Electric Wire Rope Hoist Specifications 5 Ton, 10 Ton & 30 Ton

Types of electric wire rope hoists for sale. Wide electric hoist specifications 5 ton, 10 ton, 30 ton, economical cd/md wire rope hoists, good price.

| Electric Hoist Type | Electric Wire Rope Hoist |

| Crane specifications | 0.5 ton -35 ton, 5 ton -63 ton |

| Lifting Height | As your request |

| Working Class | M3, M4 |

Category: Hoist and Crane Specifications

Your Trusted Overhead Crane Manufacturer & Supplier

Electric Wire Rope Hoist Specifications 5 Ton, 10 Ton & 30 Ton

Economical cd/md Wire Rope Hoists, Good Price

Electric wire ropehoist is one of the most typical types of electric hoistsand also the most widely used electric hoist. The conventional single-speed and double-speed electric hoists have been improved over many generations and are now the most economical electric hoists available. The explosion-proof electric hoist is appropriate for flammable and explosive environments, while low headroom hoists are designed for workshops or facilities with limited space in order to meet the requirements of special working conditions.

Our company primarily produces electric hoists with lifting capacities ranging from 0.25 to 63 tons, liftingheights of 1 to 100 meters, and working classes of M3 to M4. We can also design and produce built uphoists to meet your specific needs.

After years of development, the electric wire rope hoist is now widely used because of its advantages, including its small size, light weight, safety, and reliability, as well as its high adaptability, easy interchangeability, and large lifting capacity.Contact us to get your economical hoist with customized electric wire rope hoist specifications and drawing.

It is suitable for temperatures ranging from -25°C to +40°C, humidity levels of up to 85%, and altitudes of less than 1000m. Power is 3-phase 380v 50Hz (can be customized to meet the needs of the customer).

- Traveling electric hoists can be installed on various types of cranes or suspended on I-beams to perform straight or curved motions.

- Fixed type hook suspension electric wire rope hoists can be installed on fixed supports to perform vertical motions.

- Widely used in industrial and mining sites, rail lines, ports, and warehouses.

The following are the main benefits of using a wire rope hoist:

- Offers extremely quick lifting speeds

- Can be classified to severe and heavyduty levels.

- Offer better performance for application with capacity of 10 tons and above.

- Quieter and more smoothlifting operation.

The following are the main drawbacks of using a wire rope hoist:

- In some circumstances, wire rope might not be as durable as hoist chain.

- A chain hoist takes up less space than a wire rope drum.

- Electric wire rope hoist is more expensive than electric chain hoists under certain applications.

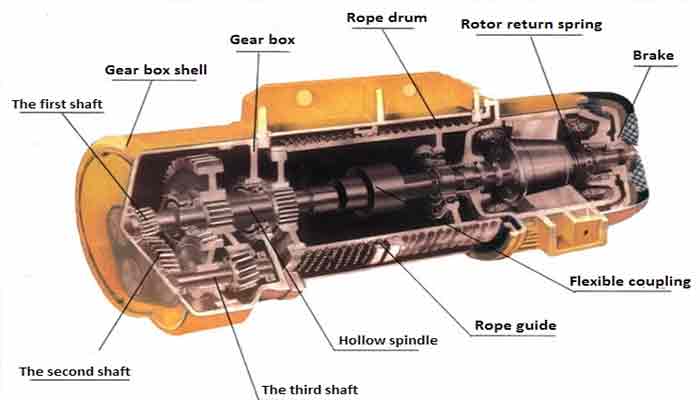

Main Structure and Features

As shown below, an electric hoist is made up of a lifting mechanism, a traveling mechanism (except for fixed types with hook suspension hoist design), and electric parts.

Lifting Mechanism

The lifting motor rotates the winding drum through the coupling and the hollow spindle of the reducer, causing the wire rope of the drum to drive the hook up and down.The CD1 type hoist is equipped with a ZD type single speed motor, while the MD1 type hoist is equipped with a ZDS type double speed motor, with a 10:1 ratio of usual speed to low speed.

- Three-phase asynchronous braking motors with tapered rotors

- High starting torque, effective braking, and a compact design

- Operation stability, small volume, and light weight

- Safety in use, ease of maintenance

- Insulation class B or F, IP44 or IP54 protection

Reducer

- Long service life, three-level dead axle helical gear rotating body.

- Gear and axle are made of high-intensity alloy steel after heat treatment.

- Fully covered box and cover made of superior cast iron.

- Excellent speed ratio and high accuracy.

- Compact design, quietoperation, and high efficiency.

- Oils for machinery.

- Simple to assemble and disassemble.

Rope Drum

- Made of cast iron or seamless steel tubes, they are lightweight and use splines to transmit dynamic force.

- High-intensity coil casing made of superior cast iron.

- The drum is the hoist's main component. It is linked to the traveling mechanism above via a balance beam, to the reducer and motor on both sides, and to the wire rope and hook below.

- Installed limited guide bar equipment in front of the outer cover.

Hook

- Forged from special steel, the thrust ball bearing is connected to the casing via the hook and beam, allowing the hook to move freely.

- No more than 5 tonfor a single pulley hook; no more than 10 tonfor a double pulley hook.

- High security, safety buckle, and a mouse hook

Travelling Mechanism

- Travelling mechanism of the electric wire rope hoist is consisted of electric trolley, traveling reducer, traveling motor, driven trolley, and so on.

- When used with a box type girder or a H beam, the wheel tread is straight.

- When used with an I-beam or monorail,the wheel tread has a circular arc.

- Its travel speed is 20m/min, but 30m/min is possible; if 1 ton -5 toncapacity with a lifting height of 12m or higher, a driven trolley is required.

Travelling Motor

- Use three-phase asynchronous braking motors with tapered rotors.

- Stable starting, safe braking, and reducer compatibility.

- The insulation grade is B or F, the structure is closed, and the motor protection grade is IP44 or IP54.

Electrical Device

- The control box has a logical layout that makes it easy to maintain.

- The control box has an IP55 protection grade and is water resistant.

- The primary power source is optional.

- Safe touch line has a high electrical conductivity and a low pressure.

- To ensure continuous power supply, the current collector has a high planing speed.

- Controlling box , switch button, stopper, and connecting wire were included.

- The switch button power voltage is 380v or 36v, standard product is designed with the powersupply of360v.

Safe and Standard Protecting Function:

- Novoltage protection,ground protection,short-circuit protection,thermal protection,over-loading protection,limit protection,overcurrent protection, and power-off protection are all available.

- Lifting limiter:broken fire limit device while traveling up and down.

- Overload protection: overload limiter, preinstall related parameters based on working conditions on site.

- Top-clashing proof device: heavy punch limiter, sensitive reaction, and compact size.

Motor

Special designed Squirrel-cage motor for the electric hoist.

Maintenance free. Insulation grade F. Protection class IP54.

Electromagnetic brake system

Electric trolley

Alloy gear and wheels, 125% testing load of the rated capacity.

Braking method please see the travelling motor details.

Hoist lifting reducer

Totally enclosed type with Splash Lubrication, gear box shell pressure casting

Winding drum

Self-produced. Drums made of high quality seamless steel processed by CNC machine.

Wire rope

Rope structure 6×37SW, fiber core

diameter 15 mm.

Hook

With safety latch

Rope guide

Installed on the winding drum to guide the wire rope, nodular cast iron

Lifting Limit switch

For lifting protection, prevent the hook from knocking the hoist

Overload limit

For lifting protection, monitor the hoist situation

Pendant control

Button: Up and down. Left and right; front and back; start and stop; emergency. Safe and reliable

High working efficiency

Working class of electric wire rope hoist

Working Class | M3(1BM) | M4(1AM) | M5(2m) |

Electrical connection sustained rate | 25%ED | 30%ED | 40%ED |

Hourly starts frequency | <150 | 180 | 240 |

Design life | <1600 hours | 3200 hours | 6300 hours |

Frequency of use | <Not often used | Often used in low and medium loads | Often used moderately |

CD1 type of electric wire rope hoist single speed

CD type electric wire rope hoists have a compact structure, stable operation, convenient operation, high part versatility, and high cost performance. It can be equipped with both manual and electric trolleys of vaiable speeds. The motorized travelling hoist can be installed on an electric overhead crane, a single beam manual overhead crane, a double girder overhead crane, a jib crane or cantilever crane, a gantry crane, and other supporting structures, as well as suspended on an I-beam, a straight line, or a curve. The fixed type electric wire rope hoist with suspension hook design can be mounted on a fixed support structure for vertical lifting.

Main parameters of the cd type electric wire rope hoist

Main parameters of single speed electric wire rope hoist

- Lifting Capacity: 0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, up to 32 ton

- Lifting Height: 6m to 50m

- Lifting Speed: 3.5/0.35m/min to 8/0.8m/min

- Working Class: M3, M4

- Ambient Temperature: -20℃ to 40℃

Click to check more specifications of CD1 types of electric wire rope hoist 0.25 ton -16 ton

CD1 | ||||||||||

Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

Hoisting speed | M/MIN | 8 | 8 | 8 | 7 | 3.5 | ||||

Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

Wirerope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

Hoisting motor | Type | Type | ZD112-4 | ZD1 21-4 | ZD1 22-4 | ZD1 31-4 | ZD1 32-4 | ZD1 41-4 | ZD1 51-4 | ZD1 51-4 |

Power | Power(kW) | 0.4 | 0.8 | 1.5 | 3.0 | 4.5 | 7.5 | 13 | 13 | |

Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

Current | (A) | 1.25 | 2.2 | 4.3 | 7.6 | 11 | 18 | 30 | 30 | |

Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

Power | AC 380V,50HZ,3P | |||||||||

CD1MD1 Double speed type of electric wire rope hoist

The MD type double speed electric wire rope hoist has the advantages of a small footprint, steady operation, ease of use, strong component versatility, and high cost performance.

Main parameters of double speed electric wire rope hoist

Main parameters of double speed electric wire rope hoist

- Lifting Capacity :0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, up to 32 ton

- Lifting Height :6m to 50m

- Lifting Speed :3.5/0.35m/min to 8/0.8m/min

- Working Class :M3, M4

- Ambient Temperature :-20℃ to 40℃

Click to check more detailed specifications of double speed electric wire rope hoist 0.25 ton -16 ton

Model | MD1 | |||||||||

Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

Hoisting speed | M/MIN | 0.8/8 | 0.8/8 | 0.8/8 | 0.7/7 | 0.35/3.5 | ||||

Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

Wirerope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

Hoisting motor | Type | Type | ZD112-4 | ZDS1 0.2/0.8 | ZDS1 0.2/1.5 | ZDS1 0.4/3.0 | ZDS1 0.4/4.5 | ZDS1 0.8/7.5 | ZDS1 1.5/13 | ZDS1 1.5/13 |

Power | Power(kW) | 0.4 | 0.2/0.8 | 0.2/1.5 | 0.4/3.0 | 0.4/4.5 | 0.8/7.5 | 1.5/13 | 1.5/13 | |

Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

Current | (A) | 1.25 | 0.72/2.4 | 0.72/4.3 | 1.25/7.6 | 2.4/11 | 2.4/18 | 5.2/30 | 5.2/30 | |

Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

Power | AC 380V,50HZ,3P | |||||||||

BCD type explosion-proof electric wire rope hoist

Eletric wire rope hoists with explosion proof, flame proof & spark resistant hoist designs to secure your electric hoist crane. The explosion roof electric wire rope hoists guard your safety in the hazardous applications, your safety hoists.

Explosion-proof electric wire rope hoists are a group of products designed and manufactured in accordance with the National Standard GB3836-2000 (Electrical Apparatus for Explosive Gas Atmospheres). Explosion-proof motors and electrical apparatuses, both self-made and factory-made, are designed, fabricated, checked, and accepted in accordance with National Standards GB3836.1-2000 (General Requirements of Electrical Apparatus for Explosive Gas Atmospheres) and GB3836.2-2000 (Electrical Apparatus for Explosive Gas Atmospheres Flame-proof Enclosure "d").

Main parameters of the bcd type electric wire rope hoist

Main parameters of the explosion proof electricc wire rope hoist

- Wire Rope Hoist Type :BCD wire rope hoists with features of explosion proof , spark resistance and flame proof

- Loading Capacity :500kg-50 ton

- Lifting Height :3 m to 100 m

- Working Class :M3, M4

Click to check more detailed specifications of explosion proof electric wire rope hoist 0.5 ton -16 ton

| Model | BCD | BMD | ||||||||||||||||||||||||||||||||

| lift capacity | Ton | 0.5 | 1 | 2 | 3 | 5 | 10-16 | |||||||||||||||||||||||||||

| lift height | M | 6 | 9 | 12 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 |

| lifting speed | m/min | 8(0.8) | 8(0.8) | 8(0.8) | 8(0.8) | 8(0.8) | 4(0.4) | |||||||||||||||||||||||||||

| travel speed | m/min | 20 | 20 | 20 | 20 | 20 | 20 | |||||||||||||||||||||||||||

| wire rope | diameter mm | 4.8 | 7.4 | 11 | 13 | 15.5 | 15.5-17.5 | |||||||||||||||||||||||||||

| line mm | 0.22 | 0.34 | 0.5 | 0.6 | 0.7 | 0.7 | ||||||||||||||||||||||||||||

| structure | D-6x37+1 | D-6x37+1 | D-6x37+1 | D-6x37+1 | D-6x37+1 | D-6x37+1 | ||||||||||||||||||||||||||||

| I beam rail (GB706-65) | 16-28b | 16-28b | 20a-30c | 20a-30c | 25a-63c | 25a-63c | ||||||||||||||||||||||||||||

| round rail Min.radius | M | 1.5 | 1.5 | 2 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2 | 2.5 | 3 | 4 | 2.5 | 2.5 | 4 | 5 | 2.5 | 3.5 | 4 | 6 | 7.5 | 9 | ||||||||||

| lifting motor | Model | BZD21-4 | BZD22-4 | BZD31-4 | BZD32-4 | BZD41-4 | BZD41-4 | |||||||||||||||||||||||||||

| capacity KW | 8 | 1.5 | 3 | 4.5 | 7.5 | 7.5 | ||||||||||||||||||||||||||||

| rotation r/min | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | ||||||||||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||||||||

| voltage V | 380 | 380 | 380 | 380 | 380 | 380 | ||||||||||||||||||||||||||||

| currency A | 2.4 | 4.3 | 7.6 | 11 | 18 | 30 | ||||||||||||||||||||||||||||

| frequency r/s | 50 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||||||||||

| traveling motor | Model | BZDY11-4 | BZDY11-4 | BZDY12-4 | BZDY12-4 | BZDY21-4 | BZDY21-4 | |||||||||||||||||||||||||||

| capacity KW | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | ||||||||||||||||||||||||||||

| rotation r/min | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | ||||||||||||||||||||||||||||

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | ||||||||||||||||||||||||||||

| voltage V | 380 | 380 | 380 | 380 | 380 | 380 | ||||||||||||||||||||||||||||

| currency A | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4x2 | ||||||||||||||||||||||||||||

| frequency r/s | 50 | 50 | 50 | 50 | 50 | 50 | ||||||||||||||||||||||||||||

| start times | t/week | 120 | 120 | 120 | 120 | 120 | 120 | |||||||||||||||||||||||||||

| work class | JC% | 25% | 25% | 25% | 25% | 25% | 25% | |||||||||||||||||||||||||||

| Dimension | H(mm) | ~630 | ~685 | ~780 | ~860 | ~960 | ~958 | ~1085 | ~1160 | ~1310 | ~1350 | |||||||||||||||||||||||

| L2(mm) | 126 | 159 | 187 | 230 | 274 | 303 | ||||||||||||||||||||||||||||

| L1(mm) | 276 | 315 | 341 | 372 | 425 | 458 | ||||||||||||||||||||||||||||

| L(mm) | 675 | 747 | 820 | 818 | 916 | 1014 | 1210 | 1406 | 1602 | 880 | 980 | 1018 | 1280 | 1480 | 1680 | 991 | 1094 | 1197 | 1403 | 1609 | 1815 | 1112 | 1217 | 1322 | 1532 | 1742 | 1952 | 1650 | 1834 | 2015 | 2377 | 2730 | 3101 | |

| m(mm) | 318 | 390 | 462 | 401 | 499 | 597 | 793 | 989 | 1185 | 412 | 512 | 612 | 812 | 1012 | 1212 | 457 | 561 | 658 | 869 | 1075 | 1281 | 488 | 615 | 704 | 895 | 1105 | 1315 | 967 | 1148 | 1329 | 1691 | 2053 | 2415 | |

| n (mm) | 190 | 196 | 240 | 264 | 264 | 375 | ||||||||||||||||||||||||||||

| h mm | 120 | 124 | 155 | 173 | 173 | 234 | ||||||||||||||||||||||||||||

| Φ mm | 14.5 | 19 | 23 | 25 | 25 | 37 | ||||||||||||||||||||||||||||

| B(mm) | ~950 | ~950 | ~1010 | ~1010 | ~1010 | ~1120 | ||||||||||||||||||||||||||||

| E(mm) | 490 | 584 | 740 | 848 | 848 | 1068 | ||||||||||||||||||||||||||||

| F(mm) | 355 | 354 | 400 | 438 | 438 | 612 | ||||||||||||||||||||||||||||

| Weight(kg) | Travel type | 215 | 218 | 223 | 247 | 256 | 264 | 282 | 300 | 318 | 325 | 344 | 363 | 401 | 439 | 471 | 411 | 431 | 471 | 511 | 551 | 591 | 617 | 640 | 688 | 733 | 778 | 823 | 1070 | 1190 | 1310 | 1501 | 1710 | 1910 |

| fixed type | 147 | 150 | 155 | 179 | 188 | 296 | 214 | 232 | 250 | 246 | 265 | 284 | 322 | 360 | 398 | 332 | 352 | 392 | 432 | 472 | 512 | 479 | 502 | 550 | 595 | 610 | 685 | 794 | 914 | 1034 | 1234 | 1434 | 1634 | |

YH type of metallurgical electric wire rope hoist

The YH type metallurgical electric wire rope hoist is designed for metallurgical casting, lifting high temperature molten liquid metal, and other heavy objects requiring a safety factor or an environmentally friendly environment. It has a compact structure, light weight, safety and reliability, a high degree of commonality, strong interchangeability, a high lifting capacity, and easy maintenance.

Single girder electric wire rope hoist system for hot metal & ladle handling in steel & metallurgic industries. 2 ton, 3 ton, 5 ton & 10 ton electric wire rope hoist for single girder ladle crane for sale.

Main parameters of the YH type electric wire rope hoist

Main parameters of metallurgic use electric wire rope hoist

- Hoist Type: YH metallurgic hot metal & ladle hoist

- Hoist Capacity : Up to 10 ton

- Lifting Height: 6~20m

- Working Class: A3

Click to check more detailed specifications of metallurgic use electric wire rope hoist 0.25 ton -16 ton

Single speed metallurgical electric wire rope hoist parameter

Model | YH | |||||||||

Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

Hoisting speed | M/MIN | 8 | 8 | 8 | 7 | 3.5 | ||||

Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

Wirerope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

Hoisting motor | Type | Type | ZD112-4 | ZD1 21-4 | ZD1 22-4 | ZD1 31-4 | ZD1 32-4 | ZD1 41-4 | ZD1 51-4 | ZD1 51-4 |

Power | Power(kW) | 0.4 | 0.8 | 1.5 | 3.0 | 4.5 | 7.5 | 13 | 13 | |

Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

Current | (A) | 1.25 | 2.2 | 4.3 | 7.6 | 11 | 18 | 30 | 30 | |

Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

Power | AC 380V,50HZ,3P | |||||||||

Double speed electric wire rope hoist parameter

Model | YH | |||||||||

Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

Hoisting speed | M/MIN | 0.8/8 | 0.8/8 | 0.8/8 | 0.7/7 | 0.35/3.5 | ||||

Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

Wirerope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

Hoisting motor | Type | Type | ZD112-4 | ZDS1 0.2/0.8 | ZDS1 0.2/1.5 | ZDS1 0.4/3.0 | ZDS1 0.4/4.5 | ZDS1 0.8/7.5 | ZDS1 1.5/13 | ZDS1 1.5/13 |

Power | Power(kW) | 0.4 | 0.2/0.8 | 0.2/1.5 | 0.4/3.0 | 0.4/4.5 | 0.8/7.5 | 1.5/13 | 1.5/13 | |

Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

Current | (A) | 1.25 | 0.72/2.4 | 0.72/4.3 | 1.25/7.6 | 2.4/11 | 2.4/18 | 5.2/30 | 5.2/30 | |

Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

Power | AC 380V,50HZ,3P | |||||||||

Low Headroom Electric Wire Rope Hoist

The CD / MD electric hoist is developpted into a low headroom electric wire rope hoist. Low headroom hoists have a compact structure, single or double speed lifting, a long effective lifting height, and a stable operation. It has a wide range of applications, particularly in new factory buildings. The low profile hoist design can be used to reduce the height of the building and thus lower the construction cost.

Electric wire rope hoist- low profile, low clearance, low headroom hoist design- for single girder crane, H beam & I beam, saving electric hoist crane costs.

- Hoist Type: Electric wire rope hoist with low headroom design

- Loading Capacity: 1ton to 32 ton

- Lifting Height: 6m-30m

- Working Class:M3-M4

Main specifications of low headroom electric wire rope hoist

1.CD1 type 0.5t-5t, lifting height 6m-9m electric hoist outline drawing

2.CD1 type 0.5t-5t, lifting height 12m-30m electric hoist outline drawing

3.CD1 type10t, lifting height 9m-30m electric hoist outline drawing

4.CD1 type 10t, lifting height 35m-100m electric hoist outline drawing

5. Lifting capacity 16t electric hoist outline drawing

6. Lifting capacity 50t electric hoist outline drawing

Custom design electric wire rope hoist for you

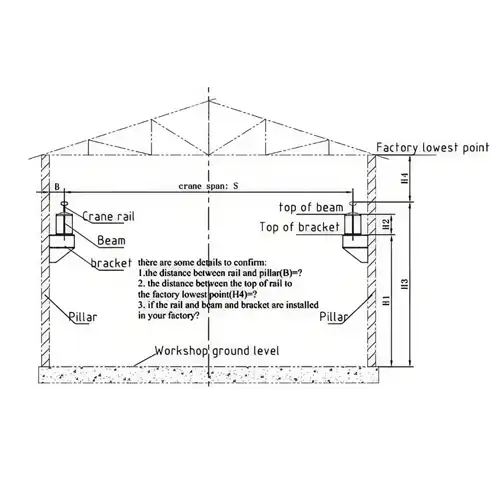

How to get your customized electric wire rope hoist? Usually, the standard wire rope electric hoist are mainly affected by the load weight, lifting height , and power supply, etc. Please help our electric wire rope hoist engineer confirm the following information as much as possible in order to provide you with a suitable electric wire rope hoist solution and specific hoist price as soon as possible:

- Types of hoist: ?

- Capacity:

- Height of Lift

- Power supply: (3phase? Voltage? Hz?)

- Quantity:

- Operation: Through Pendant/Radio Remote

- Indoor/Outdoor:

- Application (What are you planning to lift)

- Environment (Normal/ hazardous)

Electric Hoist and Crane Services

- Prompt delivery: General use electric hoist with capacity of 0.5 ton -32 ton with lifting height of 6m-12m , the delivery time is around 7 days,. General use electric hoist with capacity of 0.5 ton -32 ton with lifting height of 18m-40m, the delivery time is around 10 days; customized hoist with required gear, gear shaft parameter changes, and special motor outsourcing, the delivery time is 20 days;

- Lifetime service: providing lifelong after-sales support;

- Quality Commitment: One year warranty, excluding wearable parts;

- Customized hoist: We can design and manufacture customized products for various needs and fields based on the lifting materials and environmental conditions.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch