Choosing Right Electric Chain Hoist: Comparison of 4 Main Types of Electric Chain Blocks

Explore the best electric chain hoist for your needs with a detailed comparison of motorized, manual, hook-mounted, and low headroom types.

Category: Electric Chain Hoist Crane

Your Trusted Electric Chain Hoist Crane Manufacturer & Supplier

Comparison of 4 Main Types of Electric Chain Blocks

Choosing Right Electric Chain Hoists:Motorized Trolley Travelling, Manual Travelling, Hook-mounted & Low headroom Types

Explore the best electric chain hoist for your needs with a detailed comparison of motorized, manual, hook-mounted, and low headroom types.

Electric chain hoists are essential tools in various industrial and manufacturing settings, designed to lift and move heavy loads efficiently. This comparison aims to provide a clear understanding of the different types of electric chain hoists available, helping you make an informed choice based on your specific needs.

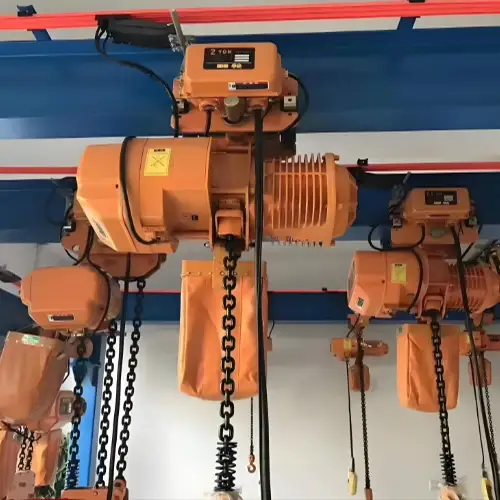

Overview of Electric Chain Hoists

Electric chain hoists use an electric motor to lift and lower loads via a chain mechanism. They are commonly used in factories, warehouses, and workshops for their ability to handle heavy loads with precision and ease. The primary components include the hoist motor, chain, and lifting mechanism, which work together to lift materials vertically.

There are several types of electric chain hoists, each with unique features and benefits. These include motorized travelling trolley hoists, manual travelling trolley hoists, hook or lug mounted hoists, and low headroom hoists. Understanding the distinctions between these types is crucial for selecting the right hoist for your operations.

Importance of Choosing the Right Type for Specific Applications

Selecting the appropriate electric chain hoist can significantly impact the efficiency, safety, and cost-effectiveness of your operations. The right hoist can improve workflow, reduce manual handling, and enhance overall productivity. Conversely, choosing an unsuitable hoist may lead to operational inefficiencies, increased maintenance costs, or even safety hazards.

For example, motorized travelling trolley hoists offer automatic movement and are ideal for high-frequency use, while manual travelling trolley hoists are more cost-effective for less frequent tasks. Low headroom hoists are specifically designed for environments with limited vertical space, making them essential for certain workshop setups.

By comparing these types, you can better match a hoist to your operational requirements, ensuring optimal performance and safety.

4 Main Types of Electric Chain Hoists

Motorized Travelling Trolley Electric Chain Hoist

The motorized travelling trolley electric chain hoist combines a chain hoist with an integrated motorized trolley. This setup allows the hoist to move automatically along a beam or rail, providing smooth and precise control over both lifting and horizontal movement. The motorized trolley is driven by an electric motor, which ensures consistent and efficient operation.

Benefits

- Enhanced Efficiency for Heavy-Duty Tasks: The motorized trolley significantly improves the efficiency of lifting and moving heavy loads. It eliminates the need for manual pushing or pulling, which is especially advantageous for tasks involving large or cumbersome items.

- Reduced Manual Effort: By automating the movement along the rail, this type of hoist minimizes the physical effort required from operators. This leads to less fatigue and potentially fewer workplace injuries, as the system handles most of the load movement automatically.

Drawbacks

- Higher Upfront Cost: The advanced features and automation of motorized travelling trolleys come with a higher initial purchase price compared to manual models. This cost can be a consideration for organizations with tight budgets.

- Maintenance Requirements: The motorized components and electronics in these hoists require regular maintenance to ensure optimal performance. This may involve more frequent checks and servicing compared to simpler manual systems.

Ideal Uses Motorized travelling trolley electric chain hoists are best suited for environments where frequent and precise load movement is require They are commonly used in industrial settings such as manufacturing plants, warehouses, and assembly lines. Their ability to handle heavy loads with minimal manual effort makes them ideal for high-volume operations where efficiency and productivity are critical.

Manual Travelling Trolley Electric Chain Hoist

Features and Definition The manual travelling trolley electric chain hoist is designed with a chain hoist mounted on a manual trolley. Unlike its motorized counterpart, this type of hoist requires operators to manually move the trolley along the beam or rail. The hoist itself is operated electrically to lift and lower loads, but horizontal movement is controlled by hand.

Benefits

- Cost-Effective Solution: Manual travelling trolley hoists generally have a lower purchase price compared to motorized models. This makes them an affordable option for businesses looking to manage costs while still benefiting from electric lifting.

- Simple Maintenance: With fewer electrical and mechanical components compared to motorized systems, manual trolleys are easier and less expensive to maintain. This simplicity reduces the frequency and cost of repairs and servicing.

Drawbacks

- Requires Manual Effort for Movement: Since the trolley movement is manual, operators need to exert physical effort to move loads horizontally. This can be tiring and may limit the efficiency of operations, especially when handling larger or heavier items.

- Less Suitable for Heavy Loads: Manual trolleys may not be as effective for very heavy or bulky loads. The physical effort required for horizontal movement can become impractical when dealing with high-weight capacities or frequent load changes.

Ideal Uses Manual travelling trolley electric chain hoists are best suited for light to moderate industrial operations. They are ideal for smaller workshops, assembly areas, or maintenance tasks where load movement is infrequent or does not involve extremely heavy items. Their cost-effectiveness and straightforward design make them a practical choice for environments where heavy-duty automation is not necessary.

Hook Mounted / Lug Mounted Electric Chain Hoist

Features and Definition Hook mounted or lug mounted electric chain hoists are designed to be attached directly to hooks or lugs. This setup does not include a trolley system for horizontal movement, making them a straightforward choice for lifting tasks. The hoist itself is suspended from a fixed point, with the lifting and lowering of loads controlled electrically.

Benefits

- Versatile and Easy to Install: Hook mounted and lug mounted hoists are easy to set up, as they require minimal installation effort. They can be quickly attached to existing hooks or lugs, making them a flexible option for various lifting applications.

- Budget-Friendly: These hoists typically come at a lower cost compared to models with integrated trolleys or advanced features. Their simplicity in design and functionality makes them a more affordable choice for many operations.

Drawbacks

- Limited Mobility Compared to Trolley Models: Without a trolley system, hook mounted and lug mounted hoists lack the ability to move horizontally along a rail. This limitation can reduce their efficiency in applications that require frequent or precise load movement across different areas.

- Fixed Positioning: The fixed mounting position of these hoists means that they are not easily repositionable. This can limit their versatility in environments where load movement or repositioning is frequently require

Ideal Uses Hook mounted and lug mounted electric chain hoists are well-suited for workshop settings and smaller-scale operations where horizontal movement is not critical. They are commonly used in maintenance tasks, small assembly areas, and applications where the hoist needs to be stationary or where cost constraints are a concern. Their ease of installation and lower cost make them a practical choice for simpler lifting tasks.

Low Headroom Electric Chain Hoists

Features and Definition Low headroom electric chain hoists are specifically engineered to operate in environments with restricted vertical space. Their compact design reduces the overall height of the hoist, allowing for more efficient use of limited headroom. This design often incorporates a shorter lifting height and a compact chain wheel arrangement to fit within tight spaces.

Benefits

- Maximizes Headroom Usage: These hoists are designed to take advantage of every inch of available vertical space. By reducing the height of the hoist and minimizing the distance between the hoist and the beam or rail, they help maximize the usable headroom in low-ceiling environments.

- Ideal for Compact Spaces: Low headroom hoists are perfect for areas where space is at a premium. Their compact design allows them to fit into tight or constrained spaces where standard hoists might not be feasible, making them valuable for specialized applications.

Drawbacks

- Limited Application Scope: Due to their specific design for low headroom scenarios, these hoists may not be suitable for all types of lifting applications. Their limited vertical lift height and compact build make them less versatile for environments where additional lifting height is neede

- Potentially Higher Cost: The specialized design and engineering required for low headroom hoists can result in a higher purchase price compared to standard hoists. This increased cost is a consideration for budgets and may not be justifiable for every application.

Ideal Uses Low headroom electric chain hoists are ideal for confined spaces with low ceilings, such as small workshops, maintenance areas, or manufacturing environments where vertical space is restricte They are particularly useful in scenarios where every bit of headroom needs to be utilized to maximize lifting capabilities while working within physical constraints.

Comparions of 4 Main Types of Electric Chain Hoists

When selecting an electric chain hoist, understanding the different types available is crucial for making an informed decision. This comparison explores four main types of electric chain hoists: Motorized Travelling Trolley, Manual Travelling Trolley, Hook Mounted/Lug Mounted, and Low Headroom. Each type offers distinct features, benefits, and limitations tailored to specific operational needs. By examining these hoists in terms of movement type, load handling, cost, maintenance, installation, ideal environment, and flexibility, you can determine which hoist best suits your requirements, ensuring efficiency and reliability in your lifting operations.

Comparison of Electric Chain Hoist Types

| Feature | Motorized Travelling Trolley Electric Chain Hoist | Manual Travelling Trolley Electric Chain Hoist | Hook Mounted / Lug Mounted Electric Chain Hoist | Low Headroom Electric Chain Hoist |

|---|---|---|---|---|

| Movement Type | Automatic horizontal movement via electric motor | Manual horizontal movement by hand | No horizontal movement; fixed at mounting point | Vertical lifting with minimal horizontal space |

| Load Handling | Efficient for frequent load movement and heavy-duty tasks | Suitable for lighter to moderate loads; manual effort required | Limited to vertical lifting; less efficient for frequent load changes | Ideal for environments with low ceiling and confined spaces |

| Cost | Higher initial cost due to motorized components | Generally more affordable | Lower cost; simple design | Potentially higher cost due to specialized design |

| Maintenance | Requires regular maintenance for motor and trolley | Easier and less expensive to maintain | Simple maintenance; fewer components | Specialized maintenance for compact design |

| Installation | Requires installation of motorized trolley system | Easy to install on existing hooks or lugs | Directly mounted on hooks or lugs; minimal setup | Designed for specific low-headroom setups; may require custom installation |

| Ideal Environment | High-frequency use in industrial settings | Light to moderate use in workshops or smaller facilities | Workshops or small operations with fixed mounting points | Workshops or facilities with restricted vertical space |

| Operational Efficiency | High efficiency with automated movement | Efficient for occasional use but manual effort involved | Fixed positioning; less efficient for dynamic tasks | Efficient in tight spaces but limited in vertical lift height |

| Flexibility | High flexibility for large and dynamic work areas | Lower flexibility; suitable for static tasks | Fixed position limits versatility | Designed specifically for confined spaces; limited versatility |

This table summarizes the core differences among the four types of electric chain hoists, helping you to assess which type best meets your specific needs based on operational requirements, cost considerations, and installation environments.

Comparison of Electric Chain Hoist Types by Movement Type

- Motorized Travelling Trolley Electric Chain Hoist Movement Type: Automatic horizontal movement via an electric motor. Provides seamless and automated movement along the beam or rail, enhancing efficiency and reducing manual effort for horizontal load transport.

- Manual Travelling Trolley Electric Chain Hoist Movement Type: Manual horizontal movement by han Requires physical effort to move the trolley along the beam or rail, which can be labor-intensive and less efficient for frequent or heavy loads.

- Hook Mounted / Lug Mounted Electric Chain Hoist Movement Type: Fixed at mounting point; no horizontal movement. Only provides vertical lifting and lowering. The hoist is stationary once mounted, limiting its use to applications where horizontal movement is not require

- Low Headroom Electric Chain Hoist Movement Type: Vertical lifting with minimal horizontal space. Designed for tight spaces with low ceilings. Focuses on maximizing vertical lift height while minimizing the need for horizontal movement, making it ideal for confined spaces.

Comparison of Electric Chain Hoist Types by Load Handling

- Motorized Travelling Trolley Electric Chain Hoist Load Handling: Efficient for frequent load movement and heavy-duty tasks. Capable of handling a wide range of loads, from moderate to heavy, due to the motorized system that supports consistent and high-capacity operations.

- Manual Travelling Trolley Electric Chain Hoist Load Handling: Suitable for lighter to moderate loads; manual effort require Designed to handle less heavy loads compared to motorized models. The manual operation limits its efficiency for heavy or frequent load handling due to the physical effort neede

- Hook Mounted / Lug Mounted Electric Chain Hoist Load Handling: Limited to vertical lifting; less efficient for frequent load changes. Handles loads that are lifted vertically but lacks the capability for horizontal movement. This can make it less efficient for applications requiring frequent or varied load handling.

- Low Headroom Electric Chain Hoist Load Handling: Ideal for environments with low ceiling and confined spaces. Designed to maximize vertical lift in tight spaces, making it suitable for handling loads where headroom is a constraint. Typically handles moderate loads effectively within its design limitations.

Comparison of Electric Chain Hoist Types by Cost

- Motorized Travelling Trolley Electric Chain Hoist Cost: Higher initial cost due to motorized components. The advanced features and motorized system contribute to a higher purchase price. This cost reflects the added convenience and efficiency for heavy-duty and automated load handling.

- Manual Travelling Trolley Electric Chain Hoist Cost: Generally more affordable. The simpler design and lack of motorized components make it a more budget-friendly option. Lower cost reflects its basic functionality and manual operation.

- Hook Mounted / Lug Mounted Electric Chain Hoist Cost: Lower cost; simple design. The straightforward design and fixed mounting result in a lower cost. It's a cost-effective choice for applications where advanced features or horizontal movement are not neede

- Low Headroom Electric Chain Hoist Cost: Potentially higher cost due to specialized design. The specialized design for low headroom environments often results in a higher price. This cost is attributed to the engineering required to accommodate confined spaces and maintain efficiency.

Comparison of Electric Chain Hoist Types by Maintenance

- Motorized Travelling Trolley Electric Chain Hoist Maintenance: Requires regular maintenance for motor and trolley. The motorized components and moving parts necessitate more frequent inspections and maintenance to ensure smooth operation. This includes checking the motor, trolley mechanisms, and electrical connections to prevent downtime.

- Manual Travelling Trolley Electric Chain Hoist Maintenance: Easier and less expensive to maintain. With fewer moving parts and no motorized system, manual hoists require less frequent maintenance. Regular upkeep generally involves inspecting the chain and manual trolley for wear and lubrication.

- Hook Mounted / Lug Mounted Electric Chain Hoist Maintenance: Simple maintenance; fewer components. The basic design and fixed mounting result in minimal maintenance requirements. Maintenance typically focuses on the chain and basic operational checks, as there are fewer parts that can wear out or malfunction.

- Low Headroom Electric Chain Hoist Maintenance: Specialized maintenance for compact design. The compact and specialized design may require specific maintenance practices to ensure proper function in confined spaces. Regular checks and maintenance are needed to address the unique design aspects and ensure reliability in low headroom environments.

Comparison of Electric Chain Hoist Types by Installation

- Motorized Travelling Trolley Electric Chain Hoist Installation: Requires installation of motorized trolley system. Installation involves setting up both the electric motor and the travelling trolley system. This may require additional infrastructure or modifications to existing beams or rails to support the motorized components.

- Manual Travelling Trolley Electric Chain Hoist Installation: Easy to install on existing hooks or lugs. Installation is straightforward, involving mounting the manual trolley on existing hooks or lugs. There is no need for complex adjustments or additional equipment, making it suitable for quick and simple setups.

- Hook Mounted / Lug Mounted Electric Chain Hoist Installation: Directly mounted on hooks or lugs; minimal setup. This type of hoist requires minimal installation effort. It is simply attached to pre-existing hooks or lugs, which makes it a quick and easy option for mounting.

- Low Headroom Electric Chain Hoist Installation: Designed for specific low-headroom setups; may require custom installation. Installation can be more complex due to the specialized design for low headroom environments. It may involve custom modifications or adjustments to fit within tight spaces, requiring precise alignment and potentially additional support structures.

Comparison of Electric Chain Hoist Types by Ideal Environment

- Motorized Travelling Trolley Electric Chain Hoist Ideal Environment: High-frequency use in industrial settings. Best suited for environments where continuous and automated load movement is require Ideal for large industrial settings such as manufacturing plants and warehouses where efficiency and high capacity are essential.

- Manual Travelling Trolley Electric Chain Hoist Ideal Environment: Light to moderate use in workshops or smaller facilities. Suitable for environments with less frequent load handling. Best for workshops, small factories, or maintenance areas where occasional load movement is needed and manual effort is acceptable.

- Hook Mounted / Lug Mounted Electric Chain Hoist Ideal Environment: Workshops or small operations with fixed mounting points. Fits well in settings where the hoist can remain in a fixed position. Ideal for workshops or smaller operations where the hoist's vertical lifting capabilities are sufficient, and horizontal movement is not a requirement.

- Low Headroom Electric Chain Hoist Ideal Environment: Workshops or facilities with restricted vertical space. Designed for use in environments with low ceilings or confined vertical space. Ideal for settings where maximizing available headroom is critical, such as in tight manufacturing areas or warehouses with height constraints.

Comparison of Electric Chain Hoist Types by Flexibility

- Motorized Travelling Trolley Electric Chain Hoist Flexibility: High flexibility for large and dynamic work areas. Provides significant flexibility with automated horizontal movement along the beam or rail. This allows for efficient and adaptable load handling across extensive work areas and dynamic operational needs.

- Manual Travelling Trolley Electric Chain Hoist Flexibility: Lower flexibility; suitable for static tasks. Limited flexibility due to the need for manual effort in horizontal movement. Best suited for tasks where the load needs to be moved occasionally, and dynamic or high-frequency movement is not require

- Hook Mounted / Lug Mounted Electric Chain Hoist Flexibility: Fixed position limits versatility. The hoist is fixed in position at the mounting point, which limits its ability to handle loads in different locations. This setup is less versatile for tasks that require movement across different areas.

- Low Headroom Electric Chain Hoist Flexibility: Designed specifically for confined spaces; limited versatility. Focuses on maximizing vertical lift in tight spaces, which may restrict its use in environments where horizontal movement or greater flexibility is neede Ideal for specific applications with height constraints but less adaptable to other settings.

Electric Chain Hoists vs. Wire Rope Hoists

Design and Mechanism Differences

Chain vs. Wire Rope

Mechanisms and Operational Differences:- Electric Chain Hoists: These hoists use a chain mechanism to lift and lower loads. The chain wraps around a chain wheel, driven by an electric motor, which moves the load vertically. The chain's links provide a sturdy and flexible method for handling loads, making it well-suited for various lifting tasks. Electric chain hoists typically have a more compact design, making them suitable for confined spaces.

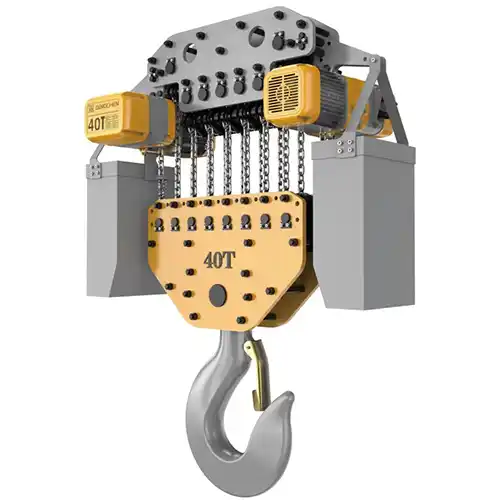

- Wire Rope Hoists: Wire rope hoists use a steel wire rope wound around a drum or pulley system. The electric motor powers the drum to lift and lower the loa The wire rope's strength and flexibility allow it to handle higher loads and provide smoother operation over longer distances. Wire rope hoists generally have a larger design and are better suited for applications where heavy-duty lifting and longer reach are require

Load Capacity Comparison

Typical Capacities and Use Cases:- Electric Chain Hoists: These hoists are commonly used for lighter to moderate loads, typically ranging from a few hundred kilograms up to several tons. They are ideal for general manufacturing, maintenance, and smaller-scale operations where frequent load handling is neede The load capacity of chain hoists is generally sufficient for most industrial applications involving moderate weight.

- Wire Rope Hoists: Wire rope hoists are designed for heavier lifting applications, with capacities ranging from several tons to over 100 tons. They are well-suited for heavy industrial tasks, construction sites, and large-scale operations where the loads are significantly heavier. Their robust design and high load capacity make them a preferred choice for environments requiring substantial lifting power and durability.

In summary, while electric chain hoists are valued for their compact design and cost-effectiveness for lighter loads, wire rope hoists excel in handling heavy-duty applications with greater load capacities and longer operational ranges. The choice between the two depends on the specific lifting requirements and operational context.

Advantages of Electric Chain Hoists

Cost and Maintenance

- Generally More Affordable and Easier to Maintain: Electric chain hoists are typically less expensive than wire rope hoists, making them a cost-effective choice for many businesses. Their simpler design involves fewer components, which translates to easier and less costly maintenance. Regular upkeep primarily involves inspecting and lubricating the chain and ensuring the motor functions correctly, which is generally less complex compared to the maintenance required for wire rope systems.

Application Suitability

- Best for Lighter Loads and Frequent Use: Electric chain hoists are particularly well-suited for applications involving lighter to moderate loads. They are designed to handle frequent lifting and lowering tasks efficiently, making them ideal for environments where regular load handling is necessary. Their ability to operate consistently without excessive strain makes them a reliable choice for manufacturing, warehousing, and other industrial settings where lighter materials are commonly move

Design Benefits

- Compact and Versatile for Confined Spaces: One of the notable advantages of electric chain hoists is their compact design. This allows them to fit into tight or constrained spaces where larger equipment might not be practical. Their vertical lifting mechanism is well-suited for areas with limited headroom or floor space, offering versatility in various environments. The compact size also facilitates easier installation and operation in confined or specialized work areas.

Advantages of Wire Rope Hoists

Strength and Durability

- Higher Capacity and Longevity: Wire rope hoists are designed to handle significantly heavier loads compared to electric chain hoists. Their robust construction and use of steel wire ropes enable them to lift and move very heavy items safely and reliably. Additionally, wire ropes are known for their durability and long lifespan, which reduces the frequency of replacements and maintenance. This makes wire rope hoists ideal for demanding industrial environments where durability and strength are crucial.

Efficiency

- Superior for Heavy-Duty and Industrial Applications: Wire rope hoists are highly efficient for heavy-duty tasks and large-scale industrial operations. They are capable of lifting very large and heavy loads with greater ease and less strain on the hoist system. This efficiency is particularly beneficial in construction sites, manufacturing facilities, and large warehouses where heavy materials and equipment are frequently handle Their high load capacities ensure that they can meet the rigorous demands of such environments.

Operation Smoothness

- Enhanced Precision and Smoothness: Wire rope hoists generally provide smoother and more precise operation compared to chain hoists. The steel wire rope mechanism allows for more gradual and controlled lifting and lowering of loads. This smooth operation is crucial for applications that require high precision and stability, such as in delicate manufacturing processes or where precise placement of loads is necessary. The enhanced smoothness also reduces wear and tear on the hoist components, contributing to longer service life and improved overall performance.

Ideal Applications for Each Hoist Type

Electric Chain Hoists

- Suitable for General Manufacturing and Maintenance: Electric chain hoists are well-suited for general manufacturing environments where frequent load handling of lighter to moderate weights is require They excel in applications such as assembly lines, small-scale production facilities, and maintenance tasks where consistent and reliable performance is neede Their compact design and affordability make them ideal for workshops and warehouses where space is limited and budget constraints are a concern.

Wire Rope Hoists

- Ideal for Large-Scale and Heavy-Duty Operations: Wire rope hoists are best utilized in large-scale industrial operations and environments where heavy-duty lifting is essential. They are ideal for construction sites, heavy manufacturing facilities, and warehouses with high load capacities. Their strength and durability make them suitable for tasks that involve lifting extremely heavy materials or equipment. The efficiency and smooth operation of wire rope hoists make them the preferred choice for applications that demand robust performance and precision over long periods.

Conclusion

In this comprehensive comparison, we explored the different types of electric chain hoists—motorized travelling trolley, manual travelling trolley, hook mounted/lug mounted, and low headroom—each with its unique features and advantages. Motorized travelling trolleys offer automation and efficiency for heavy-duty tasks but come with higher costs and maintenance needs. Manual travelling trolleys are cost-effective and easy to maintain but require manual effort and are less suitable for heavy loads. Hook mounted and lug mounted hoists provide versatility and affordability but have limited mobility and fixed positioning. Low headroom hoists are designed for confined spaces, maximizing headroom usage but may be more expensive and limited in application scope.

Additionally, we compared electric chain hoists with wire rope hoists. Electric chain hoists are generally more affordable and easier to maintain, making them ideal for lighter loads and frequent use. They are compact and versatile for confined spaces. In contrast, wire rope hoists offer higher capacity, durability, and smooth operation, making them suitable for large-scale and heavy-duty operations.

Recommendations

When selecting the most appropriate hoist, consider the following factors:

- Load Requirements: For lighter to moderate loads and frequent use, electric chain hoists are generally the best choice. If your operations involve lifting very heavy loads, wire rope hoists are more suitable.

- Operational Environment: In confined spaces with low ceilings, a low headroom electric chain hoist can maximize headroom usage. For environments requiring high mobility and automation, a motorized travelling trolley hoist would be more effective.

- Budget and Maintenance: If cost and maintenance are key considerations, electric chain hoists typically offer a more budget-friendly option with simpler upkeep. Wire rope hoists, while more expensive, provide greater durability and efficiency for heavy-duty applications.

By assessing your specific lifting needs and operational constraints, you can choose the hoist that best aligns with your requirements, ensuring optimal performance, safety, and cost-effectiveness.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch