5 Ton Overhead Crane for Saudi Arabia, Custom Eot Crane Runway

5 ton top running crane, custom bridge crane with floor mounted & ceiling mounted crane runway structure design. Design single girder eot crane 5 ton now!

Category: 5 Ton Overhead Crane

Your Trusted 5 Ton Overhead Crane Manufacturer & Supplier

5 Ton Overhead Crane for Saudi Arabia, Custom Eot Crane Runway

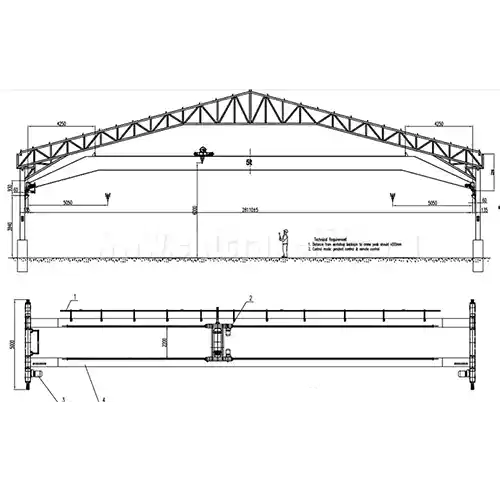

Top Running Crane 5 Ton, Custom Bridge Crane with Floor Mounted & Ceiling Mounted Crane Runway Structure Design

5 ton top running crane, custom bridge crane with floor mounted & ceiling mounted crane runway structure design. Design single girder eot crane 5 ton now!

Custom Overhead Crane 5 Ton with Custom Runway in Saudi Arabia

Custom Overhead Crane 5 Ton is one of the most frequently used material handling solution for special application environment. In the field of manufacturing and material handling, the selection of the right overhead crane is pivotal for seamless operations and heightened efficiency. In this case study, we look into the intricacies of a 5-ton capacity crane customized for a specific project location in Saudi Arabia.

In industrial operations, the choice of an overhead crane isn't merely about lifting weights; it's a strategic decision that directly impacts productivity, safety, and the overall workflow. The Custom Overhead Crane 5 Ton project is a testament to the importance of tailoring machinery to fit the unique demands of a workspace, ensuring optimal performance and resource utilization.

The project's geographical context is noteworthy – Saudi Arabia, a country experiencing rapid industrial expansion. As industries develop and diversify, the demand for specialized equipment becomes more important. The Custom Overhead Crane is a response to the specific needs of the Saudi Arabian industrial sector, aiming to provide a solution that goes beyond conventional offerings.

This case study serves as a comprehensive guide for potential buyers and users seeking to invest in a 5000kg overhead bridge crane. By scrutinizing the specifications, customization features, technical aspects, and real-world applications of the Custom Overhead Crane, readers can make informed decisions tailored to their unique operational requirements. We aim to bridge the gap between the technical aspects of the crane and the practical considerations of the buyer, ensuring a seamless integration into their industrial processes.

Project Overview

Project Location: Saudi Arabia

Saudi Arabia stands as a beacon of industrial growth and economic development. With a burgeoning manufacturing sector and an increasing demand for tailored solutions, our Custom Overhead Crane 5 Ton finds its home in this dynamic landscape.

The specific project site, carefully chosen within Saudi Arabia, is emblematic of the country's commitment to innovation and efficiency in material handling. As we navigate through the project's complexity , the location becomes more than just a geographical point; it becomes a testament to Saudi Arabia's ambition to lead the charge in industrial advancements.

Significance in the Industrial Context

The core of this project lies a profound significance in the typical industrial context.The Custom Overhead Crane 5 Ton project is not merely an addition to a facility; it represents a strategic investment in modernizing and optimizing material handling processes. It symbolizes the commitment to staying ahead in a competitive market by embracing cutting-edge solutions tailored to the unique demands of the Saudi Arabian industrial landscape.

The Need for a Custom Overhead Crane with a 5-ton Capacity

Why a 5-ton capacity crane? This question is central to understanding the rationale behind the project. In the field of manufacturing, loads vary widely in size and weight. The 5-ton capacity strikes a delicate balance – robust enough to handle substantial loads while remaining agile and versatile in various industrial applications.

Standard overhead cranes may fall short in meeting specific requirements, leading to operational inefficiencies and potential safety concerns. Thus, the demand for a Custom Overhead Crane that not only matches the load capacity needs but also addresses the unique challenges posed by the operational environment.

Let's chek the specifications of 5 ton single girder overhead cranes for Saudi Arabia, customization features, and technical considerations , the necessity for a tailored solution becomes increasingly evident.

Crane Specifications of 5 Ton Overhead Crane Saudi Arabia

Main capacity: 5 ton, Crane span: 3.06 m, Lifting height: 3.5 m , Voltage: 380V60HZ3P, Crane project location: Saudi Arabia.

Main Capacity: 5 Tons

At the core of the Custom Overhead Crane 5 Ton project lies its substantial lifting capacity. The decision to opt for a 5-ton main capacity is a result of meticulous analysis and understanding of the workload demands in the chosen industrial setting in Saudi Arabia. Striking a balance between strength and versatility, the crane can effortlessly handle diverse loads, making it an ideal choice for a variety of applications.

The 5-ton capacity is a sweet spot, offering robust lifting capabilities without compromising on precision and control. Whether dealing with heavy machinery components or delicate materials, the bridge crane ensures a smooth and efficient workflow, a critical requirement for industries aiming for maximum productivity.

Crane Span: 3.06 Meters

Precision in material handling is important, and the crane span plays a crucial role in achieving this. With a span of 3.06 meters, the Custom Overhead Crane is designed to navigate the workspace seamlessly, reaching every corner with accuracy. The carefully chosen span ensures optimal coverage, minimizing the need for manual intervention and enhancing operational efficiency.

The compact yet effective span is particularly advantageous in facilities with limited space, a common consideration in modern industrial setups. This adaptability to spatial constraints underscores the crane's commitment to meeting the specific needs of its operational environment.

Lifting Height: 3.5 Meters

The lifting height of 3.5 meters is a testament to the crane's versatility in handling loads across various vertical dimensions. From ground-level material pickups to intricate operations requiring elevation, the Custom Overhead Crane accommodates diverse lifting requirements with ease.

The 3.5-meter lifting height is strategically chosen to align with the demands of the Saudi Arabian industrial landscape. It caters to a range of applications, ensuring that the crane remains a reliable and adaptable solution for tasks that necessitate varying heights within the workspace.

Voltage: 380V60HZ3P

Power efficiency and compatibility are paramount in industrial machinery. The Custom Overhead Crane operates at a voltage of 380V with a frequency of 60Hz and a three-phase power supply. This voltage specification is not arbitrary; it aligns with the prevailing electrical standards in Saudi Arabia, ensuring seamless integration with the existing infrastructure.

The three-phase power supply enhances the crane's performance, providing a stable and reliable source of power. This voltage configuration is a result of a meticulous understanding of the local electrical landscape, emphasizing the crane's commitment to practicality and ease of implementation.

Customization Features

In the industrial machinery, customization is a necessity. The Custom Overhead Crane 5 Ton project goes beyond standard offerings by introducing tailored features to meet the unique needs of the buyer. Let's delve into the customization features, focusing on the Floor Mounted and Ceiling Mounted options, and understand how each addresses specific requirements.

Floor Mounted Option

The Floor Mounted configuration is a strategic choice for facilities where the existing infrastructure supports a floor-based installation. This option involves securely anchoring the crane to the factory floor, providing stability and reliability. Here's how this customization feature caters to specific needs:

- Space Optimization: The Floor Mounted option is ideal for maximizing floor space, a critical consideration in facilities with compact layouts. By anchoring the crane to the floor, it minimizes the impact on the available workspace, allowing for efficient material handling without compromising on the operational area.

- Stability and Load Distribution: The secure attachment to the floor ensures enhanced stability during lifting and moving operations. This configuration is particularly advantageous when dealing with heavier loads, distributing the weight evenly and preventing undue stress on the crane structure.

- Adaptability to Existing Infrastructure: Factories with established floor-based support systems find the Floor Mounted option seamlessly adaptable. It minimizes the need for extensive modifications to the facility, reducing installation time and costs.

Ceiling Mounted Option

The Ceiling Mounted configuration takes a different approach, suspending the crane from the ceiling structure. This option offers unique advantages, especially in facilities where floor space is at a premium or where specific operational requirements dictate an overhead approach:

- Optimal Floor Space Utilization: Ceiling Mounted cranes free up valuable floor space, allowing for unobstructed movement and operation. This is crucial in environments where floor-based installations might impede workflow or pose safety challenges.

- Versatility in Coverage: Suspended from the ceiling, the crane provides extensive coverage, reaching every corner of the facility. This is advantageous for facilities with irregular layouts or where the crane needs to traverse a large area, ensuring flexibility in material handling operations.

- Enhanced Safety Measures: Ceiling Mounted cranes are inherently safer in environments with heavy foot traffic. By keeping the crane off the floor, the risk of collisions and accidents is reduced, contributing to a safer working environment.

The customization features lies in their adaptability to the buyer's unique needs. Whether opting for a Floor Mounted or Ceiling Mounted configuration, the Custom Overhead Crane 5 Ton project ensures that each installation is a bespoke solution crafted to enhance operational efficiency, safety, and overall productivity.

Technical Considerations

Now that we've explored the specific features and customization options, let's turn our attention to the critical technical considerations that play a pivotal role in the performance and safety of the Custom Overhead Crane 5 Ton. These aspects is essential for buyers to make informed decisions aligning with their operational requirements.

Load Capacity and Safety Factors

- Precise Load Capacity: The cornerstone of any overhead crane is its load-bearing capacity. The 5-ton load capacity of this custom crane is a result of rigorous engineering calculations and safety assessments. Understanding the exact load demands of your operations is crucial, and the crane's capacity provides a buffer to ensure safe and efficient material handling.

- Dynamic Safety Factors: Beyond the nominal load capacity, the crane incorporates dynamic safety factors to account for real-world variations. These factors consider factors like load dynamics, acceleration, and deceleration, ensuring that the crane operates within a safe margin under diverse conditions. This commitment to safety is intrinsic to the design, providing a robust and reliable solution for industrial applications.

Precision Control Mechanisms

- Variable Frequency Drives (VFD): Precision control is the key to efficient and safe material handling. The Custom Overhead Crane is equipped with Variable Frequency Drives (VFD), allowing for precise control over the crane's movements. VFD technology ensures smooth acceleration and deceleration, reducing wear and tear on components and enhancing the overall lifespan of the crane.

- Remote Control Capabilities: Modern industrial processes demand flexibility and adaptability. The crane is designed with remote control capabilities, enabling operators to oversee and control lifting and movement operations from a safe distance. This not only enhances safety but also facilitates better visibility and control in complex operational scenarios.

Compliance with International Standards and Regulations

- ISO and CE Certifications: The commitment to quality and safety is further underscored by the crane's compliance with international standards. The Custom Overhead Crane is designed and manufactured adhering to ISO standards and carries CE certifications. This ensures that the crane meets or exceeds the stipulated safety and performance benchmarks, providing buyers with the confidence that they are investing in a globally recognized and reliable solution.

- Local Regulatory Compliance: In addition to international standards, the crane is engineered to comply with local regulations in Saudi Arabia. This includes adherence to electrical standards, safety protocols, and any specific requirements outlined by regulatory bodies. This approach ensures that the crane seamlessly integrates into the local industrial landscape, meeting all necessary legal and safety standards.

Benefits of Customization

As we navigate the intricacies of the Custom Overhead Crane 5 Ton project, it's essential to underscore the profound benefits that arise from its customized features. Beyond being a mere piece of machinery, this crane is a tailored solution designed to elevate industrial operations in Saudi Arabia. Let's delve into the advantages that customization brings to the forefront:

5 ton top running crane design with custom runway structure

Main steel structure of 5 ton singel girder overhead cranes for sale Saudi Arabia

Electric chain hoist for the cutom 5 ton bridge crane for sale Saudi Arabia

Electrical box of custom electric overhead crane for particular needs

Enhanced Efficiency and Productivity

- Optimized Workflow: Tailored to the unique needs of the operational environment, the Custom Overhead Crane enhances workflow efficiency. Whether handling routine tasks or addressing specific challenges, the crane's customization ensures that every movement is streamlined and optimized. This results in a significant boost to overall productivity, a key metric in the competitive landscape of industrial operations.

- Reduced Downtime: Precision control mechanisms, such as Variable Frequency Drives and remote control capabilities, contribute to minimizing downtime. Swift and accurate responses to operational demands translate into reduced waiting times, ultimately maximizing the crane's availability and contributing to uninterrupted workflow.

Improved Safety Measures

- Dynamic Safety Factors: The incorporation of dynamic safety factors in the crane's design goes beyond meeting minimum requirements. It provides an added layer of protection, ensuring that the crane operates within safe parameters even under varying conditions. This commitment to safety is not just a regulatory checkbox; it's a proactive approach to safeguarding both personnel and assets.

- Remote Control Capabilities: The ability to control the crane remotely adds a crucial safety dimension. Operators can oversee operations from a safe distance, minimizing the risk of accidents in scenarios involving heavy loads or intricate movements. This feature not only enhances safety but also contributes to better decision-making in complex operational environments.

Adaptability to Specific Workspace Constraints

- Floor and Ceiling Mount Options: The inclusion of Floor Mounted and Ceiling Mounted options showcases the crane's adaptability to diverse workspace constraints. In facilities where floor space is at a premium, the Ceiling Mounted configuration offers an elegant solution. Conversely, the Floor Mounted option is tailored for situations where the existing infrastructure supports ground-based installations. This flexibility ensures that the crane seamlessly integrates into the specific spatial dynamics of the operational environment.

- Minimal Facility Modification: The customization features are engineered to minimize the need for extensive facility modifications during installation. This not only reduces costs but also expedites the integration of the crane into the existing workspace. The adaptability to specific constraints ensures that the crane becomes an integral part of the facility without imposing significant changes to the operational layout.

In essence, the benefits of customization extend far beyond the physical capabilities of the crane. They embody a commitment to efficiency, safety, and adaptability, transforming the Custom Overhead Crane 5 Ton into a strategic asset for industries in Saudi Arabia. Join us in the next segment as we explore the seamless execution of the project, detailing the timeline, challenges faced, and innovative solutions devised to bring this customized crane to life.

Project Execution Timeline

Overview of the Timeline

The development of the Custom Overhead Crane 5 Ton follows a strategic plan, ensuring efficiency, precision, and timely delivery. Let's explore the key stages of the project execution, providing insights into the comprehensive timeline.

Stages of Project Execution:

- Conceptualization and Planning: The project initiation involves a detailed conceptualization phase, where the unique needs of the buyer are assessed, and a tailored solution is outlined. This includes choosing between Floor Mounted and Ceiling Mounted configurations, defining technical specifications, and establishing a comprehensive project plan.

- Engineering and Design: Once the conceptual phase is solidified, the engineering and design team takes charge. This stage involves translating conceptual ideas into detailed engineering drawings and specifications. The design accounts for load capacities, precision control mechanisms, compliance with standards, and customization features, ensuring a holistic and functional crane.

- Fabrication and Manufacturing: With designs finalized, the fabrication and manufacturing phase commences. Skilled technicians and engineers bring the crane to life, utilizing cutting-edge technology and high-quality materials. Regular quality checks ensure that each component aligns with the stringent standards set for the Custom Overhead Crane.

- Testing and Quality Assurance: Rigorous testing is a non-negotiable aspect of the project timeline. Each crane undergoes extensive testing to ensure that it meets or exceeds the specified load capacities, safety measures, and operational requirements. This phase guarantees that the crane performs seamlessly in real-world scenarios, providing reliability and peace of mind to the end-users.

- Shipping and Logistics: After successful testing and quality assurance, the cranes are prepared for shipping. Logistics play a crucial role, ensuring that the custom equipment reaches its destination in Saudi Arabia intact and within the stipulated timeframe. Coordination with shipping partners and adherence to international shipping protocols are paramount during this stage.

- Installation and Commissioning: Upon arrival in Saudi Arabia, the installation and commissioning phase begins. A team of experienced technicians ensures that the crane is assembled, calibrated, and commissioned according to the project plan. This phase is critical, as it marks the transition from theoretical design to practical application within the buyer's facility.

Key Milestones Achieved:

- Design Finalization: The completion of the engineering and design phase marks a significant milestone. Finalized blueprints and specifications provide a clear roadmap for the subsequent stages of fabrication and manufacturing.

- Successful Testing and Quality Assurance: The successful testing and quality assurance phase signify that the crane has met the rigorous standards set during the design phase. This milestone ensures that the custom crane is ready for deployment in real-world industrial environments.

- Shipping and Arrival in Saudi Arabia: The seamless execution of shipping and logistics ensures that the custom cranes arrive in Saudi Arabia without delays or damages. Coordinated efforts with logistics partners are essential for achieving this milestone.

- On-site Installation and Commissioning: The on-site installation and commissioning phase is a critical milestone, as it marks the integration of the Custom Overhead Crane into the buyer's facility. The successful commissioning ensures that the crane is operational and ready to contribute to the efficiency of industrial processes.

Navigating through these key milestones offers a glimpse into the meticulous planning and execution involved in bringing the Custom Overhead Crane 5 Ton from concept to reality. The adherence to timelines and successful achievement of these milestones are indicative of a project that prioritizes precision, reliability, and customer satisfaction. In the next segment, we will delve into the challenges encountered during the project and the innovative solutions devised to overcome them, providing a holistic understanding of the Custom Overhead Crane project in Saudi Arabia.

Challenges and Solutions

Customization Challenges:

- Challenge: Spatial Constraints in Facilities

In certain facilities, especially those with confined spaces, the challenge was to optimize the crane design to fit within spatial constraints without compromising on performance. - Solution: Tailored Design for Compact Spaces

Engineers worked closely with the design team to create a tailored crane design that maximized efficiency within limited spaces. This involved intricate adjustments to the crane's structure, ensuring it could navigate through tight spaces without sacrificing load capacity or safety. - Challenge: Specific Load Requirements

Some facilities had unique load requirements that required precision in load handling, posing a challenge in achieving the desired balance between load capacity and control. - Solution: Enhanced Control Mechanisms

To address this challenge, the control mechanisms of the crane were fine-tuned. The integration of advanced Variable Frequency Drives (VFD) allowed for precise control over acceleration and deceleration, ensuring that the crane could handle specific loads with utmost accuracy.

Installation Challenges:

- Challenge: Site-Specific Adaptations

Each installation site presented its own set of challenges, from differences in flooring to variations in structural support. Adapting the crane to these specific conditions required meticulous planning. - Solution: On-Site Engineering Evaluations

An on-site engineering evaluation was conducted at each installation location. This involved a detailed assessment of the site's conditions, allowing the installation team to make real-time adaptations to the crane's configuration and ensure seamless integration with the existing infrastructure. - Challenge: Local Regulatory Compliance

Compliance with local regulations and safety standards posed a challenge, especially given the variations in regulations across different regions in Saudi Arabia. - Solution: Collaborative Approach with Local Authorities

A collaborative approach was adopted, involving close coordination with local regulatory authorities. This proactive engagement ensured that the crane design and installation processes met or exceeded all necessary local safety and compliance standards.

Technical Challenges:

- Challenge: Voltage and Power Compatibility

Ensuring that the crane operated seamlessly with the local power supply presented a technical challenge, especially considering the specific voltage and frequency requirements in Saudi Arabia. - Solution: Customized Electrical Configuration

The crane's electrical configuration was customized to align precisely with the local power supply standards (380V60HZ3P). This bespoke electrical setup ensured a stable power source, enhancing the crane's performance and reliability. - Challenge: Precision Calibration

Achieving the desired precision and accuracy in crane movements required meticulous calibration, with challenges arising in aligning the control systems with real-world load handling scenarios. - Solution: Advanced Calibration Protocols

Advanced calibration protocols were implemented, incorporating real-time feedback mechanisms during the installation process. This iterative calibration approach allowed for fine-tuning the crane's control systems to match the specific operational demands of the facility.

The identification and resolution of these challenges showcase the commitment to delivering a solution that goes beyond standard offerings. The collaborative approach with buyers, adaptability to site-specific conditions, and a focus on precision in both design and installation underline the resilience and ingenuity involved in bringing the Custom Overhead Crane 5 Ton to operational fruition.

Cost Analysis

Understanding the financial aspects of the Custom Overhead Crane 5 Ton project is pivotal for potential buyers looking to make informed decisions. In this section, we will provide a detailed breakdown of the costs associated with the project and conduct a comparative analysis with standard overhead cranes to highlight the cost-effectiveness of this tailored industrial solution.

Breakdown of Costs:

- Design and Engineering: Costs associated with the conceptualization, engineering, and design phases, including salaries, software, and prototyping expenses.

- Fabrication and Manufacturing: Expenses related to the fabrication and manufacturing of crane components, including raw materials, labor, and manufacturing technologies.

- Testing and Quality Assurance: Costs incurred during the testing and quality assurance phase, covering equipment, testing facilities, and manpower.

- Shipping and Logistics: Expenses related to the shipping of the custom cranes from the manufacturing site to Saudi Arabia, including transportation, customs duties, and logistics coordination.

- Installation and Commissioning: Costs associated with on-site installation, commissioning, and final adjustments to ensure the crane's seamless integration into the buyer's facility.

- Regulatory Compliance: Expenses tied to compliance with international and local regulations, including certification processes and coordination with regulatory authorities.

Comparative Analysis: Custom vs. Standard Overhead Cranes

- Initial Investment: While the initial investment for a custom overhead crane may be higher due to tailored design and engineering, standard overhead cranes often require additional modifications to meet specific operational needs. The custom approach minimizes the need for post-purchase modifications, potentially offsetting the initial higher cost.

- Operational Efficiency: The precision control mechanisms, load capacity, and tailored features of the custom crane contribute to enhanced operational efficiency. Standard cranes may require additional investments in control upgrades or modifications, impacting long-term operational costs.

- Maintenance Costs: Custom cranes are designed with specific operational requirements in mind, potentially leading to lower maintenance costs over time. Standard cranes may incur higher maintenance expenses due to modifications and adaptations required to suit unique operational environments.

- Adaptability and Future-proofing: The adaptability of the custom crane to specific workspace constraints and operational needs enhances its long-term value. Standard cranes may require frequent upgrades or replacements to meet evolving industry standards, contributing to higher future costs.

While the initial investment in a Custom Overhead Crane 5 Ton may appear higher than standard offerings, the comprehensive cost analysis reveals a nuanced perspective. The tailored design, precision control mechanisms, and adaptability to specific operational needs contribute to long-term cost-effectiveness. By minimizing the need for post-purchase modifications and enhancing operational efficiency, the custom approach positions itself as a strategic investment in the seamless and reliable material handling operations within the dynamic industrial landscape of Saudi Arabia.

Custom top running overhead crane with single girder crane design

Maintenance and Support

Ensuring the longevity and optimal performance of the Custom Overhead Crane 5 Ton goes beyond its initial installation. In this segment, we will explore the maintenance requirements for the crane and shed light on the support services available from the manufacturer or supplier, emphasizing the ongoing commitment to customer satisfaction and operational efficiency.

Maintenance Requirements:

- Regular Inspection and Lubrication: Routine inspections are essential to identify wear and tear, potential issues, or any components requiring lubrication. Regular greasing of moving parts ensures smooth operation and extends the lifespan of critical components.

- Control System Calibration: The precision control mechanisms, including Variable Frequency Drives (VFD), require periodic calibration to maintain accuracy in load handling operations. This ensures that the crane continues to operate with optimal efficiency.

- Structural Integrity Checks: Regular checks on the structural integrity of the crane, including welding points and load-bearing components, are crucial for preventing unforeseen failures. Any signs of fatigue or stress are addressed promptly during these inspections.

- Electrical System Maintenance: The electrical components of the crane, including wiring, sensors, and the power supply system, require regular checks to ensure reliability. Any issues related to electrical connections or voltage fluctuations are addressed promptly.

- Software Updates and Upgrades: If the crane is equipped with advanced control software, ensuring that it remains up-to-date with the latest updates and upgrades is essential. This prevents compatibility issues and ensures that the crane benefits from the latest technological advancements.

Support Services from Manufacturer or Supplier:

- Technical Assistance: A reliable manufacturer or supplier offers ongoing technical assistance to address any queries or concerns related to the crane. This includes providing guidance on routine maintenance procedures and troubleshooting unexpected issues.

- Spare Parts Availability: Timely access to spare parts is crucial for minimizing downtime. A reputable manufacturer ensures the availability of genuine spare parts, facilitating quick and efficient replacements when necessary.

- Remote Monitoring and Diagnostics: Advanced support services may include remote monitoring and diagnostics. This allows the manufacturer to assess the crane's performance remotely, identify potential issues, and provide proactive solutions before they escalate.

- Training Programs: Manufacturers may offer training programs for the crane operators and maintenance personnel. This ensures that the end-users have the necessary skills and knowledge to perform routine maintenance tasks and handle the crane safely and efficiently.

- Scheduled Maintenance Contracts: Some manufacturers provide the option for scheduled maintenance contracts. These contracts outline regular maintenance visits from qualified technicians, ensuring that the crane is systematically inspected, calibrated, and maintained according to a predefined schedule.

The availability of comprehensive maintenance requirements and robust support services from the manufacturer or supplier is a testament to the commitment to customer satisfaction. The Custom Overhead Crane 5 Ton is not just an initial investment; it's a long-term partnership aimed at ensuring operational efficiency, safety, and reliability throughout its lifespan.

User Testimonials

The true measure of the success of the Custom Overhead Crane 5 Ton lies in the experiences and feedback of those who have integrated this industrial solution into their daily operations. In this segment, we present real-world insights through user testimonials, providing a firsthand account of the crane's impact on efficiency, safety, and overall operational dynamics.

Testimonial from Manufacturing Facility

"The Custom Overhead Crane has been a game-changer for us. Its ability to seamlessly navigate through tight spaces, coupled with precise control mechanisms, has significantly enhanced our operational efficiency. We've experienced a notable reduction in downtime and increased productivity since its installation. The tailored design perfectly aligns with our specific load requirements, making it a valuable asset in our day-to-day material handling operations."

Testimonial from Warehouse Facility

"We opted for the Ceiling Mounted configuration to maximize our floor space, and the results have exceeded our expectations. The crane's adaptability to our irregular layout and its extensive coverage have transformed our warehouse operations. The remote control capabilities add an extra layer of safety, allowing our operators to handle materials with increased visibility and control. It has become an indispensable part of our facility, contributing to both efficiency and safety."

Testimonial from Construction Site

"The challenges of our construction site demanded a crane that could adapt to dynamic conditions. The Custom Overhead Crane's on-site engineering evaluations ensured a seamless integration with our specific structural requirements. Its reliability under varying load conditions and the precision calibration have proven invaluable. The ongoing technical assistance and spare parts availability from the manufacturer have given us the confidence that our crane will continue to meet our evolving needs."

Testimonial from Heavy Industry Facility

"Investing in the Custom Overhead Crane has been a strategic decision for our heavy industry operations. The robust design, adherence to safety standards, and compliance with local regulations were crucial factors in our decision-making process. The scheduled maintenance contract has streamlined our upkeep efforts, and the crane's adaptability to our voltage and power requirements has been a significant advantage. It's a testament to the manufacturer's commitment to delivering tailored solutions for complex industrial environments."

These testimonials reflect the tangible impact of the Custom Overhead Crane 5 Ton on diverse industrial settings. From manufacturing facilities to warehouses and construction sites, the crane has proven its adaptability, efficiency, and reliability. The user experiences provide valuable insights for potential buyers, offering a glimpse into how this customized industrial solution has become an integral part of daily operations, contributing to enhanced productivity and safety.

In closing, the Custom Overhead Crane 5 Ton stands as a testament to the convergence of precision engineering, tailored design, and ongoing support services. As potential buyers consider their industrial material handling needs, the insights provided in this case study serve as a comprehensive guide, showcasing the practical benefits and real-world applications of a bespoke overhead crane solution.

Custom Overhead Crane, Your Cost-effective Solution for Your Needs

As we conclude this comprehensive case study on the Custom Overhead Crane 5 Ton, it's essential to summarize the key insights and offer conclusive thoughts on the suitability of this tailored industrial solution for potential buyers in the dynamic Saudi Arabian market.

Key Takeaway of Custom 5 Ton Top Running Cranes:

- Customization Features: The Custom Overhead Crane offers unique features, including Floor Mounted and Ceiling Mounted configurations, designed to address specific needs such as space optimization, adaptability, and load handling precision.

- Technical Considerations: The crane's technical specifications, precision control mechanisms, and compliance with international standards underscore its commitment to efficiency, safety, and reliability in diverse industrial applications.

- Benefits of Customization: Enhanced operational efficiency, improved safety measures, and adaptability to specific workspace constraints highlight the advantages of choosing a custom overhead crane tailored to the buyer's unique requirements.

- Project Execution Timeline: The meticulous execution timeline, from conceptualization to installation, showcases the dedication to a seamless and well-orchestrated project delivery.

- Challenges and Solutions: Identifying and overcoming challenges during customization and installation demonstrate the resilience and innovative problem-solving inherent in the project.

- Cost Analysis: The comprehensive cost analysis emphasizes the long-term cost-effectiveness of the Custom Overhead Crane, taking into account its tailored design, operational efficiency, and adaptability.

- Maintenance and Support: Ongoing maintenance requirements and robust support services from the manufacturer or supplier ensure the crane's longevity, reliability, and customer satisfaction.

- User Testimonials: Real-world insights from end-users provide firsthand accounts of the crane's performance and efficiency, offering valuable perspectives for potential buyers.

The Custom Overhead Crane 5 Ton isn't merely a piece of machinery; it's a tailored solution that aligns with the evolving needs of the Saudi Arabian industrial landscape. Its adaptability, precision, and commitment to safety position it as a strategic investment for buyers seeking not just a crane but a partner in operational efficiency.

In a market where innovation and efficiency are paramount, the Custom Overhead Crane stands as a beacon of progress, offering a bespoke solution that goes beyond standard offerings. As industries in Saudi Arabia continue to evolve, the need for specialized equipment that can seamlessly integrate into diverse operational environments becomes increasingly evident.

For potential buyers seeking not just a crane but a holistic solution that enhances productivity, safety, and adaptability, the Custom Overhead Crane 5 Ton presents itself as a compelling choice. In the field of industrial machinery, investing in a solution that evolves with your needs is not just practical; it's visionary.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch