1 Ton Wall Mounted Jib Crane with I Beam Cantilever Design for Sale

1 ton wall-mounted jib crane with I-beam cantilever design, offering flexible lifting & space-saving for industrial use. Get 1 ton jib crane price!

Category: Wall Crane

Your Trusted Wall Mounted Jib Crane Manufacturer & Supplier

1 Ton Wall Mounted Jib Crane with I Beam Cantilever Design for Sale

Your Handy,Small & Most Economical 1Ton Wall Jib Crane

Efficient 1 ton wall-mounted jib crane with I-beam cantilever design, offering flexible lifting and space-saving for various industries.

Overview of the 1 Ton Wall Mounted Jib Crane

The 1 ton wall-mounted jib crane is a practical and efficient lifting solution designed to meet the demands of various industrial environments. This crane offers a compact and space-saving design, making it ideal for use in workshops, warehouses, and production areas with limited floor space. With its 1 ton lifting capacity, it is well-suited for handling a range of light to medium-duty tasks, including lifting small components, materials, and finished products. Its wall-mounted configuration helps to optimize floor space, allowing for more efficient use of the work area while maintaining a high level of lifting performance.

Importance of the I Beam Cantilever Design

The I Beam cantilever design is a key feature of the 1 ton wall-mounted jib crane, contributing significantly to its overall effectiveness. This design enhances the crane's performance by offering improved load distribution and stability. The I Beam structure provides a robust and durable support for the crane, allowing it to handle loads more effectively and with greater precision. This design also extends the crane's reach, enabling it to cover a larger working area while maintaining stability. The cantilever design ensures that the crane remains steady even under the strain of heavy or off-center loads, reducing the risk of tipping and enhancing operational safety.

Target Audience

The 1 ton wall-mounted jib crane is an excellent choice for a range of industries that require efficient and reliable lifting solutions. It is particularly beneficial for:

- Manufacturing: In manufacturing facilities, the crane supports assembly lines and material handling, streamlining production processes.

- Automotive: Automotive shops and assembly plants use the crane to lift and position engine components, small parts, and tools.

- Warehousing: Warehouses benefit from the crane's space-saving design, which facilitates the movement of goods and materials in confined storage areas.

By offering a versatile and space-efficient lifting solution, the 1 ton wall-mounted jib crane meets the needs of these industries effectively.

Basics of 1 Ton Wall Moutned Jib Crane with I Beam Cantilever Design

A wall-mounted cantilever crane is a specialized lifting device fixed to a wall or building structure, designed to maximize space efficiency in industrial settings. The crane features a cantilever arm that extends out from the wall, supported by a robust I Beam structure. This cantilever design allows the crane to handle loads in areas where traditional overhead cranes might be impractical due to space constraints.

Technical Parameters of BX Wall-Mounted Jib Crane with I-Beam Cantilever Design:

- Capacity: 1 ton

- Valid Radius (R): 3 to 8 meters

- Lifting Height: 6 to 30 meters

- Lifting Speed: 8 m/min (0.8/8 m/min)

- Trolley Speed: 10 m/min (20 m/min)

- Slewing Speed: 0.5 to 1 r/min

- Slewing Angle: 0° to 180°

- Work Duty: A3 to A4

Operational Mechanics:

- Mounting and Stability: The crane is anchored to a wall or support structure, providing a stable base for lifting operations. The cantilever arm extends outward, allowing the crane to reach into the workspace without occupying floor space.

- Flexibility: The design allows for a range of lifting operations, from moving small components to positioning larger materials within the crane's reach. The cantilever arm can rotate to cover a wide area, enhancing the crane's versatility.

- Efficiency: By utilizing the wall as a support, the crane eliminates the need for floor-mounted columns, making it an ideal choice for areas with limited space. This setup not only improves workspace utilization but also allows for smooth and efficient material handling.

Key Specifications of the BX Wall Mounted Jib Crane

- Capacity: With a lifting capacity of 1 ton, the BX wall-mounted jib crane is suitable for a variety of light to medium-duty tasks, including handling smaller components and materials in industrial environments.

- Valid Radius (R): The crane offers a valid radius range of 3 to 8 meters. This flexibility allows it to reach different areas within a workshop or production line, accommodating various operational needs.

- Lifting Height: The lifting height ranges from 6 to 30 meters, making the crane adaptable to different ceiling heights and lifting requirements. This range ensures that the crane can be used effectively in both high and low-clearance areas.

- Lifting Speed: The standard lifting speed is 8 meters per minute, with an adjustable option of 0.8/8 meters per minute for precision tasks. This feature enables the crane to handle materials at varying speeds, depending on the complexity of the operation.

- Trolley Speed: The crane's trolley speed is 10 meters per minute, with an optional increase to 20 meters per minute. This ensures efficient material handling and quick movement across the crane's range.

- Slewing Speed: The slewing speed ranges from 0.5 to 1 revolution per minute. This controlled rotation allows for smooth and precise positioning of loads.

- Slewing Angle: The crane provides a slewing angle of 0° to 180°, offering comprehensive coverage within the designated radius. This wide range of motion enhances the crane's ability to handle various lifting tasks.

- Work Duty: Rated A3 to A4, the crane is designed for regular to moderately intensive usage. This rating indicates its suitability for frequent lifting operations in industrial settings.

Key Features of the 1 Ton Wall Mounted Jib Crane

Sturdy I Beam Cantilever Design

The I Beam cantilever design is a core feature of the 1 ton wall-mounted jib crane, providing numerous benefits that enhance its performance and durability.

Benefits of the I Beam Structure:

- Enhanced Load Distribution: The I Beam's robust design allows for even distribution of loads along the length of the arm. This structural integrity minimizes stress on the mounting points and ensures that heavy loads are managed safely and effectively.

- Increased Stability: The cantilever design, supported by the I Beam, offers superior stability compared to other crane types. The beam's strength and rigidity reduce the risk of tipping or swaying, which is crucial for maintaining control during lifting operations.

- Durability and Longevity: The I Beam's construction is designed to withstand continuous use and heavy loads without compromising its structural integrity. This results in a longer service life for the crane, reducing maintenance needs and ensuring consistent performance.

The I Beam cantilever design is particularly advantageous in wall-mounted applications, where stability and load handling efficiency are paramount. Its strength and stability make it ideal for various industrial tasks, ensuring that the crane remains a reliable asset in any operation.

Space Optimization and Efficiency

The wall-mounted design of the 1 ton jib crane is specifically engineered to maximize workspace efficiency, making it an excellent choice for environments where floor space is at a premium.

Advantages of the Wall-Mounted Design:

- Elimination of Floor Space Needs: By mounting the crane on the wall, there is no need for floor-mounted supports or columns. This design choice frees up valuable floor space, allowing for more flexible use of the work area.

- Improved Workspace Utilization: The crane's ability to operate without floor obstructions helps maintain a clear and organized workspace. This is especially beneficial in tight workshops or production areas where space is limited.

- Enhanced Material Handling: With the crane extending out from the wall, it can reach across various parts of the workspace without the need to maneuver around floor-mounted equipment. This enhances the efficiency of material handling tasks and reduces time spent maneuvering loads.

Overall, the wall-mounted design not only optimizes space but also contributes to a more streamlined and productive work environment. By removing floor clutter and maximizing reach, the crane helps maintain an organized and efficient workspace.

Advantages of the 1 Ton Wall Mounted Cantilever Crane

Versatility in Load Handling

The 1 ton wall-mounted cantilever crane is highly versatile, making it an invaluable tool across various industries.

Industry Applications:

- Manufacturing: Ideal for handling small to medium-sized components and tooling with precision. Its adaptability makes it suitable for assembly lines and machine shops where space is limited.

- Automotive: Perfect for lifting lighter vehicle parts, such as smaller transmissions or engine components. Its flexibility helps streamline maintenance and assembly operations in automotive workshops.

- Warehousing: Efficient in moving and positioning palletized goods and other materials within a warehouse setting. Its ability to handle different loads with ease enhances overall productivity.

Precision and Adaptability:

- Adjustable Lifting Speeds: The crane offers adjustable lifting speeds (8 m/min with an option of 0.8/8 m/min), allowing for precise control during operations. This feature is particularly useful for delicate or intricate tasks.

- Versatile Slewing Angle: With a slewing angle ranging from 0° to 180°, the crane provides extensive coverage, enabling it to handle loads across a wide area without needing to reposition frequently.

This versatility ensures that the crane can adapt to a range of tasks and environments, offering reliable performance and enhancing operational efficiency.

Ease of Installation and Maintenance

The 1 ton wall-mounted cantilever crane is designed with simplicity in mind, making both installation and maintenance straightforward and cost-effective.

Installation:

- Simplified Process: The crane is mounted directly on existing walls, eliminating the need for additional support structures. This not only reduces installation time but also minimizes associated costs.

- Minimal Downtime: The straightforward installation process helps reduce downtime, allowing for quick integration into existing operations and reducing disruptions to workflow.

Maintenance:

- Low Maintenance Requirements: The robust design of the crane ensures that it requires minimal maintenance. Its durable construction and high-quality materials contribute to long-term reliability.

- Cost Savings: The reduced need for frequent repairs and maintenance translates to lower operational costs and increased uptime, making the crane a valuable investment.

Overall, the ease of installation and low maintenance requirements enhance the crane's cost-effectiveness and operational efficiency.

Cost Efficiency

The 1 ton wall-mounted cantilever crane offers significant cost benefits, making it an attractive option for businesses.

Competitive Pricing:

- Affordable Investment: The crane is competitively priced, providing a cost-effective solution for businesses that need reliable lifting equipment without a substantial financial outlay.

Long-Term Savings:

- Durability and Efficiency: The crane's durability and efficiency translate into long-term savings. With minimal maintenance needs and a long service life, the crane proves to be a cost-effective choice over time.

- Operational Efficiency: The crane's ability to handle various tasks efficiently helps reduce operational costs and improve overall productivity.

By providing a balance of affordability and performance, the 1 ton wall-mounted cantilever crane offers excellent value for businesses seeking a reliable and economical lifting solution.

Applications of the 1 Ton Wall Jib Crane

Industrial Applications with Low Headroom Cantilever Design

The 1 ton wall-mounted cantilever crane is exceptionally suited for environments where space is constrained, particularly in workshops with low ceilings.

Benefits for Low Headroom Spaces:

- Maximized Vertical Space: The low headroom design allows for efficient use of vertical space, which is crucial in settings with limited overhead clearance. This design ensures that the crane can operate effectively without interfering with other equipment or operations.

- Optimized Performance in Tight Spaces: By utilizing the wall-mounted cantilever design, the crane maintains a compact footprint, making it ideal for maneuvering and positioning materials in confined or congested areas. This design enhances accessibility and flexibility, ensuring smooth operation even in restricted environments.

In summary, the 1 ton wall-mounted jib crane excels in workshops and facilities where space is at a premium, providing reliable and efficient material handling without compromising on performance.

Diverse Industry Uses

The versatility of the 1 ton wall-mounted jib crane makes it an invaluable asset across various industry sectors, each reaping significant benefits from its adaptability and efficiency. Here's a closer look at how this crane serves different applications:

Light to Medium-Duty Machine Parts

Applications:

- Small Engine Components: The 1 ton wall-mounted jib crane efficiently handles lighter engine parts such as cylinder heads, small assemblies, and components. These tasks require precise positioning and careful handling to avoid damage, and the crane's adjustable lifting speeds and stable I-beam design make it ideal for such tasks.

- Motors and Pumps: For lifting small to medium-sized motors or pumps, which typically weigh less than 1 ton, the crane offers reliable and controlled movement. This is crucial in environments where frequent lifting and positioning of machinery are necessary, such as in repair shops or small manufacturing units.

- Tooling: The crane supports the handling of smaller tooling or dies that do not exceed 1 ton, ensuring efficient operation in machine shops or production lines where tool changes are frequent.

Benefits:

- Precision Handling: The crane's ability to handle various weights and sizes with precision reduces the risk of damage to delicate parts.

- Operational Flexibility: Adjustable lifting speeds allow operators to manage tasks with varying complexity and weight requirements.

Raw Materials

Applications:

- Small Steel Coils or Sheets: In manufacturing and metalworking industries, the crane handles smaller steel coils or sheets within a weight range of 200 kg to 800 kg. This is crucial for industries requiring frequent movement of raw materials, such as fabrication shops or steel processing plants.

- Lightweight Pipes and Tubing: The crane also efficiently moves sections of metal or plastic pipes, with weight ranges from 50 kg to 600 kg per section. This functionality is vital in plumbing or construction projects where precise handling of long, lightweight materials is needed.

Benefits:

- Versatile Lifting: The crane's flexibility in handling different types of raw materials enhances workflow efficiency and material management.

- Space Efficiency: Wall-mounted design helps in maintaining a clutter-free workspace, crucial for operations involving heavy and bulky raw materials.

Finished Products

Applications:

- Palletized Goods: The crane is well-suited for lifting lighter palletized goods in warehouses and distribution centers. It handles loads typically ranging from 200 kg to 1000 kg, improving the efficiency of moving finished products and optimizing storage and retrieval processes.

- Assembly Line Components: In production settings, the crane manages small components or sub-assemblies, facilitating smooth operations on assembly lines. This is essential for maintaining a steady production pace and ensuring timely assembly.

Benefits:

- Enhanced Workflow: Efficient lifting of finished products and assembly components streamlines operations and reduces manual handling.

- Increased Storage Efficiency: The crane's design allows for better use of vertical space, aiding in the organization and management of finished goods.

Maintenance Equipment

Applications:

- Light Equipment Parts: The crane handles smaller, lighter equipment parts during repair or servicing. Its precise control makes it suitable for delicate operations, ensuring that maintenance tasks are completed efficiently.

- Vehicle Parts: For workshops or service centers, the crane lifts lighter vehicle components such as small transmissions or parts of the suspension system. This is crucial for automotive repair and maintenance operations where precise handling of parts is required.

Benefits:

- Improved Maintenance Efficiency: Quick and precise handling of maintenance equipment minimizes downtime and enhances repair efficiency.

- Safety: Reduced manual handling lowers the risk of injury and ensures safer working conditions.

Containers and Drums

Applications:

- Chemical Drums: The crane's ability to handle 55-gallon chemical drums, with weights ranging from 200 kg to 500 kg per drum, is vital for industries dealing with hazardous materials. This ensures safe and efficient movement of chemicals in manufacturing or laboratory environments.

- Storage Bins: For lighter storage containers used in manufacturing or warehousing, the crane facilitates easy lifting and positioning, enhancing inventory management and operational efficiency.

Benefits:

- Safe Handling of Hazardous Materials: The crane's design supports safe and efficient handling of chemical drums, crucial for compliance with safety regulations.

- Efficient Storage Solutions: The crane aids in managing storage bins, improving organization and accessibility in warehouses or production facilities.

In summary, the 1 ton wall-mounted jib crane offers exceptional versatility, making it a valuable tool across diverse industries. Its ability to handle a wide range of tasks—from delicate machine parts to heavy raw materials—combined with its space-saving design, enhances operational efficiency and safety in various settings.

Case Study: Installation of 1 Ton Wall-Mounted Jib Cranes with I-Beam Cantilever Design in the Maldives

Project Description: 1 Ton Wall-Mounted Jib Crane wit I beam Cantilever Design for Sale in the Maldives

This project involves the sale and installation of three 1 ton wall-mounted jib cranes, specifically designed for use at a construction site in the Maldives. The cranes are equipped to handle a variety of lifting tasks efficiently and reliably. Key details of the project include:

- Jib Crane Type: BX Wall-Mounted Jib Crane with I-Beam Cantilever

- Capacity: 1 ton

- Arm Length: 2.5 meters

- Lifting Height: 10 meters

- Crane Power: 380V, 50Hz, 3-phase electrical supply

- Project Application: Construction site, facilitating material handling and lifting operations

- Project Location: Maldives

- Quantity: 3 units

These BX wall-mounted jib cranes are designed with an I-beam structure for durability and stability, making them ideal for construction environments. The 2.5-meter arm length combined with a 10-meter lifting height provides flexibility and efficiency in managing materials at elevated positions. The 380V, 50Hz, 3-phase power supply ensures reliable operation in the Maldives' construction sites.

I beam cantilever of 1 ton wall mounted jib crane with 2.5 meters length and 10 meter lifting height

Mounting plate of the 1 ton wall mounted jib crane for sale

Mouting columns of wall jib crane 1 ton

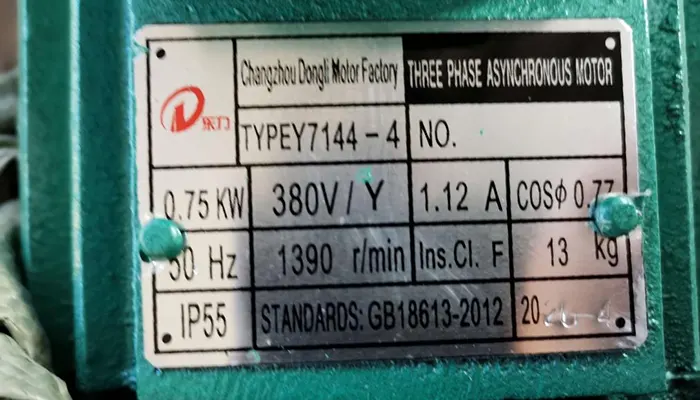

nameplate of rotating motor for 1 ton wall mounted cantilever crane

Key Features and Benefits

I-Beam Cantilever Design:

- Durability and Stability: The BX wall-mounted jib cranes are equipped with a robust I-beam cantilever structure. This design not only provides exceptional stability but also ensures long-term durability, crucial for the demanding environment of a construction site.

- Efficient Load Handling: The I-beam design contributes to improved load distribution, reducing stress on the crane and increasing its overall efficiency in handling various materials.

Flexibility in Operation:

- Arm Length: With an arm length of 2.5 meters, the cranes offer a suitable reach for maneuvering materials within the construction site, allowing operators to handle loads effectively at varying positions.

- Lifting Height: The cranes are capable of lifting up to 10 meters, providing ample height to manage materials and equipment at elevated levels. This feature is essential for optimizing space usage and enhancing productivity on site.

Power and Performance:

- Electrical Supply: The cranes are powered by a 380V, 50Hz, 3-phase electrical supply, ensuring reliable and consistent performance. This specification is well-suited for the construction site in the Maldives, where stable power supply is critical for uninterrupted operations.

Project Application

The BX wall-mounted jib cranes are strategically utilized to facilitate various material handling and lifting operations at the construction site. Their robust design and flexibility make them ideal for handling construction materials, tools, and equipment, contributing to streamlined workflows and enhanced operational efficiency.

Impact and Results

- Increased Efficiency: The cranes have significantly improved the speed and efficiency of material handling tasks on site. The ability to lift and position materials precisely at elevated heights has optimized the construction process, reducing downtime and improving overall productivity.

- Enhanced Safety: The sturdy design and reliable performance of the cranes have contributed to a safer working environment. By efficiently managing heavy loads, the risk of manual handling injuries has been minimized.

The installation of the 1 ton wall-mounted jib cranes with an I-beam cantilever design has proven to be a valuable asset for the construction site in the Maldives. The cranes' robust construction, flexibility in operation, and reliable power supply have enhanced material handling capabilities and operational efficiency. This project demonstrates the effectiveness of tailored crane solutions in addressing specific needs within challenging environments, providing significant benefits to the construction industry.

For more information on similar crane solutions and to explore tailored options for your projects, contact us today.

Why Choose the 1 Ton Cantilever Wall Mounted Jib Crane for Your Needs

Quality Assurance and Compliance

When selecting the 1 ton cantilever wall-mounted jib crane, you can trust in its adherence to rigorous industry standards and certifications. This assurance translates to:

- Safety: The crane meets all safety regulations, providing a secure lifting solution to protect both operators and materials.

- Reliability: Built with high-quality materials and precise engineering, it delivers consistent performance and minimal downtime.

- Long-Term Performance: Compliance with industry standards ensures that the crane remains operational and effective over its lifespan, offering dependable service for years to come.

Customization and Tailored Solutions

We understand that each operation has unique requirements, which is why the 1 ton cantilever wall-mounted jib crane offers:

- Customizable Lifting Heights: Adapt the crane to fit various ceiling heights, ensuring optimal functionality in different environments.

- Adjustable Lifting Speeds: Choose from different lifting speeds to match your specific operational needs, enhancing efficiency and precision.

- Flexible Slewing Angles: Modify the slewing angle to accommodate various material handling tasks and workspace configurations.

This level of customization allows you to tailor the crane to your precise needs, improving productivity and effectiveness in your specific applications.

Comprehensive Customer Support

Our commitment to customer satisfaction extends beyond the purchase of the crane:

- Installation Assistance: Professional support during installation ensures the crane is set up correctly and operates smoothly from the start.

- Operational Guidance: Detailed instructions and training are provided to ensure your team can use the crane efficiently and safely.

- After-Sales Service: Ongoing support, including maintenance advice and troubleshooting assistance, helps keep the crane in top condition, maximizing its operational lifespan.

With these comprehensive support services, you can be confident in the smooth operation and longevity of your 1 ton cantilever wall-mounted jib crane, making it a reliable investment for your business.

Conclusion: Custom 1 Ton Wall Mounted Cantilever Jib Crane for Your Needs

The 1 ton wall-mounted jib crane offers numerous advantages that make it an excellent choice for various industrial applications:

- Space-Saving Design: Its wall-mounted configuration maximizes floor space, making it ideal for workshops and warehouses with limited room. This design helps keep work areas clear and organized.

- Versatility: The crane's adjustable lifting speeds, flexible slewing angles, and broad lifting range accommodate a wide variety of tasks, from handling small machine parts to moving palletized goods.

- Cost-Effectiveness: With its competitive pricing and minimal maintenance requirements, this crane offers a cost-effective solution, delivering long-term savings through durability and efficient operation.

Investing in the 1 ton wall-mounted jib crane provides significant value for businesses seeking reliable and efficient lifting solutions. Its robust design and customizable features ensure that it meets diverse operational needs while maintaining high standards of performance and safety. This crane stands out in the market due to its combination of space optimization, operational versatility, and cost efficiency, making it a smart investment for companies looking to enhance their material handling capabilities.

Don't miss the opportunity to enhance your operational efficiency with the 1 ton wall-mounted jib crane. Explore our range of cranes to find the perfect fit for your lifting needs, and benefit from our comprehensive support services. Contact us today to learn more about the crane's technical specifications, discuss your specific requirements, and receive expert guidance on selecting the right solution for your business. Invest in a crane that offers unparalleled performance and value—take action now and elevate your material handling operations! Contact us to get your customized wall mounted 1 ton jib crane and check what we can do to save your jib crane cost.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch