Ceiling Mounted Bridge Crane for Sale 1 Ton, 2 Ton, 3 Ton, 5 Ton

Ceiling mounted bridge crane for sale, customized ceiling mounted crane, with underhung bridge crane design, hot sale 1 Ton, 2 Ton, 3 Ton, 5 Ton, 10 ton.

| Bridge crane type | Ceiling mounted bridge crane |

| Crane capacity | 500kg-10 ton |

| Lifting Height | As your request |

| Crane Span | 3-15 m |

Category: Bridge Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Ceiling Mounted Bridge Crane for Sale 1 Ton, 2 Ton, 3 Ton, 5 Ton

Ceiling mounted bridge crane for sale, customized ceiling mounted crane, with underhung bridge crane design, hot sale 1 Ton, 2 Ton, 3 Ton, 5 Ton, 10 ton.

A ceilingmounted bridge crane, also known as an overhead bridge crane or overhead travelling crane, is a type of material handling equipment used to move heavy loads horizontally within a facility. It is a versatile and efficient solution for lifting and transporting materials in industrial settings such as warehouses, manufacturing plants, and workshops.

Main types of ceiling mounted bridge cranes

Apologies for any confusion in my previous responses. Ceilingmounted bridge cranes are typically classified based on their structure and design. The main types of ceilingmounted bridge cranes are:

- Single Girder Bridge Crane: This type of ceilingmounted bridge crane features a single horizontal girder or beam that supports the hoist and trolley. It is a costeffective solution for light to mediumduty lifting applications. Single girder bridge cranes are commonly used in facilities with limited headroom.

- Double Girder Bridge Crane: In a double girder bridge crane, two parallel horizontal girders or beams support the hoist and trolley. This design provides increased lifting capacity and stability, making it suitable for heavyduty lifting operations. Double girder bridge cranes are commonly used in industries where large and heavy loads need to be moved.

These two types of ceilingmounted bridge cranes are the most common and widely used configurations. The choice between a single girder and a double girder bridge crane depends on factors such as the required lifting capacity, the span of the crane, and the specific application needs.

In some cases, a ceiling mounted bridge crane may also be referred to as a monorail crane. However, it's important to note that a monorail crane is a simpler version of the bridge crane, typically with a single rail on which the hoist and trolley move. Monorail cranes are often used for simple material handling tasks within a localized area.

Ceiling mounted monorail in straight line

Ceiling mounted monorail in curved rails

When considering a ceilingmounted bridge crane, it's crucial to assess the specific requirements of your material handling tasks, the available space and headroom in your facility, and the weight of the loads you need to lift. This evaluation will help determine which type of ceilingmounted bridge crane is the most suitable for your needs. Additionally, consulting with crane specialists or engineers can ensure you select the right crane for your application and that it can be safely installed in your facility.

Applications of ceiling mounted bridge cranes

Ceilingmounted bridge cranes are ideal for various industrial and commercial applications where heavy lifting and precise material handling are required. Here are some situations in which you might consider using a ceilingmounted bridge crane:

- Heavy Material Handling: When your facility deals with heavy materials or equipment that cannot be easily moved by manual labor, a ceilingmounted bridge crane provides an efficient solution for lifting and transporting these loads.

- Frequent and Precise Load Movement: If your facility requires frequent and precise positioning of heavy objects, a bridge crane allows for smooth and controlled movements, enhancing productivity and reducing the risk of accidents.

- Optimizing Floor Space: Ceilingmounted cranes free up valuable floor space, which can be crucial in crowded or congested facilities, allowing you to use the ground level more efficiently.

- Assembly or Production Lines: In manufacturing environments, these cranes are useful for moving materials and components along an assembly line or transferring products between workstations.

- Warehousing and Storage: Ceilingmounted cranes can be utilized in warehouses for efficient loading and unloading of goods from trucks and for moving large items within the storage area.

Key features of a ceilingmounted bridge crane:

- Mounting: The crane is attached to the ceiling structure of the building, which allows it to travel along a runway system that spans the length or width of the facility.

- Bridge: The bridge refers to the horizontal beam or girder that carries the hoist and trolley, and it travels along the runway rails. The bridge is usually made of steel and designed to withstand the weight of the loads being lifted.

- Hoist and Trolley: The hoist is the lifting mechanism that attaches to the load, and the trolley is the component that moves horizontally along the bridge, allowing the hoist to position the load precisely.

- Controls: Ceilingmounted bridge cranes are typically controlled by an operator using a pendant control or a remote control device. Some advanced systems may incorporate automation and computerized controls.

- 5. Load Capacity: Ceilingmounted bridge cranes are available in various load capacities, ranging from a few hundred kilograms to several tons, depending on the needs of the application.

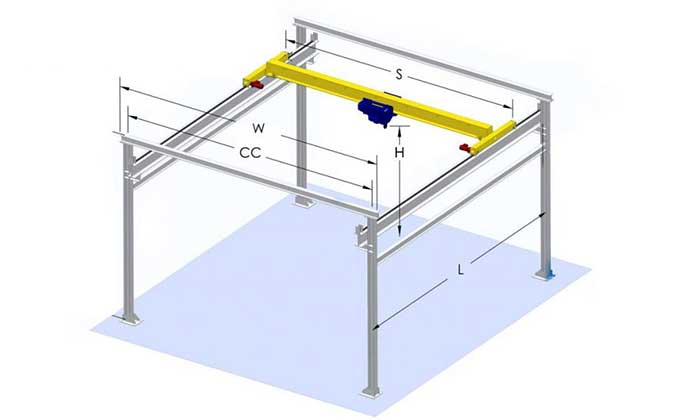

- 6. Span: The span of the crane is the distance between the runway rails, and it can be customized based on the layout and size of the facility.

Benefits of ceilingmounted bridge cranes:

- SpaceSaving: By being mounted on the ceiling, the crane does not take up valuable floor space, allowing for more efficient use of the working area.

- Flexibility: These cranes can cover a large area of the facility, and the ability to move loads in three dimensions makes them highly adaptable to various material handling tasks.

- High Load Capacity: Ceilingmounted bridge cranes can handle heavy loads with ease, making them suitable for demanding industrial applications.

- Improved Safety: When properly operated and maintained, these cranes can enhance safety by reducing the need for manual lifting and handling of heavy objects.

- Increased Productivity: With the ability to move large and heavy loads quickly and precisely, the crane can significantly improve the efficiency of material handling operations.

It's important to note that the installation and operation of a ceilingmounted bridge crane require adherence to safety regulations and guidelines. Professional engineers or crane specialists should be consulted to ensure the proper design, installation, and maintenance of the system.

Runways of ceiling mounted bridge cranes

The runway system for a ceilingmounted (under running) bridge crane consists of two parallel runway beams that are typically suspended from the building's ceiling structure. These beams provide the track on which the bridge travels. The bridge, which carries the hoist and trolley, moves along the bottom flange of the runway beams.

The main components of the runway system in a ceilingmounted (under running) bridge crane include:

- Runway Beams: The runway beams are horizontal structural members that provide the track for the bridge of the crane. They are typically made of steel and are suspended from the building's ceiling structure. The bridge moves along the bottom flanges of the runway beams.

- End Trucks: The end trucks are wheeled units located at either end of the bridge. They house the wheels or rollers that run along the bottom flanges of the runway beams. The end trucks provide support and guidance to the bridge as it travels along the runway.

- Wheel Assemblies: The wheel assemblies are sets of wheels or rollers mounted on the end trucks. These wheels roll along the bottom flanges of the runway beams, allowing the bridge to move smoothly and easily.

- Connections and Fasteners: Various connections and fasteners, such as bolts, nuts, and welding, are used to secure the runway beams to the building's ceiling structure and to attach the end trucks to the bridge. These connections must be robust and properly installed to ensure the safe operation of the crane.

The runway system is a critical component of a ceilingmounted bridge crane, as it supports the entire weight of the crane and the loads being lifted. Proper design, installation, and maintenance of the runway system are essential to ensure the safety and efficiency of the crane's operation.

Installation on Concrete Workshop and Steel Structure Workshops:

The installation process for the runway beams of a ceilingmounted (under running) bridge crane can differ depending on whether it is a concrete workshop or a steel structure workshop.

Concrete Workshop: In a concrete workshop, the runway beams are typically embedded or anchored into the concrete ceiling. This process involves drilling holes into the concrete and securing the beams using appropriate anchor bolts or inserts.

Steel Structure Workshop: In a steel structure workshop, the runway beams are attached to the steel framework of the building. This is usually done using welding or bolted connections.

In both cases, the installation should be performed by qualified professionals, taking into consideration the loadbearing capacity of the ceiling structure and complying with all relevant safety regulations and building codes.

In conclusion, a ceilingmounted (under running) bridge crane is a type of bridge crane where the main girder travels under runway beams. The main components include the bridge, hoist, trolley, end trucks, and the runway beams. The runway beams are installed by embedding or anchoring them in the ceiling for a concrete workshop or attaching them to the steel structure for a steel structure workshop. Proper installation is crucial for the safe and efficient operation of the ceilingmounted bridge crane.

Inspection of your ceiling structure for ceiling bridge crane crane installation

- Consult Structural Engineers: Engage with structural engineers or experienced crane installation specialists to assess the loadbearing capacity of your facility's ceiling structure. They will have the expertise to evaluate whether the ceiling can support the weight and forces imposed by the crane.

- Review Building Plans: Review the original building plans, if available, to gain insight into the specifications and load capacities of the ceiling structure.

- Identify Load Requirements: Determine the maximum load capacity required for your crane, including the weight of the crane itself, the maximum load to be lifted, and any potential dynamic loads.

- Inspect Ceiling Materials: Inspect the materials used in constructing the ceiling, as different materials have varying loadbearing capabilities. For example, a reinforced concrete ceiling can typically handle more weight than a lightweight metal or wooden structure.

- 5. Check for Adequate Supports: Ensure that there are adequate supporting structures, such as beams or columns, to anchor the runway system securely.

- 6. Check for Obstructions: Identify any obstructions on the ceiling, such as pipes, ducts, lighting fixtures, or HVAC systems, that might interfere with the installation and movement of the crane.

- 7. Comply with Local Regulations: Be aware of and comply with local building codes and regulations governing the installation of cranes and overhead equipment.

- 8. Professional Inspection: Engage a professional crane installer to conduct a thorough onsite inspection. They can assess the specific requirements of your facility and provide recommendations tailored to your needs.

Safety is paramount when installing overhead equipment like ceilingmounted bridge cranes. Proper planning, assessment, and adherence to safety guidelines are crucial to ensure the successful and safe implementation of the crane system.

Comparisons with other types of overhead cranes

Ceiling Mounted Bridge Cranes:

- Mounting: Attached to the facility's ceiling structure, utilizing the overhead space efficiently and leaving the floor clear.

- Advantages: Ideal for facilities with ample headroom, offer versatile horizontal movement, and can handle heavy loads efficiently.

- Limitations: Require a structurally robust ceiling to support the crane's weight and may not be suitable for facilities with limited headroom.

General Use Bridge Cranes with Top Running Design:

- Mounting: Travel on rails mounted on the top of the runway beams, supported by the building's columns or structure.

- Advantages: Offer higher hook heights and increased lifting capacities compared to under running bridge cranes. Suitable for various industrial applications.

- Limitations: May require more space for installation due to their higher hook heights and might have higher costs compared to under running bridge cranes.

- Mounting: Selfsupporting system using its own support columns anchored to the floor, independent of the building's structure.

- Advantages: Do not rely on the building's ceiling structure, making them suitable for facilities without adequate overhead support.

- Limitations: Require floor space, which may reduce usable area, and may not offer the same hook heights and lifting capacities as ceilingmounted or top running bridge cranes.

Gantry Cranes:

Strengths:

- Do not require a ceiling or building support structure as they are freestanding systems.

- Suitable for outdoor use or in facilities without overhead support for bridge cranes.

- Provide excellent flexibility as they can be moved to different locations within the facility.

- Available in various configurations and capacities to suit specific material handling needs.

- Can be equipped with different types of trolleys and hoists for specialized applications.

Weaknesses:

- Occupy floor space, which may reduce the usable area in the facility.

- The span between the legs limits the width of the area that can be covered.

- May have lower lifting heights compared to some ceilingmounted bridge cranes.

Jib Cranes:

Strengths:

- Ideal for localized material handling tasks in a specific work area or workstation.

- Provide a costeffective solution for light to mediumduty lifting requirements.

- Require minimal space and can be mounted on existing columns or walls.

- Offer 360degree rotation for easy and precise positioning of loads.

Weaknesses:

- Limited in terms of horizontal movement compared to bridge cranes or gantry cranes.

- Generally have lower lifting capacities compared to ceilingmounted bridge cranes.

- Suitable for smallscale operations and may not be efficient for large facilities.

Monorail Systems:

Strengths:

- Suitable for simple linear material handling tasks along a fixed path.

- Compact design and can be installed in tight spaces.

- Ideal for moving loads in a straight line from one point to another.

- Can be customized with curves and switches to accommodate specific layouts.

Weaknesses:

- Limited in terms of horizontal movement flexibility compared to bridge cranes or gantry cranes.

- Typically have lower lifting capacities compared to ceilingmounted bridge cranes.

- May not be wellsuited for complex material handling needs or largescale operations.

Ceiling Mounted Bridge Cranes and General Use Bridge Cranes with Top Running Design both utilize overhead space efficiently and offer versatile horizontal movement. The choice between the two depends on the specific needs of the facility and available headroom.

CeilingMounted Bridge Cranes and Freestanding Bridge Cranes have a significant difference in their mounting systems. Ceilingmounted cranes rely on the building's ceiling structure, while freestanding cranes are selfsupporting. The decision depends on whether the facility has adequate ceiling support or requires a separate support system.

General Use Bridge Cranes with Top Running Design and Freestanding Bridge Cranes are both suitable for facilities without a ceiling structure capable of supporting a ceilingmounted crane. The choice between the two depends on the specific requirements, available space, and budget considerations.

Ultimately, the selection of the most appropriate crane type depends on various factors, including the facility's layout, lifting requirements, available space, budget, and any limitations imposed by the building's structure. Consulting with crane specialists or engineers can help businesses make the right decision and choose the most suitable overhead crane for their material handling needs.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch