How to Get A Detailed Quotation On Bucket Grab for Overhead Crane

Learn how to obtain a detailed quotation for a bucket grab for overhead cranes, ensuring all specifications and requirements are covered.

Category: Grab Crane

Your Trusted Bucket Grab Overhead Crane Manufacturer & Supplier

How to Get A Detailed Quotation On Bucket Grab for Overhead Crane

Learn how to obtain a detailed quotation for a bucket grab for overhead cranes, ensuring all specifications and requirements are covered.Bucket grabs are essential tools in material handling, playing a crucial role in various industrial processes. They are particularly effective in lifting and transporting bulk materials such as sand, gravel, scrap metal, and other loose materials. By attaching to overhead cranes, these bucket grabs enhance the efficiency and safety of operations in multiple industries.

The primary function of bucket grabs is to facilitate the easy and efficient transfer of materials from one location to another. This capability is vital in industries where bulk materials are common, such as construction, mining, waste management, and shipping. The use of bucket grabs reduces manual labor, increases productivity, and improves safety by minimizing the risk of accidents associated with manual handling.

Common Types of Bucket Grabs

There are various types of bucket grabs designed to meet specific needs. Bucket grabs are designed for various material handling needs, and different types are tailored for specific applications. Here are some common types of bucket grabs, each with unique features to meet specific needs:

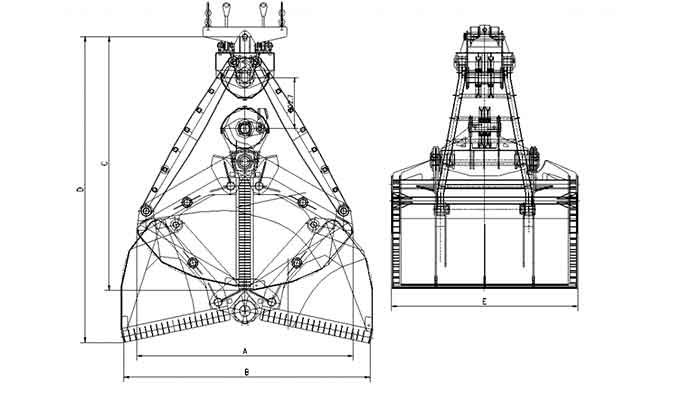

Clamshell Bucket Grab

- Design: Consists of two hinged jaws that open and close like a clamshell. Operated by hydraulic or mechanical means.

- Applications: Ideal for handling bulk materials like coal, gravel, and sand. Often used in ports and construction sites.

- Features: Can handle materials of varying sizes and shapes, with precise control over opening and closing.

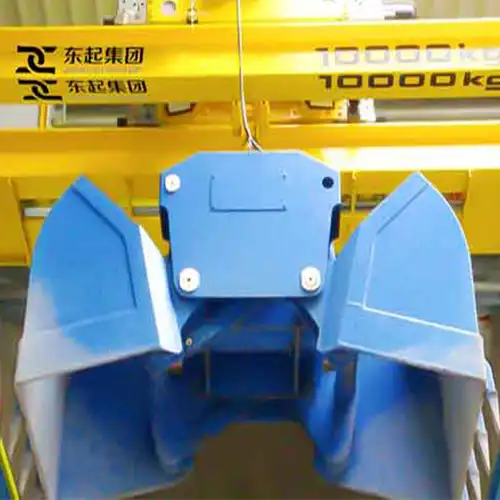

Orange Peel Bucket Grab

- Design: Has multiple tines or "fingers" that resemble the segments of an orange. These tines grip and scoop up materials.

- Applications: Suitable for handling scrap metal, demolition debris, and other irregular materials. Commonly used in recycling and demolition industries.

- Features: Effective for grabbing and lifting uneven or fragmented materials.

Double-Grip Bucket Grab

- Design: Features two separate grippers that operate independently or in unison.

- Applications: Used for handling delicate or irregularly shaped materials where precision is essential. Suitable for materials like glass or specific types of bulk cargo.

- Features: Allows for careful handling and control, reducing the risk of damage to the materials.

Hydraulic Clamshell Grab

- Design: A variant of the clamshell bucket that uses hydraulic cylinders for operation.

- Applications: Ideal for heavy-duty applications requiring significant lifting power, such as handling large quantities of bulk material or heavy scrap.

- Features: Offers powerful and smooth operation with adjustable hydraulic controls for varying material sizes and weights.

Grapple Bucket Grab

- Design: Combines a bucket with a grapple mechanism for gripping and lifting.

- Applications: Useful for handling logs, construction debris, and other bulky materials. Commonly used in forestry and construction.

- Features: Provides both scooping and gripping capabilities for versatile material handling.

Self-Dumping Bucket Grab

- Design: Includes a mechanism that allows the bucket to automatically empty its contents when tipped.

- Applications: Suitable for handling bulk materials that need to be easily and efficiently dumped, such as in waste management or material transfer operations.

- Features: Simplifies the unloading process, reducing manual labor and improving efficiency.

Side-Dump Bucket Grab

- Design: Features a side-dumping mechanism that allows the bucket to tilt to one side to unload materials.

- Applications: Ideal for applications where unloading needs to be done to the side rather than directly underneath, such as in conveyor systems or specific construction scenarios.

- Features: Provides flexibility in material unloading, making it suitable for certain operational layouts.

Each type of bucket grab is designed to address specific handling needs, ensuring that materials are managed efficiently and safely in various industrial and construction environments.

Bucket Grab for Overhead Cranes for Material Handling

On overhead cranes, various types of bucket grabs are used depending on the material being handled and the specific requirements of the application. Here are some commonly used types:

Bulk Material Bucket Grabs

- Designed for handling bulk materials like coal, gravel, or sand.

- Large, rugged buckets with reinforced edges to handle abrasive materials.

- Used in industrial plants, ports, and construction sites for bulk material transfer.

Slag Bucket Grabs

- Specifically designed for handling furnace slag and other byproducts.

- Heavy-duty construction with high wear resistance and reinforced edges.

- Common in steel mills and foundries for slag handling and disposal.

Cement Bucket Grabs

- Designed for handling cement in powdered or granular form.

- Sealing mechanisms to prevent dust leakage and smooth interior surfaces.

- Used in cement plants, construction sites, and storage facilities.

Chemical Bucket Grabs

- For handling bulk chemicals or powders, including hazardous substances.

- Corrosion-resistant materials and sealing mechanisms to prevent leaks.

- Used in chemical manufacturing and processing facilities.

Metal Ore Bucket Grabs

- For handling metal ores such as iron ore, copper ore, or bauxite.

- Heavy-duty design with reinforced edges to handle rough and abrasive ores.

- Common in mining operations and mineral processing plants.

Reef Material Bucket Grabs

- Designed for handling materials used in reef construction, like coral or rocks.

- Rugged design with reinforced jaws or tines.

- Used in marine construction and environmental projects.

Glass Bucket Grabs

- For handling broken or whole glass shards.

- Design to prevent breakage and minimize damage to fragile glass.

- Common in glass recycling facilities and manufacturing plants.

Snow Bucket Grabs

- Designed for handling snow and ice.

- Features to prevent clogging and facilitate easy unloading.

- Used in snow removal operations and winter maintenance projects.

Soil Bucket Grabs

- For handling soil and dirt.

- Wide, smooth buckets to minimize spillage and compaction.

- Used in construction, landscaping, and excavation projects.

Wood Pallet Bucket Grabs

- For handling wooden pallets and palletized goods.

- Clamps or tines specifically designed for securely lifting wooden pallets.

- Used in logistics and warehouse operations.

Pharmaceutical Bucket Grabs

- Designed for handling sensitive pharmaceutical powders and granules.

- Hygienic construction with easy-to-clean surfaces.

- Used in pharmaceutical manufacturing and processing.

Construction Debris Bucket Grabs

- For handling construction debris like rubble and bricks.

- Rugged, reinforced design to handle heavy and sharp debris.

- Used in demolition sites and renovation projects.

Liquid Slurry Bucket Grabs

- Designed for handling liquid slurries that include mixtures of liquids and solids.

- Design to manage both liquid and solid components with controlled flow mechanisms.

- Used in industries like mining, wastewater treatment, and chemical processing.

These bucket grabs are selected based on their specific design features and the material handling requirements of the overhead crane application, ensuring efficient and effective material management.

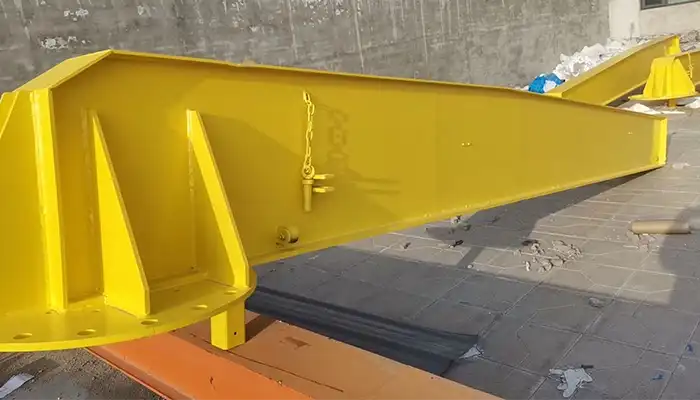

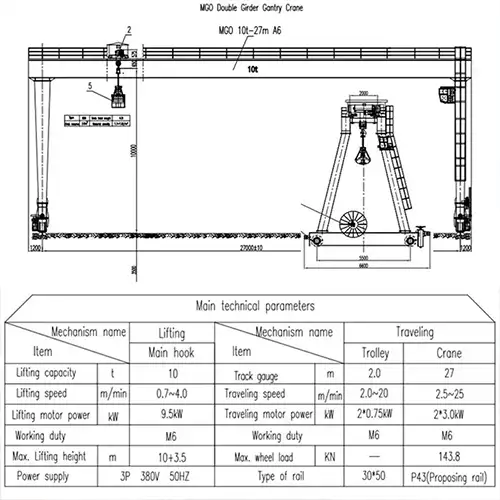

Buckets Grabs for Gantry Cranes for Indoor and Outdoor Material Handling

Gantry cranes (including Goliath cranes) are versatile material handling systems used both indoors and outdoors. They can be equipped with various types of bucket grabs to handle different materials effectively. Here are some commonly used bucket grabs for gantry or Goliath cranes in both indoor and outdoor material handling:

Bulk Material Bucket Grabs

- Designed for handling large volumes of bulk materials such as coal, gravel, or sand.

- Large, rugged buckets with reinforced edges and high capacity.

- Used in outdoor settings like construction sites, ports, and industrial yards.

Slag Bucket Grabs

- Specifically designed for handling furnace slag and other byproducts.

- Heavy-duty construction with high wear resistance, often made of heat-resistant materials.

- Common in steel mills and foundries, often used in indoor or semi-enclosed environments.

Cement Bucket Grabs

- For handling cement in powdered or granular form.

- Equipped with sealing mechanisms to prevent dust leakage and smooth interior surfaces.

- Common in indoor settings such as cement plants, warehouses, and construction sites.

Chemical Bucket Grabs

- Designed for handling bulk chemicals or powders, including hazardous substances.

- Corrosion-resistant materials and sealing mechanisms to prevent leaks.

- Used in chemical manufacturing and processing facilities, both indoor and outdoor depending on the facility.

Metal Ore Bucket Grabs

- For handling metal ores like iron ore, copper ore, or bauxite.

- Heavy-duty design with reinforced edges to manage rough and abrasive ores.

- Typically used in mining operations and mineral processing plants, both indoors and outdoors.

Reef Material Bucket Grabs

- Designed for handling materials used in reef construction, such as coral or rocks.

- Rugged design with reinforced jaws or tines.

- Used in marine construction and environmental projects, often outdoors.

Glass Bucket Grabs

- For handling broken or whole glass shards.

- Designed to prevent breakage and minimize damage to delicate glass.

- Common in glass recycling facilities and manufacturing plants, usually indoors.

Snow Bucket Grabs

- Designed for handling snow and ice.

- Features to prevent clogging and facilitate easy unloading.

- Used in outdoor snow removal operations and winter maintenance projects.

Soil Bucket Grabs

- For handling soil and dirt.

- Wide, smooth buckets to reduce spillage and compaction.

- Used in construction, landscaping, and excavation projects, both indoors and outdoors.

Wood Pallet Bucket Grabs

- For handling wooden pallets and palletized goods.

- Clamps or tines specifically designed for securely handling wooden pallets.

- Used in logistics and warehouse operations, both indoor and outdoor.

Pharmaceutical Bucket Grabs

- Designed for handling sensitive pharmaceutical powders and granules.

- Hygienic construction with easy-to-clean surfaces.

- Common in pharmaceutical manufacturing and processing facilities, typically indoors.

Construction Debris Bucket Grabs

- For handling construction debris such as rubble and bricks.

- Rugged design with reinforced construction to handle heavy and sharp debris.

- Used in demolition sites and renovation projects, both indoor and outdoor.

Liquid Slurry Bucket Grabs

- Designed for handling liquid slurries, including mixtures of liquids and solids.

- Features to manage both liquid and solid components with controlled flow mechanisms.

- Used in industries like mining, wastewater treatment, and chemical processing, both indoors and outdoors.

These bucket grabs are selected based on their specific design features and the material handling requirements of the gantry or Goliath crane application, ensuring efficient and effective management of various materials in both indoor and outdoor environments.

Steps to Get Your Quotation on Crane Bucket Grab

Step 1: Identify Your Requirements

Determine the Specific Type of Grab Bucket

Choosing the right type of grab bucket is essential to ensure that it meets the specific needs of your operations. There are several types of grab buckets, each designed for different applications. Here are some common types to consider:

- Clam Shell Grab & Clamshell Grab Bucket:This type is ideal for handling bulk materials such as grains, coal, and minerals. The clam shell design allows for efficient scooping and release of materials, making it suitable for use in ports, construction sites, and bulk material storage facilities. Similar to the clam shell grab, the clamshell grab bucket is used for lifting and transporting loose materials. Its robust construction makes it suitable for heavy-duty applications in industries such as mining and construction.

- Hydraulic Clamshell &Hydraulic Clamshell Grab:This type of grab bucket is powered by hydraulic systems, providing greater control and precision during operations. Hydraulic clamshells are commonly used in environments where precise handling of materials is required, such as waste management and recycling plants.Combining the features of hydraulic operation and clamshell design, this grab bucket offers both efficiency and control. It is ideal for applications that require the handling of heavy and dense materials.

Selecting the right type of grab bucket depends on the specific requirements of your operation. For example, if you need to handle loose materials like sand or gravel, a clam shell grab or clamshell grab bucket would be suitable. On the other hand, for operations that demand precision and control, such as handling scrap metal or waste, a hydraulic clamshell or hydraulic clamshell grab would be more appropriate.

Significance of Choosing the Right Type for Specific Applications

Choosing the appropriate grab bucket type ensures that your operations run smoothly and efficiently. The right grab bucket can:

- Improve Efficiency: Matching the grab bucket to the material type and operation can significantly increase handling speed and reduce cycle times.

- Enhance Safety: Using the correct type of grab bucket minimizes the risk of accidents and equipment damage, ensuring a safer working environment.

- Optimize Costs: The right grab bucket reduces wear and tear on equipment, leading to lower maintenance costs and longer service life.

- Increase Productivity: Efficient material handling means that more work can be done in less time, boosting overall productivity.

By carefully identifying your requirements and selecting the appropriate type of grab bucket, you can ensure that you receive a detailed and accurate quotation tailored to your specific needs. This step is crucial in obtaining the best equipment for your operations, ultimately leading to improved performance and cost savings.

Consider the Crane Type and Compatibility

Selecting the right grab bucket also involves ensuring it is compatible with the type of crane you are using. Different cranes have varying capacities, reach, and operational mechanisms that need to be considered to ensure seamless integration and optimal performance. Here's why matching the grab bucket with the crane type is essential:

- Operational Efficiency: A well-matched grab bucket and crane combination will operate more efficiently, reducing cycle times and increasing throughput.

- Safety: Compatibility between the grab bucket and the crane enhances operational safety by ensuring stable lifting and precise control, reducing the risk of accidents.

- Durability: Properly matched equipment experiences less stress and wear, leading to longer service life and reduced maintenance costs.

Examples of Crane Types and Compatible Grab Buckets

- Grab Overhead Crane: Overhead cranes are commonly used in industrial settings for heavy lifting. A grab bucket designed for overhead cranes, such as a grab overhead crane, ensures robust handling of large volumes of bulk materials.

- Overhead Gantry Crane Grab: Gantry cranes are used in various industries, including shipyards, construction, and warehouses. An overhead gantry crane grab is designed to handle heavy-duty tasks and large loads efficiently.

- Grab Bucket Jib Cranes: Jib cranes offer flexibility and are often used in workshops and manufacturing facilities. A grab bucket jib crane is tailored to work with the specific load and reach capacities of jib cranes, providing efficient material handling within a limited workspace.

Ensuring Compatibility

When considering the crane type and compatibility, it's important to:

- Check Load Capacities: Ensure the grab bucket's capacity matches or complements the crane's lifting capacity to avoid overloading and potential damage.

- Assess Operational Requirements: Consider the operational environment and specific tasks. For instance, a grab bucket for an overhead crane in a foundry will differ from one used in a port.

- Consult with Manufacturers: Engage with manufacturers or suppliers to confirm compatibility and get recommendations based on their expertise and experience with similar setups.

By taking these factors into account, you can ensure that the grab bucket you choose will work efficiently and safely with your crane, providing reliable performance and supporting your operational needs. This careful consideration is crucial in obtaining an accurate and detailed quotation that meets your specific requirements.

Step 2: Research Potential Suppliers

Finding Reputable Suppliers

Finding a reliable supplier is a crucial step in obtaining a detailed quotation for a bucket grab for your overhead crane. Here are some tips to help you identify reputable suppliers:

- Industry Experience: Look for suppliers with extensive experience in manufacturing and supplying grab buckets. Suppliers with a proven track record are more likely to provide high-quality products and reliable customer service.

- Certifications and Standards: Check if the supplier complies with international standards and holds relevant certifications. This ensures that their products meet industry safety and quality requirements.

- Customer Reviews and Testimonials: Read reviews and testimonials from other customers. Positive feedback can indicate a supplier's reliability and the quality of their products.

- After-Sales Support: Ensure that the supplier offers robust after-sales support, including warranty, maintenance, and technical assistance. This is important for addressing any issues that may arise post-purchase.

Emphasize on Checking for Listings

When researching suppliers, it's important to look for specific listings that match your geographical and operational needs. Here are some key considerations:

Grab Bucket for Sale in China

Why China?

China is renowned for its extensive manufacturing capabilities and competitive pricing in the global market. The country has established itself as a major hub for the production of industrial equipment, including grab buckets for overhead cranes. Several factors make China an attractive source for grab buckets:

- Diverse Manufacturing Base: China's vast industrial base allows for the production of a wide range of grab buckets, catering to different industries and applications. Whether you need a lightweight grab for handling loose materials or a heavy-duty grab for construction debris, Chinese manufacturers can meet your requirements.

- Competitive Pricing: Chinese suppliers often offer more competitive pricing compared to their counterparts in other countries. The lower production costs, combined with economies of scale, enable Chinese manufacturers to provide high-quality grab buckets at attractive prices.

- Innovation and Customization: Many Chinese manufacturers invest in research and development to innovate and improve their products. This focus on innovation ensures that you can find grab buckets with advanced features and customized solutions tailored to your specific needs.

- Global Supply Chain: China's well-established logistics and supply chain networks facilitate the efficient export of grab buckets worldwide. This ensures timely delivery and reliable supply, making it easier for international buyers to source products from China.

How to Find Suppliers

Finding reliable suppliers for grab buckets in China involves leveraging various online platforms and marketplaces. Here are some effective strategies:

Online Marketplaces:

Alibaba: One of the largest global B2B marketplaces, Alibaba offers a vast selection of grab buckets from various manufacturers. You can filter results based on product specifications, price, and supplier ratings. Detailed product descriptions and customer reviews help in assessing the quality and reliability of the suppliers.

- Global Sources: This platform provides access to verified suppliers and detailed product information. Global Sources often conducts supplier audits, which can give you added confidence in the quality and legitimacy of the suppliers.

- Made-in-China: Another prominent B2B platform, Made-in-China features a comprehensive directory of Chinese suppliers. The platform offers detailed product listings, including specifications and images, making it easier to find grab buckets that meet your requirements.

Supplier Verification:

Check Reviews and Ratings: Customer reviews and ratings on these platforms can provide insights into the supplier's reliability and product quality. Look for suppliers with high ratings and positive feedback from previous buyers.

- Request Samples: Before making a large purchase, request samples from potential suppliers. This allows you to assess the product quality firsthand and ensure it meets your standards.

- Communication: Engage in direct communication with suppliers to discuss your specific needs and verify their capabilities. Prompt and clear communication is a good indicator of a reliable supplier.

Trade Shows and Exhibitions:

Attending trade shows and exhibitions in China or internationally can be an effective way to meet suppliers in person and see their products up close. Events like the Canton Fair and Bauma China offer opportunities to connect with numerous manufacturers and distributors.

By leveraging these strategies, you can effectively find and evaluate suppliers for grab buckets in China, ensuring you secure high-quality products at competitive prices.

Bucket Grab for Sale in European CountriesEuropean suppliers are known for their high-quality engineering and adherence to strict safety standards. They often provide advanced technology and innovative designs. Explore B2B platforms like Europages, Euronext, and DirectIndustry. Additionally, consider attending trade shows and industrial expos in Europe to connect with reputable suppliers directly.

Grab Bucket for Sale in Europe

Why Europe?

European suppliers are renowned for their high-quality engineering, adherence to stringent safety standards, and innovative design capabilities. Several factors make Europe an attractive source for bucket grabs:

- High-Quality Engineering: European manufacturers are known for their precision engineering and attention to detail. This ensures that the bucket grabs produced in Europe are durable, reliable, and capable of performing in demanding industrial environments.

- Strict Safety Standards: European companies adhere to rigorous safety regulations and standards, ensuring that their products meet or exceed international safety requirements. This commitment to safety helps protect workers and maintain efficient operations.

- Advanced Technology and Innovation: Europe is home to many leading companies in industrial equipment manufacturing that invest heavily in research and development. This focus on innovation leads to advanced technologies and cutting-edge designs in bucket grabs, enhancing their performance and efficiency.

- Sustainability and Environmental Responsibility: European manufacturers often prioritize sustainability and environmental responsibility in their production processes. This commitment can be appealing to companies looking to minimize their environmental impact.

How to Find Suppliers

Finding reliable suppliers for bucket grabs in Europe involves utilizing various B2B platforms and attending industry events. Here are some effective strategies:

Online Marketplaces and B2B Platforms:

Europages: Europages is a comprehensive B2B directory that connects buyers with suppliers across Europe. You can search for bucket grab manufacturers, read detailed company profiles, and explore product listings to find suitable suppliers.

- Euronext: Euronext offers access to a wide range of industrial suppliers, including those specializing in bucket grabs. The platform provides information on supplier capabilities, product specifications, and contact details.

- DirectIndustry: This online platform focuses on industrial equipment and connects buyers with manufacturers and distributors. DirectIndustry features detailed product descriptions, specifications, and supplier profiles, making it easy to find bucket grabs that meet your needs.

Trade Shows and Industrial Expos:

Attending trade shows and industrial expos in Europe can be an effective way to connect with reputable suppliers directly. Events like the Hannover Messe, bauma, and Intermat bring together leading manufacturers and industry professionals. These events provide opportunities to see products firsthand, discuss your requirements, and establish relationships with potential suppliers.

Supplier Verification:

Check Certifications and Standards: Verify that potential suppliers comply with relevant European standards and certifications. This can include CE marking, ISO certifications, and other industry-specific standards that ensure quality and safety.

- Request References and Case Studies: Ask suppliers for references from previous clients or case studies that demonstrate their experience and reliability. This can provide insights into the supplier's track record and capabilities.

- Conduct Factory Visits: If possible, arrange visits to the supplier's manufacturing facilities to assess their production processes, quality control measures, and overall operations.

- By leveraging these strategies, you can effectively find and evaluate suppliers for bucket grabs in Europe, ensuring you secure high-quality products that meet your specific requirements and standards.

By focusing on these regions, you can leverage the strengths of different markets to find the best supplier for your needs. Ensure you gather detailed information about the products offered, including specifications, pricing, and delivery times, to make an informed decision.Finding the right supplier involves thorough research and careful evaluation. By considering industry experience, certifications, customer feedback, and after-sales support, you can identify reputable suppliers. Additionally, focusing on specific regions like China and Europe can help you find competitive and high-quality options. This step is crucial in obtaining a detailed and accurate quotation for your bucket grab, ensuring it meets your operational requirements and budget constraints.

Step 2: Research Potential Suppliers

Evaluating Supplier Capabilities

Assessing suppliers based on their capabilities and offerings is crucial to ensure that you choose a supplier who can meet your specific needs. Here's how you can evaluate supplier capabilities effectively:- Product Range: Look for suppliers who offer a wide range of grab buckets, including specialized types such as Orange Peel grab crane for sale and crane clamshell buckets for sale. A diverse product range indicates the supplier's expertise and ability to meet various industrial requirements.

- Customization Options: Some operations may require custom-designed grab buckets to handle specific materials or fit unique crane configurations. Check if the supplier offers customization services and has experience in delivering tailored solutions.

- Production Capacity: Ensure the supplier has the capacity to meet your demand within the required timeframe. This includes assessing their manufacturing facilities, workforce, and ability to scale production if necessary.

- Technological Expertise: Suppliers with advanced manufacturing technologies and engineering capabilities are likely to produce higher quality and more efficient grab buckets. Look for evidence of innovation and technological proficiency in their offerings.

- Quality Assurance: Reliable suppliers implement strict quality control processes to ensure their products meet high standards. Ask about their quality assurance practices, including material selection, manufacturing processes, and final product testing.

- Delivery and Logistics: Efficient logistics and timely delivery are critical. Evaluate the supplier's ability to manage shipping and delivery schedules, especially if they are located overseas. Reliable suppliers should provide clear timelines and have robust logistics arrangements.

Examples of Specific Offerings

When evaluating suppliers, consider their specific product offerings, such as:

Orange Peel Grab Crane for Sale

- Description: Orange peel grabs are designed for handling bulk materials like scrap metal, waste, and rocks. They have multiple tines or "peels" that open and close to grab materials.Use Case: These are ideal for industries involved in scrap recycling, waste management, and bulk material handling.

- Supplier Evaluation: Check if the supplier has a proven track record of manufacturing and delivering orange peel grabs. Look for detailed product specifications, case studies, and customer testimonials.

- Crane Clamshell Buckets for SaleDescription: Clamshell buckets are used for digging and loading loose materials such as soil, sand, and gravel. They are commonly used in construction, dredging, and bulk material handling.

- Use Case: Suitable for construction sites, ports, and industrial facilities where precise handling of loose materials is required.

- Supplier Evaluation: Evaluate the supplier's experience in producing clamshell buckets. Check for certifications, compliance with safety standards, and availability of different sizes and configurations.Thoroughly evaluating supplier capabilities ensures that you choose a partner who can deliver high-quality, reliable, and efficient grab buckets.

By considering factors such as product range, customization options, production capacity, technological expertise, quality assurance, and delivery logistics, you can make an informed decision. Specifically, look for suppliers offering products like orange peel grabs and clamshell buckets to meet your operational needs. This careful evaluation process is vital in obtaining a detailed and accurate quotation that aligns with your requirements.

Step 3: Prepare a Detailed Request for Quotation (RFQ)

Include Technical Specifications

When preparing a detailed RFQ for a bucket grab for an overhead crane, it's crucial to clearly outline the technical specifications required for your project. This includes:- Type: Specify the type of grab bucket required, such as a clamshell, orange peel, or double-grab bucket. Ensure to use precise terminology like grab bucket crane or crane with grab bucket to avoid ambiguity.

- Capacity: Detail the maximum load capacity the grab bucket needs to handle. This will influence the design and functionality of the bucket.

- Material: Define the material of the grab bucket, whether it's steel, alloy, or another material suited for the intended loads and working environment.

Detailed Specification to Get Your Custom Bucket Grab Design for Your Needs.

When designing a custom bucket grab for your overhead crane, it is essential to provide detailed specifications to ensure the final product meets your specific needs. Here are the key specifications to consider:

- 1. Capacity and Volume:Specify the load capacity (in tons or kilograms) and the volume of material the bucket grab needs to handle.

- 2. Material Type:Describe the type of materials to be handled, such as sand, gravel, scrap metal, or bulk goods.

- 3. Grab Type:Indicate the type of bucket grab required, such as clamshell, orange peel, or multi-jaw grab.

- 4. Opening and Closing Mechanism:Specify the preferred mechanism for opening and closing the grab, such as hydraulic, mechanical, or electro-hydraulic.

- 5. Dimensions:Provide the dimensions of the grab, including width, height, and depth, to ensure it fits within your operational space.

- 6. Operating Environment:Detail the operating conditions, such as temperature range, humidity, and exposure to corrosive materials or harsh environments.

- 7. Mounting Type:Specify the type of mounting required, such as a hook, flange, or customized attachment to fit your crane.

- 8. Cycle Time:Indicate the desired cycle time for loading and unloading operations to match your workflow efficiency.

- 9. Power Requirements:Provide details on power supply, such as voltage, frequency, and any specific power requirements for the grab's operation.

- 10. Control System:Specify the type of control system needed, such as remote control, cabin control, or automated control systems.

- 11. Safety Features:Highlight any required safety features, such as overload protection, emergency stop mechanisms, and fail-safe systems.

- 12. Material and Coating:Specify the materials to be used in the construction of the bucket grab and any special coatings needed for corrosion resistance or durability.

- 13. Compliance and Standards:Ensure that the design complies with relevant industry standards and regulations, such as ISO, DIN, or CE markings.

- 14. Customization Options:Mention any additional customization options or special requirements, such as branding, color, or specific design features.

Providing these detailed specifications will help the manufacturer design a bucket grab that precisely meets your operational needs and ensures optimal performance and safety.

Operational Requirements

In addition to technical specifications, outline the operational requirements to ensure the bucket grab meets the performance needs of your application:- Duty Cycle: Specify the duty cycle the bucket grab should support, including the frequency and intensity of use. This will help in selecting a bucket grab that can withstand the operational demands.

- Environment: Describe the operating environment where the bucket grab will be used. Mention whether it will be in a harsh or corrosive environment, extreme temperatures, or other specific conditions.

- Include details about specific applications such as a grab bucket ship unloader if the bucket grab will be used for unloading bulk materials from ships or any other specialized functions.

Additional Features and Customizations

To tailor the bucket grab to your exact needs, request information on any additional features or customizations:- Additional Features: Ask for details on any advanced features that might be beneficial, such as a hydraulic clamshell grab for enhanced control and efficiency in material handling.

- Customizations: Inquire about customization options to accommodate unique requirements or preferences. This could include modifications in size, design, or functionality to fit specific operational needs.

Step 4: Submit the RFQ to Multiple Suppliers

Contacting Suppliers

When submitting your RFQ to multiple suppliers, employ effective strategies to ensure you receive competitive and relevant quotations:- Finding Suppliers: Use targeted keywords such as grab crane for sale and bucket grab for sale to search for potential suppliers online. This can help you identify companies that offer the specific products you need.

- Initial Outreach: Reach out to suppliers via email or through their website's contact forms. Include a clear subject line indicating that you are requesting a quotation, and provide a brief overview of your requirements.

- Follow-Up: After your initial contact, follow up with a phone call if you haven't received a response within a reasonable timeframe. This helps to ensure your request is being processed and to address any potential questions promptly.

Comparing Quotations

Once you receive quotations from various suppliers, it's crucial to compare them effectively:- Technical Details: Carefully review the technical specifications provided in each quotation. Ensure that the bucket grabs meet your requirements for type, capacity, material, and operational needs. Look for compliance with your detailed RFQ.

- Pricing: Compare the pricing across different quotations. Consider not only the initial cost but also any additional costs such as shipping, installation, or maintenance.

- Quality and Features: Assess the quality of the bucket grabs and any additional features offered. Higher-quality materials and advanced features might justify a higher price.

- Supplier Reputation: Evaluate the reputation and reliability of each supplier. Consider factors such as customer reviews, experience in the industry, and after-sales support.

Step 5: Evaluate Quotations and Make a Decision

Assessing Supplier Responses

When evaluating the quotations received from different suppliers, consider the following criteria:- Price: Compare the total cost of each quotation, including any additional expenses like shipping, installation, and maintenance. Ensure the price aligns with your budget while providing value for the features and quality offered.

- Delivery Time: Review the estimated delivery times provided by each supplier. Timeliness is crucial, especially if your project has tight deadlines. Confirm that the delivery schedules meet your operational requirements.

- Warranty and Support: Examine the warranty terms and after-sales support offered. A robust warranty and reliable support can be critical for long-term performance and addressing any potential issues with the bucket grab.

- Technical Compliance: Ensure that each quotation meets the technical specifications outlined in your RFQ. Check for alignment with your operational needs and any additional features that may enhance performance.

Making an Informed Decision

To make a well-informed decision, follow these tips:- Balance Cost with Quality: While cost is an important factor, it should be balanced with the quality of the bucket grab and its alignment with your project needs. Higher quality often comes with a higher price but can offer better performance and durability.

- Consider Supplier Reputation: Evaluate the reputation and reliability of each supplier. Look for reviews, testimonials, and their history in delivering similar products. A reputable supplier is more likely to provide consistent quality and support.

- Review Total Value: Assess the overall value offered by each supplier, considering not just the price but also the quality, features, warranty, and support. Choose the supplier that provides the best combination of these factors for your specific requirements.

By carefully evaluating each quotation against these criteria and making an informed decision, you can select the best supplier and bucket grab for your needs, ensuring optimal performance and value for your investment.

Conclusion

In summary, obtaining a detailed quotation for a bucket grab for an overhead crane involves several crucial steps:- Prepare a Detailed RFQ: Clearly define the technical specifications, operational requirements, and any additional features or customizations you need. This ensures suppliers provide accurate and relevant quotations.

- Submit the RFQ to Multiple Suppliers: Utilize targeted keywords like grab crane for sale and bucket grab for sale to identify potential suppliers. Reach out to them with your RFQ and follow up to ensure your request is processed.

- Evaluate Quotations: Assess the responses based on price, delivery time, warranty, and technical compliance. Compare these factors to determine the best fit for your needs.

- Make an Informed Decision: Balance cost with quality, consider supplier reputation, and review the total value offered. Make your decision based on a combination of these factors to ensure the best outcome for your project.

- Thorough Research: Conduct comprehensive research on potential suppliers and products. This includes reviewing their reputation, product quality, and customer feedback to ensure reliability.

- Clear Communication: Maintain clear and detailed communication with suppliers throughout the process. This helps avoid misunderstandings and ensures that all your requirements are accurately addressed.

- Ongoing Relationship: Establishing a good relationship with suppliers can be beneficial for future needs. Keep open lines of communication for any future inquiries or additional requirements that may arise.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch