45 Ton RMG Crane for Handling Hazardous Chemical Containers

45 ton RMG crane to safely handle hazardous chemical tank containers in industrial environments. Contact to get gantry crane for container handling.

Category: Hazardous Environment Cranes

Your Trusted RMG Gantry Crane Manufacturer & Supplier

45 Ton RMG Crane for Handling Hazardous Chemical Containers

45 ton RMG crane to safely handle hazardous chemical tank containers in industrial environments.This case study focuses on the application of a 45 ton Rail-Mounted Gantry (RMG) crane for handling hazardous chemical tank containers in industrial environments. These tank containers often hold dangerous chemicals that require careful management due to the potential risks they pose, such as leaks, spills, or chemical reactions. The 45 ton RMG crane is chosen for its capability to lift and transport these heavy, sensitive containers with high precision and stability.

The study highlights how the crane's design and features allow it to safely handle hazardous chemical tank containers, ensuring the smooth operation of industrial processes that involve dangerous materials. It will provide insight into the crane's key features and how these solutions contribute to safer, more efficient handling in high-risk environments.

Importance of Safe Handling in Industrial Settings

The handling of hazardous chemicals requires precision and safety. Mishandling can result in significant consequences, such as:

- Chemical spills that can harm workers, damage equipment, and cause environmental pollution.

- Leaks that pose dangers to both personnel and nearby communities.

- Explosions or fires caused by improper handling of volatile substances.

In industrial settings, especially those involving the transportation of large chemical containers, the risk is even greater. Safety protocols and regulations are crucial to protect both workers and the environment. Compliance with standards set by organizations like OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) ensures that hazardous materials are handled properly.

Key safety measures required for hazardous material handling include:

- Proper equipment designed to prevent accidents.

- Regular safety checks and maintenance of equipment.

- Trained operators who understand the risks and safety procedures.

The 45 ton RMG crane is equipped with advanced safety features that address these risks, such as load monitoring, anti-sway technology, and explosion-proof electrical systems. These features reduce the chance of accidents, ensuring that hazardous materials are handled safely and efficiently.

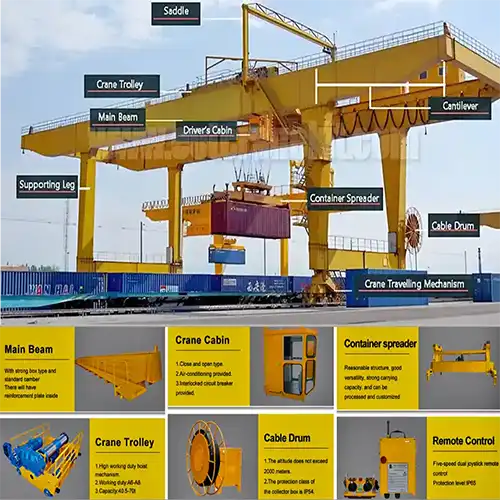

The 45 Ton RMG Crane: Design and Specifications

Overview of RMG Cranes (Rail-Mounted Gantry)

Rail-Mounted Gantry (RMG) cranes are a type of crane designed to move large and heavy loads along fixed tracks or rails. These cranes are often used in environments like ports, storage yards, and industrial facilities where the need for heavy lifting and precision handling is critical. RMG cranes are mounted on rails, allowing them to travel along a set path, typically between two fixed points, to transport large containers or materials.

Typical Applications of RMG Cranes in Industrial Settings:

- Port operations: Loading and unloading containers from ships or trucks.

- Container storage yards: Moving containers between stacks.

- Industrial facilities: Handling heavy materials such as machinery, chemical tanks, or raw materials.

- Construction sites: Transporting large construction components or equipment.

Due to their ability to handle high-capacity loads with precision, RMG cranes are particularly suited for hazardous material handling in industries like chemicals, manufacturing, and logistics.

Design Features of the 45 Ton Model

The 45 ton RMG crane is a robust, high-capacity crane designed for heavy-duty industrial applications. Its design incorporates several features that make it ideal for safely and efficiently lifting hazardous chemical tank containers.

Load Capacity and Lifting Height:

- Load Capacity: The 45 ton capacity ensures that the crane can safely lift and transport large chemical tank containers, which can often be heavy and challenging to move.

- Lifting Height: The crane's lifting height is optimized for various types of industrial settings, allowing it to lift containers from ground level to high storage positions or transport them to other areas within the facility.

Structural Integrity and Materials:

- The crane's structure is built with high-strength steel and reinforced components, ensuring it can handle the weight of hazardous materials without compromising safety or stability.

- Heavy-duty lifting arms and high-quality load-bearing structures provide the necessary support for handling loads up to 45 tons, ensuring the crane maintains its durability and reliability over time.

- The materials used in the crane's construction are resistant to wear and tear, which is especially important in harsh industrial environments.

Control Systems:

- The 45 ton RMG crane is equipped with advanced control systems that provide both safety and efficiency in its operation. These systems are designed to automate various lifting and moving functions, ensuring that tasks are completed accurately.

- Remote control operation allows operators to manage the crane from a safe distance, which is critical when handling hazardous materials.

- Advanced automation systems enable the crane to perform precise movements without human error, reducing the risk of accidents and increasing operational efficiency.

- Safety protocols are built into the control systems, such as automatic emergency stop functions and load monitoring, to prevent overloading and ensure the crane operates within safe parameters.

Customization Options for Hazardous Material Handling

To meet the specific requirements of handling hazardous chemical tank containers, the 45 ton RMG crane offers several customization options:

Specialized Components for Hazardous Chemical Handling:

- The crane can be equipped with specialized lifting attachments such as clamps, spreader bars, and tank cradle systems designed to securely grip and stabilize chemical tank containers during transport. This helps prevent movement or spills during lifting and ensures containers are handled safely.

- Enhanced stability features such as anti-sway mechanisms help prevent dangerous swinging of the load, especially important when moving heavy or hazardous materials that may be sensitive to sudden shifts.

Safety Features:

- Explosion-proof Electrical Systems: The crane's electrical components are designed to prevent sparks or overheating that could lead to fires or explosions when working with volatile chemicals. These systems are essential for meeting safety standards in hazardous environments.

- Load-Sensing Technology: The crane is equipped with load sensors to continuously monitor the weight of the container being lifted. This technology ensures that the crane does not exceed its weight limit and prevents overloading, a key safety concern when handling hazardous materials.

- Anti-collision and proximity sensors can be added to prevent accidents by detecting nearby objects and automatically adjusting the crane's movement.

These customizations make the 45 ton RMG crane an ideal solution for safely handling chemical tank containers, providing both the strength and precision necessary for these challenging tasks. The combination of specialized lifting components and advanced safety features ensures that hazardous materials are moved securely and efficiently.This section highlights the design and specifications of the 45 ton RMG crane, emphasizing its suitability for handling hazardous chemical tank containers. The combination of load capacity, advanced control systems, and customization options make it an essential tool for industrial facilities dealing with hazardous materials.

Unique Challenges of Handling Hazardous Chemical Tank Containers

Nature of Hazardous Chemical Tank Containers

Chemical tank containers are specifically designed to store and transport chemicals, many of which pose unique risks due to their volatile or hazardous nature. These containers come in different shapes and sizes, but they are commonly built to carry large volumes of materials such as:- Corrosive materials: These chemicals can damage or destroy materials and equipment on contact. Common examples include acids, alkalis, and other corrosive substances.

- Pressure vessels: Some tank containers are designed to store chemicals under high pressure, which makes them prone to catastrophic failures if mishandled.

- Volatile chemicals: Chemicals like solvents, fuels, and gases are highly reactive and can ignite or explode if exposed to heat, sparks, or improper handling.

Handling these containers requires specific precautions to prevent accidents, as even minor mishaps can result in dangerous consequences. Understanding the nature of these materials and their containers is the first step in ensuring safe transport and storage.Environmental and Regulatory Considerations:

- Environmental Protection: Hazardous chemicals pose a serious risk to the environment if spilled or released. Safe handling practices must ensure that chemicals do not leak into the soil, water, or atmosphere.

- Regulatory Compliance: Facilities that deal with hazardous chemicals must adhere to strict guidelines set by regulatory bodies like OSHA, EPA, and DOT. These regulations cover everything from proper storage and transportation to worker safety protocols and emergency response plans.

- Risk Assessment: Conducting thorough risk assessments is essential for understanding the potential hazards and establishing appropriate mitigation measures, such as spill containment systems or emergency evacuation plans.

Stabilization of Loads

Maintaining stability is one of the most critical challenges when handling hazardous chemical tank containers. These containers are typically large, heavy, and often have irregular shapes, making them difficult to stabilize during transport.Difficulties in Maintaining Stability:

- Shifting Loads: Chemical containers may shift or move inside the crane's lifting mechanism, especially if they are not secured correctly. Even small shifts can lead to spills, container damage, or unsafe swinging of the load.

- Inconsistent Weight Distribution: Many chemical containers are irregularly shaped, which can cause uneven weight distribution. This makes it harder for the crane to keep the load level during transport.

Risks of Chemical Spills, Leaks, or Structural Damage:

- Spills: If a container tips over or is mishandled during lifting, the chemicals inside can spill, creating dangerous environments for workers and potentially damaging equipment.

- Leaks: Tanks may develop leaks due to mechanical stress, poor handling, or failure of safety valves. Even a small leak of hazardous chemicals can lead to health and environmental hazards.

- Structural Damage: Mishandling or improper stabilization may cause structural damage to the container itself, compromising its integrity and increasing the risk of leaks or chemical reactions.

To address these challenges, anti-sway technology, load sensors, and specialized lifting attachments such as clamps and cradles are used to secure and stabilize the load throughout the entire transport process.

Safety Concerns

When handling hazardous chemical tank containers, there are several key safety concerns to consider, particularly for the crane operators, facility workers, and the surrounding environment.Potential Risks to Crane Operators and Facility Workers:

- Exposure to Harmful Chemicals: In the event of a spill or leak, crane operators and other workers in the facility may be exposed to toxic or corrosive chemicals. Protective equipment and emergency response plans are crucial to minimize this risk.

- Physical Injury: Due to the heavy loads and large scale of the cranes, there is a risk of crush injuries or accidents involving the crane's moving parts.

- Chemical Burns or Inhalation: Workers may also face the danger of burns, irritation, or respiratory issues due to exposure to harmful chemical vapors or direct contact with the substances being transported.

Compliance with Health, Safety, and Environmental Regulations:

Health and Safety Regulations: Cranes and their operators must comply with health and safety standards that are designed to protect workers from potential hazards. These include:

- Operator training: Proper training in crane operation, hazard recognition, and emergency response procedures.

- Safety gear: Mandatory use of personal protective equipment (PPE) such as gloves, goggles, and protective suits.

Environmental Regulations: Facilities must follow environmental standards to prevent chemical leaks or spills. This includes measures such as secondary containment systems, leak detection systems, and proper disposal methods for hazardous chemicals.

Regular Inspections: Ongoing inspections and maintenance of both the crane and containers are required to ensure compliance with safety and environmental regulations.

This section outlines the significant challenges faced when handling hazardous chemical tank containers. It highlights the need for specialized equipment, such as the 45 ton RMG crane, to manage the complexity of handling these dangerous materials safely. From maintaining stability during lifting to addressing safety concerns and meeting regulatory requirements, the proper handling of hazardous chemicals is vital to preventing accidents, protecting workers, and ensuring environmental safety.Unique Challenges of Handling Hazardous Chemical Tank Containers

Nature of Hazardous Chemical Tank Containers

Chemical tank containers are specially designed to store and transport a wide range of hazardous materials. These containers are used for storing substances that can pose significant risks to human health, the environment, and property if not handled properly. The characteristics of these containers vary depending on the type of chemical they hold, but common traits include:- Corrosive Materials: Many chemical containers carry corrosive substances that can damage materials, equipment, and infrastructure. These chemicals may react with metals, plastics, or concrete, causing severe damage to the container or surrounding environment if leaks or spills occur.

- Pressure Vessels: Some chemical tank containers are built to withstand high pressure. This is especially true for gases or liquid chemicals that are stored at elevated pressures. Any mishandling of such containers can lead to dangerous releases of gas or liquid, posing risks of explosion, fires, or toxic exposure.

- Volatile Chemicals: Volatile chemicals are substances that evaporate easily at room temperature. They may be highly flammable or explosive when exposed to heat, sparks, or friction. Transporting these materials requires precise control to avoid accidents.

In addition to these characteristics, there are environmental and regulatory considerations that must be followed when handling hazardous chemicals:

- Environmental Impact: The potential for chemical spills to contaminate soil, water, and air is a critical concern. Hazardous chemicals can have long-lasting effects on ecosystems, requiring careful handling and storage.

- Regulations: There are stringent regulations governing the handling and transport of hazardous materials, such as the Hazardous Materials Transportation Act (HMTA) and international standards like IMO (International Maritime Organization) and OSHA guidelines. Compliance with these regulations is necessary to avoid fines, legal liabilities, and safety violations.

Stabilization of Loads

One of the biggest challenges when handling hazardous chemical tank containers is ensuring load stability during lifting and transport. These containers are often heavy and cumbersome, and their contents can increase the complexity of stabilizing the load. Key challenges include:

Maintaining Load Stability: Chemical tank containers can be unevenly loaded or top-heavy, especially when liquids or gases inside shift during transport. This makes them more susceptible to tilting or swaying during lifting, which can cause the load to become unstable. This is especially dangerous for hazardous materials that can spill or leak during movement.

Risks of Spills, Leaks, or Structural Damage:

- Spills: Even a minor shift in load can cause chemical tank containers to leak, which may lead to dangerous spills. These spills pose serious risks to both people and the environment. A spill could cause chemical burns, contaminate water supplies, or trigger fires or explosions if the chemicals are volatile.

- Leaks: Over time, the structural integrity of the container may degrade due to wear, external pressures, or corrosion. A compromised container can result in leaks, which may go unnoticed during transport until it's too late.

- Structural Damage: Any improper handling or sudden movements can cause damage to the tank itself. This can compromise the safety of the entire operation, potentially leading to catastrophic failures like explosions or chemical exposure.

To mitigate these risks, cranes must be equipped with advanced load stabilization systems such as anti-sway technology and load monitoring to ensure the container remains stable throughout the lifting and transport process.

Safety Concerns

Handling hazardous chemicals comes with significant safety concerns, not only for crane operators but also for the entire facility workforce and the environment. These risks include:Potential Risks to Crane Operators and Facility Workers:

- Exposure to Hazardous Chemicals: Operators and workers are at risk of exposure to toxic, corrosive, or flammable chemicals, especially if a spill, leak, or container rupture occurs. Exposure can result in chemical burns, respiratory issues, or long-term health effects.

- Injury from Crane Malfunctions: Mechanical failures, such as brake malfunctions or power outages, can result in accidents that pose a threat to workers' safety. Operators must rely on safe crane control systems and rigorous maintenance to prevent such incidents.

Environmental Hazards: Chemical spills or leaks can have devastating effects on the environment, particularly when hazardous chemicals contaminate water supplies or harm local wildlife. Chemicals can seep into the soil, making it unsafe for agriculture, or pollute the air, leading to health risks for surrounding communities.

Compliance with Health, Safety, and Environmental Regulations:

- Health and Safety Regulations: There are strict standards that industrial facilities must follow to ensure the safety of workers handling hazardous chemicals. These include the Hazard Communication Standard (HCS), which requires workers to be trained on the risks associated with the chemicals they handle.

- Environmental Regulations: In addition to worker safety, environmental protection regulations also govern the safe handling and disposal of hazardous chemicals. Agencies like the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) provide guidelines to help minimize risks related to hazardous material handling.

In response to these risks, facilities must ensure that all safety measures are in place, including personal protective equipment (PPE) for workers, proper spill containment measures, and emergency response plans in case of accidents. Cranes used in such settings must have explosion-proof features and safety interlocks to protect operators and minimize the risk of accidents.

Case Study: An Industrial Facility Utilizing a 45 Ton RMG Crane

Background of the Industrial Facility and Its Operations

The industrial facility in focus is a chemical storage and processing plant, where hazardous chemicals are stored, handled, and transferred between various stages of production and shipping. The plant operates around the clock and is responsible for managing large volumes of chemical materials, many of which are volatile or corrosive.The facility is located near a port and serves as both a storage and transportation hub for chemicals, which are stored in tank containers that vary in size and weight. The hazardous nature of the materials requires stringent safety protocols and precise handling to prevent accidents or contamination. With operations that involve constant loading and unloading of chemical tank containers, efficiency, stability, and safety are critical factors in the facility's day-to-day operations.The 45 ton RMG crane plays a central role in these operations, particularly in handling large chemical tank containers. It is tasked with lifting and moving these containers both within the facility's storage area and between various transport vehicles (such as trucks and ships). The crane's capabilities and design are aligned with the facility's need to maintain operational efficiency while adhering to strict safety and regulatory requirements for hazardous material handling.

Description of the Crane's Role in the Handling of Hazardous Chemical Tank Containers

The 45 ton RMG crane is specifically chosen for its ability to handle large, heavy, and often unstable chemical tank containers. Its role includes:

- Moving Tank Containers Between Storage Areas: The crane is used to lift and transport containers from one storage area to another, particularly for long-term storage or temporary staging before they are moved onto trucks or ships.

- Loading and Unloading Transport Vehicles: The crane is frequently used to load chemical tank containers onto delivery vehicles, ensuring they are safely positioned and securely fixed during transport.

- Maintaining Stability During Movement: One of the most important tasks of the crane is ensuring the chemical tank containers are kept stable during lifting and transport. Due to the nature of the chemicals inside—whether liquid, gas, or hazardous solids—any instability could lead to spills, leaks, or even catastrophic failures. The crane's anti-sway technology and load sensors continuously monitor the weight distribution of the container to avoid unwanted movement or tipping. By performing these tasks with precision, the crane ensures that hazardous materials are moved safely, while also minimizing the risks of exposure, spills, or accidents.

Specific Challenges Faced and How the Crane Design Mitigates These Challenges

Handling hazardous chemical tank containers presents several challenges that require specialized equipment. The 45 ton RMG crane is specifically designed to overcome these challenges, ensuring safe and efficient operation. Below are some of the key challenges and how the crane's design addresses them:1. Load Instability

Challenge:

Tank containers, especially those containing volatile liquids or chemicals, are prone to weight shifting during movement. This instability increases the risk of spills or even container tipping, posing significant hazards in industrial settings.Crane Solution:

The anti-sway system integrated into the crane is crucial for stabilizing loads. This system automatically adjusts the crane's motion to reduce the swinging or swaying of the container during transport. By minimizing load movement, the crane helps ensure that the hazardous materials are transported safely without risking spills or accidents.Additionally, the crane is equipped with load sensors and real-time monitoring systems that continuously check the weight of the load, ensuring it remains within safe limits. This allows for precise control over the crane's operation, preventing overloading and further reducing risks.

2. Corrosive and Volatile Material Handling

Challenge:

The hazardous chemicals in the tank containers may be corrosive or volatile, which can cause dangerous leaks, spills, or even chemical reactions if not handled properly. These materials require special attention to prevent accidents that could harm both workers and the environment.Crane Solution:

The 45 ton RMG crane is constructed with explosion-proof electrical systems and corrosion-resistant materials, making it suitable for handling these hazardous chemicals. These features prevent the risk of electrical sparks or system failures that could potentially lead to dangerous situations, such as fires or chemical reactions.Furthermore, the crane is equipped with spill containment features and secondary containment structures, which help manage any small leaks or spills. This ensures that even if an incident occurs, the crane can contain the hazardous material and minimize its impact on the surrounding environment and workers.

Environmental and Safety Compliance

Challenge:

Industrial facilities that handle hazardous chemicals must adhere to strict health, safety, and environmental regulations. Ensuring compliance with these regulations is crucial for both operational safety and legal accountability.Crane Solution:

The 45 ton RMG crane is designed to meet the highest industry standards for safety and compliance. It features load-sensing technology that ensures the weight of the container is monitored continuously during operations, helping to prevent accidents related to overloading or improper handling.In addition, the crane is equipped with several advanced safety features, including:

- Emergency stop functions to quickly halt the crane's operation in case of an emergency.

- Automatic locking mechanisms for securing containers during transport, reducing the risk of accidents.

- Anti-collision sensors that prevent the crane from coming into contact with workers, other equipment, or structures, ensuring a safe working environment.

These features ensure that the crane operates within safety guidelines, protecting both personnel and the facility while maintaining full compliance with environmental and safety regulations.By effectively addressing these specific challenges, the 45 ton RMG crane ensures that hazardous chemical tank containers are handled with the utmost care and precision, enhancing safety, reducing risk, and ensuring compliance with all regulatory standards.

Insights into How the 45 Ton RMG Crane Has Improved Operational Efficiency and Safety

The introduction of the 45 ton RMG crane in this industrial facility has led to significant improvements in both operational efficiency and safety:- Increased Operational Efficiency: The crane's advanced automation systems and remote control capabilities have drastically reduced the time needed to move chemical tank containers between storage and transport areas. This has led to smoother workflow operations, less downtime, and a more organized facility.

- Improved Safety Protocols: By utilizing features like explosion-proof systems, anti-sway technology, and load-sensing monitors, the crane has minimized the risk of accidents, chemical spills, or leaks. This has significantly improved the overall safety of both the crane operators and the facility workers.

- Faster Response to Emergencies: In the event of an emergency, the crane's remote control system allows operators to quickly adjust or stop crane movement, mitigating potential risks more effectively than manually operated systems.

These improvements have contributed to a safer, more streamlined process for handling hazardous materials in the facility.

Challenges Encountered and How They Were Overcome

Despite the successful implementation of the 45 ton RMG crane, several challenges emerged throughout its operation. These challenges were addressed through a combination of training, technology upgrades, and adaptation to environmental factors. Below are the key challenges and how they were resolved.

Training and Adaptation

Challenge:Initial Struggles with Control Systems: When the crane was first introduced, some of the crane operators faced difficulties in adapting to the advanced control systems, especially the remote control operation and automation features. The sophisticated technology required a level of familiarity and precision that some operators initially found challenging. Solution:Comprehensive Training Programs: To address this issue, the company invested in detailed and hands-on training for the operators. The training program included:

- Familiarization with Remote Control Systems: Operators were trained in the safe and efficient use of the crane's remote control features, allowing them to operate the crane from a safe distance.

- Automation Features: Operators were also taught how to utilize the automated systems, including load sensors, anti-sway technology, and load stabilization mechanisms. This gave operators greater confidence in using the advanced technology and enhanced the crane's overall operational efficiency.

Weather and Environmental Conditions

Challenge:Harsh Weather: Operating the crane in extreme weather conditions, such as heavy rain, strong winds, and high humidity, presented stability and safety challenges. Adverse weather could affect the crane's stability and make it harder to control the load, especially when handling hazardous chemical containers.Solution:Enhanced Weather-Resistant Systems: To counteract these challenges, the crane was equipped with advanced weather-resistant systems, including:

- Wind-Shear Technology: This technology helped the crane adjust its operation in real-time to maintain stability even in strong winds.

- Weatherproof Electrical Systems: The crane's electrical components were sealed to prevent moisture and water ingress, ensuring they functioned properly in wet conditions.

- Environmental Protection Features: The crane's components, such as steel cables and lifting mechanisms, were designed to withstand extreme environmental conditions, minimizing wear and tear.

Outcome: These modifications ensured that the crane could continue to operate safely and efficiently, even under harsh weather conditions. The weather-resistant upgrades were crucial in maintaining operational safety and minimizing downtime due to environmental factors.

Upgrading Safety Features

Challenge:Need for Improved Spill Containment and Environmental Monitoring: As the crane was used more frequently, additional safety gaps were identified. Specifically, the spill containment systems needed to be reinforced, and the facility needed a more robust system for environmental monitoring to detect chemical leaks or other hazards.

Solution:Supplementary Containment Systems: The facility implemented additional spill containment systems designed to quickly contain and neutralize any chemical leaks or spills. This included:

- Secondary Containment Structures: These were added around key operational areas to catch potential spills before they could spread.

- Containment Mats and Barriers: Specialized mats were deployed around the crane's working area to absorb any chemical runoff.

Environmental Monitoring Integration: To improve the monitoring of hazardous materials, the facility also added environmental sensors to the crane's systems, which could detect:

- Airborne chemical vapors or toxic gases.

- Changes in temperature or pressure that might indicate a chemical leak.

Outcome: These improvements ensured that the crane could respond quickly to potential environmental hazards. The integration of environmental sensors and the addition of more robust containment systems significantly increased the facility's ability to prevent and manage spills and leaks.

The challenges encountered during the implementation of the 45 ton RMG crane were not unique, but the ways in which they were addressed played a key role in ensuring the crane's success. By investing in operator training, enhancing weather resistance, and improving safety systems, the facility ensured that the crane remained efficient, safe, and compliant with regulations. This process of continuous adaptation and ongoing improvement allowed the crane to meet the complex demands of handling hazardous chemical tank containers and ensured that safety and operational efficiency remained top priorities.

Key Takeaways and Best Practices from the Case Study

- Customization is Key: Customizing the crane for specific tasks, such as load stabilization and explosion-proof features, is essential for handling hazardous materials safely.

- Safety Measures Must Be Integrated into Every Step: From design to operation, safety features like anti-sway technology, load sensors, and remote control systems are critical for ensuring safe handling of hazardous materials.

- Training and Continuous Improvement: Ensuring that all workers are well-trained and familiar with new technology is essential for maintaining a smooth operation. Additionally, continuously evaluating and improving safety measures is key to adapting to new challenges.

Benefits of Using the 45 Ton RMG Crane for Hazardous Chemical Handling

Increased Safety and Reduced Risk

One of the primary benefits of using the 45 ton RMG crane in hazardous chemical handling is its ability to enhance safety and minimize risks associated with human exposure to dangerous materials.

- Minimized Human Exposure: By using an automated control system and remote operation features, crane operators can maintain a safe distance from hazardous materials. The crane can lift, transport, and position hazardous chemical tank containers without the need for workers to be directly in contact with the containers, significantly reducing the chances of accidental exposure to harmful chemicals.

- Safety Protocols Built-In: The crane's explosion-proof electrical systems, anti-sway technology, and load-sensing monitors help ensure that hazardous chemicals are handled with utmost care. These features are particularly important for handling volatile or corrosive chemicals, as they prevent accidents like chemical spills, leaks, or even explosions by stabilizing the load and responding to any unusual shifts in weight.

- Emergency Response: In case of an emergency, the remote control system allows operators to stop crane movements quickly, mitigating risks and providing more control over potentially dangerous situations.

By reducing the need for direct human involvement in high-risk tasks, the 45 ton RMG crane significantly enhances safety in facilities handling hazardous chemicals, protecting both personnel and the surrounding environment.

Improved Operational Efficiency

The 45 ton RMG crane contributes significantly to operational efficiency in handling hazardous chemical tank containers.

- Faster Loading and Unloading: The crane's advanced automation systems and precise control features allow for faster and more efficient loading and unloading of chemical containers. With its ability to handle large loads up to 45 tons and perform precise maneuvers, the crane accelerates material transfer between storage areas and transport vehicles, reducing downtime and improving overall throughput.

- Continuous Operation: With its heavy-duty construction and ability to work in demanding conditions, the crane can operate continuously for long periods, making it ideal for high-volume operations where quick turnaround times are crucial.

- Reduced Handling Time: Thanks to its high lifting capacity and advanced lifting mechanisms, the crane reduces the amount of time required to move hazardous chemical containers between storage and transportation, thereby optimizing workflows and improving overall productivity.

Overall, the crane's ability to speed up the material handling process—while maintaining accurate control over the containers—improves the facility's operational efficiency, allowing for faster processing times and smoother workflow management.

Compliance with Regulatory Standards

In the handling of hazardous chemicals, complying with safety and environmental regulations is essential. The 45 ton RMG crane plays an integral role in ensuring that the facility meets all necessary regulatory standards.

- Adherence to Safety Regulations: The crane is designed with features that comply with OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) regulations. Its explosion-proof electrical systems, for example, meet standards for handling flammable or volatile chemicals, while load sensors and anti-sway technology help prevent accidents that could lead to hazardous chemical spills or environmental contamination.

- Environmental Compliance: Facilities handling hazardous materials must follow strict guidelines on spill containment, waste management, and toxic chemical handling. The 45 ton RMG crane is equipped with systems that monitor and control the load in real-time, ensuring the safe transport of chemicals within the facility and minimizing the risk of spills, leaks, or contamination.

- Documentation and Reporting: The crane's data logging and monitoring systems allow for accurate tracking of lifting operations, providing the necessary documentation for regulatory compliance. This ensures that the facility can provide proof of compliance during inspections or audits and demonstrate adherence to safety and environmental regulations.

By helping the facility comply with industry regulations, the crane ensures not only the safety of workers and the environment but also protects the facility from potential legal and financial penalties due to non-compliance.

Cost-Effectiveness

While the initial investment in a 45 ton RMG crane may seem significant, its long-term benefits far outweigh the costs, particularly when it comes to cost-effectiveness.

- Fewer Accidents and Spills: The crane's advanced safety features—such as load monitoring, anti-sway technology, and explosion-proof systems—reduce the likelihood of accidents or spills. By minimizing the risk of hazardous chemical spills, which can be costly to clean up and result in regulatory fines, the crane contributes to cost savings over time.

- Reduced Maintenance Costs: The crane's durable design and robust components minimize wear and tear, reducing the frequency and cost of repairs. It is also equipped with self-diagnostic systems, which help detect potential maintenance issues before they become serious problems, reducing downtime and maintenance costs.

- Increased Productivity: The ability of the crane to perform quick and efficient operations means that fewer workers are required for material handling tasks, reducing labor costs. Furthermore, the crane's automation reduces human error and improves the accuracy of lifting and placement, ensuring that operations run more smoothly and efficiently.

- Long-Term Durability: The crane is built to withstand harsh industrial environments, meaning it has a long operational lifespan. This makes it a cost-effective investment in the long term, as it provides years of reliable service without needing to be replaced or heavily repaired.

In summary, the 45 ton RMG crane provides significant cost savings by reducing the likelihood of accidents, lowering maintenance requirements, increasing productivity, and offering long-term durability. These factors collectively contribute to the overall cost-effectiveness of the crane over its operational lifespan.

The 45 ton RMG crane offers substantial benefits for industrial facilities handling hazardous chemical tank containers. From increasing safety and improving operational efficiency to ensuring regulatory compliance and providing cost-effectiveness, the crane addresses the unique challenges of this demanding task. Its design and advanced features make it an essential tool for facilities looking to enhance their chemical handling operations while minimizing risks and maximizing productivity.

Conclusion

Handling hazardous chemical tank containers in industrial settings presents a unique set of challenges. These challenges include the inherent risks of spills, leaks, and chemical exposure, the need for stability when transporting heavy and unstable loads, and the regulatory requirements for ensuring safety and environmental protection. The 45 ton RMG crane addresses these challenges effectively by combining advanced technology with robust design features.

- The crane's anti-sway technology, explosion-proof systems, and load-sensing monitors help minimize the risks of accidents, ensuring that hazardous materials are handled safely.

- Its remote control operation and automated systems increase operational efficiency, reducing human exposure to dangerous chemicals and speeding up loading and unloading processes.

- The crane is also designed to comply with safety regulations and environmental standards, offering facilities a reliable solution for meeting industry requirements.

- In addition, the crane's cost-effectiveness is demonstrated by reduced accident-related costs, lower maintenance expenses, and longer operational lifespans.

Together, these features make the 45 ton RMG crane an essential tool for industrial facilities that handle hazardous chemical tank containers, offering enhanced safety, efficiency, and regulatory compliance.

Selecting the right equipment for handling hazardous materials is critical in industrial facilities. The 45 ton RMG crane exemplifies the importance of choosing technology that not only meets operational demands but also prioritizes safety and regulatory compliance. In industries dealing with dangerous chemicals, having the right tools to mitigate risk, enhance productivity, and ensure worker and environmental safety is non-negotiable. As crane technology advances, the importance of continuous innovation in safety features, automation, and efficiency will only grow, ensuring that hazardous materials are handled in the safest and most efficient way possible.

Choosing a crane that is equipped with the latest safety systems and designed for heavy-duty, hazardous material handling will be essential in safeguarding both people and the environment, while also maintaining a streamlined and efficient operation. The future of crane technology promises even greater advancements, ensuring safer and more sustainable operations in industrial environments for years to come.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch