency, reduced downtime, and improved safety after integrating our cranes into their operations. The robust construction and precision engineering of our cranes ensure that they handle heavy loads with ease and maintain consistent performance over time. This reliability has earned us a reputation for quality, with many customers returning to us for additional crane purchases as their operations grow. Our commitment to customer satisfaction extends beyond the sale, with dedicated after-sales support to ensure your crane continues to meet your needs.

Testimonials and Case Studies

We have numerous testimonials from satisfied customers who have experienced the benefits of our single girder overhead cranes firsthand. For example, a manufacturing plant that needed to streamline its material handling processes found that our 10-ton single girder crane significantly reduced their production time and increased throughput. Another case study involves a shipyard that required a crane with specific corrosion-resistant features; our customized solution not only met their requirements but exceeded their expectations in terms of durability and performance. These real-world examples demonstrate the tangible value that our cranes bring to diverse industrial operations, reinforcing why we are the preferred choice for single girder overhead cranes.

How to Get Your Single Girder Crane

Simple Ordering Process:

Acquiring your single girder crane from us is straightforward and hassle-free. Start by exploring our range of single girder cranes or discussing your specific needs with our sales team. We'll help you select the right crane capacity and customization options to perfectly match your operational requirements. After you make your selection, we'll provide a detailed quotation and a clear timeline for delivery. Our ordering process is transparent, ensuring that all costs and specifications are clearly outlined so you know exactly what to expect.

Acquiring your single girder crane from us is designed to be a straightforward and hassle-free experience. Here's how it works:

- Explore Our Range: Begin by browsing our comprehensive selection of single girder cranes. Our website features detailed product descriptions, technical specifications, and images to help you understand the options available. If you have specific requirements or need assistance, you can reach out to our sales team directly.

- Discuss Your Needs: Contact our sales team to discuss your operational needs. Whether you have precise requirements for lifting capacity, span length, or environmental conditions, our experts will provide personalized recommendations. We'll work with you to identify the best crane configuration and customization options to ensure it meets your unique needs.

- Select and Customize: Based on your discussion, choose the appropriate single girder crane capacity and any additional features or customizations. Our cranes come with various options such as lifting speeds, control systems, and power supplies to tailor the crane to your specific application.

- Receive Detailed Quotation: Once you've made your selection, we'll prepare a detailed quotation outlining the cost of the crane, any custom features, and additional services such as installation. This quotation will include a breakdown of all costs, so you have a clear understanding of the financial commitment involved.

- Clear Timeline for Delivery: Along with the quotation, we'll provide a transparent timeline for the delivery and installation of your single girder crane. Our timeline will include key milestones such as order confirmation, manufacturing, and shipping dates, ensuring you're informed every step of the way.

- Transparent Ordering Process: Our ordering process is designed for clarity and simplicity. We ensure that all aspects of the purchase are clearly communicated, including costs, specifications, and delivery schedules. This transparency helps you make an informed decision and ensures that there are no surprises along the way.

By following these steps, we make the process of acquiring your single girder crane efficient and transparent, ensuring that you get the right equipment for your needs with minimal hassle.

In addition to supplying your single girder crane, we offer a range of services to ensure seamless integration into your facility. Our professional installation team will manage the entire setup process, ensuring that your crane is properly installed and ready for operation. We also provide comprehensive maintenance services to keep your single girder crane in optimal condition, extending its lifespan and maintaining reliable performance. Whether you need routine inspections, repairs, or upgrades, our experienced technicians are here to support you, ensuring that your investment in a single girder crane delivers long-term value and efficiency.

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

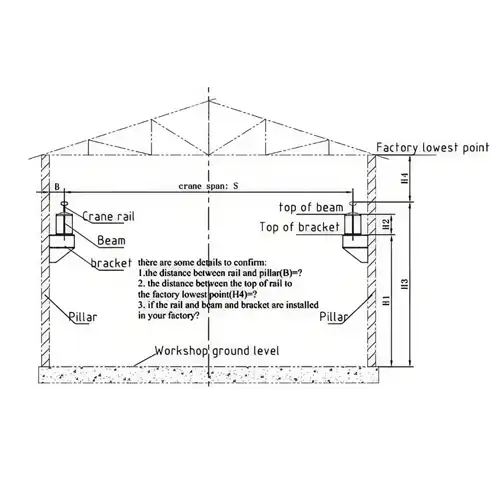

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch