European Style Single Girder Top Running Crane Specs 1 to 20 Ton

European style single girder top running overhead crane 1 ton to 20 ton specifications for reference, get your tailored single girder crane design & specs.

Category: Hoist and Crane Specifications

Your Trusted Overhead Crane Manufacturer & Supplier

European Style Single Girder Top Running Cranes 1 Ton to 20 Ton

HD Low Headroom Hoist Crane Features and Specifications, Affordable Avanced Single Girder Crane for You

HD types single girder top running cranes are essential pieces of equipment in many modern industrial settings. These cranes are designed to efficiently lift and move heavy loads within a workspace, maximizing the use of vertical space. They feature a single girder construction that supports the crane's hoist mechanism, allowing for greater maneuverability and versatility compared to traditional multi-girder designs.

The significance of these cranes in contemporary industries cannot be overstated. As businesses strive to enhance productivity and streamline operations, the demand for effective material handling solutions continues to grow. Single girder top running cranes play a crucial role in this landscape, offering reliable lifting capabilities for various applications, from manufacturing to logistics.

European design principles greatly influence the development of HD types single girder top running cranes. These principles emphasize efficiency, safety, and user-friendliness. European manufacturers focus on creating cranes that not only meet strict safety standards but also optimize energy consumption and reduce operational costs. Key features, such as low headroom designs and advanced safety systems, are integrated into these cranes, ensuring they can operate safely in tight spaces and under challenging conditions. By prioritizing these elements, European-style single girder cranes provide businesses with the tools they need to enhance productivity while ensuring the safety of their workforce.

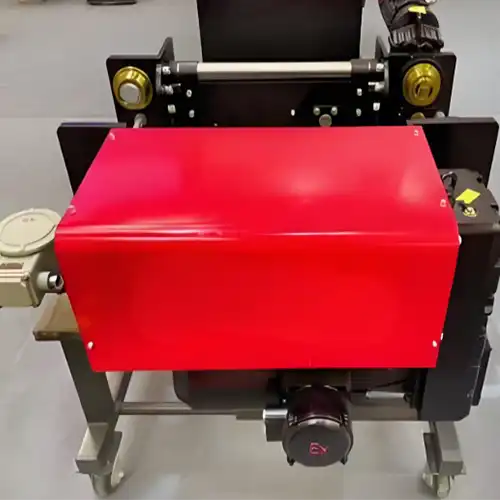

European Style Single Girder Top Running Cranes 1 Ton to 20 Ton, customzied 10 ton overhead crane single girder for your reference

Key Features of Top Running Cranes

Top running cranes, characterized by their rail-mounted design on the top of the supporting structure, offer several advantages that make them a preferred choice in various industrial applications. One of the primary benefits of top running cranes is their ability to efficiently utilize vertical space. By operating from the top of the support beams, these cranes can achieve greater lifting heights, allowing for more effective use of the available workspace. This is particularly advantageous in facilities with high ceilings or where maximizing vertical storage is essential.

Another notable feature of top running cranes is their enhanced stability and load handling capabilities. Due to their design, they provide superior balance, making them ideal for lifting heavy and oversized loads. This stability reduces the risk of tipping or swaying during operation, ensuring safer handling of materials. In contrast, under running cranes, which are mounted on the bottom of the runway beams, may have limitations in load capacity and stability, particularly when lifting heavier items or operating at greater heights.

When comparing top running cranes to under running cranes, one can observe key differences in their operational mechanisms. Top running cranes typically utilize a double girder system, which offers increased strength and durability. This design allows them to handle heavier loads and operate more efficiently in demanding environments. Conversely, under running cranes often employ a single girder design, making them suitable for lighter loads and applications where space constraints are a concern.

The suitability of each crane type is largely dependent on the specific operational environment and lifting requirements. Top running cranes excel in industrial settings with high load demands and ample vertical space, such as manufacturing facilities, warehouses, and shipping yards. They are particularly effective in environments requiring frequent lifting and moving of materials. In contrast, under running cranes are often preferred in smaller workshops or spaces where lower lifting capacities are needed, and overhead space is limited.

Overall, top running cranes offer numerous advantages in terms of stability, load capacity, and operational efficiency, making them an invaluable asset in a wide range of industrial applications. Their design not only meets the rigorous demands of modern material handling but also ensures safety and reliability for operators and equipment alike.

Overview of European Style HD Single Girder Top Running Overhead Crane

European Style HD Single Girder Top Running Overhead Cranes are engineered for high performance and efficiency in various industrial applications. These cranes feature a single girder design, which significantly reduces the overall weight compared to traditional double girder models, allowing for easier handling and installation.

Design and Construction

The design of these cranes adheres to rigorous European standards, ensuring exceptional quality and safety. They are constructed from high-strength steel, such as Q235B or Q345B, which provides durability while minimizing weight. This results in a compact structure that maximizes lifting capacity and minimizes headroom requirements, making them ideal for facilities with height limitations.

Key Features

- Load Capacity: European Style HD Single Girder Cranes typically have load capacities ranging from 1 ton to 20 tons, catering to a wide array of lifting needs across various sectors, including manufacturing, logistics, and construction.

- Span Range: These cranes can accommodate span lengths from 3 to 31 meters, providing flexibility to adapt to different industrial setups and workflows.

- Lifting Height Options: Available lifting heights usually range from 6 to 18 meters, ensuring that operations can be tailored to specific site requirements.

- Low Headroom Design: The low headroom feature is particularly beneficial in maximizing vertical space, allowing for higher lifts without compromising safety or stability.

- Advanced Safety Features: Equipped with safety systems like overload protection and emergency stop mechanisms, these cranes prioritize operator safety while enhancing operational reliability.

- Energy Efficiency: Many models incorporate variable frequency drives and other energy-efficient technologies that reduce power consumption and lower operational costs.

Applications

European Style HD Single Girder Top Running Cranes are widely used in diverse industries, including:

- Manufacturing: For material handling and assembly line operations.

- Automotive: In assembly plants for the efficient movement of components.

- Aerospace: For precise lifting and positioning of heavy aircraft parts.

- Logistics: In warehouses for loading and unloading goods.

The European Style HD Single Girder Top Running Overhead Crane stands out for its combination of advanced engineering, robust construction, and focus on safety. Its versatility, efficiency, and adaptability to various industrial environments make it an essential piece of equipment for modern material handling operations. With a focus on innovative design and technology, these cranes not only improve productivity but also enhance the overall safety of the workplace

European Style HD Single Girder Top Running Crane Specifications

General Specifications

European style HD single girder top running cranes are designed with precision engineering and adhere to the highest safety and performance standards. These cranes comply with FEM (Fédération Européenne de la Manutention) and DIN (Deutsches Institut für Normung) standards, which ensure that they meet rigorous requirements for performance, reliability, and safety in various industrial environments. This compliance guarantees that the cranes are suitable for heavy-duty operations while minimizing maintenance needs.

Dimensions and Design Standards The design of these cranes promotes compact construction, enabling them to fit seamlessly into various facility layouts. Their dimensions are optimized for efficient operation in spaces where headroom is limited, allowing for maximum lifting height and operational efficiency. The compact design not only maximizes usable space but also reduces the overall footprint of the crane, making it ideal for facilities with limited space.

Materials Used in Construction European style HD single girder top running cranes are constructed using high-quality materials that contribute to their durability and strength. The primary material used is high-strength steel, such as Q235B and Q345B, which offers a favorable balance of strength and weight. This choice of material allows for reduced weight without compromising the crane's load-carrying capacity, leading to improved performance and lower operational costs. Additionally, the use of high-strength steel enhances the crane's resistance to wear and tear, ensuring longevity even in demanding environments.

These specifications make European style HD single girder top running cranes a reliable choice for industries requiring robust and efficient material handling solutions. Their adherence to strict standards, combined with thoughtful design and high-quality materials, ensures optimal performance in various applications, ranging from manufacturing to logistics.

Top Running Overhead Single Girder Crane Specifications

The specifications of European style HD single girder top running cranes are designed to cater to a broad spectrum of industrial applications, ensuring that they meet the diverse needs of different sectors.

Lifting Capacity (t) |

Span (m) |

Lifting Height(m) |

Working Duty | Lifting Speed (m/ min) | Weight | Crane Track |

Total Power (KW) | Maximum Wheel Pressure (KN) | Basic Dimensions (mm) | |||||||

Hoist (kg) | Crane (kg) |

H | h |

C1 |

C2 | b |

W |

B | ||||||||

1 | 7.5 |

6 |

A5 |

4/1 |

380 | 1180 |

P24 |

2 | 8.7 | 618 |

354 |

665 |

940 |

100 | 1600 | 1972 |

10.5 | 1900 | 9.5 | ||||||||||||||

13.5 | 2250 | 10.4 | 698 | 2000 | 2372 | |||||||||||

16.5 | 2674 | 11.5 | 768 | |||||||||||||

19.5 | 3269 | 13 | 798 | 2500 | 2872 | |||||||||||

22.5 | 3900 | 14.5 | 858 | |||||||||||||

2 | 7.5 |

6 |

A5 |

4/1 |

380 | 1680 |

P24 |

3 | 13.5 | 708 |

356 |

665 |

940 |

100 | 1600 | 1972 |

10.5 | 2060 | 14.4 | ||||||||||||||

13.5 | 2430 | 15.5 | 778 | 2000 | 2372 | |||||||||||

16.5 | 3164 | 17.4 | 818 | |||||||||||||

19.5 | 3753 | 18.9 | 888 | 2500 | 2872 | |||||||||||

22.5 | 4320 | 20.3 | 968 | |||||||||||||

3.2 | 7.5 |

6 |

A5 |

4/1 |

380 | 1840 |

P24 |

5 | 18.9 | 758 |

356 |

665 |

940 |

100 | 1600 | 1972 |

10.5 | 2070 | 20.1 | ||||||||||||||

13.5 | 2667 | 21.8 | 808 | 2000 | 2372 | |||||||||||

16.5 | 3324 | 23.5 | 908 | |||||||||||||

19.5 | 4100 | 25.4 | 948 | 2500 | 2872 | |||||||||||

22.5 | 4725 | 27 | 1028 | |||||||||||||

5 | 7.5 |

6 |

A5 |

4/1 |

450 | 2200 |

P24 |

6.3 | 28.2 | 788 |

410 |

665 |

940 |

100 | 1600 | 2012 |

10.5 | 2521 | 29.7 | ||||||||||||||

13.5 | 3200 | 31.8 | 908 | 2000 | 2412 | |||||||||||

16.5 | 3928 | 33.8 | 978 | |||||||||||||

19.5 | 4598 | 35.6 | 1138 | 2500 | 2912 | |||||||||||

22.5 | 6230 | 39.7 | 1258 | |||||||||||||

10 | 7.5 |

6 |

A5 |

4/1 |

600 | 2660 |

P30 |

11.5 | 51.8 | 908 |

465 |

675 |

1020 |

100 | 1600 | 2080 |

10.5 | 3160 | 54.4 | ||||||||||||||

13.5 | 4040 | 57.7 | 1008 | 2000 | 2480 | |||||||||||

16.5 | 5257 | 60.8 | 1208 | |||||||||||||

19.5 | 6410 | 64 | 1308 | 2500 | 2980 | |||||||||||

22.5 | 7640 | 67.2 | 1358 | |||||||||||||

16 | 7.5 |

6 |

A5 |

4/1 |

1500 | 4484 |

P38 |

20.9 | 51.8 | 1000 |

820 |

1025 |

1630 |

175 | 1600 | 2080 |

10.5 | 5184 | 54.4 | ||||||||||||||

13.5 | 6634 | 57.7 | 1220 | 2000 | 2480 | |||||||||||

16.5 | 7789 | 60.8 | 1330 | |||||||||||||

19.5 | 9179 | 64 | 1480 | 2500 | 2980 | |||||||||||

22.5 | 10514 | 67.2 | 1630 | |||||||||||||

20 | 7.5 |

6 |

A5 |

4/1 |

1500 | 4484 |

P38 |

20.9 | 51.8 | 1000 |

820 |

1025 |

1630 |

175 | 1600 | 2080 |

10.5 | 5434 | 54.4 | ||||||||||||||

13.5 | 6754 | 57.7 | 1250 | 2000 | 2480 | |||||||||||

16.5 | 7904 | 60.8 | 1400 | |||||||||||||

19.5 | 9399 | 64 | 1580 | 2500 | 2980 | |||||||||||

22.5 | 10719 | 67.2 | 1710 | |||||||||||||

Load Capacities These cranes offer a wide range of load capacities, typically spanning from 1 to 20 tons. This flexibility enables operators to select the right crane for their specific lifting requirements. The cranes are available in specific configurations for varying capacities, including common options like 1 ton, 2 tons, 3.2 tons, 5 tons, 10 tons, 16 tons, and 20 tons. This variety allows industries to match their operational needs precisely, ensuring optimal performance during lifting tasks.

Span Range The span range of these cranes extends from 3 to 31 meters, allowing them to adapt to various industrial setups and workspace configurations. This versatility makes them suitable for both small workshops and larger manufacturing facilities, where different spans can optimize the lifting operations and material handling processes.

Lifting Heights Operators can choose from a range of lifting heights, typically available at 6, 9, 12, 15, and 18 meters. This adaptability ensures that the crane can maximize effective lift based on the operational needs of specific applications, whether lifting loads to high storage areas or facilitating low-level handling tasks.

Voltage and Environmental Conditions European style HD single girder top running cranes are designed to accommodate diverse operational environments, with a wide voltage range of 220-660V at 50/60Hz. This versatility enables seamless integration into various power systems, making them suitable for different geographical regions and industrial setups.

Additionally, these cranes can operate effectively within a temperature range of -20°C to +40°C, ensuring reliability and performance in both cold and warm environments. This adaptability is crucial for industries that may face fluctuating environmental conditions, as it guarantees that the crane maintains its operational integrity regardless of external temperatures.

In summary, the specifications of European style HD single girder top running cranes provide the necessary flexibility and robustness to meet the demands of various industrial applications, ensuring that they are a valuable asset in enhancing productivity and efficiency in material handling processes.

Single Girder Top Running Overhead Crane for Sale 1 Ton - 20 Ton, European style Low Headroom Crane

Features Enhancing Performance and Safety

Low Headroom Design The single girder Electric Overhead Traveling (EOT) crane boasts a low headroom design, which is a key advantage for facilities with restricted vertical space. This innovative feature allows for higher lifting capabilities while effectively maximizing the use of vertical clearance. As a result, operators can raise loads to greater heights without compromising space, leading to improved workflow and efficient material movement within the workspace.

Advanced Safety Systems In industrial settings, safety is of utmost importance, and single girder EOT cranes are equipped with several advanced safety systems to safeguard both operators and loads. Notable safety features include:

- Overload Protection: This critical system ensures the crane does not lift loads that exceed its rated capacity. By maintaining load limits, the risk of accidents and equipment failure is significantly reduced. Operators can perform their tasks with confidence, knowing that safety measures are in place.

- Emergency Stop Mechanisms: Designed for rapid response in unforeseen situations, the emergency stop feature allows operators to instantly halt crane operations. This capability is essential for preventing accidents and ensures a quick reaction during emergencies, thereby fostering a safer work environment.

Enhanced Performance The design elements of single girder EOT cranes also enhance their overall performance. With an emphasis on efficient material handling, these cranes are engineered for smooth operation, rapid lifting speeds, and precise load control. This enables operators to maneuver loads effortlessly throughout the workspace. The cranes' robust construction guarantees durability and reliability, making them an invaluable investment for industries that demand consistent and high-performance operation.

In conclusion, the single girder EOT crane merges advanced design with essential safety features, offering a comprehensive solution for modern industrial material handling. Its low headroom design, coupled with superior safety systems, ensures it meets the diverse operational requirements of various applications while prioritizing the safety of both personnel and equipment.

Low Headroom Hoists for Cranes

Importance of Low Headroom Hoists in Optimizing Lifting Height Low headroom hoists play a critical role in maximizing lifting capabilities in environments where vertical space is limited. By integrating these hoists into crane systems, operators can significantly increase the effective lifting height without compromising safety or stability. This optimization is particularly advantageous in facilities with low ceilings, allowing for more efficient use of space and enhanced workflow.

Design Benefits The design of low headroom hoists features compact dimensions that minimize the overall height of the crane system. This reduction in height not only frees up vertical space but also enables better clearance for overhead obstacles. The streamlined design of low headroom hoists contributes to a more efficient lifting mechanism, ensuring that loads can be raised and lowered with minimal interference in the working environment.

Specifics on Low Headroom Hoist Options Low headroom hoists offer several advantageous features and specifications:

- Capacities Available These hoists are typically compatible with cranes ranging from 1 ton to 20 tons, making them versatile for various lifting applications. The wide range of capacities ensures that industries can select the appropriate hoist for their specific load requirements, whether it's for light-duty tasks or heavier material handling.

- Energy Efficiency Many low headroom hoists are equipped with variable frequency drives (VFDs) that allow for adjustable speed control and energy efficiency. VFDs enable smooth acceleration and deceleration during lifting operations, reducing energy consumption and minimizing wear and tear on the equipment. This feature not only contributes to lower operational costs but also promotes sustainable practices within the facility.

- Noise Reduction Technologies Low headroom hoists often incorporate noise reduction technologies, such as vibration dampening materials and optimized gear systems, to minimize operational noise. This consideration is essential in environments where noise levels can impact employee comfort and productivity. By employing quieter hoists, companies can create a more conducive working atmosphere.

- Maintenance-Free Components Many low headroom hoists are designed with maintenance-free components, such as sealed bearings and self-lubricating materials. This reduces the need for regular maintenance checks and servicing, allowing operators to focus on their core tasks without frequent interruptions. By minimizing maintenance requirements, businesses can enhance productivity and reduce downtime.

In summary, low headroom hoists are an essential component of modern crane systems, providing significant advantages in optimizing lifting height while maintaining safety and efficiency. Their compact design, compatibility with various crane capacities, energy-efficient features, noise reduction technologies, and maintenance-free components make them a valuable investment for industries seeking to improve their material handling capabilities.

Applications of HD Single Girder Cranes

Common Industries Utilizing Top Running Single Girder Cranes HD single girder top running cranes are highly versatile and are employed across various industries, showcasing their adaptability and efficiency. The following sectors frequently utilize these cranes to enhance operational productivity:

- Manufacturing In manufacturing environments, these cranes facilitate the movement of heavy components and materials along production lines. They are integral to processes such as assembly, welding, and quality control, ensuring smooth workflows and reduced manual handling.

- Automotive The automotive industry relies heavily on single girder cranes for assembling vehicles and transporting parts. Their ability to handle components of varying weights, from engines to chassis, makes them indispensable on assembly lines where precision and speed are crucial.

- Aerospace In aerospace applications, top running cranes are used for handling delicate and heavy aircraft components. They provide the necessary lifting capacity and stability required for assembling complex systems, ensuring safety and precision during the manufacturing process.

- Logistics Logistics and warehousing operations benefit significantly from HD single girder cranes. These cranes streamline material handling, allowing for efficient loading and unloading of goods. Their flexibility enables operators to adapt to various load types and warehouse configurations, enhancing overall operational efficiency.

Specific Tasks and Load Handling HD single girder cranes excel in a variety of tasks and load handling applications, which include:

- Material Handling These cranes are ideal for lifting and transporting raw materials, finished products, and components within industrial facilities. Their design allows for smooth and safe movements, minimizing the risk of damage to loads.

- Assembly Lines In assembly line setups, single girder cranes contribute to the swift and efficient assembly of products. They can be positioned strategically to deliver components directly to assembly stations, reducing transit times and improving productivity.

- Warehouse Operations In warehouse settings, HD single girder cranes facilitate the storage and retrieval of heavy items, making inventory management more efficient. They can be utilized for stacking and organizing goods, enhancing space utilization within the warehouse.

In conclusion, HD single girder top running cranes are invaluable across a multitude of industries. Their capabilities in material handling, assembly, and logistics make them essential for maintaining high efficiency and productivity in various operational environments. The diverse applications of these cranes demonstrate their significance in modern industrial settings, highlighting their role in enhancing workflow and operational effectiveness.

Capacity of Top Running Single Girder Overhead Crane European style

Demand for 5 Ton and 10 Ton Cranes in Small to Medium-Sized Operations

Among these popular capacities, 5 Ton and 10 Ton cranes are particularly favored in small to medium-sized operations. These cranes strike a balance between sufficient lifting power and maneuverability, making them ideal for tasks such as:

- Material Handling: Efficiently transporting moderate-weight loads within manufacturing and warehouse environments.

- Assembly Line Operations: Facilitating the assembly of components without occupying excessive floor space.

The flexibility and efficiency offered by these capacities make them highly sought after in industries where space and weight considerations are critical.

20 Ton Capacity Cranes for Heavy-Duty Industrial Applications

For heavy-duty industrial applications, 20 ton capacity cranes are increasingly popular. These cranes are designed to handle substantial loads, making them suitable for sectors such as:

- Aerospace Manufacturing: Lifting and positioning large aircraft components safely and precisely.

- Heavy Equipment Assembly: Managing the assembly and maintenance of large machinery and equipment.

The robustness and reliability of 20 ton cranes enable industries to streamline their operations while ensuring safety and efficiency.

Market Demand and Trends for Specific Capacities

The market for HD single girder top running cranes is evolving, with increasing preferences for specific capacities based on operational needs. Notable trends include:

- Customized Solutions: Businesses are increasingly seeking tailored solutions to meet their unique lifting requirements. This trend is particularly evident in industries with specialized tasks or unique operational environments, leading to a demand for cranes that can be customized in terms of load capacity, span, and other specifications.

- Sustainability Considerations: As industries focus on sustainable practices, there is a growing demand for cranes equipped with energy-efficient features, such as variable frequency drives and lightweight materials, to minimize energy consumption during operations.

- Technological Integration: The integration of smart technologies, such as load monitoring systems and automated controls, is becoming a key consideration in the selection of crane capacities. This enhances safety, reduces operational risks, and improves overall efficiency.

In summary, the hot sale capacities of HD single girder top running cranes reflect the diverse demands of modern industries. With a focus on practical lifting solutions, customized designs, and technological advancements, these cranes play a pivotal role in enhancing operational efficiency across various sectors.

Hot Sale Capacities

HD single girder top running cranes are available in a variety of lifting capacities, each designed to meet specific industrial needs. The most common capacities and their typical applications are as follows:

- 1 Ton: Ideal for light material handling tasks, these cranes are often used in workshops, small manufacturing facilities, and assembly lines. They can easily handle items like small machinery, tools, and components.

- 2 Tons: This capacity is commonly found in automotive repair shops and light manufacturing applications. These cranes can efficiently lift items such as engine components, transmissions, and other moderate-weight materials.

- 3.2 Tons: Suitable for small to medium-sized assembly operations, 3.2-ton cranes are often used to move components in production lines, handling items like metal frames, subassemblies, and other moderately heavy loads.

- 5 Tons: The 5-ton crane is widely used in various industrial sectors, including logistics, warehousing, and construction. It can lift heavier loads like machinery, pallets of materials, and large components for assembly.

- 10 Tons: Common in manufacturing plants and large warehouses, 10-ton cranes handle heavier materials, such as large equipment, machinery parts, and bulk materials. They are particularly valuable in industries like automotive and aerospace for lifting substantial loads efficiently.

- 16 Tons: These cranes are utilized in heavy-duty applications, including steel production, large-scale manufacturing, and heavy equipment maintenance. They can handle substantial loads, such as steel beams, heavy machinery, and large containers.

- 20 Tons: The 20-ton crane is designed for the most demanding industrial applications. Commonly used in construction, shipbuilding, and heavy manufacturing, these cranes are capable of lifting extremely heavy loads, such as large machinery, steel structures, and bulk materials.

These capacities illustrate the versatility of single girder cranes, allowing them to accommodate diverse lifting requirements across various sectors. The ability to select a crane based on specific lifting needs ensures efficient operations, making HD single girder top running cranes a popular choice in today's industrial landscape.

Optional Features

Advanced Technology Options for Enhanced Crane Functionality HD types single girder top running cranes come with a variety of optional features designed to enhance their functionality and overall performance. These features cater to modern operational demands, ensuring safety and efficiency in various industrial settings. Key advancements include:

- Remote Control Operation: This feature allows operators to control the crane from a safe distance, significantly improving workplace safety. By minimizing the need for personnel to be near the load, the risk of accidents and injuries is greatly reduced. Additionally, remote control systems can improve efficiency by allowing operators to manage multiple cranes or tasks simultaneously.

- Integration of Smart Sensors: Smart sensors can be incorporated into the crane system to monitor load conditions in real time. These sensors provide valuable data on load weight, distribution, and operational status, allowing for precise adjustments and optimal performance. Furthermore, maintenance alerts can be generated based on sensor readings, helping to prevent equipment failure and reduce downtime through proactive maintenance scheduling.

- Customizable Design Features: The ability to customize various aspects of the crane, such as lifting height, span length, and auxiliary equipment, allows businesses to tailor their crane systems to their specific operational requirements. This flexibility ensures that the cranes can efficiently handle the unique demands of different applications, optimizing workflow and productivity.

Conclusion

In summary, HD types single girder top running cranes offer numerous benefits that make them an invaluable asset in modern industrial operations. Their cost-effective and space-saving design promotes efficient workflow, allowing businesses to maximize productivity without compromising safety.

As industries continue to evolve, future trends in crane technology will likely focus on automation and AI integration. These innovations will further enhance performance and safety, enabling cranes to operate with greater precision and efficiency. With advancements such as predictive maintenance, automated load handling, and smart control systems, the capabilities of single girder cranes will expand, ensuring they remain essential tools in various industrial applications. Overall, investing in HD single girder top running cranes equips businesses with the tools needed to thrive in an increasingly competitive landscape.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch