Clamshell Grab Bucket Overhead Crane 5 Ton for Sale Saudi Arabia

5-ton Clamshell Grab Bucket Overhead Crane for efficient coal handling, ideal for harsh Saudi Arabia coal plant environments.

Category: 5 Ton Overhead Crane

Your Trusted Grab Bucket Overhead Crane Manufacturer & Supplier

Clamshell Grab Bucket Overhead Crane 5 Ton for Sale in Saudi Arabia

This case study examines the QZ 5-Ton Grab Bucket Overhead Crane used in coal plants in Saudi Arabia. Specifically built for handling bulk materials, the crane features a four-rope grab bucket, which is a critical component for managing large quantities of coal and other bulk materials effectively.

- Crane Type: QZ 5-Ton Grab Bucket Overhead Crane

- Key Component: Four-rope grab bucket designed for efficient bulk material handling

- Industry Focus: Coal plants in Saudi Arabia

The purpose of this case study is to evaluate the QZ 5-Ton Grab Bucket Overhead Crane's role in enhancing operational efficiency within coal plants. We will explore the crane's specifications, the benefits of its design, and how it plays a significant part in improving productivity and minimizing downtime in material handling processes.

Focus Areas:

- Crane specifications and design features

- The crane's role in boosting operational efficiency

- Impact on reducing downtime and improving productivity

- Suitability for the harsh operating conditions of coal plants

Project Location

The QZ 5-Ton Grab Bucket Overhead Crane is stationed in Saudi Arabia, a country with a growing coal industry. Efficient material handling in coal plants is crucial, particularly given the extreme operational challenges such as high dust levels and high temperatures.

- Location: Saudi Arabia

- Key Challenge: Managing bulk materials in a harsh environment characterized by dust, extreme heat, and heavy loads

Industry Application

In the coal industry, bulk material handling is essential for maintaining smooth and efficient operations. The QZ 5-Ton Grab Bucket Overhead Crane is specifically designed to meet these needs by offering high lifting capacity, reliable performance, and precision material handling.

- Primary Application: Bulk material handling in coal plants

- Benefits for Coal Industry:Efficient, reliable, and safe handling of bulk coalIncreased productivity in loading, unloading, and transporting materials

- Environmental Considerations: The crane is built to withstand the challenging working conditions of coal plants, including high temperatures and dust exposure, ensuring its durability and long-term reliability.

Crane Specifications

- Model: QZ 5-Ton Grab Bucket Overhead Crane

- Lifting Capacity: 5 tons

- Span: 6 meters

- Trolley Rail Gauge: 2 meters

- Lifting Height: 14 meters

- Lifting Speed: 1.5/15 m/min

- Traveling Speed: 2.0~20 m/min

- Working Duty: M7 (Heavy-duty, continuous operation)

- Trolley Rail: P18

- Crane Rail: P43

- Power Supply: 3-phase, 380V, 50Hz

- Control Mode: Cabin control

- Grab Type: Four-rope grab bucket, 1.2 m³ capacity

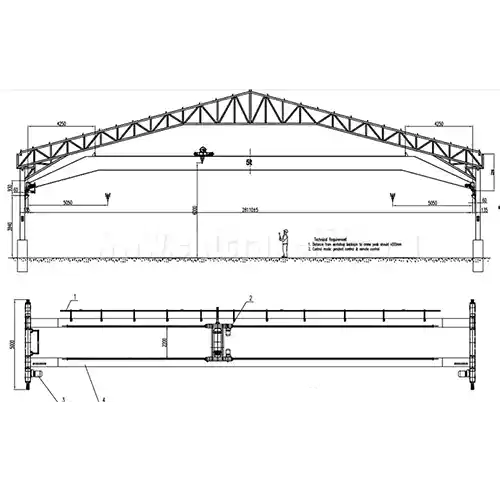

5 ton grab bucket eot crane for sale Saudi Arabia, document picture for your reference

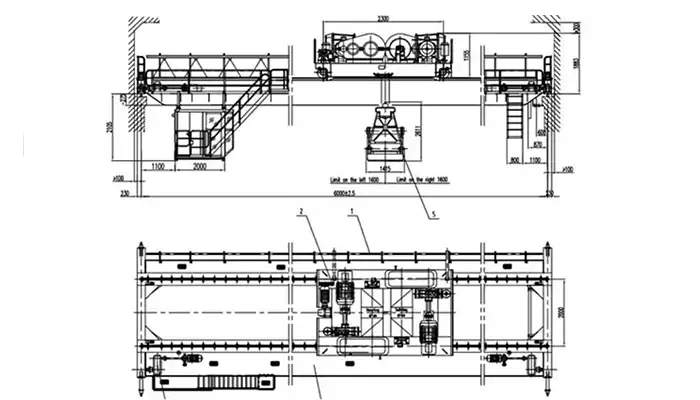

Grab bucket overhead crane 5 ton drawing desigend for client's project in Saudi Arabia

Crane Design Features

Double Girder Configuration

Stability and Strength: The double girder configuration ensures excellent stability and strength for the crane. It enhances the crane's lifting capacity and provides efficient load distribution, which is essential when handling heavy loads like coal. The design minimizes deflection, ensuring the crane operates with high precision and safety.

Heavy-Duty Operations: Built to withstand the high demands of continuous operations, the double girder design is perfect for the heavy-duty nature of coal handling. It supports constant lifting and material transport, making it ideal for use in coal plants, where operational reliability is key.

Key Benefits:

- Increased lifting capacity (5 tons)

- Better load distribution for improved stability

- Minimal deflection for precise lifting

- Built for continuous heavy-duty operations in coal plants

Four-Rope Grab Bucket

Precision Grabbing: The crane features a 1.2m³ four-rope grab bucket, designed to efficiently handle bulk materials like coal. The grab bucket is equipped with precision-engineered tines that penetrate and securely grip materials, ensuring safe and efficient lifting with minimal material loss.

Self-Closing Mechanism: To enhance operational efficiency, the grab bucket includes a self-closing mechanism. This feature allows for quick and reliable material capture without the need for manual intervention, reducing labor costs and improving workflow speed.

Key Features:

- 1.2m³ capacity for efficient bulk handling

- Precision tines for secure and efficient material gripping

- Self-closing mechanism for fast material capture

- Reduced manual labor and faster operation

- Enhanced safety and reduced human error in material handling

Operational Performance

Lifting and Traveling Speeds

Lifting Speed: The QZ 5-Ton Grab Bucket Overhead Crane offers adjustable lifting speeds, providing flexibility for different material handling needs. The slower speed of 1.5 m/min is ideal for precise lifts, allowing for careful positioning of bulk materials. Conversely, the faster speed of 15 m/min allows for efficient, rapid lifting, improving overall throughput when handling large quantities of coal or other materials.

Traveling Speed: With a traveling speed range of 2.0 to 20 m/min, the crane can move materials swiftly across the plant, which is essential for maintaining a smooth and efficient workflow. The variable speed capability ensures that the crane can adjust to the operational needs of the plant, from slow, controlled movements to quick transport over longer distances.

Benefits:

- Lifting Speed (1.5/15 m/min) for flexibility in material handling

- Traveling Speed (2.0~20 m/min) for efficient material transport across the plant

- Enhanced workflow and reduced downtime with optimized speed ranges

Working Duty (M7)

Heavy-Duty Operations: The crane is rated with an M7 working duty, which indicates that it is built for high-cycle, continuous operations. This classification is particularly suited for the coal plant environment, where heavy-duty material handling is required throughout the day. The M7 rating ensures that the crane can endure high operational demands, such as frequent lifting and moving of coal, while maintaining consistent performance and reliability.

M7 Classification Benefits:

- Designed for continuous, heavy-duty operations

- High-cycle capacity for demanding environments like coal plants

- Durable performance under constant use and high workload

- Minimal downtime and long service life in high-demand operations

main girder

travelling open winch trolley for your reference

main parts and components for delivery to Saudi Arabia

Clamshell grab bucekt for 5 ton overhead crane for delivery to Saudi Arabia

Main parts and components of 5 ton grab bucket crane

Truck loaded for delivery to Saudi Arabia

Grab bucket overhead crane for delivery to Saudi Arabia

Advantages for Coal Plant Applications

Heavy-Duty Load Handling

The 5-ton lifting capacity of the crane, combined with its robust double girder design, makes it perfectly suited for the demanding environment of coal plants. The crane is built to handle heavy, bulk materials consistently, ensuring smooth operations even under high-load conditions.

Benefits:

- 5-ton capacity to manage heavy loads of coal

- Sturdy construction for continuous use in challenging environments

- Reliable performance during high-demand operations in coal plants

Bulk Material Handling

The crane's four-rope grab bucket with a 1.2m³ capacity is designed for the efficient handling of bulk materials such as coal. The precision-engineered tines ensure secure material grip, making the crane ideal for loading, unloading, and transporting coal within the plant. This feature greatly improves the efficiency of material handling, reducing manual labor and the risk of material spillage.

Key Features:

- 1.2m³ grab bucket for efficient bulk material handling

- Secure and precise material gripping for safe and reliable lifting

- Improved material transport within the plant, reducing operational delays

Enhanced Productivity

The crane's adjustable lifting and traveling speeds contribute to enhanced operational efficiency. The ability to switch between slow, precise lifts and fast lifting speeds allows operators to handle materials more effectively. Additionally, the high traveling speeds ensure that coal is transported quickly across the plant, minimizing downtime and allowing for faster material processing.

Efficiency Gains:

- Reduced downtime due to optimized lifting and traveling speeds

- Faster material processing with quick transport across the plant

- Increased throughput in coal handling and transportation

- Improved workflow efficiency throughout plant operations

Safety Features and Control

Cabin Control

Superior Visibility and Precision: The cabin control system provides the crane operator with an elevated and clear view of the entire work area, enabling precise and controlled operations. This enhanced visibility is crucial for ensuring safe handling of bulk materials, especially in high-demand environments like coal plants where spatial awareness is key. The operator can easily monitor the crane's movements and adjust accordingly, reducing the risk of errors during lifting and material transport.

Improved Operational Safety: With the cabin control system, the operator has full control over crane movements, ensuring that each lift and transport action is performed with high precision. This results in safer operations, minimizing the likelihood of accidents, particularly in confined or crowded areas.

Key Benefits:

- Enhanced operator visibility for safer operations

- Precise control over crane movements

- Reduced risk of operational errors in busy environments

Safety Mechanisms

Overload Protection: The crane is equipped with overload protection systems to prevent the lifting of loads beyond its rated capacity. This ensures that the crane operates within its safe limits, preventing damage to both the crane and the materials being handled.

Emergency Stop System: In the event of an emergency, the crane is fitted with a quick-response emergency stop function that immediately halts all operations, ensuring the safety of personnel and equipment. This safety feature is critical in preventing accidents during unexpected situations.

Anti-Collision System: The crane also features an anti-collision system designed to prevent the crane from making contact with obstacles or other equipment in the area. This system ensures smooth and safe movement, even in congested work environments, such as coal plants.

Key Safety Features:

- Overload protection to prevent overloading and damage

- Emergency stop system for immediate halting of operations in emergencies

- Anti-collision system for safe movement and obstacle avoidance

Reliability

Designed for Harsh Environments: The QZ 5-Ton Grab Bucket Overhead Crane is built to withstand the harsh and demanding environment of coal plants. It is designed to endure exposure to dust, high temperatures, and heavy usage. The crane's reliable performance under these conditions ensures minimal downtime and continued material handling efficiency.

Consistent Operation: With its heavy-duty M7 classification and robust construction, the crane provides long-term reliability, ensuring that operations run smoothly with minimal maintenance. This contributes to a steady material handling process, allowing for uninterrupted productivity in coal plants.

Reliability Features:

- Built for harsh industrial environments like coal plants

- Heavy-duty design for long-lasting performance

- Minimal downtime for continuous material handling

Energy Efficiency and Maintenance

Power Supply and Energy Use

Stable Power Supply: The crane operates on a 3-phase, 380V, 50Hz power supply, ensuring reliable and consistent energy use in coal plant operations. This power configuration provides stable performance, even under heavy load conditions, which is essential for maintaining operational efficiency in demanding environments.

Energy Efficiency: Designed with energy-efficient components, the crane minimizes energy consumption during operation. This contributes to lower operational costs and enhances the overall energy efficiency of the plant, making it a cost-effective solution for continuous material handling. By optimizing energy use, the crane also supports sustainable operational practices.

Key Benefits:

- Stable power supply for consistent performance

- Energy-efficient design to reduce operational costs

- Lower energy consumption for more sustainable operations

Low Maintenance Requirements

- Durability and Reliability: The QZ 5-Ton Grab Bucket Overhead Crane is constructed with high-quality materials and durable components that are designed to withstand the rigorous demands of coal plant operations. This reduces the frequency of repairs and ensures that the crane continues to operate at peak performance for extended periods.

- Minimal Maintenance: With its robust construction and engineered components, the crane requires minimal maintenance. Regular checks and maintenance intervals are sufficient to keep the crane running smoothly, lowering overall maintenance costs and reducing the risk of unplanned downtime.

Key Features:

- Durable construction with high-quality components

- Minimal maintenance requirements for long-term reliability

- Reduced maintenance costs through efficient design

Environmental Impact and Durability

Durability in Harsh Environments

- Built for Tough Conditions: The crane is designed to handle the harsh working conditions found in coal plants, where dust, high temperatures, and constant heavy use are common. Its heavy-duty construction ensures that it can withstand these extreme environments without compromising on performance or safety.

- Continuous Operation: The crane's durability ensures continuous operation in coal plants, even in challenging conditions, making it a reliable asset for long-term material handling tasks. This reduces the risk of downtime and ensures efficient workflow management.

Key Advantages:

- Built to endure harsh industrial environments like coal plants

- Continuous operation in tough conditions without performance loss

- Long-term durability for reliable material handling

Corrosion Protection

Anti-Corrosion Coatings: Given the abrasive nature of coal dust and moisture exposure in coal plants, the crane is equipped with corrosion-resistant coatings. These coatings protect the crane from wear and tear caused by prolonged exposure to dust, moisture, and chemicals, ensuring long-term performance and reducing maintenance needs.

Long-Term Protection: The crane's corrosion protection extends its service life, even in the harshest environments. The added protection allows for sustained performance, reducing the need for costly repairs or part replacements and ensuring the crane operates efficiently for years.

Key Features:

- Corrosion-resistant coatings for long-lasting protection

- Extended service life despite challenging working conditions

- Reduced maintenance costs and improved crane longevity

Conclusion

The QZ 5-Ton Grab Bucket Overhead Crane provides a powerful and efficient solution for bulk material handling in coal plants. Its combination of a four-rope grab bucket and heavy-duty double girder design ensures optimal performance, even in the most challenging industrial environments. The crane's design delivers enhanced stability, allowing for precise and reliable lifting and transporting of bulk materials such as coal. With a 5-ton lifting capacity and high-performance features, this crane is well-suited for continuous operations in coal plants, offering minimal downtime and maximum productivity.

Key Advantages:

- Heavy-duty double girder design for enhanced stability

- Four-rope grab bucket for efficient material handling

- Optimized for harsh coal plant conditions with minimal maintenance requirements

- Energy-efficient operation, reducing operational costs

Recommendation

Given the robust performance and energy efficiency of the QZ 5-Ton Grab Bucket Overhead Crane, it is highly recommended for coal plants seeking to improve material handling efficiency. The crane's reliable design, high lifting capacity, and advanced safety features make it a valuable investment for any coal plant aiming to increase productivity, reduce operational costs, and maintain safe, efficient operations.

Key Recommendations:

- Ideal for coal plants looking to improve material handling operations

- Reduces downtime with minimal maintenance

- Enhances safety and productivity with advanced control and safety mechanisms

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch