Single Girder Bridge Crane Prices: From Selection to Pricing Strategies

Selection tips & pricing strategies for single girder bridge crane 1, 2, 3 5, 10, 15, 20 ton to optimize cost-efficiency & performance. Get crane price!

Category: Bridge Crane

Your Trusted Single Girder Bridge Crane Manufacturer & Supplier

Single Girder Bridge Crane Prices: From Selection to Pricing Strategiese

Economical Single Girder Bridge Crane Price 1, 2, 3, 5, 10, 15, 20 Ton

Selection tips & pricing strategies for single girder bridge crane 1, 2, 3 5, 10, 15, 20 ton to optimize cost-efficiency & performance. Get crane price!

Overview of Single Girder Bridge Cranes

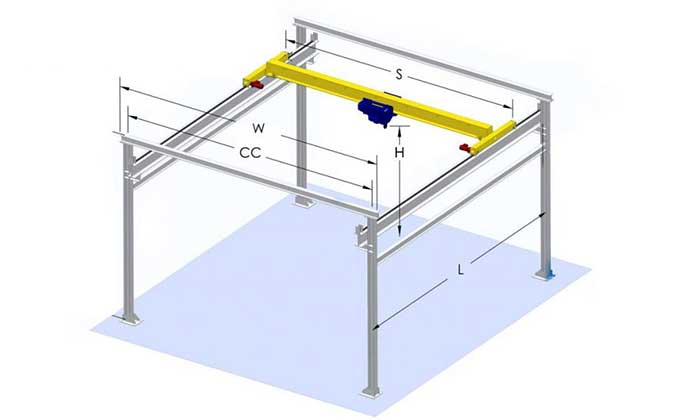

Single girder bridge cranes are versatile lifting solutions designed to handle a variety of tasks in industrial and manufacturing environments. They consist of a single main girder that spans the width of the work area, supported by two end trucks that travel along overhead rails. These cranes are commonly used for lifting and moving heavy loads across a horizontal plane, making them ideal for applications where vertical space is limited but horizontal reach is required.

Key Features and Advantages

- Simplicity and Efficiency: Single girder bridge cranes are known for their straightforward design, which allows for efficient operation and maintenance. Their single-girder setup results in a more lightweight structure compared to double girder cranes, which can reduce both the initial purchase cost and the overall installation effort.

- Cost-Effectiveness: Due to their simpler design, single girder bridge cranes generally offer a more budget-friendly option without compromising on performance. They are well-suited for moderate lifting tasks and smaller spans, making them a practical choice for many businesses.

- Space Optimization: The design of single girder bridge cranes allows for maximum utilization of overhead space. By minimizing the amount of vertical clearance required, these cranes help optimize the use of valuable floor space in warehouses and manufacturing facilities.

- Ease of Installation: With fewer components and a less complex structure, single girder bridge cranes are easier and quicker to install compared to their double girder counterparts. This can lead to reduced downtime and faster operational readiness.

Importance of Pricing in Procurement

Impact on Budget and Cost Management

When acquiring a single girder bridge crane, pricing is a crucial factor that significantly impacts a company's budget and cost management. The cost of the crane is not just about the initial purchase price but also includes installation, maintenance, and operational expenses. Understanding the total cost of ownership helps businesses plan their budgets more effectively and avoid unexpected financial strains.

Role in Decision-Making for Buyers

Pricing plays a central role in the decision-making process for buyers. It affects choices related to:

- Supplier Selection: Buyers must compare prices from different suppliers to ensure they get the best value for their investment. This includes evaluating what each price covers—such as warranty, service, and support—and how these factors influence the overall cost.

- Specification and Customization: The budget often dictates the level of customization and features a buyer can afford. Higher prices may be associated with advanced features, specialized designs, or additional components that enhance crane functionality.

- Cost-Benefit Analysis: Buyers need to assess whether the benefits of a more expensive crane, such as enhanced durability or advanced technology, justify the higher cost. This involves weighing the long-term advantages against the initial financial outlay.

- Negotiation and Financing: Pricing also impacts negotiations with suppliers and potential financing options. A clear understanding of pricing allows buyers to negotiate better deals and explore financing solutions that fit their financial situation.

In summary, a thorough understanding of the pricing dynamics for single girder bridge cranes is essential for effective procurement. It ensures that businesses make informed decisions that align with their operational needs and budget constraints.

Basics of Single Girder Bridge Cranes

Components and Specifications

Main Girder

The main girder is the primary horizontal support structure of a single girder bridge crane. It runs the full length of the crane's span and supports the hoist and trolley system. Typically made from steel or high-strength alloys, the main girder must be robust enough to handle the maximum load capacity of the crane. Its design and material affect the crane's overall strength, durability, and performance.

Hoist and Trolley System

The hoist is the component responsible for lifting and lowering loads. It is mounted on a trolley that moves along the main girder, allowing for horizontal movement of the load. The hoist can be electric, manual, or pneumatic, depending on the application and load requirements. The trolley system is designed to run smoothly along the girder, with minimal friction and wear, ensuring efficient operation and longevity.

End Trucks and Supporting Structures

End trucks are mounted at each end of the main girder and provide the mechanism for the crane to travel along the overhead rails. They include wheels or rollers that run on the rails, allowing the crane to move across the work area. Supporting structures, such as columns or wall mounts, provide stability and support to the crane system. These components must be precisely aligned and robustly constructed to ensure safe and reliable operation.

Main Types and Configurations

Top Running vs. Undergung

Top Running:

In a top running crane, the wheels or rollers of the end trucks are positioned on top of the overhead rails or beams. This configuration is widely used in industrial settings where there is ample vertical clearance.

Advantages:

- Higher Load Capacities and Wider Spans: Top running cranes can leverage the full height of the building, which allows them to support heavier loads and span wider distances. This makes them suitable for heavy-duty applications.

- Integration with Building Infrastructure: The design facilitates easier integration with existing building structures and can be adapted to various industrial layouts, offering greater versatility in placement and operation.

Undergung:

In an underhung crane, the wheels or rollers are mounted underneath the overhead rails. This design is particularly advantageous in buildings with limited headroom.

Advantages:

- Optimal Use of Overhead Space: Undergung cranes are ideal for facilities with lower ceiling heights, as they utilize the available space more effectively.

- Reduced Structural Support Requirements: Typically, these cranes require less structural reinforcement compared to top running cranes, making them less intrusive in spaces where height constraints are a factor.

Standard vs. Custom Designs

Standard Designs:

Standard single girder bridge cranes are built to meet general industry specifications and come in predefined sizes and configurations. These cranes are designed to address typical lifting needs with standard features.

Advantages:

- Cost-Effective: Due to their mass production and the absence of special modifications, standard designs generally have a lower cost.

- Simplicity and Availability: Ideal for common applications where standard dimensions and features are sufficient, making them readily available and easy to procure.

Custom Designs:

Custom-designed cranes are tailored to meet specific operational needs and environmental conditions. These cranes might include unique load capacities, special dimensions, or additional features tailored to particular applications.

Advantages:

- Flexibility and Optimization: Custom designs allow for adjustments to meet specific operational requirements, such as handling unique loads, adapting to extreme environmental conditions (e.g., high temperatures or corrosive environments), and incorporating specialized safety systems or advanced controls.

- Enhanced Performance: By aligning the crane's design with specific operational needs and existing infrastructure, custom designs can improve overall crane performance and efficiency, though they may involve a higher cost.

Understanding the distinctions between top running and underhung configurations, as well as between standard and custom designs, is crucial in selecting the appropriate single girder bridge crane for your application. This ensures that the crane aligns with both your operational requirements and budget constraints, maximizing efficiency and performance in your facility.

Hot Sale Types of Single Girder Bridge Cranes and Their Price Ranges

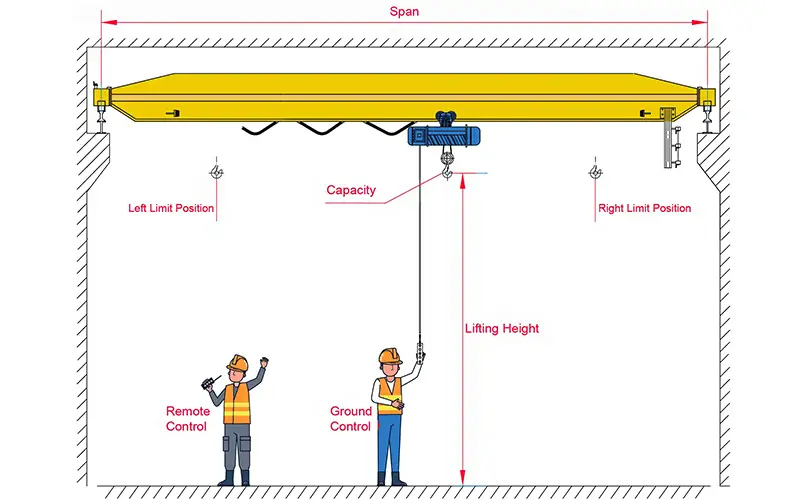

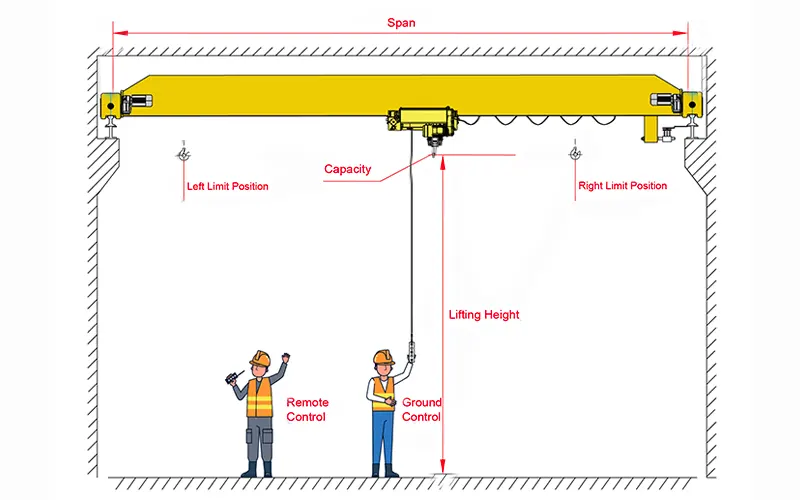

Single Girder Bridge Crane with Standard CD/MD Electric Hoist

Single girder electric overhead traveling cranes (EOT cranes) are renowned for their cost-effectiveness and versatility. They are suitable for a variety of indoor and outdoor applications, handling capacities from 0.5 to 20 tons and spans up to 31.5 meters. Common uses include machining, machine assembly, equipment maintenance, and warehousing.

Main Specifications:

- Capacity: 1t, 2t, 3t, 5t, 10t, 16t, 20t (custom sizes available upon request)

- Span Length: 7.5m to 31.5m

- Lifting Height: 6m to 30m

- Work Duty: A3/A4

- Voltage Options: 220V, 380V, 400V, 415V, 660V, 50-60Hz, 3-phase AC

- Control Modes: Floor control, Remote control, Cabin room control

- Traveling Speed: 20-30m/min

Price Range:

- 1 Ton: $1,830 - $5,100

- 2 Ton: $2,000 - $5,900

- 3 Ton: $2,130 - $7,680

- 5 Ton: $3,130 - $8,680

- 10 Ton: $3,890 - $12,000

- 16 Ton: $4,180 - $13,100

- 20 Ton: $7,100 - $18,300

Note: Prices are for reference only. Customized single girder bridge cranes are available based on your specific crane specifications.

Typical Applications:

- Manufacturing Facilities: Efficient for handling heavy machinery and large parts.

- Warehouses: Ideal for moving and organizing stock.

- Maintenance Workshops: Perfect for equipment repair and assembly.

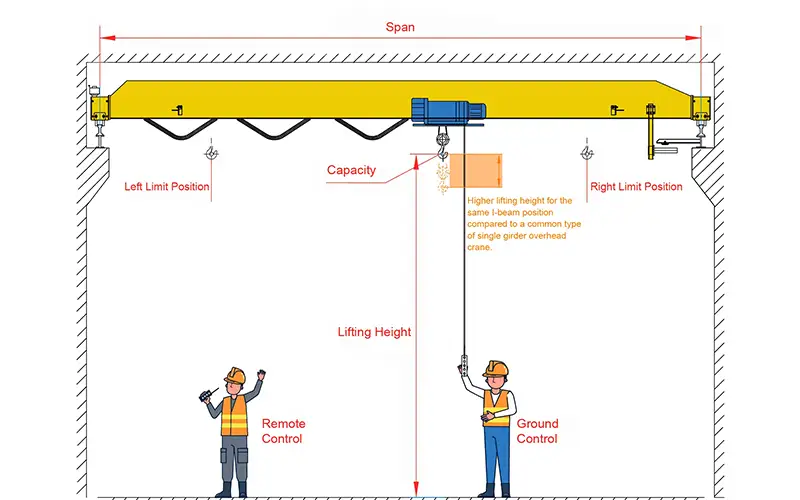

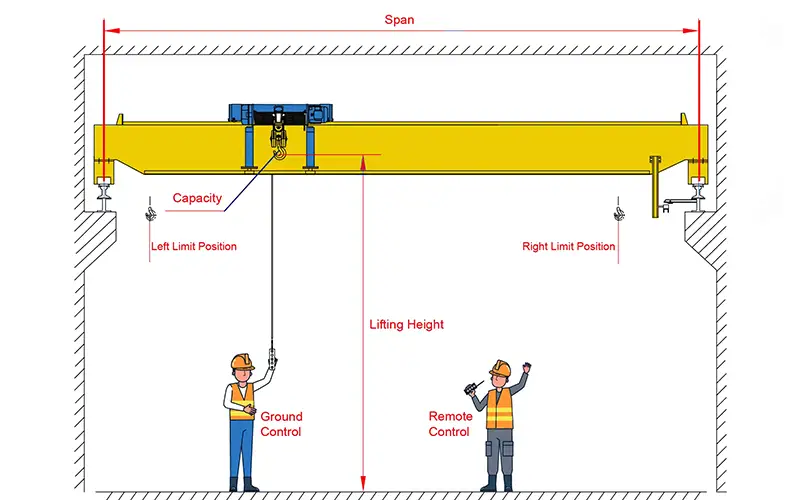

Low Headroom Single Girder Bridge Crane

Low headroom single girder bridge cranes are designed to optimize height space in facilities with limited vertical clearance. These cranes are essential where vertical space is limited but high lifting heights are necessary.

Main Specifications:

- Capacity: 1t, 2t, 3t, 5t, 10t, 16t, 20t (custom sizes available upon request)

- Span Length: 7.5m to 31.5m

- Lifting Height: 6m to 30m

- Work Duty: A3/A4

- Voltage Options: 220V, 380V, 400V, 415V, 660V, 50-60Hz, 3-phase AC

- Control Modes: Floor control, Remote control

- Traveling Speed: 20-30m/min

Price Range:

- 1 Ton: $1,920 - $5,360

- 2 Ton: $2,100 - $6,200

- 3 Ton: $2,240 - $8,100

- 5 Ton: $3,290 - $9,120

- 10 Ton: $4,085 - $12,600

- 16 Ton: $4,400 - $13,800

- 20 Ton: $7,500 - $19,300

Note: Prices are for reference only. Customized single girder bridge cranes are available based on your specific crane specifications.

Typical Applications:

- Tight Workshops: Maximizes lifting height in restricted spaces.

- Small-Batch Manufacturing: Ideal for precise handling in limited vertical clearance.

- Maintenance Areas: Useful where ceiling height constraints are present but operational flexibility is required.

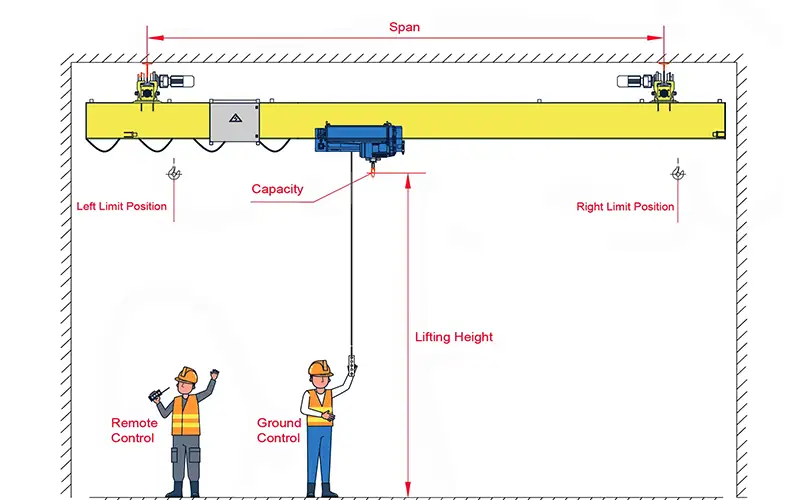

Underslung Single Girder Bridge Crane

Underslung single girder bridge cranes are ideal for facilities where the roof is load-bearing but columns are not. These cranes maximize space utilization by using the roof structure.

Main Specifications:

- Capacity: 0.5t, 1t, 2t, 3t, 5t, 10t

- Span Length: 3m to 16m

- Lifting Height: 6m to 30m

- Work Duty: A3/A4

- Voltage Options: 220V, 380V, 400V, 415V, 660V, 50-60Hz, 3-phase AC

- Control Modes: Ground control, Remote control

- Traveling Speed: 20-30m/min

Price Range:

- 1 Ton: $1,830 - $5,100

- 2 Ton: $2,000 - $5,900

- 3 Ton: $2,130 - $7,680

- 5 Ton: $3,130 - $8,680

- 10 Ton: $3,890 - $12,000

Note: Prices are for reference only. Customized single girder bridge cranes are available based on your specific crane specifications.

Typical Applications:

- Industrial Plants: Utilizes roof space efficiently.

- Small Manufacturing Facilities: Avoids the need for load-bearing columns.

- Assembly Lines: Provides close headroom advantages for smooth operation.

FEM/DIN Single Girder Bridge Crane

FEM/DIN single girder bridge cranes are characterized by their compact design and maintenance-free components, making them ideal for high precision and minimal operational downtime.

Main Specifications:

- Capacity: 1t to 20t

- Span Length: 7.5m to 28.5m

- Lifting Height: 6m to 12m (customizable)

- Work Duty: A5

- Voltage Options: 220V, 380V, 400V, 415V, 660V, 50-60Hz, 3-phase AC

- Control Modes: Pendant control, Remote control

- Traveling Speed: 20-30m/min

Price Range:

- 1 Ton: $4,750 - $8,800

- 2 Ton: $4,800 - $10,380

- 3 Ton: $4,980 - $11,050

- 5 Ton: $5,580 - $12,200

- 10 Ton: $7,400 - $17,300

- 16 Ton: $11,700 - $22,800

Note: Prices are for reference only. Customized single girder bridge cranes are available based on your specific crane specifications.

Typical Applications:

- Precision Workshops: For exact positioning and high precision tasks.

- Large Parts Assembly: Requires precision and minimal downtime.

- Material Handling in Various Industries: Including manufacturing, electronics, and food processing.

Offset Trolley Single Girder Bridge Crane

Offset trolley single girder bridge cranes are designed to optimize lifting height in spaces with limited headroom. Their angular trolley structure allows for better height utilization.

Main Specifications:

- Capacity: 1t, 2t, 3t, 5t, 10t, 16t, 20t (custom sizes available upon request)

- Span Length: 7.5m to 31.5m

- Lifting Height: 6m to 30m

- Work Duty: A3/A4

- Voltage Options: 220V, 380V, 400V, 415V, 660V, 50-60Hz, 3-phase AC

- Control Modes: Floor control, Remote control

- Traveling Speed: 20-30m/min

Price Range:

- 1 Ton: $2,930 - $9,180

- 2 Ton: $3,200 - $5,220

- 3 Ton: $3,400 - $13,800

- 5 Ton: $5,000 - $15,600

- 10 Ton: $6,220 - $21,600

- 16 Ton: $6,680 - $23,500

- 20 Ton: $11,360 - $32,940

Note: Prices are for reference only. Customized single girder bridge cranes are available based on your specific crane specifications.

Typical Applications:

- Low-Headroom Areas: Maximizes vertical space.

- Specialized Manufacturing: Elevated lifting capabilities.

- Heavy Equipment Handling: Suitable for spaces where standard cranes cannot fit.

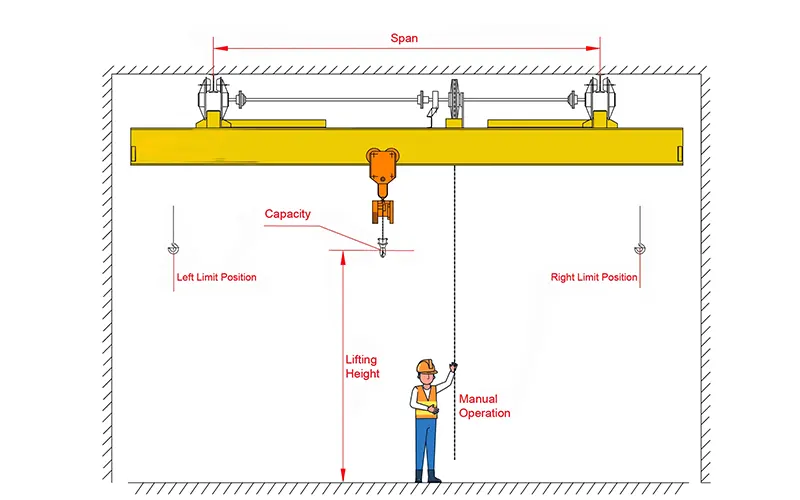

Manual Single Girder Bridge Crane

Manual single girder bridge cranes are ideal for environments where electrical power sources are unavailable. They are compact and simple, making them suitable for small-scale operations and maintenance tasks.

Main Specifications:

- Capacity: Up to 5t

- Span Length: 4m to 12m

- Lifting Height: 3m to 10m

- Work Duty: A1

- Voltage Options: Manual operation

- Control Modes: Floor control

Price Range:

- 1 Ton: $840 - $1,800

- 2 Ton: $880 - $1,900

- 3 Ton: $930 - $2,000

- 5 Ton: $1,600 - $3,060

Note: Prices are for reference only. Customized single girder bridge cranes are available based on your specific crane specifications.

Typical Applications:

- Maintenance and Repair Shops: For equipment installation and servicing.

- Small Factories: Where power availability is limited.

- Workshops with Specific Needs: In areas requiring manual lifting and moving capabilities.

Factors Influencing Single Girder Bridge Crane Prices

Load Capacity and Span

The load capacity of a single girder bridge crane is a major determinant of its price. Cranes with higher load capacities demand more robust materials and advanced engineering to safely handle greater weights. This requirement results in increased manufacturing costs and, subsequently, higher prices. For example, a crane designed for heavier loads will require a more durable main girder, a stronger hoist system, and additional safety features to ensure safe operation under these conditions.

The span of the crane, which refers to the distance between its supporting structures, also affects its cost. A crane with a larger span requires a more substantial and reinforced main girder, which increases both material and structural expenses. Additionally, the complexity of installing a crane with a wider span can lead to higher labor costs. Therefore, both load capacity and span are crucial factors that influence the pricing of single girder bridge cranes.

Design and Material Specifications

Material choices and design specifications significantly impact the cost of a single girder bridge crane. Standard materials, such as mild steel, are typically used in crane construction and are more affordable. While suitable for general applications, these materials may not provide the same load-bearing capacity or durability as high-strength alternatives.

High-strength materials, such as advanced alloys, offer enhanced durability and the ability to support heavier loads. However, these materials are more expensive due to their higher cost and the specialized manufacturing processes required. Therefore, the use of high-strength materials increases the overall cost of the crane.

Custom design features can also influence crane pricing. Customization, such as unique dimensions, specialized functionalities, or adaptations for specific environmental conditions, involves additional engineering and design work. This customization leads to higher production costs compared to standard models.

Additional Features and Accessories

Additional features and accessories play a significant role in determining the price of single girder bridge cranes. Control systems vary in cost based on their type. Manual controls are the most basic and cost-effective, requiring physical effort from the operator. Electric controls provide more precise and user-friendly operation but come with a higher price. Remote control systems offer the greatest flexibility and convenience, though they are the most expensive option.

Safety features are another key consideration. Limit switches, which prevent the crane from exceeding its designated range, are essential for safe operation and regulatory compliance. Emergency stop systems also contribute to safety by allowing immediate halting of crane operations in emergencies, adding to the overall cost.

Environmental adaptations, such as corrosion resistance and temperature control, are important factors for cranes operating in harsh environments. Corrosion-resistant coatings and materials are necessary for longevity in challenging conditions, while temperature control features ensure the crane functions effectively in extreme temperatures. These adaptations typically involve additional costs for specialized materials and design modifications.

Understanding these factors helps in making well-informed decisions regarding the purchase and customization of single girder bridge cranes, ensuring they meet operational needs while staying within budget constraints.

Pricing Strategies and Models

Cost Breakdown

Initial Purchase Cost

The initial purchase cost of a single girder bridge crane encompasses the base price of the crane itself, which includes the main girder, hoist, trolley system, end trucks, and supporting structures. This cost is determined by factors such as load capacity, span, materials used, and design complexity. Cranes with higher capacities, custom features, or specialized materials will generally have a higher initial purchase cost.

Installation and Commissioning Costs

Beyond the purchase price, installation and commissioning costs are significant. These costs cover the labor and materials required to install the crane and ensure it operates correctly. Installation costs can vary depending on the complexity of the setup, the crane's span, and any modifications needed to integrate the crane into the existing infrastructure. Commissioning involves testing and calibrating the crane to ensure it meets all operational and safety standards, which can also influence the total cost.

Maintenance and Operational Costs

Ongoing maintenance and operational costs are essential considerations for the total cost of ownership. Maintenance costs include regular inspections, servicing, and repairs to keep the crane in optimal working condition. Operational costs involve energy consumption, potential downtime, and any additional expenses related to the crane's operation. Cranes with higher maintenance requirements or those operating in harsh environments may incur greater ongoing costs.

Pricing Models

Fixed Pricing vs. Variable Pricing

- Fixed Pricing: This model involves a set price for the crane and its associated services, providing clear costs from the outset. Fixed pricing is beneficial for budget planning as it eliminates uncertainties about additional charges. However, it may not account for potential variations in project scope or unforeseen costs.

- Variable Pricing: Variable pricing involves a cost structure that can change based on factors such as customization, additional features, or unforeseen requirements. This model offers flexibility but can make budgeting more challenging due to the potential for fluctuating costs.

Cost-Plus Pricing vs. Competitive Pricing

- Cost-Plus Pricing: This approach calculates the price based on the cost of production plus a markup to cover profit. Cost-plus pricing ensures that all production costs are covered while providing a predictable profit margin. This model is often used in custom or complex crane projects where exact costs can be calculated.

- Competitive Pricing: Competitive pricing sets the crane's price based on market rates and competitor pricing. This strategy aims to offer a competitive edge in the market by aligning prices with those of similar products. It can be advantageous for attracting price-sensitive customers but may require careful market analysis to avoid undervaluation.

Discounts and Financing Options

Volume Discounts

Volume discounts are often available for customers purchasing multiple cranes or making bulk orders. These discounts can significantly reduce the per-unit cost and are typically negotiated based on the quantity of cranes ordered. Volume discounts incentivize larger purchases and can be a cost-effective option for companies with extensive crane needs.

Lease vs. Purchase Considerations

When deciding between leasing and purchasing a crane, several factors come into play. Leasing can provide lower upfront costs, flexible terms, and the ability to upgrade equipment regularly. It is often suitable for businesses with short-term needs or those wanting to preserve capital. On the other hand, purchasing a crane involves a higher initial investment but provides long-term ownership and potential cost savings over time. The decision between leasing and purchasing depends on factors such as financial strategy, usage duration, and overall budget.

Financing and Leasing Options

Various financing and leasing options can help manage the cost of acquiring a single girder bridge crane. Financing options include loans or lines of credit that spread the cost over time, making it easier to manage cash flow. Leasing options, such as operating leases or capital leases, offer different terms and conditions that can align with the company's financial situation and operational needs. Exploring these options can provide flexibility in managing crane acquisition costs and aligning payments with budgetary constraints.

By understanding these pricing strategies and models, buyers can make informed decisions about purchasing and financing single girder bridge cranes, ensuring they achieve the best value while managing costs effectively.

How to Choose the Right Single Girder Bridge Crane for Your Needs

Assessment of Requirements

Load and Span Requirements

Choosing the right single girder bridge crane begins with a thorough assessment of your load and span requirements. Determine the maximum load capacity the crane needs to handle, as this will influence the crane's design, material specifications, and overall cost. Assessing the span, or the distance between the crane's supporting structures, is equally important. A larger span requires a more robust main girder and may affect installation complexity and cost. Both load and span requirements are fundamental to ensuring the crane meets operational needs and safety standards.

Operating Environment

The operating environment where the crane will be used plays a crucial role in selecting the appropriate model. Consider factors such as temperature extremes, humidity levels, and exposure to corrosive substances. For harsh environments, such as outdoor or corrosive settings, you may need a crane with additional protective features, such as corrosion-resistant coatings or temperature control systems. The crane's design should also account for factors like space constraints and the need for specific operational functionalities.

Customization Needs

Evaluate any customization needs based on your specific operational requirements. Custom features might include unique dimensions, specialized lifting mechanisms, or integration with existing systems. Customization can improve the crane's efficiency and effectiveness but may also increase the cost. Determine whether standard models can meet your needs or if custom solutions are necessary for optimal performance.

Supplier Selection

Evaluating Suppliers and Manufacturers

Selecting a reliable supplier or manufacturer is essential for ensuring the quality and performance of your single girder bridge crane. Evaluate potential suppliers based on their reputation, experience, and expertise in crane manufacturing. Look for manufacturers with a proven track record of delivering high-quality cranes and providing excellent customer service. Consider checking customer reviews, industry certifications, and case studies to gauge the reliability of the supplier.

Comparing Quotes and Offers

Once you have shortlisted potential suppliers, compare their quotes and offers. Obtain detailed quotations that outline the cost of the crane, including any additional features or customization. Compare these quotes to ensure you are getting the best value for your investment. Look beyond the initial cost and consider factors such as installation, maintenance services, and any included warranties or support.

Understanding Warranty and Support Services

Understanding the warranty and support services provided by the supplier is crucial for long-term satisfaction. Review the warranty terms to ensure they cover essential components and potential issues that may arise. Support services should include technical assistance, maintenance, and repair options. A comprehensive warranty and reliable support services contribute to the crane's long-term reliability and reduce the risk of unexpected costs.

By thoroughly assessing your requirements, selecting a reputable supplier, and comparing quotes and support services, you can make an informed decision and choose the right single girder bridge crane that meets your operational needs and budget.

Case Studies and Examples

Typical Cost Scenarios

Examples of Single Girder Bridge Crane Installations in Various Industries

To understand the typical costs associated with single girder bridge cranes, examining real-world examples can be insightful. For instance:

- Manufacturing Industry: In a manufacturing plant, a single girder bridge crane with a 5-ton load capacity and a 20-meter span might cost around $20,000 to $30,000. This installation typically includes standard features and basic customization to fit the plant's layout.

- Warehouse and Logistics: For a warehouse application, a 3-ton crane with a 15-meter span might be priced between $15,000 and $25,000. The focus in this setting is on efficient operation and ease of integration into existing systems.

- Construction Sites: A construction site requiring a robust single girder bridge crane with a 10-ton capacity and a 30-meter span might see costs ranging from $35,000 to $50,000. Custom features such as enhanced durability and weatherproofing are often included in these installations.

Comparative Pricing for Standard vs. Custom Cranes

The cost differences between standard and custom single girder bridge cranes are substantial. Standard cranes, which are mass-produced and readily available, typically have lower costs due to economies of scale. For example, a standard 5-ton crane with a 20-meter span might be priced around $20,000, while a custom crane with similar specifications but tailored design features might cost $30,000 to $40,000.

Custom cranes, designed to meet specific operational needs or environmental conditions, often involve higher costs due to additional engineering, design work, and material requirements. These costs reflect the tailored solutions provided to address unique requirements or challenges.

Lessons Learned

Common Pitfalls in Pricing and Selection

Several pitfalls can affect the pricing and selection of single girder bridge cranes:

- Underestimating Total Costs: Often, buyers focus solely on the initial purchase price without considering additional costs such as installation, maintenance, and operational expenses. This can lead to unexpected budget overruns.

- Overlooking Environmental Factors: Failing to account for the operating environment can result in selecting a crane that does not meet durability requirements, leading to higher maintenance costs and potential operational issues.

- Neglecting Customization Needs: Not adequately addressing customization needs can lead to inefficiencies or operational challenges, which may require costly modifications later on.

Best Practices for Cost-Effective Procurement

To ensure a cost-effective procurement process, consider the following best practices:

- Conduct Thorough Research: Investigate different crane models and suppliers to understand the range of options available and their associated costs. Use case studies and industry benchmarks to guide your decisions.

- Evaluate Total Cost of Ownership: Consider not only the purchase price but also installation, maintenance, and operational costs. Factor in long-term expenses to assess the true cost of ownership.

- Plan for Customization Early: Identify any specific needs or custom features early in the planning process. This helps avoid last-minute changes that can lead to higher costs.

- Get Multiple Quotes: Obtain quotes from multiple suppliers and compare them comprehensively. Look beyond the initial price to include factors like warranty, support services, and additional features.

- Ensure Reliable Support: Choose suppliers who offer robust support services and warranties. Reliable after-sales support can prevent costly issues and ensure smooth operation over the crane's lifecycle.

By learning from these case studies and applying best practices, buyers can make informed decisions and secure the most cost-effective solutions for their single girder bridge crane needs.

Conclusion

In reviewing the factors influencing the pricing of single girder bridge cranes, several key elements stand out. First, load capacity and span are primary determinants of cost, with higher capacities and larger spans leading to increased expenses due to the need for stronger materials and more complex design. Design and material specifications also play a crucial role, as high-strength materials and custom features drive up costs. Additionally, the inclusion of advanced control systems, safety features, and environmental adaptations further impacts pricing.

These factors is essential for making informed decisions. Proper assessment of requirements, careful supplier selection, and consideration of various pricing models and financing options can help buyers achieve the best value for their investment.

Importance of Informed Decision-Making

Making well-informed decisions is critical to ensuring that the selected crane meets operational needs while staying within budget. By thoroughly evaluating load and span requirements, the operating environment, and any customization needs, buyers can select a crane that optimally fits their specific application. Furthermore, understanding pricing strategies and models, and being aware of the total cost of ownership, including installation, maintenance, and operational costs, is vital for effective budgeting and cost management.

Future Trends and Considerations

Emerging Technologies and Their Impact on Pricing

The future of single girder bridge cranes is likely to be influenced by emerging technologies. Innovations such as advanced automation, smart control systems, and improved materials may enhance crane performance and efficiency but could also impact pricing. For example, cranes equipped with IoT capabilities for real-time monitoring and predictive maintenance could involve higher upfront costs but offer long-term savings through reduced downtime and maintenance.

Evolving Market Trends and Their Influence on Costs

Market trends will also affect crane pricing. Increased competition and technological advancements may lead to more cost-effective solutions as manufacturers strive to offer better value. Additionally, changes in regulations and industry standards can influence costs, as manufacturers adapt to new requirements and invest in compliance. Keeping abreast of these trends will help buyers make strategic decisions and anticipate future cost implications.

By understanding the factors affecting crane pricing and staying informed about emerging trends, buyers can navigate the procurement process effectively, ensuring they select the right single girder bridge crane for their needs while managing costs efficiently.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch