Single Girder Bridge Cranes 1 to 20 Ton: A Complete Buyer's Guide

Single girder bridge crane for sale 3 ton, 5 ton, 10 ton, 15 ton, 20 ton. All types of single girder bridge cranes for wide industrial sectors, good price.

| Crane type | Single girder bridge crane |

| Top running crane | 1 ton - 20 ton |

| Underhung crane | 0.5 ton - 10 ton |

| Lifting height | As customer requirement |

| Crame span | As customer requirement |

Category: Bridge Crane

Your Trusted Bridge Crane Manufacturer & Supplier

Single Girder Bridge Cranes 1 Ton -20 Ton : A Complete Buyer's Guide

Single girder bridge crane for sale 3 ton, 5 ton, 10ton, 15 ton, 20 ton. All types of single girder bridge cranes for wide industrial sectors, good price.

In the realm of material handling and lifting equipment, single girder bridge cranes play an indispensable role. Whether you're a seasoned industry professional or someone embarking on the journey of optimizing your material handling processes, this comprehensive guide is tailored to meet your needs. We will delve into the world of single girder bridge cranes, exploring their different aspects and capabilities across a wide capacity spectrum from 1 ton to 20 tons.

Material handling is a critical part of various industries, including manufacturing, construction, warehousing, and logistics. Single girder bridge cranes offer an efficient and reliable solution for lifting and transporting heavy loads within these sectors. Their versatility and capacity range make them ideal tools for both light-duty and heavy-duty applications. This guide aims to equip you with the knowledge and insights necessary to make informed decisions when considering the purchase and use of single girder bridge cranes, whether it's a 1-ton crane for a specific task or a 20-ton crane for more heavy-duty operations. Let's dive into the details and explore the world of single girder bridge cranes.

What is a Single Girder Bridge Crane?

At its core, a single girder bridge crane is a type of overhead crane used to lift and move heavy loads horizontally within a facility. The term "single girder" refers to the crane's overhead structure, which consists of a single horizontal beam running parallel to the runway. This beam supports the hoist and trolley mechanism, allowing for the precise and controlled movement of loads. Single girder bridge cranes are known for their efficiency, adaptability, and the ability to cater to a wide range of capacity requirements, from 1 ton to 20 tons.

Main parts and components of single girder bridge cranes

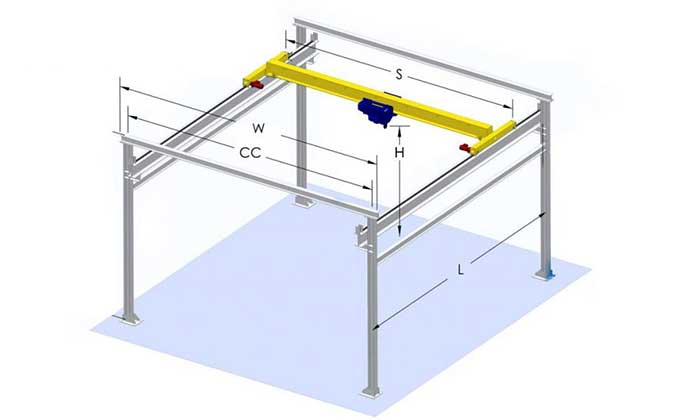

Single girder bridge crane 3 D presentation

Key Components and Design

Single girder bridge cranes are composed of several key components that work in harmony to facilitate the lifting and movement of loads. These components include the following:

- Bridge Girder: The horizontal beam that spans the width of the runway and carries the hoist and trolley mechanism.

- Hoist: The lifting device responsible for raising and lowering loads.

- End Trucks: These support the bridge girder and allow it to move along the runway beams.

- Runway: The system of tracks on which the crane operates.

- Electrical System: Controls and power supply that enable the crane's operation.

Key Components and Design

Single girder bridge cranes are marvels of engineering that comprise various key components, each playing a vital role in their operation. Understanding these components and the design options available is crucial for making informed decisions when choosing the right crane for your specific application. Let's delve into the heart of single girder bridge cranes and explore their key components and diverse design configurations.Learn more about the bridge crane main parts and components to get your custom single girder bridge crane design.

Essential Components of a Single Girder Bridge Crane

Bridge Girder

The bridge girder is the backbone of the crane. It's a horizontal beam that spans the width of the runway. This component carries the load and supports the hoist and trolley. The design and construction of the bridge girder must be robust to ensure stability and safety during lifting operations. Depending on the load capacity and the crane's design configuration, the bridge girder can come in various shapes, such as I-beams or box girders.

Hoist

The hoist is the lifting device responsible for raising and lowering loads. It is attached to the bridge girder and comes in different types, including electric wire rope hoists and electric chain hoists. The choice of hoist depends on the crane's intended application and the weight of the loads it will handle. A well-maintained and appropriately chosen hoist is essential for safe and efficient lifting operations.

End Trucks

End trucks are located on both ends of the bridge girder and support the entire crane's structure. They contain wheels or casters that allow the crane to move along the runway beams. The quality and design of end trucks impact the crane's stability and maneuverability, making them an integral part of the crane's construction.

Runway

The runway consists of the parallel tracks on which the crane operates. It provides the path for the crane's movement within a facility. Ensuring that the runway is straight, level, and free of obstructions is essential for the crane's smooth operation.

Electrical System

The electrical system of a single girder bridge crane includes the controls and power supply that enable the crane's operation. It encompasses various components, such as the control panel, pendant controls, electrical cables, and power sources. An efficient electrical system is vital for precise and safe crane movement.

Types of Single Girder Bridge Cranes

Single girder bridge cranes offer versatile solutions for a wide range of lifting applications. They come in various types based on design configuration, mounting, support structure, application, span, hoist type, and capacity. Understanding these classifications is essential for choosing the right crane to meet your specific needs. Let's explore the main types of single girder bridge cranes.

By Design Configuration and Mounting Types:

Top Running Single Girder Bridge Crane: In this design, the bridge runs on top of the runway beams, and the crane is mounted on the building's runway beams. Top running single girder cranes are known for their stability, making them suitable for heavy-duty lifting applications. They maximize the available workspace beneath the crane, enabling efficient material handling in various industries.

Under Running Single Girder Bridge Crane: Under running single girder cranes feature a bridge that runs beneath the runway beams. The crane is suspended from the building's runway beams, allowing for versatile load handling. This design is often chosen when headroom is limited or when the building structure cannot support the crane's weight. Under running cranes are commonly used for lighter loads and in settings with space constraints.

Understanding these design options and components is crucial when selecting the right single girder bridge crane for your needs. The flexibility offered by these configurations allows you to choose a crane that best suits your application's requirements, whether you need it for heavy-duty lifting or operations with spatial limitations. Next, we will explore the diverse range of single girder bridge crane types based on different classifications.

Top Running Single Girder Bridge Cranes 1 Ton to 20 Ton :

In a top-running configuration, the bridge runs on top of the runway beams. The wheels or casters of the end trucks are attached to the top flange of the runway beams. This design configuration is often used for heavier loads and offers stability, making it a suitable choice for a wide range of industrial applications. Top-running cranes maximize the available workspace beneath the crane and allow for efficient load handling.

Features:

- Stability: Top running single girder bridge cranes are renowned for their stability, which makes them well-suited for heavy-duty lifting applications. Their robust design ensures safe and reliable material handling.

- Maximized Workspace: These cranes maximize the available workspace beneath them. By running on top of the runway beams, they do not interfere with floor-level operations, providing an efficient solution for material handling in various industries.

- High Load Capacity: Top running single girder cranes are designed to handle substantial loads, making them ideal for applications that involve lifting heavy materials.

- Durable Construction: They are built with durability in mind, ensuring a long service life even in demanding industrial environments.

Benefits:

- Heavy-Duty Applications: Top running single girder bridge cranes are well-suited for heavy-duty lifting tasks. They are commonly used in industries where robust and reliable lifting solutions are required.

- Efficient Material Handling: These cranes optimize workspace usage, enabling efficient material handling and production processes. Their design allows them to cover a large area without compromising floor space.

- Increased Productivity: By streamlining material handling and reducing downtime, top running single girder cranes contribute to increased productivity within industrial settings.

- Enhanced Safety: The stability and precision of these cranes enhance workplace safety by reducing the risk of accidents during material handling operations.

Typical Applications:

- Manufacturing Facilities: Top running single girder bridge cranes are commonly used in manufacturing facilities to move heavy components and materials during the production process.

- Steel Mills: Due to their capacity to handle heavy loads, these cranes are found in steel mills where they facilitate the movement of raw materials and finished products.

- Warehouses: Warehouses benefit from the efficient use of vertical space provided by top running cranes, allowing for streamlined storage and retrieval operations.

- Aerospace Industry: In the aerospace sector, these cranes are used to lift aircraft components and assemblies.

- Automotive Industry: The automotive industry employs top running single girder bridge cranes for various tasks, such as moving vehicle parts on assembly lines.

- Heavy Machinery Manufacturing: Industries that produce heavy machinery rely on these cranes for the assembly and movement of equipment.

Under Running Single Girder Bridge Cranes 5 Ton:

Under running single girder bridge cranes feature a bridge that runs beneath the runway beams. In this configuration, the end trucks are suspended from the building's structure, and the wheels or casters are attached to the bottom flange of the runway beams. Under running cranes are ideal when headroom is limited or when the building structure is unable to support the crane's weight. They are often used for lighter loads and are commonly found in settings where space constraints are a concern.

Features:

- Versatility: Under running single girder bridge cranes feature a bridge that runs beneath the runway beams, allowing for versatile load handling. Their design enables them to adapt to various types of lifting tasks.

- Space-Efficient: These cranes are an excellent choice when headroom is limited, as they do not require as much overhead space as top running cranes. They are also suitable for facilities with space constraints.

- Suspended Design: The crane is suspended from the building's runway beams, which makes them a practical solution when the building structure cannot support the crane's weight.

Benefits:

- Headroom Optimization: Under running single girder bridge cranes are ideal for facilities with limited headroom. The suspended design allows efficient use of vertical space.

- Customizable Solutions: These cranes can be tailored to the specific needs of an application, making them a versatile choice for diverse industries.

- Space-Saving: They maximize floor space and are particularly useful in settings where every inch of space counts.

Typical Applications:

- Workshops: Under running single girder bridge cranes are commonly found in workshops where they handle various tasks, from machine maintenance to materials handling.

- Assembly Lines: These cranes are used to assist in the assembly of products on production lines, particularly in settings with space constraints.

- Textile Industry: The textile industry benefits from the space-saving design of under running cranes when moving rolls of fabric and other materials.

- Small Warehouses: Smaller warehouses use under running cranes to optimize space while enabling efficient storage and retrieval operations.

- Light Manufacturing: Industries involved in light manufacturing, such as electronics and small parts assembly, utilize these cranes for handling components and finished products.

In summary, the choice between top running and under running single girder bridge cranes depends on the specific requirements of an application. Top running cranes excel in heavy-duty applications where stability and high load capacity are crucial. On the other hand, under running cranes are versatile and space-efficient, making them suitable for a range of applications, especially in settings with space limitations. Understanding the features, benefits, and typical applications of both types helps users make informed decisions when selecting the most appropriate crane for their needs.

By Support Structure:

Freestanding Single Girder Bridge Crane: Freestanding single girder cranes are self-supporting structures that do not rely on the building for support. They are an excellent choice for facilities where the building's structure is not suitable for crane installation. These cranes offer flexibility and can be positioned where needed within the facility.

Supported Single Girder Bridge Crane: Supported single girder cranes rely on the building's structure for support. They are installed on existing support columns or other structural elements within the facility. Supported cranes are often used when the building structure can accommodate the crane's weight and load requirements.

Freestanding Single Girder Bridge Crane 2 Tons:

Features:

- Self-Supporting Structure: Freestanding single girder bridge cranes are self-supporting, meaning they don't rely on the building's structure for support. They have their support systems, such as columns, eliminating the need for attachment to the building.

- Flexibility: These cranes offer high flexibility in terms of placement within a facility. Their self-supporting nature allows them to be installed where they are needed most, making them adaptable for various tasks.

- Customizable: Freestanding cranes are customizable to fit the specific needs of an application, and they can be designed with various options, such as different lifting mechanisms.

Benefits:

- No Building Attachment: The fact that they do not require attachment to the building's structure can be advantageous in facilities where the building's structure is not suitable for crane installation. This ensures minimal interference with existing structures.

- Quick Installation: Installation of freestanding cranes tends to be quicker and more straightforward than other crane types that require attachment to the building.

- Space Optimization: These cranes maximize floor space since they are not reliant on the building's structural support, providing efficient utilization of available space.

Typical Applications:

- Manufacturing and Production: Freestanding single girder bridge cranes are widely used in manufacturing and production environments for tasks such as assembly, material handling, and machine loading/unloading.

- Workshops: They are often found in workshops, where they assist in various tasks, including equipment maintenance and parts handling.

- Storage and Warehousing: In warehousing and storage facilities, freestanding cranes are employed to move and stack goods efficiently.

- Auto Repair and Maintenance: Facilities involved in auto repair and maintenance use these cranes for lifting and maneuvering vehicles and components.

Single Girder Bridge Cranes:

Features:

- Building Attachment: Supported single girder bridge cranes rely on the building's structure for support. They are installed on existing support columns or other structural elements within the facility.

- Stability: The attachment to the building's structure provides stability and strength, making supported cranes suitable for heavy-duty lifting tasks.

Benefits:

- Heavy-Duty Lifting: Supported cranes are often chosen for their ability to handle heavy loads and frequent use. They are a dependable choice for industries requiring robust lifting solutions.

- Use of Existing Structure: These cranes utilize the facility's existing support elements, making them a cost-effective option when the building's structure can accommodate the crane's weight and load requirements.

Typical Applications:

- Steel Mills: Supported single girder bridge cranes are commonly used in steel mills for the movement of raw materials and finished products due to their capacity to handle substantial loads.

- Manufacturing: In manufacturing facilities, these cranes assist in lifting heavy components and materials during the production process.

- Warehousing: Supported cranes are employed in warehousing applications for heavy-duty material handling, particularly when storage and retrieval of large items are required.

- Construction Sites: Construction sites utilize these cranes for lifting and positioning heavy construction materials and equipment.

- Automotive Industry: Supported single girder bridge cranes are frequently found in the automotive industry for lifting vehicle parts and components during the manufacturing process.

The choice between freestanding and supported single girder bridge cranes depends on the specific requirements and constraints of an application. Freestanding cranes offer flexibility and are ideal for facilities where building attachment is not feasible. In contrast, supported cranes are chosen when the building's structure can accommodate the crane's weight and when heavy-duty lifting capabilities are necessary. Understanding the features, benefits, and typical applications of both types helps users make informed decisions when selecting the most suitable crane for their specific needs.

By Application and Usage:

General-Purpose Single Girder Bridge Cranes 10 ton example:

Features:

- Versatility: General-purpose single girder bridge cranes are known for their adaptability and versatility. They are designed to handle various loads and can be customized to fit a broad range of applications.

- Efficiency: These cranes are built with a focus on efficient material handling. They are equipped with features that enhance lifting and moving tasks.

- Customization: General-purpose cranes can be tailored to specific application requirements, including the choice of hoist type and other accessories.

Benefits:

- Multi-Industry Use: General-purpose cranes are ideal for industries where lifting needs vary across applications. Their adaptability makes them a valuable asset for businesses with diverse requirements.

- Productivity: These cranes are designed to improve productivity by offering efficient load handling and transportation, reducing downtime.

- Reduced Costs: By providing a single crane solution for multiple applications, general-purpose cranes can help reduce costs associated with having multiple specialized cranes.

Typical Applications:

- Warehousing: General-purpose cranes are commonly used in warehousing environments for the efficient loading and unloading of goods, as well as material handling tasks.

- Manufacturing: Manufacturing facilities benefit from the versatility of general-purpose cranes, which can assist in various stages of production, from raw material handling to assembly.

- Maintenance and Repair: These cranes are found in maintenance and repair shops, where they help lift heavy equipment and components for servicing.

- Construction: In the construction industry, general-purpose cranes provide support for lifting construction materials, equipment, and structural components.

- Shipping and Freight Handling: Ports and shipping facilities use these cranes for loading and unloading cargo, making them essential for logistics operations.

Hazardous Environment Single Girder Bridge Cranes:

Features:

- Safety Measures: Cranes designed for hazardous environments incorporate special safety features to prevent sparks, fires, and other potential hazards.

- Corrosion Resistance: These cranes are built to withstand the corrosive effects of chemicals and gases found in hazardous settings.

- Custom Components: They often include explosion-proof components, specialized electrical systems, and spark-resistant features.

Benefits:

- Safety: Hazardous environment cranes are designed to ensure the safety of both workers and the workplace in settings where flammable materials or explosive atmospheres are present.

- Reliability: These cranes offer reliable performance even in challenging conditions, reducing downtime and maintenance costs.

Typical Applications:

- Chemical Processing: Hazardous environment cranes are commonly used in chemical processing facilities where the presence of flammable materials requires strict safety measures.

- Oil and Gas Industry: In oil refineries and natural gas processing plants, these cranes are used for lifting and moving equipment and materials.

- Aerospace and Defense: Facilities working with sensitive aerospace and defense components employ hazardous environment cranes for safe and reliable material handling.

- Pharmaceutical Manufacturing: Pharmaceutical manufacturing facilities require specialized cranes to handle chemicals and substances safely.

- Grain Handling: In grain elevators and processing facilities, hazardous environment cranes help manage the movement of grains in potentially explosive atmospheres.

Understanding the features, benefits, and typical applications of general-purpose and hazardous environment single girder bridge cranes is crucial for selecting the most suitable crane based on the specific needs and environmental conditions of an application. General-purpose cranes offer versatility and efficiency, making them ideal for a wide range of industries. In contrast, hazardous environment cranes prioritize safety and reliability in settings where explosive or flammable materials are present, ensuring the well-being of workers and protecting valuable equipment.

By Span and Width:

- Wide Span Single Girder Bridge Crane: Wide span cranes are designed for applications that require a broader coverage area. They are ideal for facilities with a need to cover a large workspace efficiently.

- Narrow Span Single Girder Bridge Crane: Narrow span cranes are tailored for applications with limited space. These cranes are suitable for operations in facilities where available space is a concern.

Wide Span Single Girder Bridge Crane 5 Ton:

Features:

- Expansive Coverage: Wide span cranes are engineered to cover large work areas efficiently. They can handle materials and loads across a broad span, reducing the need for multiple crane installations.

- Increased Productivity: Their wide coverage optimizes workflow, enabling more efficient and productive material handling operations.

- Flexibility: These cranes are adaptable to various industries and can accommodate diverse load requirements.

Benefits:

- Enhanced Efficiency: Wide span cranes provide significant operational efficiency by eliminating the need for additional cranes or extended material handling distances.

- Cost Savings: By reducing the number of cranes required, businesses can save on equipment, installation, and maintenance costs.

- Versatility: These cranes are suitable for applications where flexibility in moving materials across a large area is crucial.

Typical Applications:

- Warehousing: Warehouses with large storage areas and high shelving benefit from wide span cranes to efficiently handle and transport goods.

- Metal Fabrication: In metal fabrication facilities, wide span cranes can move large metal sheets and components across expansive workspaces.

- Shipbuilding: Shipyards use these cranes to lift and transport heavy ship components and equipment during construction.

- Agriculture: In agricultural settings, wide span cranes facilitate the movement of bulk goods such as grains and feed within storage facilities.

Narrow Span Single Girder Bridge Crane with Underhung Design 1 Ton :

Features:

- Space Efficiency: Narrow span cranes are designed to function optimally in confined spaces where larger cranes cannot operate effectively.

- Precise Control: They provide precise and controlled load handling in tight areas, reducing the risk of accidents and damage.

- Ease of Maneuverability: Their compact design allows them to navigate through narrow aisles and tight workspaces with ease.

Benefits:

- Space Utilization: Narrow span cranes maximize the utilization of limited space, making them a suitable choice for facilities with spatial constraints.

- Safety: Their precise control and maneuverability help prevent accidents and damage in confined workspaces.

- Cost-Effective: Businesses can save on construction costs and workspace modification by using narrow span cranes.

Typical Applications:

- Manufacturing Cells: In manufacturing cells, narrow span cranes provide support for assembly and material handling in limited space configurations.

- Automotive Industry: Automotive plants use narrow span cranes in assembly lines and during the handling of car parts.

- Small Workshops: Small workshops with limited space for material handling and equipment rely on narrow span cranes.

- Retail Storage: Retailers with limited backroom storage space employ narrow span cranes for efficient stock management.

Understanding the features, benefits, and typical applications of wide span and narrow span single girder bridge cranes helps businesses make informed decisions when selecting cranes based on their workspace requirements and available operating area. Wide span cranes offer expansive coverage and improved productivity for applications with substantial workspaces. In contrast, narrow span cranes are optimized for tight areas, providing space efficiency, precise control, and safety for tasks in confined workspaces.

By Hoist Type:

- - Electric Wire Rope Hoist Single Girder Bridge Crane: These cranes are equipped with electric wire rope hoists for lifting. Electric wire rope hoists are known for their durability and precision in handling heavy loads.

- - Electric Chain Hoist Single Girder Bridge Crane: Electric chain hoists are utilized in these cranes for lifting operations. They offer reliable performance and are well-suited for various industrial applications.

Electric Wire Rope Hoist Single Girder Bridge Crane 2 Ton :

Features:

- Durability: Electric wire rope hoists are designed for heavy-duty lifting, making them ideal for robust material handling tasks.

- Precision: They provide precise and controlled load handling, ensuring safe and accurate positioning of loads.

- Versatility: These cranes can handle a wide range of load capacities, making them adaptable to various industrial applications.

Benefits:

- Heavy-Duty Operations: Electric wire rope hoists excel in lifting heavy and oversized loads, contributing to increased productivity.

- Safety: Their precision and control reduce the risk of accidents, safeguarding both personnel and valuable assets.

- Long Lifespan: These cranes are built to last, offering an extended service life and reducing maintenance costs.

Typical Applications:

- Steel Manufacturing: Electric wire rope hoist cranes play a vital role in moving heavy steel coils and materials within manufacturing facilities.

- Foundries: Foundries use these cranes to handle molten metal, molds, and other heavy components.

- Construction Sites: Construction projects with heavy lifting requirements employ electric wire rope hoist cranes for material handling.

- Mining Industry: Mines utilize these cranes to transport extracted materials, machinery, and equipment.

Electric Chain Hoist Single Girder Bridge Crane 1 Ton :

Features:

- Reliability: Electric chain hoists are known for their dependable performance, ensuring consistent and efficient load handling.

- Compact Design: They have a compact and lightweight design, making them suitable for applications with space constraints.

- Ease of Maintenance: These cranes are easy to maintain and service, minimizing downtime.

Benefits:

- Efficiency: Electric chain hoists are efficient in lifting operations, contributing to improved productivity and reduced labor costs.

- Space-Saving: Their compact design allows them to operate effectively in confined workspaces and small manufacturing units.

- Affordability: Electric chain hoist cranes are a cost-effective solution for various industrial setups.

Typical Applications:

- Automotive Assembly: Automotive manufacturers use electric chain hoist cranes for material handling in assembly lines.

- Workstations: Workstations with limited space and overhead clearance rely on these cranes for efficient load handling.

- Warehousing: Warehouses employ electric chain hoist cranes for moving and storing goods efficiently.

- Retail Storage: Retailers with backroom storage areas utilize these cranes for stock management and organization.

Understanding the features, benefits, and typical applications of electric wire rope hoist and electric chain hoist single girder bridge cranes assists businesses in choosing the right crane based on their specific needs. Electric wire rope hoist cranes excel in heavy-duty operations, ensuring durability, precision, and versatility. In contrast, electric chain hoist cranes offer reliability, space-saving advantages, and affordability for various applications with limited space and overhead clearance.

By Capacity:

These classifications offer a comprehensive understanding of the diverse range of single girder bridge cranes available. When selecting a crane, it's essential to consider the specific requirements of your application, whether it involves space constraints, load capacities, or usage frequency. The right choice will enhance productivity and safety in your material handling operations. Next, we will explore how to find and purchase single girder bridge cranes and factors to consider during the buying process.

Benefits and Common Usage of Different Capacity Single Girder Bridge Cranes:

When it comes to single girder bridge cranes, choosing the right capacity is essential to ensure efficiency and safety. These cranes are available in various tonnage options, each tailored to specific industrial applications. Let's explore the benefits and common usage of different capacity single girder bridge cranes, ranging from 1 ton to 10 tons:

1 Ton Single Girder Bridge Crane:

Benefits:

- Light-Duty Operations: These cranes are designed for light-duty tasks that require precision and control, ensuring efficient material handling.

- Space Efficiency: Their compact design and lightweight structure make them ideal for settings with limited space.

- Affordability: 1-ton cranes offer a cost-effective solution for businesses with modest lifting requirements.

Common Usage:

- Workstations: Workstations and assembly lines rely on 1-ton single girder bridge cranes for small load handling and part assembly.

- Warehousing: Small-scale warehouses use these cranes for organizing and managing inventory.

2 Ton Single Girder Bridge Crane:

Benefits:

- Versatility: 2-ton cranes provide versatility and can adapt to a wide range of industrial applications, accommodating moderate lifting needs.

- Efficiency: They offer efficient material handling solutions for various work environments.

Common Usage:

- Manufacturing Facilities: Manufacturing units employ 2-ton cranes for moving components and equipment.

- Agriculture: Farms utilize these cranes for lifting and transporting heavy agricultural products.

3 Ton Single Girder Bridge Crane:

Benefits:

- Moderate Lifting: These cranes are well-suited for applications with moderate lifting requirements, ensuring efficient load handling.

- Durability: Their design focuses on durability and reliability in industrial settings.

Common Usage:

- Metal Fabrication: Metal fabrication facilities use 3-ton cranes for handling steel materials and products.

- Automotive Industry: The automotive sector relies on these cranes for various assembly line operations.

5 Ton Single Girder Bridge Crane:

Benefits:

- Efficiency: 5-ton cranes are known for their efficiency in material handling tasks, contributing to enhanced productivity.

- Versatility: They offer versatility and can adapt to a wide range of applications in various industries.

Common Usage:

- Foundries: Foundries use 5-ton cranes for handling molds, metal materials, and heavy components.

- Warehousing: Large warehouses rely on these cranes for organizing and moving goods efficiently.

5 Ton Single Girder Bridge Crane:

Benefits:

- Heavy-Duty Operations: These cranes excel in lifting heavy and oversized loads, providing robust material handling solutions.

- Efficiency: They contribute to increased productivity in industrial applications with demanding load requirements.

Common Usage:

- Heavy Machinery Manufacturing: Manufacturing plants use 5-ton cranes for transporting heavy machinery and equipment.

- Construction Sites: Construction projects with substantial lifting requirements employ these cranes for material handling.

10 Ton Single Girder Bridge Crane:

Benefits:

- High Capacity: These cranes are engineered for heavy lifting, making them suitable for demanding industrial applications.

- Durability: Their design focuses on durability, ensuring longevity and minimizing maintenance costs.

Common Usage:

- Steel Manufacturing: Steel manufacturing facilities use 10-ton cranes for handling large steel coils and materials.

- Mining Industry: Mines employ these cranes for transporting heavy mining equipment and materials.

Understanding the benefits and common usage of different capacity single girder bridge cranes assists businesses in selecting the appropriate crane based on their specific requirements. Whether it's a 1-ton crane for light-duty precision tasks or a 10-ton crane for heavy-duty industrial applications, these cranes offer efficiency, versatility, and reliability in various settings.

For Sale and Purchase

Purchasing a single girder bridge crane now involves considering a broader range of capacities, from 1 ton to 20 tons. Here's how to find and buy the right crane:

- Identify Your Specific Needs: Determine your precise lifting and material handling requirements within the expanded capacity range of 1 ton to 20 tons.

- Seek Reputable Manufacturers and Suppliers: Look for established manufacturers and suppliers who offer a diverse range of capacities, ensuring that your specific needs can be met.

- Request Quotes: Reach out to multiple manufacturers and suppliers to request quotes for cranes within your desired capacity range.

- Compare Offerings: Compare the various crane offerings, considering factors such as price, features, and customization options to ensure they align with your requirements.

- Evaluate Warranties and After-Sales Services: Pay close attention to the warranties and after-sales services offered by different manufacturers and suppliers. Each capacity range may have specific maintenance and support needs, so it's crucial to evaluate these services for their suitability to your requirements.

By following these steps, you can make an informed decision when purchasing a single girder bridge crane within the extended capacity range of 1 ton to 20 tons. Whether you need a smaller capacity crane for light-duty tasks or a larger one for heavy-duty operations, considering your specific needs is essential in the procurement process.

Advantages and Common Usage

Features and Benefits

Single girder bridge cranes offer several advantages, including:

- Efficient and precise material handling, catering to a broader range of load capacities from 1 ton to 20 tons.

- Improved productivity and workflow, enhancing operations across diverse industries.

- Versatile applications suitable for light-duty, medium-duty, and heavy-duty scenarios.

Common Usage

Single girder bridge cranes find common usage in numerous industries and scenarios, with applications spanning:

- Manufacturing Facilities: These cranes efficiently move materials and products along the assembly line, aiding in the manufacturing process.

- Warehouses: Single girder bridge cranes help in organizing and transporting goods within warehouses, optimizing storage space and speeding up logistics.

- Steel Mills: The cranes handle the heavy loads required in steel production, contributing to the efficiency of the mill.

- Automotive Workshops: Single girder bridge cranes assist in lifting car parts and vehicles for maintenance and assembly.

- Construction Sites: They facilitate the lifting and placement of construction materials and equipment.

- Aerospace Industry: These cranes are used for the precise positioning of aircraft components.

- Power Plants: Single girder bridge cranes are vital for managing heavy equipment and materials in power generation facilities.

The adaptability of single girder bridge cranes across these diverse industries underscores their utility for both light and heavy lifting operations, making them a preferred choice within the 1-ton to 20-ton capacity range.

Safety and Maintenance

Ensuring the safety and maintenance of single girder bridge cranes spanning the capacity range from 1 ton to 20 tons is essential for smooth and secure operations. Here's a more detailed look at safety and maintenance practices:

Regular Inspections and Maintenance Checks:

- Establish a regular inspection schedule, tailored to the specific capacity of your crane. For 1-ton to 20-ton cranes, inspections may vary in frequency and complexity.

- Routine inspections should cover crucial components such as the bridge, hoist, end trucks, electrical systems, and runway beams. Pay special attention to load-bearing components, as they are vital for safety.

- Develop a checklist that includes critical points to examine during each inspection, ensuring that nothing is overlooked.

- Address any identified issues promptly, irrespective of capacity. Timely maintenance and repairs are key to preventing safety hazards and minimizing downtime.

Operator Training and Certification:

- Operator training is essential for the safe operation of single girder bridge cranes across the entire capacity range. Different tonnage capacities require specific knowledge and skills.

- Ensure that operators receive comprehensive training that aligns with the capacity of the crane they will be operating. Training should cover crane controls, load management, and safety procedures.

- Certification programs, recognized in your region or industry, can validate an operator's skills. Operators should obtain certification relevant to the crane's capacity, ensuring they are well-qualified for the task.

Compliance with Safety Standards:

- Adherence to safety standards and regulations is crucial to the safe operation of single girder bridge cranes, regardless of their capacity. These standards exist to protect both personnel and equipment.

- Ensure that your crane complies with the safety standards applicable to its capacity. These standards may include requirements for load limits, crane design, safety devices, and operator qualifications.

- Regularly review and update your safety protocols and practices to stay in compliance with evolving safety regulations and industry best practices.

Preventive Maintenance:

- Implement a proactive maintenance program that addresses both the general maintenance needs of cranes and capacity-specific requirements.

- For cranes with higher capacities, more frequent and comprehensive preventive maintenance may be necessary. This approach can extend the lifespan of your equipment and ensure optimal performance.

- Consult your crane's manual and manufacturer recommendations for guidance on preventive maintenance tasks, which may include lubrication, component inspections, and adjustments.

In conclusion, the safety and maintenance of single girder bridge cranes spanning the capacity range from 1 ton to 20 tons are essential for safe and efficient operations. To ensure the longevity and performance of your crane, regular inspections, operator training, and compliance with safety standards are crucial. Developing and following a comprehensive preventive maintenance plan is equally important to minimize downtime and costly repairs.

Choosing the Right Crane

Selecting the right crane within the 1-ton to 20-ton capacity range involves considering factors like capacity, span, support structure, and hoist type. It's crucial to choose a reputable manufacturer with the necessary certifications and positive customer reviews.

Choosing the right single girder bridge crane, especially within the 1-ton to 20-ton capacity range, is a crucial decision that can significantly impact your material handling operations. Here are some more details to help you make an informed choice:

- Define Your Specific Needs: Before you start your search, it's essential to have a clear understanding of your specific needs. Consider factors like the type of materials you'll be handling, the frequency of lifts, the working environment, and any space constraints. This information will guide you in selecting the right crane.

- Determine the Capacity: The broad capacity range from 1 ton to 20 tons gives you the flexibility to choose a crane that precisely matches your load requirements. Be sure to assess your maximum load capacity and choose a crane that can comfortably handle it. It's better to have some excess capacity for safety and future needs.

- Evaluate the Span: The span is the distance between the runway beams and directly affects the coverage area of the crane. Ensure that the crane's span is suitable for the size of your workspace. You may need a wider span for larger work areas and a narrower span for limited space environments.

- Consider Support Structure: You have the option to choose between freestanding and supported single girder bridge cranes. If your facility's structure is not suitable for crane installation, a freestanding crane is a practical choice. Supported cranes are an option when the building structure can accommodate the crane's weight.

- Determine Hoist Type: Electric wire rope hoists and electric chain hoists are commonly used in single girder bridge cranes. The choice depends on your lifting needs, precision requirements, and load capacity. Ensure that the hoist type aligns with your application.

- Research Manufacturers: A reputable manufacturer is crucial to ensure the quality and reliability of your crane. Look for manufacturers with a history of producing high-quality cranes and equipment. Check for certifications, such as ISO and safety standards compliance, which can vouch for the manufacturer's commitment to quality and safety.

- Read Customer Reviews: Customer reviews and testimonials can provide valuable insights into the manufacturer's reputation and the performance of their cranes. Pay attention to feedback from users who have similar capacity requirements to yours.

- Get Multiple Quotes: Don't settle for the first offer you receive. Request quotes from several manufacturers and compare them. This process can help you find the best pricing, warranty options, and after-sales services that align with your needs.

- Prioritize Safety: Safety should always be a top concern. Ensure that the crane you select adheres to safety standards and regulations applicable to your capacity range. Proper operator training is also crucial to ensure the safe operation of the crane.

In conclusion, selecting the right single girder bridge crane from the broad capacity range of 1 ton to 20 tons requires careful consideration of your specific needs, compliance with safety standards, and thorough research into reputable manufacturers. By taking these steps, you can make an informed decision that enhances your material handling efficiency and ensures the safety of your operations.

In the realm of material handling and lifting, single girder bridge cranes prove to be indispensable tools that cater to a broad capacity spectrum, ranging from 1 ton to 20 tons. This comprehensive guide has provided you with the knowledge essential to make well-informed decisions when contemplating the acquisition and utilization of single girder bridge cranes. Select the crane that perfectly aligns with your specific capacity requirements and witness how it can significantly enhance efficiency and productivity across a diverse array of operations. Whether you're managing light-duty tasks or handling heavy loads, there's a single girder bridge crane designed to meet your needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch