Hoist and Crane Examination, Testing & Commissioning

Commissioning is an important part of the installation process since it ensures that the Hoist and Crane are safe, functional, and technically accurate.

Our design engineers validate through computation during the design phase, and this is used as part of the design quality review and final approval process. Our engineers execute proof load tests and functionality testing during the manufacturing process to ensure that all Hoist and Crane supplied for installation are certified and approved to the required lifting capacity and operational function.

Further testing may be required on-site depending on the Hoist and Crane being installed and it's installation method. If the Hoist and Crane is to be bolted or mounted onto an existing surface, structure or material then our engineers will need to test the surface and/or fixing to ensure this is suitably safe and fit for purpose before putting the lifting system into service and providing the appropriate documentation and certification for use.

European Style Electric Hoist

The jib hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder cranes, etc.

Chinese Style Electric Wire Rope Hoist

The Chinese type jib hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder cranes, etc.

Electric Trolley Electric Chain Hoist

Types of jib crane hoist designes are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Low Headroom Electric Chain Hoist

Types of jib crane hoist designes are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Mini small electric chain hoist with single phase

Mini electric wire ropes hoists - fixed hoist design & electric trolley type- 0.2 ton- 1 ton mini rope lift, single phase mini electric hoists, cheap small hoist for sale.

Manual and hand chain hoist & chain block

Manual chain block & manual chain hoist for sale. Light,economical & handy manual hoists & hand hoists of 250kg, 1 ton, 1.5 ton , 2 ton , 3 ton , 4 ton , 5 ton , 6 ton,etc.

Befor hoist and crane is put into service

Before a lifting appliance or lifting gear is put into service for the first time, it must be tested and thoroughly examined by a qualified person. A proof load test, which consists of a thorough examination, a test, and then a re-examination, may be required by law in order to verify that the lifting solution or Hoist and Crane is physically sound, suitable for purpose, and safe to use. Under the Lifting Operations and Lifting Hoist and Crane Regulations, a thorough examination is required before a piece of Hoist and Crane can be put into operation.

What is a proof load test?

When a new piece of Hoist and Crane is manufactured, a proof load test is performed to ensure that the supporting structure on which the Hoist and Crane is installed is appropriate for the loadings of the Hoist and Crane we install. When the Hoist and Crane are originally installed and before they are used, they are subjected to a proof load test. Our engineers conduct the test using load test weights and a calibrated load cell, and the Hoist and Crane are evaluated to ensure that they are operating appropriately and safely.

Inspections by compentent engineers

How often should a lifting hoist and crane, as well as their attachments, be fully inspected?

- Unless the Hoist and Crane has an EC Declaration of Conformity that is less than one year old and was not assembled on site, before using it for the first time. If it was assembled on site, it must be examined by a competent person to ensure that the assembly was correct and safe, such as a platform lift installed in a building. Always have a lifting Hoist and Crane thoroughly examined after 'exceptional circumstances,' such as if it is damaged or fails, is out of use for long periods of time, or if there is a major change in how it is used that is likely to affect its integrity.

- If the Hoist and Crane is regularly in service, it is subjected to conditions that cause degradation and are likely to result in unsafe situations. If this applies to your Hoist and Crane, you have two options: have the thorough examination done (a) at regular intervals (at least every 6 months or 12 months depending on whether the lifting Hoist and Crane is for lifting people or not); or (b) according to an examination scheme drawn up by a competent person.

For Hoists and Cranes that require assembly or installation before use, such as tower cranes, after assembly and before usage at each location.

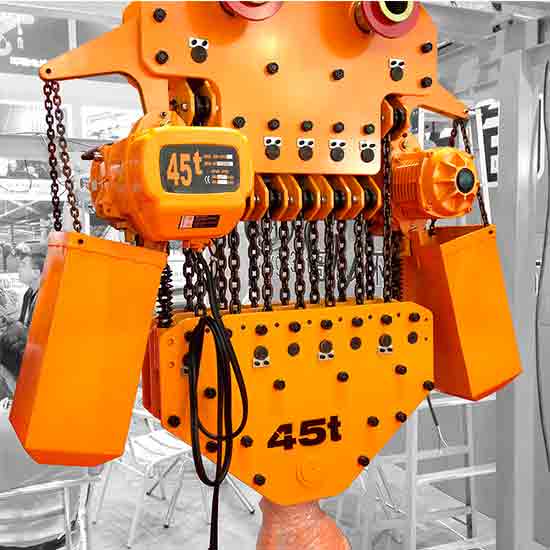

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.