What to Consider When Buying a Jib Crane? Jib Crane Selection Tips

To buy a jib crane, the tips on jib crane selection & installation for you to get the right slewing jib crane for the particular application. Check jib crane selection tips.

What is a jib crane? Jib cranes are versatile pieces of material handling equipment, and they're often the best solution for applications within a small area.

How can you buy a jib crane for use at work? What factors might have an impact on the features or requirements of a jib crane? What factors should be taken into account while buying a jib crane? From jib crane engineers, find out how to purchase a jib crane right now.

A jib crane is a great option for managing localized loads if you want to improve workplace efficiency and lower the risk of accidents, but what are the alternatives?Jib crane is a type of overhead travelling crane . The electric jib crane is made of a mast and a cantilever beam with a hoist suspended. They are typically utilized for repetitive lifting activities in smaller work locations.

They are an excellent way to increase workplace productivity while lowering the risk of worker injury when moving weights in a small space.This article will help you about the various types of jib cranes, their benefits and drawbacks, and whether you would be better off with another crane system.Before you invest in a jib crane, make sure it is the right solution for your work environment.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

What to Consider on Jib Crane Purchasing

Custom Jib Design, Good Jib Hoist Price

What should I know before buying a jib crane?

Jib cranes are typically used to fulfill specific tasks and provide hoist solutions in more constrained spaces. As a result, the precise limitations of your workspace and the lifting requirements will determine the type of jib crane you require.

Floor jib cranes are versatile pieces of material handling equipment that are frequently the best solution for applications that require a small area and confined space.

What is the purpose of a jib crane?

A jib crane is designed to handle a variety of loads in constrained spaces. They have a basic and compact design that is ideal for production since it can improve worker productivity while also improving workplace safety by providing convenient material lifting.

Jib cranes all have a small footprint, or even none at all, which makes them particularly useful in smaller work spaces, despite the fact that installation might vary in complexity.

For another reason, jib cranes are most commonly used in smaller work areas. Because of their ability to rotate 360 degrees, jib cranes are extremely versatile and efficient in moving loads within smaller work areas or around corners.There are also options that require little headroom and can be used in conjunction with other overhead crane systems.

What do you need to move?

What kind of jib crane is best for your work area? It depends on the size and weight of the object you need to move. The maximum load weight is the ideal place to begin:

- Free-standing jib crane with capacity from 1 ton to 16 ton.

- Wall-mounted jib crane with a capacity up to 3 ton .

- Wall travelling jib crane with a capacity up to 3 ton.

Each jib crane system also has maximum span of the cantilever limits, which determine the dimensions of load can be lifted and moved. Whatever the dimensions, you should also consider the available space in the work area to allow for the rotation of the cantilever.

Where do you need to move it?

What type of jib crane is appropriate depends on whether you need to move the load or simply support it (perhaps in conjunction with another piece of machinery).

All jib cranes will be able to rotate up to 360 degrees, making them ideal for maneuvering loads around corners or between workstations. Wall-mounted jib cranes have a limited rotation of 180 to 200 degrees and thus have more limited applications.

An articulated jib crane is another option for maximum maneuverability. They have two swivel arms for lifting loads around corners and columns, as well as reaching into and under other spaces. The primary boom arm can rotate 200 degrees (360 degrees if equipped with the proper electrification system), and the second arm can rotate 360 degrees.

Articulating jib systems can also be attached to the floor, wall, ceiling, or a bridge or track system. This means that a jib crane can provide more precise load positioning in tighter and more difficult-to-access areas where a standard crane would struggle.

If this sounds like the right solution for your workplace, keep in mind that the cantilever span is limited to 16' and the capacity is usually limited to one ton.

Know how you'll get electricity to the jib.

If the jib crane has a powered hoist, electrical service must be supplied, and the jib crane motion must be considered. Base mounted jib cranes that rotate 360 degrees have a slip ring collector to facilitate rotation. For outdoor jibs, the electrical service must be fed rom the jib's bottom, but indoor jibs can receive electricity through either the bottom or top. For column mounted jibs (or any jib that rotates less than 360 degrees) a flexible power cord is required. For all types of jib cranes with electrical service, be sure a dedicated electrical disconnect is within reach of the operator.

What structural support options are available?

Both wall-mounted and mast-mounted jib cranes require structural support. This is typically found at the top of a mast-type jib crane or in the main attachment to a vertical surface of a wall-mounted jib crane.

In both cases, structural support beams or solid walls are critical to their installation, but structurally sound support is especially important for wall-mounted jib cranes. As a result, before installation, a structural engineering survey of your work area must be performed and approved.

A self-supporting free standing jib crane does not require a foundation if it has a capacity of 1,000 lbs or less.

Consider the cost of the concrete foundation.

- A reinforced, poured concrete foundation is an essential component of a base-mounted jib crane.

- The jib quote includes the size of this foundation, and anchor bolts with the template for setting these bolts in concrete can be included with the jib crane.

- The masonry work, which includes saw cutting the concrete and digging to the proper depth, is not included in the price. The jib crane supplier or a separate contractor can perform this work.

Be sure to account for hook coverage.

- The span is the distance from the center of rotation to the end of the jib boom for base mounted jibs or 360 degrees for column mounted jibs.

- However, the trolley hoist will travel from the inner stop to the outer stop.

- Make sure the hook coverages of the jib trolley hoist reaches all the working areas that need material handling service.

Outdoor jib cranes with optional features

- The industrial jib cranes can be used for indoor use and outdoor use.

- If the jib crane will be operating outdoors, the special coating will be used to ensure safety.

- If the jib crane will be used at dockside, a hot-dipped galvanized finish is recommended, of course, the galvanized jib crane will be expensive.

- Locating a jib crane outside or in any corrosive environment without the right finish will cause the equipment to fail soon.

Consider the strength of your building column.

- It is critical that the building column is robust enough to carry the load for column-mounted jib cranes, both tie rod and full cantilever design.

- Because the column will support both the jib crane and the loading from the building, it will deflect if it is too light, and this could result in a catastrophic failure.

What kind of hoist can be used on a jib crane?

On jib cranes, manual and electric chain hoists are frequently employed.

Wire rope hoists are preferable on some high-capacity jib cranes due to their speed and low headroom design.

What are the advantages of a jib crane?

A jib crane's greatest advantage is its ability to serve a small area efficiently. A jib crane's footprint is much smaller than that of other overhead cranes due to its minimal structural design, allowing you to maximize your work area.

Because of the options for increased headroom clearance, the minimal structure can be combined with other overhead cranes. By providing a convenient and efficient lifting solution for a small area, this can improve productivity and reduce the risk of workplace accidents.

When dealing with challenges at work, this convenience is extremely crucial. Jib cranes are particularly useful in a number of work environments, such as: Production areas; Assembly lines; Brake press and die equipment where it is difficult to reach or set equipment from overhead; Loading heavy equipment into a semi trailer or shipping container. Jib cranes have the special ability to reach around obstacles—even underneath or into awkward spaces using an articulating system.

Additionally, they are reasonably priced when compared to other overhead cranes.

What are the disadvantages of a jib crane?

A jib crane's greatest benefit is also one of its worst drawbacks. Because jib cranes are designed to service a confined region, they cannot span long distances.

A jib crane's boom / arm length determines its maximum working span.

Jib cranes aren't often known for having a big capacity. The largest capacity jib crane will typically be around 16 ton . You would need to use a free-standing jib crane to reach this load level, which requires accounting for the additional foundation and (possible) surveying costs.

Are there better alternatives to jib cranes?

- An adjustable gantry crane can be as cost-effective as or more cost-effective than a jib crane, and it offers more flexibility because it is portable while remaining compact.

- If you need more load capacity from a crane system while also catering to a large work area with limited space, a bridge crane could be a great solution. A bridge crane is a more costly and long-term solution. For these reasons, it is worthwhile to consider how your output will be increased and whether the investment will be worthwhile.

- Workstation cranes have several advantages over jib cranes. They frequently have a wider span and can service multiple work zones.

- Because of their structural design, most do not require any foundation work during installation, and because they are modular, they allow for future expansion.

- Furthermore, if properly planned, the support structure for a workstation crane support structure can be installed outside of the hectic working environment.

Contact us for questions about standards jib cranes or specialty applications. Or learn more about jibs with this blog post on jib crane mounting types.We supply a variety of overhead lifting equipment, such as bridge cranes and hoists, along with related services. Contact us for more information.WhatsApp/ WeChat: + 86 151 3871 1597.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Types of Jib Cranes for Your Selection

Wall Jib Crane & Floor Jib Cranes for Sale

Pillar jib crane

Pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: A3.Ask for free standing jib crane price.

Wall mounted jib crane

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for wall mounted jib crane price.

Wall travelling jib crane

Wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3. Ask for wall travelling jib crane price.

Slewing jib crane

Slewing jib cranes -floor & wall jib cranes- flexible swing or slewing jib arm & rotary crane design, 180, 270 &360 degree rotating jib crane for sale. Ask for slewing jib crane price.

Portable jib crane

Portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.Ask for portable jib crane price.

Process jib crane

Process jib cranes for your specific application to lower your jib crane cost. Contact us to get your customized process jib crane design and your jib crane rate and crane price.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Buyer Guide for Jib Crane

Confirm Jib Specifications to Custom Jib Crane Design

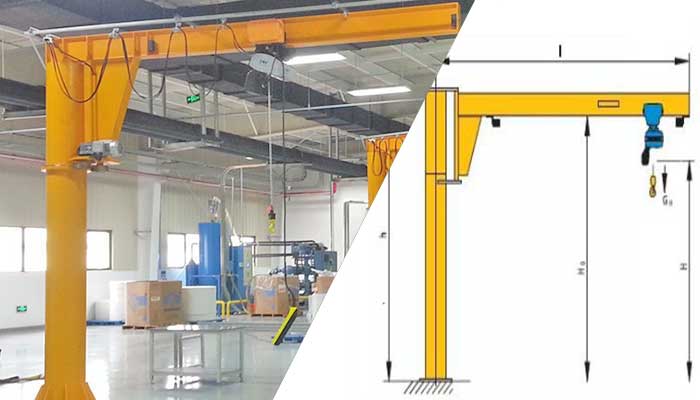

Jib crane is an industrial component and is a light-duty crane. It consists of a column, a slewing arm slewing drive device and an electric hoist. It has light weight, large span, large lifting capacity, economical and durable.

Floor jib crane drawing for your reference to confirm jib crane specifications

Wall jib crane drawing for you to confirm crane specifications

Basic Information

- Company

- Name

Parameter Confirmation Table

- Column mounted jib crane data: ____

- Jib length: ____mm

- Capacity: ____kg

- Hook height : ____ mm

- Clear building height mm

- Height above ground: ____mm

On jib crane mounting types

Type of mounting required: ____ (please tick as appropriate)

- □ on foundation with anchor bolts

- □ on reinforced concrete floor plate

- □ on reinforced concrete celling

Rotation Mode □ Manual(S) □ Electric(E)

Trolley Movement Mode □ Manual(P) □ Electric(M)

Hoist □ Wire Rope Hoist(H) □ Chain Hoist(C)

Others :______

Copy and fill in the required information to send us to get your customized jib crane design and crane price.