Compact Space Underhung Telescoping Bridge Cranes Benefits for You

Underhung telescoping bridge crane for sale. Benefits of underhung telescoping bridge cranes, compact design & space-saving, hot sale 500kg, 1 ton, 2 ton.

| Crane type | Telescoping bridge underhung overhead crane |

| Features | Low headroom, with low profiile chain hoist & rope hoist |

| Crane capacity | 500kg, 1 ton, 2 ton |

| Lifting height | As customer requirement |

| Crane Span | As customer requirement |

Category: Telescoping Overhead Crane

Your Trusted Telescoping Bridge Crane Manufacturer & Supplier

Compact Space Underhung Telescoping Bridge Cranes 0.5 T, 1 T, 2 T

Telescoping Bridge Underhung Overhead Crane for Sale, Compact Design & Space-Saving

Underhung telescoping bridge crane for sale. Benefits of underhung telescoping bridge cranes, compact design & space-saving, hot sale 500kg, 1 ton, 2 ton.

In the realm of industrial operations, the pursuit of efficiency is unceasing. Every inch of available floor space holds value, each moment of production time is precious, and the orchestration of material movement must be finely tuned for optimal results. Enter underhung telescoping bridge cranes, a formidable answer to the enduring challenge of making the most of limited space.

The effective handling of materials stands at the heart of industrial endeavors, whether within a manufacturing facility, a workshop, or a storage warehouse. With space often in short supply, the demand for equipment that maximizes every square foot is a pressing reality. Underhung telescoping bridge cranes, distinguished by their streamlined and space-efficient design, are poised to rise to this challenge. In this exploration, we embark on a journey to unravel the unique advantages of underhung telescoping bridge cranes, shedding light on their contributions to compact design and space-saving capabilities that are reshaping the landscape of material handling across various industries. From small-scale manufacturing operations to confined warehouses, the quest for compact efficiency commences here.

Underhung Telescoping Bridge Cranes: A Closer Look

Underhung telescoping bridge cranes are a specialized breed of lifting equipment, designed to fulfill a precise set of requirements. They are characterized by a compact, sleek design that hangs from the facility's overhead structure, making them an ideal choice for situations where floor space is limited. Unlike traditional floor-mounted cranes, underhung cranes free up valuable ground space, allowing for more efficient use of the available area.

When it comes to optimizing material handling and space utilization in industrial settings, it's essential to understand the mechanics and features of underhung telescoping bridge cranes. These innovative systems offer a unique approach to efficient material transport. Let's take a closer look at what underhung telescoping bridge cranes are, their core design attributes, and their primary function in material handling while making the most of available space.

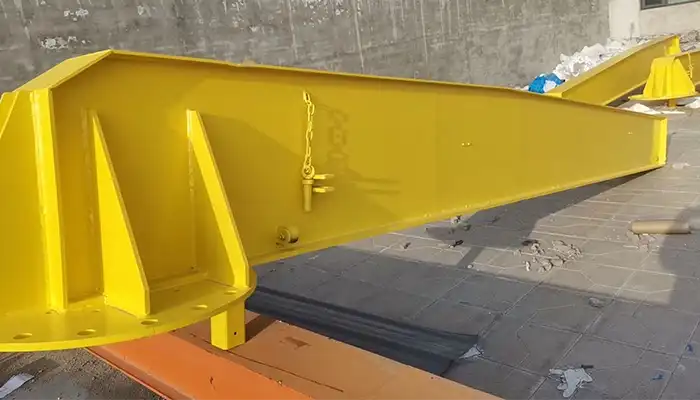

Telescoping bridge under running overhead crane for high building use for material handling

Ceiling mounted overhead bridge crane with telescoping bridge crane and electric chain hoist

Underhung bridge crane with telescoping cantilever for material handling accross doors, columns and other obstacles efficiently.

Key Design Features

- Telescoping Mechanism: The defining feature of these cranes is their telescoping mechanism. This feature enables the extension and retraction of the crane's horizontal beam, offering unparalleled flexibility in reaching various points within the workspace. The ability to extend and retract the crane's reach allows for precise material positioning.

- Suspended from Overhead Structure: Underhung cranes are attached to the overhead structure of the facility, often utilizing existing building support systems. This configuration eliminates the need for floor-level support structures, creating an uncluttered and spacious work environment.

- Compact and Lightweight Design: These cranes are designed with a focus on compactness and minimal weight. This ensures that they have a minimal impact on the available space and do not place unnecessary strain on the facility's structure.

Primary Function in Material Handling

Underhung telescoping bridge cranes are purpose-built to facilitate material handling in a way that optimizes space utilization. Their primary functions include:

- Material Transport: These cranes excel at moving materials from one point to another with precision. The telescoping feature allows for the extension and retraction of the crane, enabling the accurate placement of materials.

- Workspace Optimization: By being suspended from the overhead structure, underhung cranes maximize the workspace available on the floor. This is particularly valuable in scenarios where floor space is limited or where open areas are needed for other operations.

- Efficient Load Positioning: The telescoping mechanism enhances load positioning accuracy. This is crucial for tasks that demand a high degree of precision, such as manufacturing processes and assembly lines.

In essence, underhung telescoping bridge cranes are tailored for a compact and efficient approach to material handling. Their design and features make them a go-to choice for industries that seek to make the most of their available space while ensuring precise and efficient material transport.

The Challenge of Limited Space

Industrial facilities are often grappling with a challenge that profoundly affects their productivity and operational efficiency: limited space. The importance of space cannot be overstated in the industrial world, as it directly impacts the flow of work, accessibility, and overall productivity. In this section, we will delve into the challenge posed by limited space in industrial settings and explore how compact design solutions, such as underhung telescoping cranes, offer a remedy to this persistent challenge.

The Limited Space Predicament

Industrial spaces are diverse and encompass various sectors, including manufacturing plants, workshops, warehouses, and more. Regardless of the specific industry, one commonality prevails: the struggle to make the most of available space. This challenge manifests in several ways:

- Congestion: Limited space often leads to congestion, with machinery, equipment, and workstations occupying every available nook and cranny. The resulting crowded environment hampers the smooth flow of materials and personnel, which can lead to bottlenecks in production processes.

- Inefficient Material Flow: In a space-starved environment, the movement of materials becomes less efficient. Material handling equipment and personnel may have to navigate through narrow pathways, increasing the risk of accidents and slowing down operations.

- Storage Dilemmas: Limited space impacts storage capabilities. Finding room for raw materials, work-in-progress, and finished products can be a logistical puzzle. Overcrowded storage areas can lead to disorganization and difficulties in locating specific items.

- Workspace Constraints: Workspaces, including assembly lines, machining areas, and quality control stations, are often restricted by the available square footage. This can hinder the optimization of workflow and reduce the overall efficiency of operations.

Compact Design Solutions

Compact design solutions come to the rescue in this challenging scenario. Underhung telescoping cranes, with their streamlined and overhead-mounted design, offer a clear advantage in addressing the limited space dilemma. Here's how they tackle the problem:

- Floor Space Liberation: Underhung cranes free up precious floor space. Unlike floor-mounted counterparts that require substantial ground-level support structures, underhung cranes are suspended from the overhead structure. This configuration eliminates the need for floor-level support systems and paves the way for a more open, less cluttered workspace.

- Improved Material Flow: With more open floor space, the movement of materials and equipment becomes smoother. Underhung telescoping cranes enable unobstructed material flow and provide a safe and efficient means of transporting items from one point to another.

- Enhanced Storage Efficiency: Underhung cranes contribute to improved storage efficiency. Their overhead design allows materials to be stored at greater heights, maximizing vertical space and reducing the footprint required for storage.

- Optimized Workspaces: Compact crane design solutions, including underhung telescoping cranes, optimize workspaces. They facilitate the efficient layout of workstations and assembly lines, ensuring that operations can be organized for maximum efficiency.

In essence, the challenge of limited space is a pervasive issue in industrial facilities. The introduction of compact design solutions, such as underhung telescoping cranes, is a strategic response to this challenge. These cranes liberate floor space, streamline material flow, enhance storage efficiency, and optimize workspaces, contributing to improved productivity and overall operational efficiency.

Unique Benefits of Underhung Telescoping Cranes

Underhung telescoping cranes stand as a testament to innovative engineering in the realm of material handling. Their unique design and features provide a range of distinct advantages that go a long way in addressing the challenge of limited space. In this section, we will delve into the exceptional benefits these cranes offer, emphasizing their space-saving capabilities and their ability to optimize workspace and ensure precise load positioning.

Space-Saving Advantages

- Maximized Floor Space: The most prominent advantage of underhung telescoping cranes is their ability to free up precious floor space. Traditional floor-mounted cranes require substantial support structures at ground level, which can impede material flow and consume workspace. In contrast, underhung cranes are suspended from the overhead structure, eliminating the need for floor-level support systems. This design liberates floor space, creating a more open and efficient work environment.

- Compact and Lightweight: Underhung cranes are designed with a focus on compactness and minimal weight. This not only reduces the impact on the facility's structure but also ensures that they can be installed in locations where heavy-duty floor-mounted cranes might not be viable.

Efficient Material Handling

- Precise Load Positioning: Underhung telescoping cranes are engineered to provide precise load positioning. The telescoping mechanism allows for the extension and retraction of the horizontal beam, enabling materials to be placed with accuracy. This feature is invaluable in applications where precision is paramount, such as manufacturing processes and assembly lines.

- Maximized Vertical Space: These cranes make full use of available vertical space. By being suspended from the overhead structure, they can reach greater heights, allowing for the storage of materials and equipment in elevated positions. This not only maximizes storage capacity but also ensures that items can be easily accessed.

- Streamlined Material Flow: Underhung cranes facilitate streamlined material flow within the workspace. Their overhead configuration ensures unobstructed pathways for materials and equipment, reducing the risk of congestion and bottlenecks in production processes.

The unique benefits of underhung telescoping cranes go beyond efficient material handling; they directly address the pressing issue of limited space in industrial facilities. By maximizing floor space, providing precise load positioning, and optimizing vertical storage, these cranes offer a comprehensive solution that enhances workspace efficiency and operational productivity. Whether it's a compact workshop, a manufacturing plant, or a bustling warehouse, underhung telescoping cranes prove to be an invaluable asset in the quest for space-saving material handling solutions.

Application

To fully appreciate the advantages of underhung telescoping cranes, it's essential to explore their real-world applications and the industries where they excel. These cranes find their niche in a variety of settings, offering tailored solutions to industries facing the challenges of limited space. Let's dive into some application scenarios where underhung telescoping cranes prove their worth.

Small Manufacturing Facilities

In small manufacturing facilities, floor space is often at a premium. These facilities need efficient material handling solutions that can maximize the available workspace. Underhung telescoping cranes are ideally suited for such environments. They can be strategically placed to provide precise material positioning without eating into the limited floor area. This ensures that production processes can continue smoothly, and materials can be handled with precision.

Workshops

Workshops, whether they focus on metal fabrication, woodworking, or other crafts, require the flexibility to move heavy materials and equipment in tight spaces. Underhung telescoping cranes come to the rescue by allowing for compact and efficient material handling. Their ability to reach greater heights ensures that workshops can make use of vertical space for storage and workspace optimization, all while maintaining a clutter-free floor.

Compact Warehouses

Compact warehouses and storage facilities are often faced with the challenge of storing a vast array of products and materials in limited space. Underhung telescoping cranes are a game-changer in these scenarios. They can assist in the efficient stacking of goods, ensuring that vertical space is utilized to its fullest potential. Additionally, their precise load positioning capabilities are invaluable for retrieving items from high shelves without the need for specialized equipment.

Auto Repair Shops

Auto repair shops are bustling hubs of activity where the efficient movement of vehicle parts and equipment is crucial. Underhung telescoping cranes provide an ideal solution for these settings. They can be used to position engines, transmissions, and other heavy components with precision. By hanging from the overhead structure, they don't interfere with the repair bays, allowing mechanics to work unencumbered.

Retail Backrooms

In the backrooms of retail stores, inventory management and restocking require efficient material handling. Underhung telescoping cranes offer a practical solution to move boxes, merchandise, and supplies in compact spaces. The ability to reach high storage areas ensures that vertical space is effectively utilized for storage.

These application scenarios represent just a glimpse of where underhung telescoping cranes shine. Their adaptability to limited space environments makes them a valuable asset across a diverse range of industries. Whether in manufacturing, repair, warehousing, or even retail, these cranes play a pivotal role in optimizing material handling and enhancing operational efficiency in constrained workspaces.

Space Optimization and Workflow Efficiency

The magic of underhung telescoping cranes lies not only in their compact design but also in their remarkable ability to optimize space utilization and enhance workflow efficiency. In this section, we will explore how these cranes contribute to the art of streamlined operations and improved productivity within confined spaces.

Space Utilization Mastery

- Maximizing Floor Space: Underhung telescoping cranes are champions of floor space maximization. By suspending from the overhead structure, they eliminate the need for ground-level support systems that often consume valuable square footage. The result is a more open, uncluttered workspace, which, in turn, creates room for additional workstations, storage, or equipment.

- Vertical Storage Optimization: Underhung cranes empower businesses to make the most of vertical space. Their telescoping mechanism allows materials and products to be stored at greater heights, efficiently utilizing the often-underused overhead space. This is a game-changer in environments where horizontal space is limited.

Workflow Efficiency Enhancement

- Unobstructed Material Flow: The overhead configuration of underhung telescoping cranes ensures unobstructed material flow within the workspace. This translates into smoother operations, as materials and equipment can be easily transported from one location to another without navigating through tight corridors or overcrowded floor areas.

- Reduced Congestion: Reduced congestion is a key benefit of these cranes. In scenarios where multiple tasks are being performed in a limited space, the risk of congestion is high. Underhung telescoping cranes play a pivotal role in decluttering the workspace, reducing the chances of bottlenecks, and creating an environment where activities can proceed seamlessly.

Improved Productivity in Tight Spaces

- Optimized Workstations: With more available floor space and the efficient use of vertical storage, workstations can be thoughtfully laid out. This optimization leads to a significant improvement in workflow efficiency, as tasks can be performed with minimal disruptions and delays.

- Quick Load Positioning: The precise load positioning capabilities of underhung telescoping cranes have a direct impact on productivity. In manufacturing processes, assembly lines, and repair shops, the ability to quickly and accurately place materials or components enhances overall efficiency.

- Minimized Downtime: The streamlined operations and reduced congestion created by these cranes contribute to minimized downtime. Fewer interruptions mean more time dedicated to productive tasks, resulting in increased output and improved productivity.

Underhung telescoping cranes are not just about lifting and moving materials; they are about creating a workspace where each inch of floor space is optimized, and every operational process is streamlined. In tight spaces, their unique combination of compact design, vertical storage optimization, and unobstructed material flow is a catalyst for improved productivity and workflow efficiency, leading to more efficient and profitable operations.

Safety and Compliance

The commitment to safety is paramount in any industrial setting, and the use of underhung telescoping cranes is no exception. In this section, we will explore the safety features and compliance considerations associated with these cranes, emphasizing their role in fostering a safe and regulated working environment.

Safety Features

- Load Capacity Monitoring: Underhung telescoping cranes are equipped with load capacity monitoring systems. These systems provide real-time information about the weight being lifted, ensuring that the crane operates within safe limits. If the load exceeds the crane's capacity, alarms are triggered to alert operators.

- Emergency Stop Functionality: Emergency stop buttons are strategically placed within easy reach of crane operators. In case of any unforeseen circumstances or safety concerns, the crane can be swiftly halted, preventing accidents or damage.

- Overhead Obstruction Sensors: To enhance safety, these cranes often come with overhead obstruction sensors. These sensors detect any potential obstructions or obstacles in the crane's path and automatically stop or reverse the crane to prevent collisions.

Compliance Considerations

- Regulatory Compliance: Underhung telescoping cranes must adhere to regulatory standards and guidelines. Compliance ensures that the crane's design and operation meet safety requirements set by relevant authorities.

- Operator Training and Certification: Proper operator training and certification are essential for the safe operation of underhung telescoping cranes. Operators must be well-versed in the crane's controls, load capacities, and safety protocols.

- Regular Inspections and Maintenance: Routine inspections and maintenance are crucial to ensure that the crane operates safely and efficiently. These checks include structural assessments, load testing, and component examinations. Any issues are addressed promptly to prevent accidents.

Contributions to a Safe Working Environment

Underhung telescoping cranes play a significant role in fostering a safe working environment in the following ways:

- Reduced Risk of Accidents: Their compact and overhead design minimizes the risk of accidents caused by ground-level obstructions. The absence of floor-level support structures means fewer obstacles that personnel and equipment can collide with.

- Enhanced Operator Visibility: Operators of underhung cranes benefit from an unobstructed view of the workspace. This increased visibility helps operators avoid potential hazards and make precise load placements.

- Efficient Load Positioning: The ability to position loads with precision reduces the risk of damage to materials, products, or equipment. This not only enhances safety but also protects valuable assets.

In essence, safety is an inherent aspect of underhung telescoping cranes. Their safety features, regulatory compliance, and contributions to a safe working environment make them a trusted choice for material handling in confined spaces. By prioritizing the well-being of workers and the protection of assets, these cranes ensure that operations can proceed with confidence and adherence to established safety standards.

Customization Options

One of the standout features of underhung telescoping cranes is their versatility when it comes to customization. In this section, we will explore the numerous ways in which these cranes can be tailored to meet specific material handling needs in compact spaces. We will also delve into the additional features and accessories that can be integrated to enhance their functionality.

Tailoring to Specific Needs

- Load Capacity: Underhung telescoping cranes can be configured to accommodate a wide range of load capacities. Whether you need to move light materials or heavy machinery, these cranes can be adjusted to match your requirements.

- Span Length: The span length, or the distance between the runways, can be customized to fit the dimensions of the workspace. This ensures that the crane effectively covers the required area.

- Telescoping Mechanism: The telescoping mechanism itself can be tailored to extend to the desired length. This customization enables precise load positioning at various heights.

Additional Features and Accessories

- Remote Control Systems: Remote control systems can be integrated, allowing operators to control the crane from a safe and optimal vantage point. This enhances visibility and safety during material handling.

- Load Handling Accessories: A variety of load handling accessories can be added to the crane, including specialized hooks, slings, and attachments designed to secure and lift specific types of materials or equipment.

- Automation and Smart Technologies: Underhung telescoping cranes can be equipped with automation and smart technologies that enhance their functionality. This includes features like load sensing, automated path planning, and remote monitoring.

- Enhanced Safety Systems: Safety can be further bolstered with the integration of enhanced safety systems such as anti-collision sensors, light indicators, and audible alarms that alert operators to potential hazards.

Customization options allow businesses to tailor underhung telescoping cranes to their exact material handling needs in compact spaces. Whether it's adjusting load capacities, span lengths, or integrating advanced features, these cranes can be fine-tuned to optimize workflow efficiency and operational performance. Additionally, the availability of load handling

Conclusion

In the bustling world of industrial material handling, where space is often a premium commodity, underhung telescoping bridge cranes emerge as the unsung heroes of efficiency. As we draw this exploration to a close, it's time to reflect on the multitude of benefits these cranes bring to compact industrial settings and how they transform challenges into opportunities.

Underhung telescoping bridge cranes redefine the spatial landscape. By suspending from overhead structures and eliminating the need for ground-level support systems, they maximize floor space and provide a clear canvas for efficient operations. Their telescoping design takes full advantage of vertical storage, offering a solution to the age-old problem of space constraints.

These cranes don't just optimize space; they enhance workflow efficiency and safety. Precise load positioning, unobstructed material flow, and reduced congestion are key contributors to streamlined operations. With the ability to quickly and accurately handle materials, they minimize downtime and improve overall productivity.

Safety is a non-negotiable aspect of underhung telescoping bridge cranes. Load capacity monitoring, emergency stop functionality, and overhead obstruction sensors ensure a secure working environment. Compliance with regulatory standards, operator training, and routine maintenance add layers of protection.

In conclusion, underhung telescoping bridge cranes are more than machines; they are solutions that enable businesses to thrive in compact spaces. They empower industries to make the most of their workspace, ensuring every inch is utilized efficiently and safely. Whether in small manufacturing facilities, workshops, compact warehouses, or other constrained settings, these cranes are a testament to ingenuity and adaptability. They exemplify the art of turning limitations into strengths, making the impossible possible, and elevating compact efficiency to new heights.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch