Portable Electric Chain Hoist for Sale, Buying Guide 1 to 35 Ton

Comprehensive guide on portable electric chain hoist for sale: essential information, features, applications, and benefits for industrial use.

Category: Electric Chain Hoist Crane

Your Trusted Overhead Electric Chain Hoist Crane Manufacturer & Supplier

Portable Electric Chain Hoist for Sale, Buying Guide To Get Cost-effective 1 Ton, 2 Ton, 3 Ton, 5 Ton, 10 Ton, 15 Ton, 20 Ton to 35 Ton Electric Chain Block

Comprehensive Guide on Portable Electric Chain Hoist for Sale

Overview of Portable Electric Chain Hoists

Portable electric chain hoists are versatile lifting devices designed for easy maneuverability and efficient handling of heavy loads. These hoists use an electric motor to lift and lower loads via a chain mechanism, offering precise control and reliable performance. Unlike traditional manual hoists, electric chain hoists automate the lifting process, reducing manual effort and enhancing safety.

Key Advantages and Applications

Advantages:

- Ease of Use: Electric chain hoists are user-friendly, allowing for effortless operation with minimal physical strain on the operator. Controls are typically straightforward, making them accessible for various skill levels.

- High Lifting Capacity: These hoists can handle substantial loads, with models available for capacities ranging from light to heavy-duty, including 10 tons and more.

- Efficiency: The electric motor provides consistent and powerful lifting, increasing productivity and reducing the time required to move materials.

- Portability: Designed for easy transport and setup, portable hoists can be quickly relocated to different job sites or areas within a facility, offering flexibility in material handling.

Applications:

- Manufacturing: Ideal for assembly lines and production areas, where they facilitate the lifting and positioning of heavy components and machinery.

- Construction: Used on construction sites to lift building materials, equipment, and tools, helping streamline operations and reduce manual lifting tasks.

- Warehousing and Logistics: Enhances efficiency in warehouses by quickly moving pallets, containers, and other heavy items, optimizing storage and distribution processes.

Importance in Industrial Settings

Role in Material Handling

In industrial settings, portable electric chain hoists play a critical role in material handling by simplifying the process of lifting and transporting heavy items. They improve the efficiency of operations by allowing for faster and safer movement of materials, reducing the need for manual lifting and minimizing the risk of workplace injuries. By automating the lifting process, these hoists also contribute to consistent and reliable handling, which is essential for maintaining smooth workflow and meeting production targets.

Benefits of Portability and Electric Operation

- Flexibility: The portability of electric chain hoists allows them to be easily moved between different work areas or job sites, adapting to various operational needs. This flexibility is particularly valuable in dynamic industrial environments where tasks and locations frequently change.

- Convenience: Electric operation eliminates the physical effort required by manual hoists, making it easier to handle heavy loads with less physical strain. The consistent power provided by the electric motor ensures reliable performance and reduces the risk of errors associated with manual lifting.

- Safety: With automated lifting and lowering, electric chain hoists reduce the risk of accidents and injuries caused by manual handling. Safety features such as overload protection and emergency stop functions further enhance operator safety.

In summary, portable electric chain hoists offer significant advantages in terms of ease of use, efficiency, and portability. Their role in industrial settings is crucial for effective material handling, providing a safer and more efficient solution for lifting and transporting heavy loads.

Types and Features

Types of Portable Electric Chain Hoists

Standard vs. Heavy-Duty Models

Standard Models:

- Design and Functionality: Standard portable electric chain hoists are designed for general-purpose lifting tasks with moderate load requirements. They are typically suitable for lighter industrial applications, such as handling components on assembly lines or moving materials in smaller warehouses.

- Capacity: These models generally handle loads ranging from a few hundred kilograms up to 5 tons, depending on the specific hoist.

- Features: Standard models come with basic features and are often more cost-effective, making them a practical choice for everyday lifting needs.

Heavy-Duty Models:

- Design and Functionality: Heavy-duty portable electric chain hoists are built for demanding applications where high load capacities and continuous operation are required. They are ideal for industries with heavy lifting needs, such as construction sites, large-scale manufacturing, or heavy machinery handling.

- Capacity: These hoists can handle loads from 5 tons up to 10 tons or more, depending on the model.

- Features: Heavy-duty models often include advanced features and robust construction to withstand rigorous use, providing greater durability and reliability.

Key Features

Lifting Capacity and Range:

- Capacity: The lifting capacity of portable electric chain hoists varies depending on the model. Standard models typically handle up to 5 tons, while heavy-duty versions can manage 10 tons or more. The capacity should be matched to the specific lifting requirements of the application.

- Range: The lifting range, or height, is determined by the length of the chain. Hoists come with different chain lengths to accommodate various lifting heights, ensuring they meet the needs of different work environments.

Motor Power and Efficiency:

- Power: The motor power of the hoist determines its lifting strength and efficiency. Standard models usually have lower power ratings suitable for lighter tasks, while heavy-duty models feature more powerful motors to handle heavier loads and prolonged use.

- Efficiency: Electric motors are designed for optimal efficiency, providing consistent performance and reducing energy consumption. The efficiency of the motor impacts the overall cost of operation and maintenance.

Chain Length and Material:

- Length: The chain length is crucial for determining the lifting height and operational flexibility of the hoist. Standard lengths are available, but some models offer adjustable or extended chain options for specific requirements.

- Material: Chains are typically made from high-strength steel or alloy materials to ensure durability and safety under heavy loads. The material affects the chain's resistance to wear and stress, contributing to the hoist's overall reliability.

Control Options (e.g., Pendant, Wireless):

- Pendant Control: Most portable electric chain hoists feature a pendant control with a wired connection, allowing operators to control lifting and lowering functions from a safe distance.

- Wireless Control: Advanced models offer wireless control options, providing greater freedom of movement and flexibility. Wireless controls are ideal for environments where operators need to be mobile or where space is limited.

Safety Features (e.g., Overload Protection, Emergency Stop):

- Overload Protection: This feature prevents the hoist from lifting loads that exceed its rated capacity, reducing the risk of equipment damage and ensuring safe operation.

- Emergency Stop: An emergency stop button allows operators to quickly halt the hoist in case of an emergency, preventing accidents and ensuring operator safety.

- Additional Safety Features: Many hoists also include features such as limit switches to prevent over-travel, braking systems for controlled lowering, and thermal protection to prevent motor overheating.

In summary, understanding the types and key features of portable electric chain hoists is essential for selecting the right model for your needs. Whether choosing a standard or heavy-duty hoist, consider factors such as lifting capacity, motor power, chain material, control options, and safety features to ensure optimal performance and safety in your industrial applications.

Load Capacities and Applications of Portable Electric Chain Hoists

Portable Electric Chain Hoist 500 kg

Typical Applications:

Lightweight Industrial Tasks: Ideal for small workshops or light manufacturing operations where lifting lighter components or tools is required.

Maintenance Work: Used for hoisting small machinery or components for repair and maintenance in confined spaces.

Small Assembly Lines: Suitable for handling lighter parts in small-scale assembly operations.

Typical Loads Handling:

Components: Small parts, tools, and light equipment.

Examples: Light automotive parts, small machinery components, or assembly line materials.

Portable Electric Chain Hoist 1 Ton

Typical Applications:

Small to Medium Industrial Tasks: Suitable for medium-sized components and equipment in various industrial settings.

Construction Sites: Used for lifting and positioning medium-weight materials or tools.

Warehouse Operations: Handling moderate-sized items and goods.

Typical Loads Handling:

Components: Medium-sized machinery parts, heavy tools, or equipment.

Examples: Small engine parts, industrial equipment, and large assembly line components.

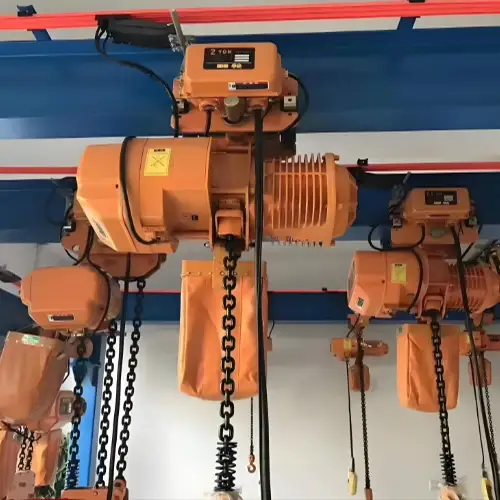

Portable Electric Chain Hoist 2 Ton

Typical Applications:

Manufacturing and Assembly: Ideal for lifting and positioning larger components in manufacturing environments.

Construction: Used for heavier construction materials and equipment.

Maintenance: Handling medium-weight machinery for repairs or servicing.

Typical Loads Handling:

Components: Larger machinery parts, construction materials, and heavy tools.

Examples: Medium-sized engine blocks, structural steel, and heavy workshop tools.

Portable Electric Chain Hoist 3 Ton

Typical Applications:

Heavy Equipment Handling: Suitable for lifting larger equipment and machinery in industrial settings.

Construction Sites: Ideal for positioning heavy construction materials and structural components.

Warehousing: Handling large and heavy goods in logistics and warehouse operations.

Typical Loads Handling:

Components: Large machinery components, heavy construction materials.

Examples: Large engine components, heavy steel beams, and bulky warehouse items.

Portable Electric Chain Hoist 5 Ton

Typical Applications:

Heavy Industrial Work: Used for lifting and positioning very heavy machinery and components.

Construction and Building: Handling large structural elements and equipment.

Heavy Maintenance Tasks: Suitable for heavy-duty repair and maintenance work.

Typical Loads Handling:

Components: Very large machinery, heavy equipment, and structural materials.

Examples: Heavy-duty motors, large construction panels, and substantial machinery parts.

Portable Electric Chain Hoist 7.5 Ton

Typical Applications:

Industrial Operations: Ideal for very heavy lifting in industrial and manufacturing settings.

Construction Projects: Handling large and heavy construction materials.

Heavy Maintenance: Suitable for servicing and repairing large equipment.

Typical Loads Handling:

Components: Large industrial machines, heavy construction materials, and sizable equipment.

Examples: Large motors, industrial machinery, and heavy-duty construction materials.

Portable Electric Chain Hoist 10 Ton

Typical Applications:

Heavy Industrial Work: Used for very heavy loads in manufacturing, assembly, and construction.

Major Construction Projects: Lifting and positioning large structural components and machinery.

Maintenance of Large Equipment: Handling substantial machinery parts for servicing.

Typical Loads Handling:

Components: Very heavy machinery, large structural components.

Examples: Heavy industrial equipment, large steel beams, and extensive construction materials.

Portable Electric Chain Hoist 25 Ton

Typical Applications:

Large-Scale Industrial Projects: Suitable for handling extremely heavy loads in industrial operations.

Heavy Construction: Used for very large construction projects involving massive materials and equipment.

Large Equipment Maintenance: Ideal for servicing and maintaining very large machinery.

Typical Loads Handling:

Components: Massive machinery, large structural elements.

Examples: Heavy-duty industrial machines, large construction modules, and substantial structural components.

Portable Electric Chain Hoist 30 Ton, 35 Ton

Typical Applications:

Heavy Industrial Lifting: Used for exceptionally heavy loads in major industrial and construction projects.

Large-Scale Construction: Handling extremely large and heavy materials and equipment.

Maintenance of Large Industrial Machinery: Suitable for very large machinery in maintenance and repair operations.

Typical Loads Handling:

Components: Extremely heavy machinery, very large construction materials.

Examples: Massive engines, large structural steel elements, and substantial equipment for major industrial applications.

In summary, portable electric chain hoists come in various capacities to meet different lifting needs, ranging from lightweight tasks to extremely heavy-duty applications. Selecting the appropriate hoist depends on the specific weight requirements and operational contexts.

Comparison of Hook Mounted Portable Electric Chain Hoists and Motorized Travelling Electric Chain Hoists

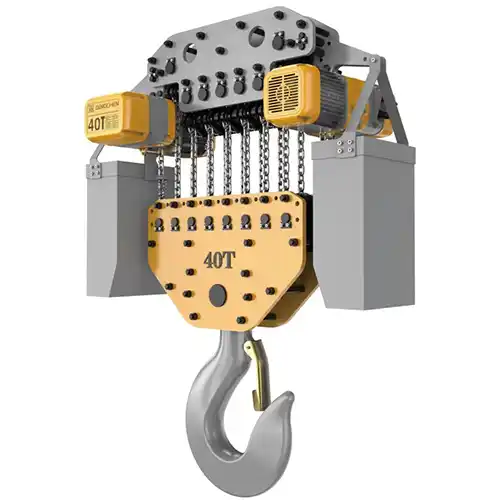

Hook Mounted Portable Electric Chain Hoist 20 Tons

Hook mounted portable electric chain hoists are designed for lifting and lowering loads using a hook that attaches to the load. These hoists are typically used in stationary applications where the lifting device is anchored in place.

Key Features:

- Portability: These hoists are designed for easy relocation and can be moved between different locations or workstations.

- Simple Operation: They operate by lifting loads directly from the hook, making them straightforward and easy to use.

- Cost-Effective: Generally more affordable than motorized travelling hoists due to their simpler design and lack of travel mechanisms.

Advantages:

- Flexibility: Ideal for environments where lifting needs vary and the hoist needs to be moved frequently.

- Ease of Use: Straightforward setup and operation without the need for complex adjustments.

- Lower Cost: Less expensive due to the absence of motorized travel components.

Disadvantages:

- Limited Movement: Lifting is confined to a fixed location, and the hoist cannot move horizontally or traverse the workspace.

- Manual Handling: The hoist must be repositioned manually, which can be time-consuming and labor-intensive if frequent adjustments are needed.

Typical Applications:

- Workshops and Small Factories: For lifting light to medium loads in a fixed area.

- Maintenance and Repair: Ideal for scenarios where heavy equipment needs to be lifted at a single location.

- Small Assembly Lines: Used for lifting and positioning materials in a stationary setup.

Motorized Travelling Electric Chain Hoist 20 Tons

Motorized travelling electric chain hoists are equipped with a motorized trolley or carriage that allows the hoist to move horizontally along a beam or rail. This functionality enables the hoist to travel across different areas of a workspace, offering greater flexibility.

Key Features:

- Motorized Travel: Includes a motorized system that allows horizontal movement along a track or rail.

- Enhanced Versatility: Capable of covering a large work area without needing to reposition the hoist manually.

- Higher Cost: More expensive due to the added complexity of motorized travel mechanisms.

Advantages:

- Increased Reach: Can move loads across a broad area, enhancing productivity by allowing the hoist to cover multiple workstations or areas.

- Reduced Manual Effort: Motorized travel reduces the need for manual repositioning, improving efficiency and reducing labor.

- Higher Load Handling: Often designed for heavier and more demanding applications compared to hook-mounted models.

Disadvantages:

- Higher Cost: Generally more expensive due to the added motorized components and complex design.

- Installation Requirements: Requires installation of tracks or rails, which can involve additional setup and maintenance.

Typical Applications:

- Large Factories and Warehouses: Ideal for environments where the hoist needs to cover extensive areas and perform multiple lifting tasks.

- Construction Sites: Used for moving heavy materials across a site, enhancing workflow efficiency.

- Assembly Lines and Production Facilities: Suitable for large-scale operations requiring horizontal movement of materials.

Summary

- Hook Mounted Portable Electric Chain Hoists are best suited for stationary applications with simpler lifting needs. They offer flexibility in terms of relocation but lack the ability to move horizontally across a workspace.

- Motorized Travelling Electric Chain Hoists are designed for more dynamic applications where horizontal movement is required. They provide enhanced versatility and efficiency but come with a higher cost and more complex installation requirements.

The choice between the two types depends on the specific operational needs, budget, and the desired level of mobility and flexibility in your lifting tasks.

Applications of Portable Electric Chain Hoists

Industrial Applications

Manufacturing and Assembly:

- Overview: Portable electric chain hoists are extensively used in manufacturing and assembly operations to lift and position heavy components, machinery, and tools. Their flexibility allows them to be moved easily between different workstations or assembly lines.

- Benefits: They enhance productivity by streamlining material handling processes, reduce manual lifting efforts, and improve safety by minimizing the risk of injury. Efficient lifting and positioning of parts also contribute to a smoother production flow and faster assembly times.

Construction and Heavy Equipment Handling:

- Overview: In the construction industry, portable electric chain hoists are crucial for lifting and moving building materials, machinery, and heavy equipment. They are used on construction sites to handle tasks such as hoisting steel beams, concrete panels, and large equipment.

- Benefits: These hoists increase operational efficiency by facilitating the quick and safe movement of heavy items. They reduce the need for manual lifting and can be easily relocated as construction sites evolve. The ability to handle substantial loads with precision helps in meeting tight project deadlines and ensuring smooth construction processes.

Warehousing and Logistics:

- Overview: In warehouses and logistics operations, portable electric chain hoists are used to move and position heavy goods, pallets, and containers. They play a key role in optimizing storage and retrieval processes by facilitating efficient material handling.

- Benefits: The use of hoists in warehousing improves inventory management by enabling quick access to stored items. It reduces manual handling, speeds up loading and unloading processes, and enhances safety by reducing the risk of injuries associated with lifting heavy objects.

Case Studies

Real-World Examples of Usage:

Example 1: Automotive Assembly Line

- Situation: A major automotive manufacturer required a solution for lifting heavy engine components and assembling vehicles on the production line.

- Solution: A portable electric chain hoist with a 10-ton capacity was deployed, allowing for efficient lifting and precise positioning of engine parts.

- Results: The hoist improved assembly line efficiency by reducing the time required for component handling and increasing production throughput. The flexibility of the portable hoist allowed it to be used at different assembly stations, contributing to overall operational flexibility.

Example 2: Construction of High-Rise Building

- Situation: A construction company needed to lift and position heavy steel beams and concrete panels for a high-rise building project.

- Solution: Heavy-duty portable electric chain hoists were utilized to handle the substantial loads required for the project.

- Results: The hoists facilitated the efficient movement of heavy materials, enabling timely completion of the construction phases. The ability to quickly relocate the hoists as needed on the site enhanced overall productivity and safety.

Example 3: Warehouse Optimization

- Situation: A logistics company faced challenges in moving and positioning large pallets and containers in their warehouse.

- Solution: Portable electric chain hoists were implemented to assist with the lifting and placement of heavy goods.

- Results: The hoists streamlined the warehousing process by speeding up material handling and reducing manual labor. Enhanced safety and efficiency contributed to improved warehouse operations and better inventory management.

Benefits Observed in Various Industries:

- Enhanced Efficiency: Across industries, portable electric chain hoists have demonstrated significant improvements in operational efficiency by speeding up material handling and reducing manual effort.

- Increased Safety: By automating the lifting process, these hoists have reduced the risk of workplace injuries associated with manual lifting.

- Flexibility and Adaptability: The portability of these hoists has allowed for versatile use in different applications, from manufacturing lines to construction sites and warehouses, adapting to various operational needs.

In summary, portable electric chain hoists are valuable across multiple industrial applications, including manufacturing, construction, and warehousing. Case studies highlight their benefits in improving efficiency, safety, and flexibility in real-world scenarios.

Special Operations of Hook Mounted Portable Electric Chain Hoists

Hook mounted portable electric chain hoists are versatile tools used in various applications where lifting and lowering loads are required. They are particularly useful in situations where specific operations or conditions demand unique features or techniques. Here's an overview of special operations involving hook-mounted portable electric chain hoists:

Precision Lifting and Positioning

- Precision Control: These hoists offer fine control over lifting operations, making them ideal for tasks requiring accurate positioning of loads.

- Application: Used in assembly lines, repair shops, and maintenance tasks where precise placement of heavy components is critical.

Special Techniques:

- Slow Speed Operation: Utilizing the hoist's slow speed settings to make delicate adjustments to the load's position.

- Load Balancing: Employing techniques to ensure even lifting and balanced load distribution to prevent shifting or tilting.

Overhead Lifting

- Overhead Operation: Hook-mounted hoists are often used for overhead lifting applications where the load must be moved above the operator's head.

- Application: Common in factories, warehouses, and workshops where loads need to be lifted to elevated positions.

Special Techniques:

- Clearance Management: Ensuring sufficient clearance above the load and work area to prevent collisions and ensure safe operation.

- Suspension Checks: Regularly inspecting the hoist's suspension components to ensure they are in good condition and capable of supporting overhead loads.

Lifting in Confined Spaces

- Compact Design: The portability and compact nature of hook-mounted hoists make them suitable for use in confined or restrictive spaces.

- Application: Ideal for lifting tasks in narrow aisles, small workshops, or cramped maintenance areas.

Special Techniques:

- Space Management: Carefully planning the lifting path and operation to navigate around obstacles and make efficient use of limited space.

- Operator Safety: Ensuring operators have adequate space to work safely and avoiding overloading or excessive strain on the hoist in tight areas.

Portable and Temporary Installations

- Temporary Use: Hook-mounted portable hoists are designed for temporary setups and can be relocated as needed.

- Application: Useful in temporary installations, such as construction sites or events, where a permanent hoist system is not feasible.

Special Techniques:

- Quick Setup: Efficiently setting up and securing the hoist for immediate use, including anchoring and power connections.

- Relocation Procedures: Implementing safe and effective procedures for moving the hoist between different locations.

Heavy Load Handling

- Heavy Duty Capability: Designed to handle heavy loads within their rated capacity, making them suitable for demanding lifting tasks.

- Application: Common in industrial environments where heavy equipment, machinery, or components need to be lifted.

Special Techniques:

- Load Distribution: Using appropriate rigging techniques to distribute the load evenly and prevent excessive strain on the hoist.

- Safety Checks: Performing thorough safety inspections before lifting to ensure the hoist is in good working condition and capable of handling the load.

Emergency Lifting and Rescue Operations

- Emergency Use: Portable hoists can be used in emergency situations for quick lifting and rescue operations.

- Application: Useful in scenarios such as recovery of equipment or materials, or assisting in emergency evacuations.

Special Techniques:

- Rapid Deployment: Quickly deploying the hoist for immediate use in emergency situations.

- Emergency Protocols: Following established safety protocols and procedures for emergency lifting and ensuring the safety of all involved.

Load Securing and Stabilization

- Secure Lifting: Ensuring that loads are securely fastened and stabilized during lifting operations to prevent shifting or falling.

- Application: Essential in operations where load stability is crucial to safe and efficient handling.

Special Techniques:

- Rigging Methods: Using appropriate rigging methods and equipment to secure the load properly.

- Stabilization Techniques: Implementing techniques to stabilize the load during lifting, such as using spreader bars or slings.

Hook-mounted portable electric chain hoists are adaptable tools suitable for a wide range of special operations, including precision lifting, overhead lifting, confined space operation, temporary installations, heavy load handling, emergency operations, and load stabilization. Proper techniques and safety measures are essential to ensure effective and safe operation in these specialized scenarios.

Buying Guide

Factors to Consider

Capacity and Operational Needs:

- Capacity Requirements: When selecting a portable electric chain hoist, ensure that its lifting capacity meets or exceeds the heaviest load you expect to handle. Hoists come in various capacities, so choosing the right one is crucial for safe and efficient operation.

- Operational Needs: Consider the specific tasks and environments where the hoist will be used. Factors such as lifting height, frequency of use, and the type of materials being handled can influence the choice of hoist. For example, if you need to frequently lift heavy loads to considerable heights, a hoist with a higher capacity and longer chain length may be required.

Budget and Cost Considerations:

- Initial Investment: Portable electric chain hoists vary in price based on capacity, features, and brand. Determine your budget while keeping in mind the cost of purchasing the hoist. Higher capacity and advanced features typically come with a higher price tag.

- Long-Term Costs: Factor in potential costs such as maintenance, repairs, and energy consumption. Investing in a higher-quality hoist may reduce long-term operational costs due to fewer breakdowns and lower maintenance needs. Consider total cost of ownership to ensure you're making a cost-effective choice.

Brand Reputation and Reliability:

- Brand Reputation: Research brands known for their reliability and quality in the market. Established brands often have a proven track record of performance and customer satisfaction. Look for manufacturers with a strong presence in the industry and positive feedback from users.

- Reliability: Assess the reliability of the hoist by checking the manufacturer's reputation for producing durable and high-performance equipment. Reliable hoists are less likely to experience frequent breakdowns and will perform consistently under demanding conditions.

Warranty and After-Sales Support:

- Warranty Coverage: Review the warranty terms offered by the manufacturer. A comprehensive warranty indicates the manufacturer's confidence in their product and provides peace of mind. Look for warranties that cover major components and offer protection against defects and premature failure.

- After-Sales Support: Consider the availability of after-sales support, including maintenance services and technical assistance. Reliable customer support can be crucial for resolving issues promptly and ensuring the continued performance of the hoist.

Top Vendors and Suppliers

Recommended Suppliers and Manufacturers:

- Leading Suppliers: Identify reputable suppliers and manufacturers known for their high-quality portable electric chain hoists. Look for companies with a strong market presence and a history of supplying reliable equipment.

- Authorized Dealers: Purchasing from authorized dealers ensures that you receive genuine products and have access to official support and warranty services. Authorized dealers often provide detailed product information and can offer expert advice.

Comparison of Product Offerings:

- Product Range: Compare the product offerings of different vendors to find the hoist that best matches your requirements. Consider factors such as lifting capacity, features, and pricing.

- Customization Options: Some manufacturers offer customization options to tailor the hoist to specific needs. Compare these options to see if they align with your operational requirements.

Customer Reviews and Ratings:

- User Feedback: Read customer reviews and ratings to gain insights into the performance and reliability of different hoists. User reviews can provide valuable information on real-world experiences, highlighting both strengths and potential issues.

- Rating Systems: Check ratings on trusted review platforms and forums. High ratings and positive feedback from users can be indicators of a well-regarded product and manufacturer.

In summary, when purchasing a portable electric chain hoist, carefully consider factors such as capacity, budget, brand reputation, and warranty. Evaluate top vendors and suppliers by comparing their product offerings and reading customer reviews to make an informed decision that meets your operational needs and ensures long-term satisfaction.

Installation and Maintenance

Installation Tips

Site Preparation and Setup:

- Site Assessment: Before installation, assess the installation site to ensure it can support the hoist's weight and operational requirements. Check for sufficient clearance and structural integrity to accommodate the hoist and its lifting range.

- Mounting: Ensure that the hoist is mounted on a stable and level surface. For portable hoists, verify that the installation area allows for easy movement and positioning. For fixed installations, ensure that mounting points are securely anchored and aligned.

- Power Supply: Verify that the power supply matches the hoist's requirements (e.g., voltage, phase). Ensure that electrical connections are properly installed and comply with local electrical codes.

- Alignment: Properly align the hoist with the load path to avoid uneven wear and ensure smooth operation. Misalignment can cause strain on the hoist and affect its performance.

Safety Precautions During Installation:

- Personal Protective Equipment (PPE): Ensure that all personnel involved in the installation are wearing appropriate PPE, including gloves, helmets, and safety glasses.

- Electrical Safety: Turn off the power supply before making electrical connections to prevent electrical shocks or damage. Follow proper lockout/tagout procedures to ensure safety.

- Load Testing: Perform load testing after installation to verify that the hoist operates correctly and safely under its rated capacity. Check for any unusual noises, vibrations, or issues.

Maintenance Guidelines

Routine Maintenance Tasks:

- Inspection: Regularly inspect the hoist for signs of wear, damage, or malfunction. Check components such as chains, gears, and brakes for proper functioning and signs of deterioration.

- Lubrication: Keep moving parts well-lubricated according to the manufacturer's recommendations. Proper lubrication reduces friction and extends the life of the hoist.

- Cleaning: Clean the hoist periodically to remove dust, debris, and contaminants that can affect its performance. Ensure that the hoist is powered off and safe to handle before cleaning.

Troubleshooting Common Issues:

- Unresponsive Operation: If the hoist is unresponsive or does not lift properly, check the power supply and electrical connections. Ensure that the controls are functioning correctly and that there are no obstructions.

- Strange Noises: Unusual noises, such as grinding or squealing, may indicate worn or damaged components. Inspect the hoist for issues and replace damaged parts as needed.

- Overload Protection: If the hoist stops working, it may have triggered the overload protection. Check the load and ensure it does not exceed the hoist's capacity. Reset the protection mechanism as per the manufacturer's instructions.

Professional Servicing and Repairs:

- Certified Technicians: For complex repairs or servicing, contact certified technicians who are trained to handle portable electric chain hoists. They can provide expert diagnostics and repair services.

- Manufacturer Support: Use authorized service centers and follow the manufacturer's guidelines for repairs and servicing to ensure that the hoist remains in optimal condition.

Safety and Compliance

Safety Standards

Overview of Relevant Safety Standards (e.g., ANSI, CE):

- ANSI (American National Standards Institute): ANSI standards ensure that lifting equipment, including electric chain hoists, meets safety and performance requirements. Look for ANSI compliance to ensure the hoist adheres to established safety protocols.

- CE (Conformité Européenne): CE marking indicates that the hoist complies with European safety, health, and environmental protection standards. This certification is crucial for equipment used within the European Union and demonstrates adherence to strict safety requirements.

Compliance Requirements:

- Local Regulations: Adhere to local regulations and industry standards for the safe use of electric chain hoists. This includes compliance with electrical codes, load limits, and installation requirements.

- Inspection and Certification: Ensure that the hoist undergoes regular inspections and certifications as required by local laws and industry standards. This helps maintain safety and compliance throughout the hoist's operational life.

Operational Safety

Best Practices for Safe Operation:

- Load Limits: Never exceed the hoist's rated load capacity. Overloading can cause equipment failure and pose serious safety risks.

- Proper Use: Operate the hoist according to the manufacturer's instructions and avoid using it for tasks it is not designed for. Ensure that all operators are familiar with the hoist's functions and limitations.

- Regular Checks: Perform routine safety checks before each use, including inspecting the chain, brakes, and controls. Ensure that the hoist is in good working condition and address any issues before operation.

Training Requirements for Operators:

- Operator Training: Provide comprehensive training for all operators on the safe use and maintenance of the hoist. Training should cover operating procedures, safety protocols, and emergency response.

- Certification: Depending on local regulations, operators may need to obtain certification for using electric chain hoists. Ensure that operators have the necessary credentials and are knowledgeable about the equipment.

In summary, proper installation and maintenance of portable electric chain hoists are essential for ensuring safe and efficient operation. Adhering to safety standards, performing regular maintenance, and providing thorough operator training contribute to the longevity and reliability of the hoist, while ensuring compliance with industry regulations.

Conclusion: Get Your Custom Portable Electric Chain Hoists

Summary of Key Points

In this comprehensive guide, we have explored the critical aspects of portable electric chain hoists, highlighting their versatility and importance across various industrial applications. Key benefits include:

- Flexibility and Portability: These hoists are designed for easy relocation and adaptability, making them ideal for diverse applications from manufacturing to construction and warehousing.

- Enhanced Efficiency: By automating the lifting process, portable electric chain hoists streamline material handling, improve workflow, and reduce manual labor.

- Safety Features: Modern hoists come equipped with essential safety features such as overload protection, emergency stops, and user-friendly controls to ensure safe and reliable operation.

- Customization: Hoists can be tailored to specific needs, including lifting capacity, chain length, and control options, allowing them to meet unique operational requirements.

Final Recommendations

For potential buyers considering a portable electric chain hoist, here are some final recommendations to ensure you make the right choice:

- Assess Your Needs: Carefully evaluate your operational requirements, including lifting capacity, height, and frequency of use. Choose a hoist that meets these needs and aligns with your budget.

- Consider Quality and Reliability: Invest in a hoist from a reputable manufacturer with a track record of reliability. Look for well-known brands and verify their product offerings through customer reviews and ratings.

- Check Compliance and Safety: Ensure the hoist complies with relevant safety standards and regulations. Review safety features and consider how they align with your operational safety practices.

- Evaluate Support and Warranty: Opt for a hoist that comes with a comprehensive warranty and reliable after-sales support. This ensures you have access to service and repairs when needed.

Choosing the right portable electric chain hoist is crucial for enhancing operational efficiency, ensuring safety, and meeting specific lifting requirements. By considering factors such as capacity, design, brand reputation, and support services, you can select a hoist that not only fits your current needs but also provides long-term value and reliability. Invest in a high-quality hoist to support your operations and achieve greater productivity and safety in your industrial activities.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch